| Articles | https://doi.org/10.21041/ra.v13i3.697 |

Circular economy in the Latin American cement and concrete industry: a sustainable solution of design, durability, materials, and processes

Economia circular na indústria latino-americana de cimento e concreto: uma solução sustentável de design, durabilidade, materiais e processos Economía circular en la industria latinoamericana del cemento y el concreto: una solución sustentable de diseño, durabilidad, materiales y procesos

J. M.

Mendoza-Rangel1

![]() , J. H. Díaz-Aguilera1

*

, J. H. Díaz-Aguilera1

*

![]()

1 Universidad Autónoma de Nuevo León, Facultad de Ingeniería Civil, Nuevo León, México.

*Contact author: jhda_ic24@hotmail.com

Reception:

July

19,

2023.

Acceptance:

August

31,

2023.

Publication: September 01, 2023.

| Cite as: Mendoza-Rangel, J. M., Díaz-Aguilera, J. H. (2023),“Circular economy in the Latin American cement and concrete industry: a sustainable solution of design, durability, materials, and processes”, RevistaALCONPAT, 13 (3), pp. 328 –348, DOI: https://doi.org/10.21041/ra.v13i3.697 |

Abstract

Conventional models of production in the cement and concrete industry (CCI) associate important environmental problems; on the other hand, there are emerging technologies that could reduce them. However, the multidimensional approach of the circular economy is required to guide sustainable development in a lasting manner, modeling the life cycle from design to final disposal aiming to optimize the value-environmental impact relationship; since only a circular, resilient, and proactive industry can meet the 2030 Agenda of sustainable development (ONU) or the goal of zero emissions. This work presents general concepts of circular economy, as well as an analysis of alternatives and applicability in order to raise awareness among CCI actors in Latin America.

Keywords:

circular economy,

sustainability,

cement and concrete industry,

efficient design,

durability

1. Introduction

In the global context, there is an urgency to mitigate the problems associated with climate change, which involves the activities of various industries, including the cement and concrete industry (Adesina, 2020; Villagrán‐Zaccardi et al., 2022; Zajac et al., 2022). One of the guidelines to achieve this goal is the 17 Sustainable Development Goals (SDGs) of the 2030 agenda (United Nations, 2023), among which there are some related to the need to promote sustainability in the cement and concrete industry (CCI). SDG 6 on clean water and sanitation implies optimizing the use of water resources in production and construction processes (Muñoz-Zapata et al., 2022; Nodehi et al., 2022; United Nations, 2023). SDG 7 promotes sustainable access to energy, which implies reducing greenhouse gas emissions (GHGs) associated with the production of construction materials such as cement (Colangelo et al., 2020). SDG 9 favors sustainable innovation and infrastructure, including the promotion of green and efficient technologies in the production of cement and concrete (GCCA, 2023; NoParast et al., 2021). SDG 11 focuses on achieving sustainable cities and communities, which impact construction practices, the carbon footprint associated with buildings and infrastructure, the planning of transportation systems, urban design, energy-efficient buildings, and sustainable mobility solutions (Mostert et al., 2021). SDG 12 aims to achieve sustainable production-costs models, which involve the reduction of non-renewable material use and alternatives such as the use of low-clinker-content cements (Geisendorf et al., 2018; GCCA, 2023). SGD13 is related to promoting initiatives to reduce the effects of climate change, such as the reduction of GHG emissions associated with cement and concrete (Maury-Ramírez et al., 2022; United Nations, 2023). SDG 15 is associated with raw material extraction processes, quarry rehabilitation, as well as the protection and restauration of biodiversity (Adesina, 2020; Villagrán‐Zaccardi et al., 2022). Likewise, SDG 17 encourages the formation of partnerships to achieve the SDGs, e. g., the collaboration among various stakeholders for the development of sustainable construction materials research and technology (Marsh et al., 2022).

Furthermore, Latin America concentrate a diversity of developing countries, which leads to the need for infrastructure construction at various scales and the subsequent consumption of large volumes of cement and concrete (Zajac et al., 2022). In terms of installed capacity, cement plants in the region reach 271 Mt, but production was 170 Mt in 2019, of which 68% was distributed in bags, 25% in ready-mix concrete, 2% in precast concrete, and 5% in other forms (mortars, etc.). It is worth noting that the expected optimal scenario for 2020, 2030 and 2050 is an increase in production to 196, 198 and 227 Mt, respectively; however, the Clinker factor should be reduced to 0.66, 0.53 and 0.51, respectively (GCCA, 2023). These reductions are of interest as they involve: i) significant exploitation of natural resources such as water, limestone, clay, sand, etc. (Nodehi et al., 2022); ii) CO2 emissions and energy consumption due to the thermal decomposition of limestone, mining machinery, transportation, etc. (Colangelo et al., 2020; NoParast et al., 2021); and iii) the generation of waste such as construction debris, demolition products, etc. (Mostert et al., 2021). Therefore, according to Federación Interamericana del Cemento (FICEM), to achieve the goal of zero CO2 emissions, it is expected that emissions will need to be reduced from 110 Mt in 2020 to 0 Mt by 2050. This Will require the implementation of various technologies and strategies such as the use of supplementary cementitious materials, the development of new cements, optimizing concrete design and construction, carbon capture technologies, and obtaining value-added materials such as the carbonation of industrial waste, natural minerals, and others (Villagrán‐Zaccardi et al., 2022; Zajac et al., 2022).

Faced with the challenges described below, the proposal of the circular economy (EC) emerges, which is based on the assessment of the life cycle of materials and processes in order to maximize the relationship between product value and long-term environmental impact (GCCA, 2023). This promotes a circular route of production-consumption-management so that construction materials remain in use for as long as possible, instead of the linear model of exploiting natural resources, manufacturing a product, using it, and disposing of it (Geisendorf et al., 2018). Some strategies of this approach include (Corvellec et al., 2022; Romero et al., 2021; Sehnem et al., 2019): i) resource optimization, which means reducing waste or resources improperly used during the production and use of cement and concrete; ii) reuse and recycling, which promotes the closure of the life cycle of materials from the CCI or other industries; iii) regeneration, which involves extending the life cycle of materials. In this way, the CE allows the CCI to adapt, recover and respond to environmental and socio-economic challenges, thriving in a changing context and seizing the opportunities offered by the transition to more sustainable practices, ensuring and maintaining its functionality sustainably over time.

However, the principles of CE and their implementation in the CCI are not yet fully widespread in Latin America. This is evidenced by the limited scientific literature reported by research institutes in the region, as found for this study (Caldas et al., 2021; Colorado et al., 2020; Hentges et al., 2021; Londoño et al., 2021; Maury-Ramírez et al., 2022; Muñoz-Zapata et al., 2022; Xavier et al., 2021). Additionally, it is necessary to present the information with both a general and specific focus. This article as the first in a series aimed at introducing individuals involved in the CCI, regardless of whether they belong to the scientific-academic, business, technical, or student community. With these works it expected to contribute to the dissemination, discussion, and promotion of this international trend in Latin America, laying the groundwork to stimulate and enhance its development, as well as catalyzing a significant impact in the region. In the following sections, the fundamentals of CE are discussed, and a classification is proposed for international research in seven areas of implementation in CCI: 1) Concrete digitization, 2) Technological innovations, 3) Efficient design, 4) Recycled aggregates, 5) Extension of the service life, 6) Local resources, 7) Efficient processes. Subsequently, an analysis of applicability of CE in Latin American CCI is conducted.

