| Basic Research | https://doi.org/10.21041/ra.v13i2.684 |

Influence of sand proportion in the physical and mechanical properties of construction and building mortars

Influência da proporção de areia nas propriedades físicas e mecânicas de argamassas para construção

Influencia de la proporción de arena en las propiedades físicas y mecánicas de morteros para la edificación

M.

Navarrete-Seras1

*

![]() ,

W.

Martinez-Molina1

,

W.

Martinez-Molina1

![]() ,

H. L.

Chavez-Garcia1

,

H. L.

Chavez-Garcia1

![]() ,

A.

Sanchez-Calvillo2

1

,

A.

Sanchez-Calvillo2

1

![]() ,

M.

Arreola-Sanchez1

4

,

M.

Arreola-Sanchez1

4

![]() ,

J. A.

Borrego-Perez1

4

,

J. A.

Borrego-Perez1

4

![]() ,

N. A.

Perez-Castellanos5

4

,

N. A.

Perez-Castellanos5

4

![]() ,

R. P.

Ruiz-Torres6

,

R. P.

Ruiz-Torres6

![]() ,

A. M.

Duran-Ramos1

,

A. M.

Duran-Ramos1

![]() ,

E. M.

Alonso-Guzman1

3

*

,

E. M.

Alonso-Guzman1

3

*

![]()

1 Materials Department, Faculty of Civil Engineering, Universidad Michoacana de San Nicolás de Hidalgo, Morelia, Michoacán, México, 58040.

2 Sustainable Energy, Machinery and Buildings (SEMB), Universitat de Lleida, Lleida, Spain, 25002.

3 PIDA, Faculty of Architecture, Universidad Michoacana de San Nicolás de Hidalgo, Morelia, Michoacán, México 58040.

4 Consejo Nacional de Ciencia y Tecnología, CONACYT, México.

5 Instituto de Investigaciones Estéticas, UNAM, Coyoacán, CDMX, México, 04510.

6 Faculty of Architecture, UNACH, Tuxtla Gutiérrez, Chiapas, México, 29050.

*Contact author: mnavarrete@umich.mx

Reception:

April

01,

2023.

Acceptance:

April

19,

2023.

Publication: May 01, 2023.

| Cite as: Navarrete-Seras, M., Martinez-Molina, W., Chavez-Garcia, H. L., Sanchez-Calvillo, A., Arreola-Sanchez, M., Borrego-Perez, J. A., Perez-Castellanos, N. A.,Ruiz-Torres, R. P., Duran-Ramos, A. M., Alonso-Guzman, E. M. (2023), “Influence of sand proportion in the physical and mechanical properties of construction and building mortars”, Revista ALCONPAT, 13 (2), pp. 158 –174, DOI: https://doi.org/10.21041/ra.v13i2.684 |

Abstract

The influence of the sand proportion in mortars Type II was studied, according to the standard N-CMT-2-01-004/02, using three fine aggregates from the region of Morelia, in Michoacan, and determining their influence in the physico-mechanical properties, while considering the use of different cementitious materials (CM): Portland cement plus lime (B1), and Portland cement plus construction cement (B2). Mortar mixtures were designed for B1 and B2 with volume ratios of aggregates/CM, from 2.25 to 4, determining the fluency, the uniaxial compressive strength (UCS) and the wet electrical resistivity (WER). The relation between the fluency and the ratio water/CM were studied, concluding that the aggregate type and the proportions employed modify the fluency and the water demand in the fresh state of the mortar, and consequently impact the UCS and WER.

Keywords:

construction mortars,

electrical resistivity,

fine aggregates,

mechanical resistance,

sieve analysis.

1. Introduction

Traditionally, the residential buildings have been built with different construction materials like the regular and irregular stones, ceramic bricks, wood, or earthen blocks among many others. These walls and floors often have joining mortars to bind the masonries, or to act as the coatings or refurbishments (which are called “plasters” or plastering” by archaeologists) that cover the wall systems (Álvarez Galindo et al., 1995). Mortars are mixtures of inorganic conglomerates, aggregates, water, and other elements used as additives. Their main purpose is joining the construction elements, filling the void spaces as binding agents, and protecting the surfaces and systems from external agents (Sánchez Tizapa et al., 2017; Wu et al., 2021).