2. Fundamental principles of circular economy

The fundamental principles of the circular economy (CE) are related to the 5R (Reduce, Reuse, Recycle, Recover, Redesign) and aim to transform the way in which resources are produced and consumed through a comprehensive vision that addresses enviromental and economic challenges. The goal is to achieve more sustainable and resilient industries, as reported in various sectors such as: industry 4.0 (Romero et al., 2021), mining (Xavier et al., 2021), 3D printing of biomaterials (Wijk et al., 2015), food processing (Hamam et al., 2021), industrial design (Dam et al., 2020) and others (Gallaud et al., 2016; González-Domínguez et al., 2020; Londoño et al., 2021). In these cases, improvements were related to efficient management of natural raw materials and waste quantities, suggesting that the CCI can also benefit from this approach. The principles of the CE can be summarized in four:

1) Natural systems regeneration (Romero et al., 2021; Wijk et al., 2015; Xavier et al., 2021): instead of depleting natural resources and degrading ecosystems, the CE advocates for a harmonious integration with nature through the conscious use of renewable and non-renewable resources on the planet. This involves designing products and processes that regenerate and restore natural resources rather than deplete them.

2) Resource use optimization (Hamam et al., 2021; Sehnem et al., 2019): it involves the efficient use of materials and the generation of minimal waste. This principle encourages the use of durable and high-quality materials, as well as technologies and processes that optimize waste.

3) Circularity (Gallaud et al., 2016): it involves keeping materials in use for as long time as possible, which includes reuse, repair, remanufacture and recycling of materials. It also involves designing modular products that easy to disassemble, which streamlines repair and maintenance procedures. This approach allows for the recovery and reintroduction of materials into the next production cycle.

4) Collaboration and synergy creation: in order to maximize benefits through the exchange of knowledge, diversification of solutions and the utilization of available resources. Also, it advocates for partnerships between companies, governments, civil society organizations, consumers, etc. (Camilleri et al., 2020; Corvellec et al., 2022).

2.1. The 5Rs of the circular economy

The 5Rs are defined as follows (Corvellec et al., 2022; Marsh et al., 2022):

- Reduce resources, industrial waste, and emissions associated with the production of a material; this involves optimizing manufacturing processes and energy consumption, as well as integrating durability-focused design criteria. For example, reducing the cement consumption in concrete production through mixture design optimization and the use of additives to achieve project-specified properties (NoParast et al., 2021; Velvizhi et al., 2020).

- Reuse materials at the end of their life cycle instead of disposing of them, which may involve repairing them for reintroduction to the market. An example is the reuse of existing concrete structures, such as bridges or buildings, through their rehabilitation and adaptation for new purpose, instead of demolition or reconstruction (Maury-Ramírez et al., 2022).

- Recycle involves transforming waste into valuable products for an industry, reducing the extraction of raw materials. This can include recycling wastewater from concrete production and washing through treatment and purification systems (Maury-Ramírez et al., 2022).

- Recover means obtaining valuable resources from waste that are not feasible to recycle, such as raw materials, electric, or thermal energy. For example, it is possible to recover waste from other industries to manufacture cement, like fly ash or slags (Roychand et al., 2021).

- Renew refers to restoring the functionality of materials, which may involve remanufacturing processes. In concrete structures, durability properties of elements exposed to corrosive environments can be restored using chloride extraction techniques. This reduces corrosion of reinforcements and extends their service cycle (Kosmatka et al., 2004; Taylor, 1997).

3. Circular economy models applied to the cement and concrete industry

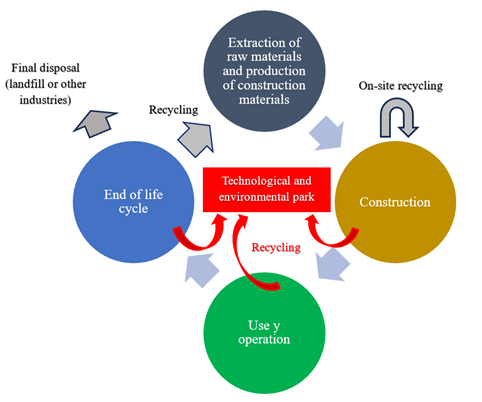

In order to discuss the integration of the CE into the CCI, it is necessary to explore some models proposed in the literature, among which the work of Maury-Ramírez et al. (2022) stands out. This work assesses the processes within the construction industry with the aim of improving them based on the analysis of the process of exploitation of raw materials and the manufacture of construction materials, the stage of infrastructure construction, the use and operation of the property, as well as the end of its useful life, which includes the generation of waste and its final disposal in a landfill or recycling within this industry or other sectors (Figure 1). This model was applied in Santiago de Cali (Colombia), but it could be extended to variables related to cement and concrete, encompassing the stages of production, design, construction, use, maintenance, and end-of-life management.

|

||||

| Figure 1. Model for the extraction, construction, operation, and waste management in construction projects based on the circular economy. | ||||

It is worth noting that the models proposed will require collaboration among all parties involved in the value chain of the CCI to achieve their goals, including manufacturers, contractors, designers, regulatory bodies, and consumers (Corvellec et al., 2022; Marsh et al., 2022). Likewise, it is essential to encourage the exchange of ideas among various participating sectors (industrial, academic institutions, government organizations, and civil society), this will drive innovation, technological development, and best industrial practices. Similarly, regulatory frameworks and public policies that promote the transition to CE in the CCI are required such as tax incentives, support for research and technological advancements, sustainability standards, environmental regulations, and training programs (Marsh et al., 2022; Villagrán‐Zaccardi et al., 2022). The successful implementation of CE models will not only contribute to reducing environmental impacts but also generate economic opportunities such as job creation in research and waste management sectors, production based on recycled materials, and the development of sustainable technologies, as well as more durable materials. Below, seven areas of CE implementation in the CCI are described, along with some related research in each area.

3.1 Digitalization of cement and concrete

Digitalization offers the possibility to optimize the chemical composition of cement and the formulation of concrete mixtures, minimize material waste, and enhance their performance in terms of both volume and resulting properties (NoParast et al., 2021). To achieve such control, different types of sensors are required (Marsh et al., 2022; Maury-Ramírez et al., 2022) to monitor in real-time (Hossain et al., 2020; Velvizhi et al., 2020) and model cement production processes (Atta et al., 2021), such as griding and calcination. Also, there is a need for technological improvements in concrete mixing, transportation, and placement, which require advancements in mixer trucks, concrete pumps, and other equipment (Adesina, 2021). For example, sensors collect data on the desired characteristics of cement or concrete (such as temperature, humidity, strength, flowability, greenhouse gas emissions, or energy consumption during the process, etc.) which is then transmitted to digital platform for analysis (Marsh et al., 2022; Maury-Ramírez et al., 2022; Velvizhi et al., 2020). Additionally, digitalization facilitates the optimization of ingredient dosage and real-time adjustments (NoParast et al., 2021; Velvizhi et al., 2020).

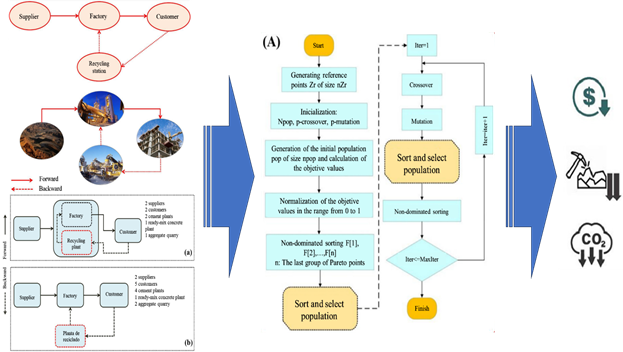

Another advantage is that enables material tracking (traceability) and efficient management in the supply process through tracking activities from the production plant to the construction site, which includes precise knowledge of volumes used, delivery times, and other variables. M. NoParast et al. (2021) developed a model to optimize the concrete manufacturing and supply chain, which involves the analysis of different subsystems: customers, suppliers, as well as manufacturing and recycling locations. The aim was to minimize raw material extraction, transportation costs, and greenhouse gas emissions (Figure 2).

|

||||

| Figure 2. Model applied to concrete supply activities based on the circular economy (NoParast et al., 2021). | ||||

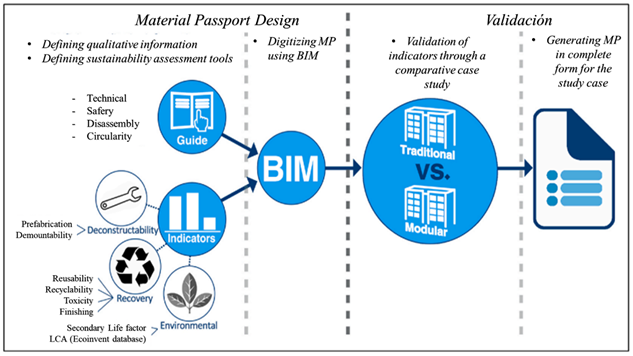

On the other hand, Building Information Modeling (BIM) and 3D printing are important components of digitalization. The former is a methodology that allows creating three-dimensional digital models of buildings, infrastructure, and construction projects, containing detailed information about construction elements such as design parameters, concrete type, structure dimensions and location in the building, installation characteristics, etc. (Sudarsan et al., 2023). Thus, BIM enables the optimization of project planning, design, and management, which is affected by variables associated with the use of cement and concrete in supply logistics, simulation and structural analysis, construction procedures, etc. This allows for better decision-making that reduces errors during construction (Atta et al., 2021). Highlight that BIM facilitates communication and collaboration among project stakeholders by providing real-time access and updates to model information (Atta et al., 2021; Sudarsan et al., 2023), optimizing the use of cement and concrete, waste, and construction times. I. Atta et al. (2021) proposed a sustainable design method based on the Material Passport (MP) tool (Figure 3), which require input parameters such as sustainability assessment tools, technical material details, and the establishment of indicators to determine the final disposition. With these data, the MP is designed and digitized using BIM and the information is then processed to validate the manufacturing characteristics and the specific case study where the material will used.

|

||||

| Figure 3. Sustainable concrete design using the Material Passport (Atta et al., 2021). | ||||

3D printing (additive manufacturing) allows the layer-by-layer creation of three-dimensional objects from a digital design (Wijk et al., 2015). In the context of cement and concrete, this method enables the automated fabrication of structural and architectural elements with precision, offering greater efficiency in terms of design, planning, and construction compared to traditional techniques (Colorado et al., 2020; Şahin et al., 2022).

In summary, digitalization of cement and concrete leverages technology to enhance quality control, efficiency and traceability throughout the projected service life. This promotes better control over properties, avoids overproduction, and ensures the specific requirements of a project, all of which reduce the environmental footprint.

3.2. Technological innovations in construction

The adoption of technological innovations suach as 3D printing (Şahin et al., 2022), the use of advanced materials (Chakartnarodom et al., 2022; Colorado et al., 2020), and the prefabrication (Minunno et al., 2018), optimizes resource utilization. The wide range of advanced materials offers superior properties compared to conventional concrete, enhancing mechanical and durability properties through various physical and chemical mechanisms, contributing to its efficiency and sustainability in the context of the CE. Some examples include reinforcing fibers (Tari et al., 2022), nanomaterials (Cosentino et al., 2020), and special additives (Dikshit et al., 2022). The former can be made of steel (Liew et al., 2020), glass (Tari et al., 2022) or a polymer (Vitale et al., 2021), and can reduce cracking under imposed loads; moreover, it can replace or reduce the amount of steel rods in concrete structure (Liew et al., 2020), which decreases the consumption of natural resources. Natural fibers like sargassum (Rossignolo et al., 2022) or agave (Juárez-Alvarado et al., 2020), should also be mentioned as these materials can enhance the thermal and comfort properties of concrete blocks. On the other hand, nanomaterials like carbon nanotubs (Yousef et al., 2021) or nanosilica (Al-mousa et al., 2022), reduce the porosity of cementitious matrix, resulting in lower diffusivity of aggressive agents that could deteriorate the concrete or reinforcing steel. Another innovation of interest is alkali-activated cements (AAC), which can replace the use of Portland cement in some applications where higher resistance to aggressive environments or high mechanical strength in a shorter setting time is required (Shi et al., 2006). Although AAC can be elaborated from waste materials such as slag, fly ash, and bauxite residues, those made with metakaolin and limestone stand out; this is because their raw materials are similar to Portland cement, but with the advantage that the transformation of kaolin-metakaolin can be carried out at approximately half the temperature of clinker production, and limestone does not require calcination, only pulverization. Furthermore, it has recently been reported that the use of sodium silicate and hydroxide alkali activators can be optimized, further reducing the environmental impact, cost, and energy consumption in comparison to ordinary Portland cement or blended Portland cement (Pérez-Cortes y Escalante-García, 2020).

On the other hand, special additives are chemicals added to concrete during mixing; some examples include (Taylor, 1997): i) water-reducing additives, which minimize the water amount without compromising the workability of the mixtures, facilitating their placement and compactation (Muñoz-Zapata et al., 2022); ii) setting and hardening accelerating additives, which are used in low-temperature conditions or projects that require rapid putting into operation (Roychand et al., 2021); iii) setting-retarding additives, which are useful in warm climates, in projects that require extended mixing times due to the long-distance transportation of fresh concrete, or for special placement conditions (Tari et al., 2022); iv) expansive additives, to control concrete shrinkage during setting and reduce cracking (Zhang et al., 2023); v) waterproofing additives, which reduce water passage and prevent leaks (Akchurin et al., 2016).

Lastly, prefabrication is a construction technique for structural elements (walls, beams, columns, slabs, etc.) in a controlled environment, which then transported to the construction site and assembled (Kosmatka et al., 2004). It enables greater quality control through monitoring systems and laboratory testing, reduces construction timelines, facilitates installation, minimize material waste on site, and enhances resources efficiency, since both the design and manufacturing of elements are carried out in accordance with the requirements of the project (Minunno et al., 2018).

3.3. Efficient design projects

Efficient design of concrete structures contributes to minimize resource use and environmental impacts while maximizing the performance of the elements through various design techniques such as the structural optimization (Yang et al., 2022), life cycle analysis (Mostert et al., 2021), and emergy analysis (Wang et al., 2022).

Structural optimization or efficient structural design involves finding the optimal geometry and material proportions for a concrete structure, minimizing the amounts of concrete and steel, and reducing the environmental footprint through natural resources optimization. This is achieved through mathematical modeling based on the mechanical and durability properties of materials, while considering safety factors, cost-benefit relationships, and potential structural pathologies (Marsh et al., 2022; Yang et al., 2022). Manufacturing high-performance and durable concrete may implies the use of advanced materials, as well as lightweight or highly efficient construction systems (e.g., lightweight slabs, appropriate bracing, or the optimization of joins and welding) (Adesina, 2021).