In the ancient Rome the containers where the mixtures of lime paste and sand were transported were called “mortarius”; and over time this term has derived to the one utilized to designate the actual mixture. As a matter of fact, the first records of lime mortars can be found in the Vitruvius works, where the selection and manufacturing process of limestone are described to be used for building purposes (Navarro-Mendoza et al., 2023). These traditional systems were utilized for centuries in the construction of foundations, walls, pavements and coatings; until the appearance and popularization of Portland cement (Álvarez Galindo et al., 1995; Navarro-Mendoza et al., 2020).

The mortars have had multiple uses in the construction industry over time; for instance, in residential buildings, they were utilized to provide thermal and acoustic insulation properties, to avoid the proliferation of harmful or problematic fauna and flora, or to obtain certain aesthetic features. Regarding the joining purposes of the mortars, they need to achieve adequate mechanical resistances to allow the masonries of the structural elements to withstand the required loadings of the constructions.

Before the emergence of the contemporary construction cement, in Mexico, the artisans and builders used to add lime for increasing the setting times of the mortars. Lime had the function of retaining the water and allow the internal curing and hydration of the mortar. This mixture, resulting from the experience at works, receives the name of tertiary mortar, on account of the three employed elements: Portland cement, lime and fine aggregates.

This mortar is easy to purchase, as the basic elements required (water, adhesives and sand) to make the mixture are affordable, and the application of the product is simple. Nevertheless, the users have neglected the importance of the proper proportions of the components, and this situation has brought problems such as the decrease of the adherence and the mechanical resistance, structural deterioration, or shrinkage resulting into cracks that reduce the lifetime of the mortar (Jacques et al., 2023; Li et al., 2023). Additionally, in most cases, the physical and mechanical properties of the FA extracted from quarries are unknown, and the selection of the materials is determined by the cheap prices and proximity.

The type and proportions of the constituent materials of a mortar will influence the properties in the fresh state (Giordani & Masuero, 2019), and consequently, their performance in the hardened state (Haach et al., 2011). One of the most desired features during the fresh state is the workability, which must be adequate for the execution of the coating or render, to guarantee its performance in terms of adhesion to the substrate (Ribeiro & Oliveira Rey, 2019; Tena et al., 2017). Some elements which affect directly the mortar properties are the raw materials and their quality, especially the FA. Therefore, an adequate rheology analysis must be performed to determine if they comply with the established standards, and that the FA are not affecting the mortar viscosity and workability (Danish & Ozbakkaloglu, 2023; Li et al., 2022; Westerholm et al., 2008).

Typically, the FA represent more than 35% of the total volume of the mortar, being one of the most important components of the mixture. Consequently, using different FA with irregular shapes and an ineffective distribution will result in a deterioration of fluency properties, decreasing the density and increasing the specific surface area while reducing the paste thickness (Hafid et al., 2016; Stolz & Masuero, 2018). The morphology of these FA also plays an important role in the physical properties, due to impact on mortar rheology (Durán Ramos, 2021; Ren et al., 2021).

Different studies have been carried out to understand the importance of the FA and their feasible substitution in mortar mixtures. It was reported how the single use of FA increased by 30% the plastic viscosity of the mortar designs (Hu, 2005); another research compared the difference in the performance of Portland cement mortars and geopolymers with residual fine glass aggregate (Gao et al., 2022); the carbonation behavior of mortars was also analyzed by adding different waste materials with cementitious and/or pozzolanic properties as replacements of the Portland cement, determining if the additions could limit or improve the carbonation of the mixtures when they harden (Martinez-Molina et al., 2021).

Other works investigated the suitability of waste plastic aggregates instead of FA, reporting that proportions from 10 to 20% may decrease the compressive strength and splitting tensile strength (Ullah et al., 2021). The influence of fiber additions was also analyzed on the fresh properties, as well as the deformability and the mechanical behavior (Brazão Farinha et al., 2021); also, the effects of additions like silica flume, superplasticizer and the water/binder ratio have been studied (Senff et al., 2009). The partial substitution of cement by limestone powder (0, 9, 16, 23 and 30 %) has proven an affectation in the rheological, mechanical and durability properties (Souza et al., 2020), as well as fine eggshell powder (Beng Wei et al., 2021), or natural pozzolans (HAMMAT et al., 2021).

The issues described about the importance of the FA properties within the mortars, as well as the ambiguity of the Mexican standards (NMX-C-486-ONNCCE-2014 and N-CMT-2-01-004/02) regarding the water and CM proportions led to this research. It is important to note that the analyses were performed with sand quarries from a particular region of Mexico (in Morelia). The relevance of the research relies on the visualization of the differences in the workability and the hardened state of the mortars in function of the different FA quarries of the same region; furthermore, it allows to assess the reliability and quality of the mortars used as structural coatings.

The present research work focuses on the analysis of the relation FA/CM to comply with the existing regulations, while determining the maximum amount of sand utilized to design a mortar with structural purposes. Additionally, three different natural sands (FA) were studied, with different combinations of hydraulic cement (Portland cement), construction cement, and lime; analyzing the influence of sand proportion in the physico-mechanical properties of the mortars. These mixtures were characterized with non-destructive techniques and mechanical tests to assess the better combinations in function of the regulation requirements. All of this, with the objective of increasing the scientific and technical knowledge of the common construction and building mortars, impacting positively on their quality and durability.

2. Materials and procedure methods

The mortars were designed to be used outside and inside the buildings, but they were particularly conceived for self-construction purposes in residential housing. In the standard N-CMT-2-01-004/02, the masonry mortars are classified into three classes: I, II, and III, depending on the components and the minimum mechanical resistance value. The mixtures were based on the mortars Type II (ONNCCEE, 2002), consisting in a combination of cement, lime, and different proportions of sand to determine the better behaviors. The sand proportion should not be less than 2.25 nor more than 4 times the sum of the CM in volume.

In this research, all the mortar mixtures were designed and tested in the materials laboratory, starting from the characterization and quality control of the prime materials. The cement employed, CPC 30R RS, is classified as Type II according to the standard ASTM C150-C150M-22 (ASTM International, 2022c). Conversely, the lime complies with the standard ASTM E1266-20 (ASTM International, 2020b). The sands were sampled from quarries in the State of Michoacan, in Mexico, and tested in the laboratory, with each data being the average of three tests. The physical characterization of the sands was performed as indicated in American Society and Testing and Materials (ASTM) international standards, and the Organismo Nacional de Normalización y Certificación de la Construcción y Edificación (ONNCCE) of Mexico.

The mixtures were elaborated and then the fluency in fresh state was determined, later they were tested to obtain mechanical properties like the Uniaxial Compressive Strength (UCS), considering the minimum resistance of 75 kgf/cm2 requested by the standard NMX-C-486-ONNCCE-2014 (ONNCCE, 2014); or other characteristics by means of non-destructive techniques (NDT), like the Wet Electrical Resistivity (WER) at 7 and 28 days of age.

2.1 Design of the mixtures

The mortar specimens, all being type II according to the standards, were prepared in laboratory conditions with different proportions of cement, lime, aggregates and water, as it is shown in Table 1. Half of the mortars (B1) were prepared with hydraulic cement, lime and sand; while the other half (B2) were prepared mixing hydraulic cement, construction cement and sand. For both kind of mortars, different proportions of sand (from 2.25 to 4) were used, obtaining a great quantity of samples; for all of them the standard fluidity, which must range between 105% and 130% (ONNCCE, 2015b), was calculated. Later, the samples were cured in water as it is indicated in the standard ASTM C31-C31M-22 (ASTM International, 2022a), and the water employed was obtained from the public water network of the UMSNH university campus. 6 cubes were made for each mixture, resulting in 96 cubes for each type of sand due to the multiple combinations and proportions.