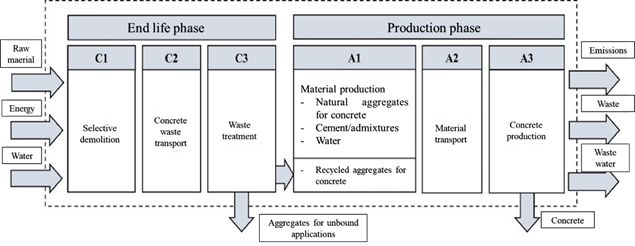

Life Cycle Analysis (LCA) allows to determine the environmental impact of a concrete structure associated with its useful life (Wang et al., 2022), by identifying the biggest environmental issues and enables the development of strategies to minimize them during different project stages. Some examples include the embodied energy in cement and concrete components, the GHG emissions during manufacturing and transportation, as well as the potential recycling of waste (Mostert et al., 2021; Wang et al., 2022). LCA enables informed decisions-making from the structural design stage, selecting materials and construction systems with lower environmental impact based on energy demand, emissions, and resources use. Among LCA research, the work of C. Mostert et al. (2021) stands out, which evaluates the climate and resource footprint of recycled concrete. Figure 4 shows the LCA model that covers all stages for the life cycle of concrete: raw material extraction, transportation, concrete production, its demolition, and recycling as an aggregate for new concrete with/without structural application.

|

||||

| Figure 4. Life Cycle Assessment Model for recycled concrete (Mostert et al., 2021). | ||||

On the other hand, emergy analysis is an efficient design tool that is based on the principles of thermodynamics to evaluate the amount of energy that has been invested in a material throughout its life cycle, both directly (such as electricity consumed during production and transportation) and indirectly (such as solar, fossil, y other energy sources needed for extraction, processing, and manufacturing), that is, in relation with the natural resources utilized to elaborate a material (Amaral et al., 2016). Consequently, it allows for the evaluation of the energy efficiency of a system, identifying energy bottlenecks, and determining the most significant sources of energy in terms of their contribution to the system. Regarding of concrete structures, it is possible to evaluate alternatives in terms of energy demand and select options with lower consumption, which includes choosing materials with lower energy content, optimizing the production and transportation process, as well as implementing design, construction, and maintenance strategies that minimize energy consumption throughout the life cycle of the element (Wang et al., 2022).

3.4. Responsible use of recycled aggregates

The reuse of aggregates obtained from crushing concrete or others waste materials (Marsh et al., 2022; Nodehi et al., 2022) can reduce the demand of primary raw materials and waste generation, which enables the closing of the life cycle of concrete and other materials simultaneously, promoting more efficient resource management. Some examples include waste from: brick (Fořt et al., 2020), vitroceramic (Rada et al., 2023), paving blocks (Neves et al., 2022), ceramic blocks (Barreto et al., 2021) concrete blocks (Fořt et al., 2020), asphalt (Delwar et al., 1997; Linek et al., 2023), polymers like PVC (Taghvaee et al., 2022), PET (Al-Sinan et al., 2022) and tire rubber (Díaz-Aguilera et al., 2021), agroindustrial waste like rice husk ash (Althoey et al., 2022) and sugarcane bagasse ash (Ariza-Figueroa et al., 2022), pulverized glass (Nodehi et al., 2022), among others. These recycled materials are processed and used as substitutes for conventional aggregates (gravel and sand) in concrete mixtures.

Some benefits of using these recycled materials are:

- Minimization of the demand for natural raw materials, reducing the extraction and processing of resources like sand and gravel from rivers (Nodehi et al., 2022).

- Efficient waste management, meaning the productive use of materials that would otherwise be considered waste and end up in landfills, giving them a second life as aggregates in new concrete structures (Marsh et al., 2022).

- Reduction in energy demand and GHG emissions, as the production of recycled aggregates requires less energy compared to the extraction and processing of natural materials (Ariza-Figueroa et al., 2022).

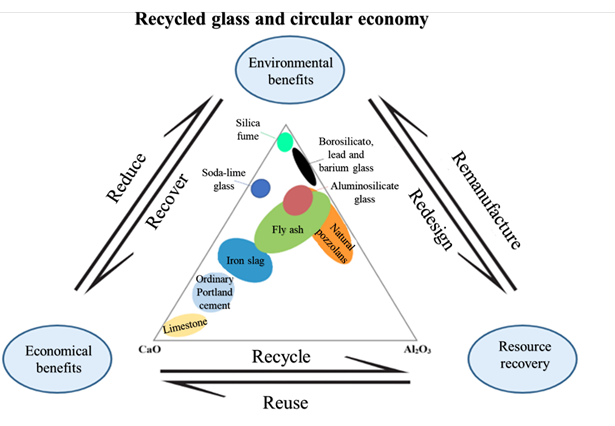

It is worth mentioning that the utilization of recycled aggregates requires a proper process of selection, classification, and processing to ensure their quality, meeting the requirements of strength, durability, and other properties of interest for concrete (Al-Sinan et al., 2022; Althoey et al., 2022; Díaz-Aguilera et al., 2021). An example of implementation of the CE and recycled glass aggregates was published by M. Nodehi et al. (2022). Figure 5 is a triangular model that relates environmental benefits with economics ones and resources recovery base on the concept of the 6Rs: remanufacture, redesign, recycle, reuse, recover, and reduce waste.

|

||||

| Figure 5. Circular economy model for recycled glass aggregates (Nodehi et al., 2022). | ||||

3.5. Extension of the life cycle of concrete structures

By promoting the maintenance, rehabilitation, and renovation of concrete structures, the projected lifecycle can be extended, reducing the need for new construction (Breugel, 2017). This implies adopting design procedures that aim to increase the durability of materials, as well as implementing techniques for repair, renovation, and structural strengthening. Therefore, extending the lifecycle refers to prolonging the operational life of concrete structures rather than opting to demolish and rebuild them (Anastasiades et al., 2020; Bourke et al., 2019).

To achieve a longer lifecycle in concrete, the following approaches can be applied:

i) Durability-based design consists of proposing new concrete structures considering criteria that promotes the minimization of deterioration phenomena and maximize the longevity of the elements. This entails using high-quality materials, appropriate construction techniques accompanied by rigorous supervision, corrosion protection systems, as well as considering the loads and environmental conditions to which the concrete element will be exposed throughout its lifecycle (Breugel, 2017); therefore, this type of design reduces the probability of damage and premature degradation.

ii) Regular and adequate preventive maintenance is essential to ensure the durability and good condition of concrete structures over time. Constant monitoring and inspection allow for the timely identification and addressing of any signs of deterioration, wear, or damage (Anastasiades et al, 2020; Ariza-Figueroa et al., 2022). This may include activities such as cleaning, crack sealing, replace of deteriorated elements, maintenance of drainage systems, and corrosion control, all of which help to prevent more significant issues over time.

iii) Structural repair and reinforcement are applied to concrete structures with significant damage or deterioration instead of demolishing and reconstructing. These techniques address identified problems and restore structural integrity through repairs such as strength restauration, waterproofing, replacement of damaged elements, and crack repair (Bourke et al., 2019). Structural reinforcement involves adding elements or systems that strengthen and improve its load-carrying capacity. All of these measures effectively and economically extend the service life.

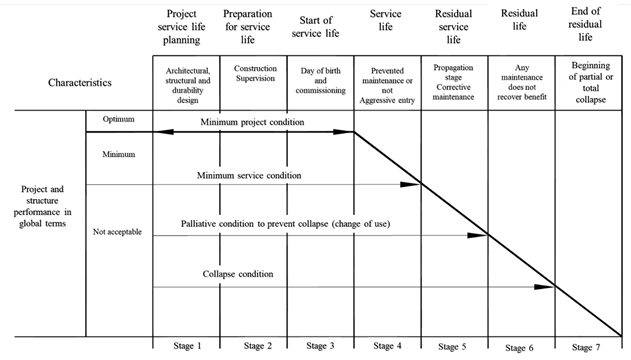

However, to consolidate these approaches, schematics service life models are required to guide the stage at which the concrete structure is located and the actions that can be taken to extend its durability. In this regard, an example is shown in Figure 6 (Castro y Helene, 2007), in which service life is divided into 7 stages. This model is presented under a comprehensive philosophy, which divides the life cycle into stages that align with project planning, as well as with the application of the CE according to the specific needs of each stage. For example, to achieve optimal performance, the first three stages, including planning, preparation, and the day of putting into service, are analyzed. The minimum service condition is maintained only during the fourth stage, where preventive maintenance against the ingress of aggressive substances is required (approach ii to extend the life cycle). In general, stages five, six, and seven are where the structure no longer exhibits acceptable performance. These states include residual service life, remaining life, and end of remaining life, in which the approach iii of structural repair and reinforcement described earlier would be analyzed.

Consequently, extending the life cycle of concrete involves saving resources, energy, and emissions associated with new constructions. Additionally, it minimizes waste produced by demolition and reduces dependence on non-renewable resources by maintaining and making the most of existing structures (Anastasiades et al., 2020).

|

||||

| Figure 6. Schematic model of a 7-stage life cycle (Castro y Helene, 2007). | ||||

3.6. Identification and use of local resources

The use of local resources in the manufacturing of cement and concrete involves using raw material sources close to the production plants, reducing transportation distances and, therefore, environmental impact (Caldas et al., 2021; Mostert et al., 2021). It also minimizes the need to import raw materials, production, and transportation costs, as well as vulnerability to price fluctuations of materials from outside the region (Iacovidou et al., 2017), making the CCI more economically resilient and sustainable.

At the same time, it promotes socio-economic progress in the areas where materials are extracted; this is due to the creation of local employment, strengthening the region's supply chains (Geisendorf et al., 2018). It is important to note that this strategy should be carried out responsibly and sustainably by considering socio-environmental aspects (Corvellec et al., 2022; Maury-Ramírez at al., 2022), meaning that appropriate practices for resource extraction and management should be established to ensure the protection of ecosystems and respect for local communities.

Some examples include the use of metallurgical slag (Phiri et al., 2021), fly ash from thermal power plants (Ghosh et al., 2020), natural pozzolans like volcanic sands (Contrafatto, 2017), silica fume (Al-Hamran et al., 2021), pumice (Ulusu et al., 2023) rice husk ash (Althoey et al., 2022), recycled concrete products (Lederer et al., 2020), and locally sourced sands and gravels, among others. These materials can be used as replacements for cement or aggregates, improving the properties of cementitious mixtures through their pozzolanic reactivity and other processes (Kosmatka et al., 2004); however, it is always important to evaluate the quality of these resources to ensure their suitability.

3.7. Process optimization

Process improvement can focus on cement manufacturing or concrete construction processes (Fay et al., 2014; Guimarães et al., 2021; Pérez et al., 2009). For example, EC involves the adoption of cleaner technologies such as carbon capture (Kaliyavaradhan et al., 2020) and storage (Hanif et al., 2023), the use of low-emission alternative fuels (Chatterjee et al., 2019; Villagrán‐Zaccardi et al., 2022), as well as the implementation of energy optimization practices like cogeneration of heat and power, waste heat recovery, and the utilization of renewable energy sources (Mathews et al., 2011; Sharifikolouei et al., 2021).

On the other hand, optimization of construction processes can be achieved through the efficient use of construction materials (Geisendorf et al., 2018), proper utilization of machinery and equipment (Marsh et al., 2022), as well as efficient logistics planning (Sehnem et al., 2019). Therefore, improving these processes involves implementing practices and techniques that optimize the systems used (Hentges et al., 2021), while simultaneously significantly reducing resource consumption and associated environmental degradation.

An area key to improving efficiency is the management of material resources, such as construction and demolition waste with concrete (Hentges et al., 2021; Lederer et al., 2020). Instead of considering waste as discarded materials, management strategies can be implemented to promote the reuse, recycling, and recovery of materials. This involves separating materials during demolition, establishing waste collection and sorting systems at construction sites, with the aim of using these materials in new projects (Lederer et al., 2020). Another way to improve resource management is through increased training in concrete technology and cement chemistry, with the goal of optimizing the handling and supervision of these materials on-site (Kosmatka et al., 2004; Taylor, 1997).

Also, the proper use of machinery and equipment in construction can contribute to greater efficiency and reduced resource consumption (Hentges et al., 2021; Karlsson et al., 2020; Villagrán‐Zaccardi et al., 2022). The selection of efficient machinery with low energy consumption and reduced emissions technologies can optimize performance and minimize environmental impacts (Karlsson et al., 2020). Likewise, the implementation of proper maintenance practices and training ensures the appropriate use of equipment and extends their life cycle, avoiding the need for frequent replacement.

Efficient logistics related to construction processes is another important aspect; for example, this involves optimizing transportation routes, travel distance, vehicle loads, emissions, and fuel consumption (Karlsson et al., 2020; NoParast et al., 2021); this would also increase the life cycle of roads. On the other hand, proper scheduling and coordination of construction activities can prevent unnecessary delays, reduce construction time, and make optimal use of resources.

Improving construction processes can also involve the use of modular and prefabricated systems, as this reduces the need for on-site work, saving time and resources (Minunno et al., 2018). Another strategy can be standardization based on the use of materials, construction processes, and manufacturing in the construction industry (Villagrán‐Zaccardi et al., 2022).

4. Applicability of the circular economy in the latin american cement and concrete industry

The CE presents a great opportunity to achieve sustainability in the CCI in Latin America; however, it is important to consider the constraints of the region to effectively apply these circular principles. Some factors include the regulatory framework, recycling infrastructure, the availability and quality of recycled materials, socio-economic and cultural conditions, as well as regional cooperation (Maury-Ramírez et al., 2022).

- The successful implementation of CE in CCI in Latin America requires a robust regulatory framework (United Nations, 2023; Villagrán‐Zaccardi et al., 2022). This entails understanding or developing policies and regulations that promote the adoption of circular practices for waste reuse, the adoption of efficient design in infrastructure projects, proper management of demolition products, etc.

- It is necessary to have recycling and waste management infrastructure for separation and classification at construction sites (Colangelo et al., 2020; NoParast et al., 2021). Investing in infrastructure and training professionals in waste management is crucial to achieving effective CE in the region.

- The use of recycled materials requires control over their availability and quality (Muñoz-Zapata et al., 2022; Wang et al., 2022). Therefore, it is essential to promote both research and technological innovation to produce high-quality recycled aggregates, as well as the establishment of standards and certifications to ensure that these materials are suitable for use in construction. This helps build trust and acceptance of these resources in the industry.

- Socioeconomic factors such as the availability of investment sources for circular technologies, education, and awareness of sustainability importance should be considered (GCCA, 2023; United Nations, 2023). Highlight that in an ideal scenario for CE, active collaboration from the local community during project development would be present.

- The cooperation between Latin American countries is required to consolidate knowledge, experiences, and best practices. This can drive the adoption of circular solutions and optimize both efforts and available resources (GCCA, 2023; Maury-Ramírez et al., 2022; Villagrán‐Zaccardi et al., 2022). Establishing regional collaboration networks and promoting joint projects can accelerate the transition towards a more sustainable industry in Latin America.

5. Conclusions

To meet international sustainability goals, the cement and concrete industry in Latin America requires a systematic approach to the circular economy to guide efforts in education, research, technological development, infrastructure, regulatory framework, standardization, investment, and regional cooperation. Global alternatives have demonstrated the suitability of this approach, as various models result in sustainable practices that add value to cement and concrete materials by minimizing GHG emissions, conserving resources, and waste reduction. Furthermore, it makes the industry and the regions that implement it more resilient and economically sustainable. However, the adoption and development of advanced technologies are required, as well as a design and construction approach based on optimization and durability criteria, in addition to greater training of the stakeholders involved in the industry and society. Therefore, it is expected that this work will contribute to the integration between the circular economy and the cement and concrete industry through the dissemination of this vision.

6. Acknowledgments

J.H. Díaz-Aguilera acknowledges CONAHCYT for the scholarship provided with CVU 929098.