| Table 1. Mixture design and proportions. | ||||||||||||||

| Code | Hydraulic cement (Portland cement) | Construction cement | Lime | Sand | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| B1 | 1 | - | ½ | 2.25, 2.5, 2.75, 3, 3.25, 3.5, 3.75, 4 | ||||||||||

| B2 | 1 | 1 | - | 2.25, 2.5, 2.75, 3, 3.25, 3.5, 3.75, 4 | ||||||||||

2.2 Characterization and properties of the fine aggregates

The FA were extracted from surrounding quarry stones in the state of Michoacan, in Mexico. The State of Michoacan is located in the Trans-Mexican Volcanic Belt, where the extrusive igneous rocks and the siliceous materials are abundant, like the river aggregates or the quartz sands. The three FA utilized in this research are all natural sands, not being submitted to any grinding or artificial procedures. First, we find the “El Coro” quarry (CH) in the municipality of Zinapecuaro, near the Cuitzeo Lake, in Latitude 19.893889, Longitude -100.875833; secondly, the “ El Cuervo” quarry (R), near the Huajumbaro river in the Balsas basin region, in Latitude 19.626110, Longitude -100.636667; last, the “Joyitas” quarry (J), in Morelia, Latitude 19.727222, Longitude -101.385278. The three sands are displayed in figure 1.

|

||||

| Figure 1. Sand aggregates: a) Joyitas volcanic sand; b) El Coro volcanic silty sand; (c) El Cuervo river sand. Image sources: (Durán, 2021; Durán, 2021; Mondragón, 2021). | ||||

The sands were sampled from the mentioned quarries and transported to the materials laboratory to be analyzed. They were dried and prepared as representative sampling quantities (100 kg) to undertake the mortars design process. The geomaterials don’t have the same strict quality control as the cement, because of their natural origin; instead, commonly, the mortars are based on the previous experience of users, artisans and builders. The table 2 presents the set of characterization methods applied for the three different FA utilized in the research work before the manufacturing of the mortars (ASTM International, 2017, 2018, 2019b, 2022b; ONNCCE, 2004, 2006, 2020).

| Table 2. Test methods performed on the aggregates. | |||||||||||||||||||

| Test method | Standard | CH | R | J | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Standard Practice for Sampling Aggregates (kg) | ASTM D75/D75M-19 | 100 | 100 | 100 | |||||||||||||||

| Standard Test Method for Relative Density (Specific Gravity) and Absorption of Fine Aggregate (g/cm3) | ASTM C128-22 | 2.22 | 2.13 | 2.40 | |||||||||||||||

| Aggregates – Determination of the relative density and water absorption of fine aggregate – Test method (g/cm3) | NMX-C-165-ONNCCE | ||||||||||||||||||

| Standard Test Method for Relative Density (Specific Gravity) and Absorption of Fine Aggregate (%) | ASTM C128-22 | 7.02 | 5.92 | 4.75 | |||||||||||||||

| Aggregates – Determination of the relative density and water absorption of fine aggregate – Test method (g/cm3) | NMX-C-165-ONNCCE | ||||||||||||||||||

| Standard Test Method for Bulk Density and Voids in Aggregate (g/cm3) | ASTM C29/C29M-17a | 1.18 | 1.23 | 1.36 | |||||||||||||||

| Aggregate for Concrete - Volumetric Mass - Test Method (g/cm3) | NMX-C-073-ONNCCE | ||||||||||||||||||

| Standard Test Method for Bulk Density and Voids in Aggregate (g/cm3) | ASTM C29/C29M-17a | 1.28 | 1.36 | 1.42 | |||||||||||||||

| Aggregates Particles Finer Than 0.075 mm (No. 200) Sieve by Washing – Test Method (g/cm3) | NMX-C-084-ONNCCE | ||||||||||||||||||

| Standard Specification for Concrete Aggregates (fineness modulus) | ASTM C33-C33M-18 | 3.51 | 2.98 | 3.87 | |||||||||||||||

| * The density and absorption values are detached in the table but they correspond to the same standards. | |||||||||||||||||||

The bulk density was calculated for all the sands, obtaining similar results for each specimen (ASTM International, 2017); on the other hand, the CH material had an absorption coefficient higher than 7%, while J had a lower value of 4.75%, being a prominent feature. This condition can have a direct affectation on the mortar’s properties, as it could increase the water demand and consequently decrease the compression strength.

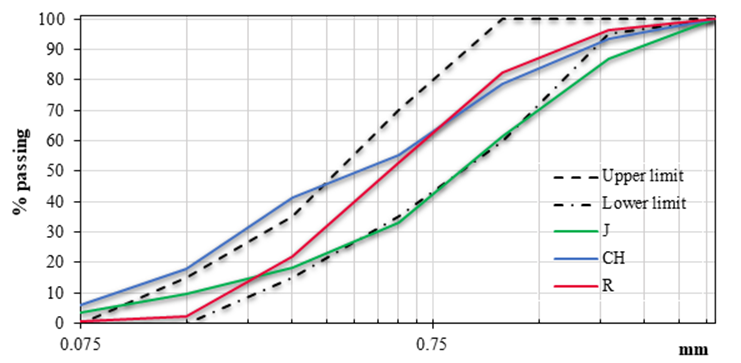

The figure 2 displays the sieve analysis and particle size of the different FA used in the research. The upper and lower limits of the standard are represented (ASTM International, 2018), showing how R adapts perfectly to the granulometric curve; on the other hand, CH presents an excess of fine material from the 0.1 to 0.4 mm range approximately, while R slightly oversteps the lower limit. These conditions can have consequences on some properties of the mortar mixtures like the fluency and the water demand in the fresh state of the mortars, as it will be displayed later in figures 6 and 7.

|

||||

| Figure 2. Sieve analysis of the sand aggregates. | ||||

2.3 Test methods performed on the mortars

The Table 3 displays the set of test methods used for the characterization of the mortar mixtures in both fresh and hardened state. The international and Mexican standards (ASTM and ONNCCE) were followed to analyze the different combinations. Additionally, the three trials and their procedure are detailed in the following section (ASTM International, 2019a, 2020a, 2021; ONNCCE, 2014, 2015a, 2019).

| Table 3. Test methods performed on the mortars. | |||||||||||||||||||

| Test methods | Standard | Conditions | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Uniaxial Compression Strength (UCS) | ASTM C109/C109M-21 | Solid cubes 5x5x5 cm3 | |||||||||||||||||

| NMX-C-486-ONNCCE-2014 | |||||||||||||||||||

| Wet Electrical Resistivity (WER) | ASTM C1876-19 | Solid cubes 5x5x5 cm3 | |||||||||||||||||

| NMX-C-514-ONNCCE-2016 | |||||||||||||||||||

| Mechanical Mixing of Hydraulic Cement Pastes and Mortars of Plastic Consistency | ASTM C305-20 | Fresh state mixture | |||||||||||||||||

| NMX-C-061-ONNCCE-2015 | |||||||||||||||||||

| Nota | |||||||||||||||||||

2.3.1. Fluency

The fluency test (see figure 3) allows to determine the flow or workability of the mortar mixture in fresh state, according to the water content utilized. The trial denotes the consistency of the mixture as well as its suitability for each specific technique and application, according equation 1. The limits required for this the test rely in a range between 105 and 130 %

|

||||

| Figure 3. Trials on the mortar mixtures: a) Mixture in mold; b) Consistency; c) Adherence. Image source: (Duran, 2021). | ||||

2.3.2. Wet Electrical Resistivity (WER)

The WER is an alternative test to evaluate the homogeneity in concrete matrices, allowing us to obtain relevant information about the performance of the material, without physically compromising the structure, being a NDT. The test was performed according to standards NMX-C-514-ONNCCE and ASTM C1876-19 (see figure 4). The procedure is based on the Ohm's Law, that indicates that the electrical resistivity is a reciprocal property of the conductivity, as it is considered a volumetric property of materials that indicates their resistance to the passage of electric charges. The WER is represented by the following equation 2, where R is the electrical resistivity in kΩ-cm, l is the specimen length in cm and A is the specimen cross-sectional area in cm2.

|

||||

| Figure 4. Nilsson resistivity apparatus. | ||||

2.3.3. Uniaxial compressive strength (UCS)

The objective of this test is determining the uniaxial compressive strength (UCS) of 50 mm cubic specimens (see figure 5), standardized by the standards NMX-C-486-ONNCCE and ASTM C109/C109M-21. The UCS is obtained with equation 3, where UCS is the uniaxial compressive strength in kgf/cm2, W is the maximum load of the specimen in kgf, and A is the specimen contact area, in cm2.

|

||||

| Figure 5. Uniaxial compressive strength (UCS) testing machine for mortars. | ||||