References

Adesina, A. (2020), Recent advances in the concrete industry to reduce its carbon dioxide emissions. Env. Challen. 1:100004. https://doi.org/10.1016/j.envc.2020.100004

Adesina, A. (2021). Circular Economy in the Concrete Industry, en: Baskar, C., Ramakrishna, S., Baskar, S., Sharma, R., Chinnappan, A., Sehrawat, R. “Handbook of Solid Waste Management”, Singapore, Springer. https://doi.org/10.1007/978-981-15-7525-9_64-1

Akchurin, T. K., Tukhareli, V. D., Yu., O., Pushkarskaya (2016), The Modifying Additive for Concrete Compositions Based on the Oil Refinery Waste. Proc. Eng. 150:1485-1490. https://doi.org/10.1016/j.proeng.2016.07.087

Al-Hamrani, A., Kucukvar, M., Alnahhal, W., Mahdi, E., Onat, N. C. (2021), Green Concrete for a Circular Economy: A Review on Sustainability, Durability, and Structural Properties. Maters. 14(2):351. https://doi.org/10.3390/ma14020351

Al-mousa, E. M., Al-Zboon, K.K. (2022), Recycling of Nano Silica Waste from Aluminum Fluoride Industry in Cement Mortar. J. Sol. Was. Tech. Manag. 48(3):459-464. https://doi.org/10.5276/JSWTM/2022.459

Al-Sinan, M. A., Bubshait, A. A. (2022), Using Plastic Sand as a Construction Material toward a Circular Economy: A Review. Sust. 14(11):6446. https://doi.org/10.3390/su14116446

Althoey, F., Zaid, O., de-Prado-Gil, J., Palencia, C., Ali, E., Hakeem, I., Martínez-García, R. (2022), Impact of sulfate activation of rice husk ash on the performance of high strength steel fiber reinforced recycled aggregate concrete. J. Build. Eng. 54:104610. https://doi.org/10.1016/j.jobe.2022.104610

Amaral, L. P., Martins, N., Gouveia, J.B. (2016), A review of emergy theory, its application and latest developments. Ren. Sust. Ene. Rev. 54:882-888. https://doi.org/10.1016/j.rser.2015.10.048

Anastasiades, K., Blom, J., Buyle, M., Audenaert, A. (2020), Translating the circular economy to bridge construction: Lessons learnt from a critical literature review. Ren. & Sust. Ene. Rev. 117:109522. https://doi.org/10.1016/j.rser.2019.109522

Ariza-Figueroa, H. A., Bosch, J., Baltazar-Zamora, M. A., Croche, R., Santiago-Hurtado, G., Landa-Ruiz, L., Mendoza-Rangel, J. M., Bastidas, J. M., Almeraya-Calderón, F., Bastidas, D. M. (2020), Corrosion Behavior of AISI 304 Stainless Steel Reinforcements in SCBA-SF Ternary Ecological Concrete Exposed to MgSO4. Maters. 13(10):2412. https://doi.org/10.3390/ma13102412

Atta, I., Bakhoum, E. S., Marzouk, M. M. (2021), Digitizing material passport for sustainable construction projects using BIM. J. Build. Eng. 43:103233. https://doi.org/10.1016/j.jobe.2021.103233

Barreto, E. S., Stafanato, K. V., Marvila, M. T., Garcez de Azevedo, A. R., Ali, M., Pereira, R. M. L., Monteiro, S. N. (2021), Clay Ceramic Waste as Pozzolan Constituent in Cement for Structural Concrete. Maters. 14(11):2917. https://doi.org/10.3390/ma14112917

Bourke, K., Kyle, B. (2019), Service life planning and durability in the context of circular economy assessments - initial aspects for review. Can. J. Civ. Eng. 46(11):1074-1079. https://doi.org/10.1139/cjce-2018-0596

Caldas, L. R., Saraiva, A. B., Lucena, A. F. P., Da Gloria, M. Y., Santos, A. S., Filho, R. D. T. (2021), Building materials in a circular economy: The case of wood waste as CO2-sink in bio concrete. Res. Cons. Recyc. 166:105346. https://doi.org/10.1016/j.resconrec.2020.105346

Camilleri, M. A. (2020), European environment policy for the circular economy: Implications for business and industry stakeholders. Sust. Dev. 28(6):1804-1812. https://doi.org/10.1002/sd.2113

Castro-Borges, P., Helene, P. (2007), Service Life of Reinforced Concrete Structures. New Approach. in Corrosion of Infrastructure. Cancun, México: ECS Transactions.

Chakartnarodom, P., Wanpen, S., Prakaypan, W., Laitila, E. A., Kongkajun, N. (2022), Development of High-Performance Fiber Cement: A Case Study in the Integration of Circular Economy in Product Design. Sust. 14(19):12263. https://doi.org/10.3390/su141912263

Chatterjee, A., Sui, T. (2019), Alternative fuels - Effects on clinker process and properties. Cem. Concr. Res. 123:105777. https://doi.org/10.1016/j.cemconres.2019.105777

Colangelo, F., Navarro, T. G., Farina, I., Petrillo, A. (2020), Comparative LCA of concrete with recycled aggregates: a circular economy mindset in Europe. Inter. J. of LCA. 25:1790-1804. https://doi.org/10.1007/s11367-020-01798-6

Colorado, H. A., Velásquez, E. I. G., Monteiro, S. N. (2020), Sustainability of additive manufacturing: the circular economy of materials and environmental perspectives. J. Mater. Res. Tech. 9(4):8221-8234. https://doi.org/10.1016/j.jmrt.2020.04.062

Contrafatto, L. (2017), Recycled Etna volcanic ash for cement, mortar and concrete manufacturing. Constr. Build. Maters. 151:704-713. https://doi.org/10.1016/j.conbuildmat.2017.06.125

Corvellec, H., Stowell, A. F., Johansson, N., (2022). Critiques of the circular economy. J. Indus. Eco. 26(2):421-432. https://doi.org/10.1111/jiec.13187

Cosentino, I., Liendo, F., Arduino, M., Restuccia, L., Bensaid, S., Deorsol, F., Ferro, G. A. (2020), Nano CaCO3 particles in cement mortars towards developing a circular economy in the cement industry. Proc. Struc. Int. 26:155-165. https://doi.org/10.1016/j.prostr.2020.06.019

Delwar, M., Fahmy, M., Taha, R. (1997), Use of Reclaimed Asphalt Pavement as an Aggregate in Portland Cement Concrete. Maters. J. 94(3):251-256. https://doi.org/10.14359/306

Díaz-Aguilera, J. H., Rodríguez-Reyna, S. L., Flores-Véles, L. M., Dominguez, O. (2021), Improvement of Mechanical Behavior of Rubber-Cement Mortars by Catalytic Hydration. J. Mater. Civ. Eng. 33(10):04021282. https://doi.org/10.1061/(ASCE)MT.1943-5533.0003897

Dikshit, A. K., Sahoo, B. B., Gupta, S. K., Chaturvedi, S. K. (2022). “A study on utilization of paper mill lime sludge in the manufacture of cement under circular economy” in: International Conference on Cement, Concrete and Building Materials, 17th National Council for Cement and Building Materials, New Dheli (India), pp. 1-6.

Fay, L., Cooper, P., de Morais, H. F. (2014), Innovative interlocked soil-cement block for the construction of masonry to eliminate the settling mortar. Constr. Build. Maters. 52:391-395. https://doi.org/10.1016/j.conbuildmat.2013.11.030

Fořt, J., Černý, R. (2020), Transition to circular economy in the construction industry: Environmental aspects of waste brick recycling scenarios. Was. Manag. 118:510-520. https://doi.org/10.1016/j.wasman.2020.09.004

Gallaud, D., Laperche, B. (2016), “Circular Economy, Industrial Ecology and Short Supply Chain”. John Wiley & Sons Inc, London, U.K.

Geisendorf, S., Pietrulla, F. (2018), The circular economy and circular economic concepts-a literature analysis and redefinition. Thund. Inter. Buiss. Rev. 60(5):771-782. https://doi.org/10.1002/tie.21924

Ghosh, S. K., Kumar, V. (2020), “Circular Economy and Fly Ash Management”. Springer, Singapore, 2020.

Global Cement and Concrete Association (GCCA) (2023), GCCA and FICEM Take Next Steps to Accelerate Regional Net Zero Progress at LatAm and the Caribbean Climate Week. Accedido el 8 de junio de 2023 en: https://gccassociation.org/news/gcca-and-ficem-take-next-steps-to-accelerate-regional-net-zero-progress-at-latam-and-the-caribbean-climate-week/

González-Domínguez, J., Sánchez-Barroso, G., Zamora-Polo, F., García-Sanz-Calcedo, J. (2020), Application of Circular Economy Techniques for Design and Development of Products through Collaborative Project-Based Learning for Industrial Engineer Teaching. Sust. 12(11):4368. https://doi.org/10.3390/su12114368

Guimarães, A. S., Delgado, J. M. P. Q., Lucas, S. S. (2021), Additive Manufacturing on Building Construction. Def. Dif. For. 412:207-216. https://doi.org/10.4028/www.scientific.net/ddf.412.207

Hamam, M., Chinnici, G., Di Vita, G., Pappalardo, G., Pecorino, B., Maesano, G., D’Amico, M. (2021), Circular Economy Models in Agro-Food Systems: A Review. Sust. 13(6):3453. https://doi.org/10.3390/su13063453

Hanif, M., Agarwal, R., Sharma, U., Thapliyal, P. C., Singh, L. P. (2023), A review on CO2 capture and sequestration in the construction industry: Emerging approaches and commercialised technologies. J CO2 Util. 67:102292. https://doi.org/10.1016/j.jcou.2022.102292

Hentges, T. I., da Motta, E. A. M., Fantin, T. V. L., Moraes, D., Fretta, M. A., Pinto, M. F., Böes, J. S. (2021), Circular economy in Brazilian construction industry: Current scenario, challenges and opportunities. Was. Manag. Res. 40(6):642-653. https://doi.org/10.1177/0734242X211045014

Hossain, M. U., Ng, S. T., Antwi-Afari, P., Ben, Amor (2020), Circular economy and the construction industry: Existing trends, challenges and prospective framework for sustainable construction. Ren. Sust. Ener. Rev. 130:109948. https://doi.org/10.1016/j.rser.2020.109948

Iacovidou, E., Millward-Hopkins, J., Busch, J., Purnell, P., Velis, C. A., Hahladakis, J. N., Zwirner, O., Brown, A. (2017), A pathway to circular economy: Developing a conceptual framework for complex value assessment of resources recovered from waste. J. Clean. Prod. 168:1279-1288. https://doi.org/10.1016/j.jclepro.2017.09.002

Juárez-Alvarado, C. A., Magniont, C., Escadeillas, G., Terán-Torres, B. T., Rosas-Díaz, F., Valdez-Tamez, P. L. (2020), Sustainable Proposal for Plant-Based Cementitious Composites, Evaluation of Their Mechanical, Durability and Comfort Properties. Sust. 14:14397. https://doi.org/10.3390/su142114397

Kaliyavaradhan, S. K., Tung-Chai, L., Mo, K. H. (2020), CO 2 sequestration of fresh concrete slurry waste: Optimization of CO 2 uptake and feasible use as a potential cement binder. J. CO2 Util. 42:101330. https://doi.org/10.1016/j.jcou.2020.101330

Karlsson, I., Rootzén, J., Johnsson, F. (2020), Reaching net-zero carbon emissions in construction supply chains - Analysis of a Swedish road construction project. Ren, Sust. Ene. Rev. 120:109651. https://doi.org/10.1016/j.rser.2019.109651

Kosmatka, S. H., Wilson, M. L. (2004), “Design and control of concrete mixtures”, Portland Cement Association, Illinois, USA.

Lederer, J., Gassner, A., Kleemann, F., Fellner, J., (2020), Potentials for a circular economy of mineral construction materials and demolition waste in urban areas: a case study from Vienna. Res. Cons. Recy. 161:104942. https://doi.org/10.1016/j.resconrec.2020.104942

Liew, K. M., Akbar, A. (2020), The recent progress of recycled steel fiber reinforced concrete. Constr. Build. Maters. 232:117232. https://doi.org/10.1016/j.conbuildmat.2019.117232

Linek, M., Bacharz, M., Piotrowska, P. (2023), Surface Cement Concrete with Reclaimed Asphalt. Maters. 16(7):2791. https://doi.org/10.3390/ma16072791

Londoño, N. A. C., Cabezas, H. (2021), Perspectives on circular economy in the context of chemical engineering and sustainable development. Cur. Opin. Chem. Eng. 34:100738. https://doi.org/10.1016/j.coche.2021.100738

Marsh, A. T. M., Velenturf, A. P. M., Bernal, S. A. (2022), Circular Economy strategies for concrete: implementation and integration. J. Clean. Produc. 362:132486. https://doi.org/10.1016/j.jclepro.2022.132486

Mathews, J. A., Tan, H. (2011), Progress Toward a Circular Economy in China: The Drivers (and Inhibitors) of Eco-industrial Initiative. J. Ind. Eco. 15(3):435-457. https://doi.org/10.1111/j.1530-9290.2011.00332.x

Maury-Ramírez, A., Illera-Perozo, D., Mesa, J. A. (2022), Circular Economy in the Construction Sector: A Case Study of Santiago de Cali (Colombia). Sust. 14(3):1923. https://doi.org/10.3390/su14031923

Minunno, R., O’Grady, T., Morrison, G. M., Gruner, R. L., Colling, M. (2018), Strategies for Applying the Circular Economy to Prefabricated Buildings. Build. 8(9):125. https://doi.org/10.3390/buildings8090125

Mostert, C., Sameer, H., Glanz, D., Bringezu, S. (2021), Climate and resource footprint assessment and visualization of recycled concrete for circular economy. Resour. Cons. & Recy. 174:105767. https://doi.org/10.1016/j.resconrec.2021.105767

Muñoz-Zapata, A., Cifuentes-Mosqueda, S. (2022), Portland Cement Mortars Tested with Two Superplasticizers: A Case Study to Reduce Cement and Water in Concrete. Tecn. 26(72):114-146. https://doi.org/10.14483/22487638.16824

Neves, J., Freire, A. C. (2022), Special Issue “The Use of Recycled Materials to Promote Pavement Sustainability Performance”. Recyc. 7(2):12. https://doi.org/10.3390/recycling7020012

Nodehi, M., Taghvaee, V. M. (2022), Sustainable concrete for circular economy: a review on use of waste glass. G. Struc. & Eng. 7:3-22. https://doi.org/10.1007/s40940-021-00155-9

NoParast, M., Hematian, M., Ashrafian, A., Amiri, M. J. T., Jafari, H. A. (2021), Development of a non-dominated sorting genetic algorithm for implementing circular economy strategies in the concrete industry. Sust. Prod. & Cons. 27:933-946. https://doi.org/10.1016/j.spc.2021.02.009

Pérez, J. L., González-Fonteboa, B., Martínez-Abella, F. (2009), “EC Techniques in the Structural Concrete Field”, IGI Global.

Pérez-Cortes, P., Escalante-García, J. I. (2020), Design and optimization of alkaline binders of limestone-metakaoline A comparison of strength, microstructure and sustainability with portland cement and geopolymers. J. Crean. Prod. 273:123118. https://doi.org/10.1016/j.jclepro.2020.123118

Phiri, T. C., Singh, P., Nikoloski, A. N. (2021), The potential for copper slag waste as a resource for a circular economy: A review - Part II. Min. Eng. 172:107150. https://doi.org/10.1016/j.mineng.2021.107150

Rada, R., Manea, D. L., Chelcea, R., Rada, S. (2023), Nanocomposites as Substituent of Cement: Structure and Mechanical Properties. Maters. 16(6):2398. https://doi.org/10.3390/ma16062398

Romero, C. A. T., Castro., D. F., Ortiz, J. H., Khalaf, O. I., Vargas, M. A. (2021), Synergy between Circular Economy and Industry 4.0: A Literature Review. Sust. 13(8):4331. https://doi.org/10.3390/su13084331

Rossignolo, J. A., Duran, A. J. F. P., Bueno, C., Filho, J. E. M., Junior, H. S., Tonin, F. G. (2022), Algae application in civil construction: A review with focus on the potential uses of the pelagic Sargassum spp. biomass. J. Env. Manag. 303:114258. https://doi.org/10.1016/j.jenvman.2021.114258

Roychand, R., Patel, S., Halder, P., Kundu, S., Hampton, J., Bergmann, D., Surapaneni, A., Shah, K., Pramanik, B. K. (2021), Recycling biosolids as cement composites in raw, pyrolyzed and ashed forms: A waste utilisation approach to support circular economy. J. Build. Eng. 38;102199. https://doi.org/10.1016/j.jobe.2021.102199

Şahin, H. G., Mardani-Aghabaglou, A. (2022), Assessment of materials, design parameters and some properties of 3D printing concrete mixtures; a state-of-the-art review. Constr. Build. Maters. 316:125865. https://doi.org/10.1016/j.conbuildmat.2021.125865

Sehnem, S., Vasquez-Brust, D., Pereira, S. C. F., Campos, L. M. S. (2019), Circular economy: benefits, impacts and overlapping. Sup. C. Manag. Inter. J. 24(6):784-804. https://doi.org/10.1108/SCM-06-2018-0213

Sharifikolouei, E., Ferraris, M. (2021), Potential Role of Vitrification and Waste Vitrification in the Circular Economy. En: Baino, F., Tomalino, M., Tulyaganov, D. “Ceramics, Glass and Glass-Ceramics. PoliTO Springer Series”, Cham, Springer.

Shi, C., Krivenko, P.V., Roy, D. (2006), “Alkali-Activated Cements and Concretes”, Taylor and Francis Group, London, U.K.

Sudarsan, J. S., Gavali, H. (2023), Application of BIM in conjunction with circular economy principles for sustainable construction. Envir. Dev. Sust. 2:2023. https://doi.org/10.1007/s10668-023-03015-4

Taghvaee, V. M., Nodehi, M. (2022), Applying Circular Economy to Construction Industry through Use of Waste Materials: A Review of Supplementary Cementitious Materials, Plastics, and Ceramics. Cir. Eco. & Sust. 2:987-1020. https://doi.org/10.1007/s43615-022-00149-x

Tari, H., Siddique, R. M. A., Shah, S. A. R., Azab, M., Attiq-Ur-Rehman Qadeer, R., Ullah, M. K., Iqbal, F. (2022), Mechanical Performance of Polymeric ARGF-Based Fly Ash-Concrete Composites: A Study for Eco-Friendly Circular Economy Application. Pol. 14(9):1774. https://doi.org/10.3390/polym14091774

Taylor, H. F. W. (1997), “Cement chemistry”, Thomas Telford Services Ltd, London, U.K.

Ulusu,, H., Aruntaş, H. Y., Gültekin, A. B., Dayı, M., Çavuş, M., Kaplan, G. (2023), Mechanical, durability and microstructural characteristics of Portland pozzolan cement (PPC) produced with high volume pumice: Green, cleaner and sustainable cement development. Consftr. Build. Maters. 378:131070. https://doi.org/10.1016/j.conbuildmat.2023.131070

United Nations (2023), The 17 goals, sustainable development. Accedido el 12 de julio de 2023 en https://sdgs.un.org/goals

Van Breugel, K. (2017). “Ageing Infrastructure and Circular Economy: Challenges and Risks”, in: Proceedings of the 2nd World Congress on Civil, Structural, and Environmental Engineering, CSEE’17, Barcelona (España), pp. 1-8.

Van Dam, K., Simeone, L., Keskin, D., Baldassarre, B., Niero, M., Morelli, N. (2020), Circular Economy in Industrial Design Research: A Review. Sust. 12(24):10279, https://doi.org/10.3390/su122410279

Van Wijk, A., Van Wijk, I. (2015), “3D Printing with biomaterials: Towards a sustainable and circular economy”, IOS Press - Delft University Press, Amsterdam, Netherlands.

Velvizhi, G., Shanthakumar, S., Das, B., Pugazhendhi, A., Priya, T. S., Ashok, B., Nanthagopal, K., Vignesh, R., Karthick, C. (2020), Biodegradable and non-biodegradable fraction of municipal solid waste for multifaceted applications through a closed loop integrated refinery platform: Paving a path towards circular economy. Sci. T. Env. 731:138049. https://doi.org/10.1016/j.scitotenv.2020.138049

Villagrán‐Zaccardi, Y., Pareja, R., Rojas, L., Irassar, E., Torres‐Acosta, A., Tobón, J., John, V. M. (2022), Overview of cement and concrete production in Latin America and the Caribbean with a focus on the goals of reaching carbon neutrality. RILEM techn. Let. 7:30-46. https://doi.org/10.21809/rilemtechlett.2022.155

Vitale, P., Napolitano, R., Colella, F., Menna, C., Asprone, D. (2021), Cement-Matrix Composites Using CFRP Waste: A Circular Economy Perspective Using Industrial Symbiosis. Maters. 14(6):1484. https://doi.org/10.3390/ma14061484

Wang, H., Liu, Y., Zhang, J., Zhang, H., Huang, L., Xu, D., Zhang, C. (2022), Sustainability Investigation in the Building Cement Production System Based on the LCA-Emergy Method. Sust. 14(24):16380. https://doi.org/10.3390/su142416380

Xavier, L. H., Giese, E. C., Ribeiro-Duthie, A. C., Lins, F. A. F. (2021), Sustainability and the circular economy: A theoretical approach focused on e-waste urban mining. Res. Pol. 74:101467. https://doi.org/10.1016/j.resourpol.2019.101467

Yang, M., Chen, L., Wang, J., Msigwa, G., Osman, A. I., Fawzy, S., Rooney, D. W., Pow-Seng, Y. (2022), Circular economy strategies for combating climate change and other environmental issues. Env. Chem. Let. 21:55-80. https://doi.org/10.1007/s10311-022-01499-6

Yousef, S., Kalpokaitė-Dičkuvienė, R., Baltušnikas, A., Pitak, I., Lukošiūtė, S. I. (2021), A new strategy for functionalization of char derived from pyrolysis of textile waste and its application as hybrid fillers (CNTs/char and graphene/char) in cement industry. J. Clean. Prod. 314:128058. https://doi.org/10.1016/j.jclepro.2021.128058

Zajac, M., Skocek, J., Ben Haha, M., Deja, J. (2022), CO2 Mineralization Methods in Cement and Concrete Industry. Ener. 15(10):3597. https://doi.org/10.3390/en15103597

Zhang, J., Lv, T., Hou, D., Dong, B. (2023), Synergistic effects of fly ash and MgO expansive additive on cement paste: Microstructure and performance. Constr. Build. Maters. 371:130740. https://doi.org/10.1016/j.conbuildmat.2023.130740