3. Results

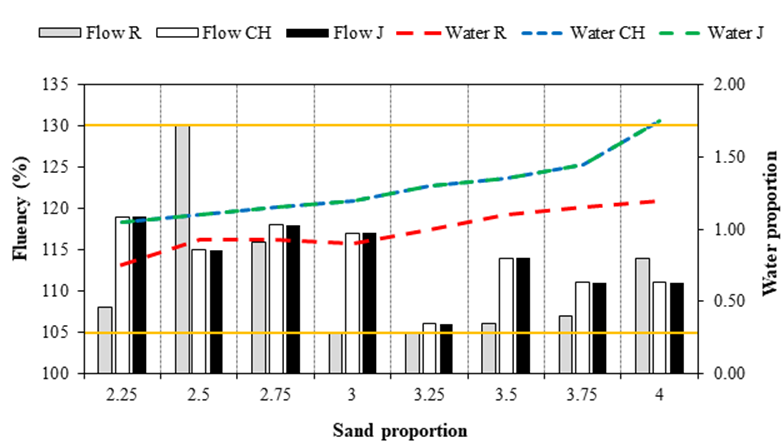

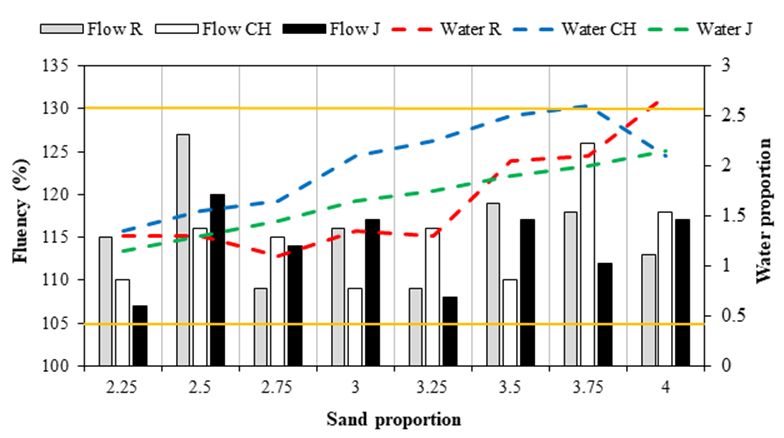

The research work analyzed the properties of the three FA in the mortar mixtures and their different dosages. The figure 6 displays the comparison between the fluency of the three FA and the volumetric relation of the water content and the CM of each B1 specimen; in this case the aggregates CH and J required the same amount of water (the curves overlap), while R needed less content, similar than the research performed by Hu et al. (2005). On the other hand, the figure 7 shows the results of the B2 mortars; in this case, each sand required different quantity of water, and until the 3.25 proportion, the water demand for R was the lower of all the FA, like other authors reported before (Durán Ramos, 2021; Ren et al., 2021). As it was mentioned before, the fluency limits must range between 105 and 130 %, and all the samples fulfilled this condition. For both classes of mortars, it was corroborated that with a higher sand proportion the water/CM ratio also increases, according to Giordani and Masuero (2019).

|

||||

| Figure 6. Fluency and and volumetric relation of water/CM of B1 mortars. | ||||

|

||||

| Figure 7. Fluency and volumetric relation of water/CM of B2 mortars. | ||||

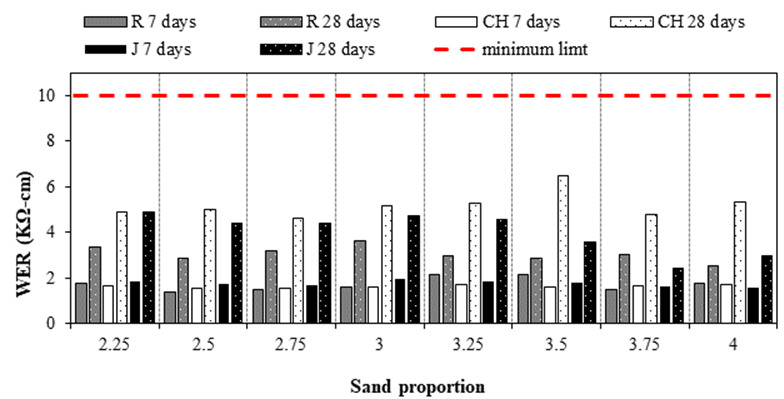

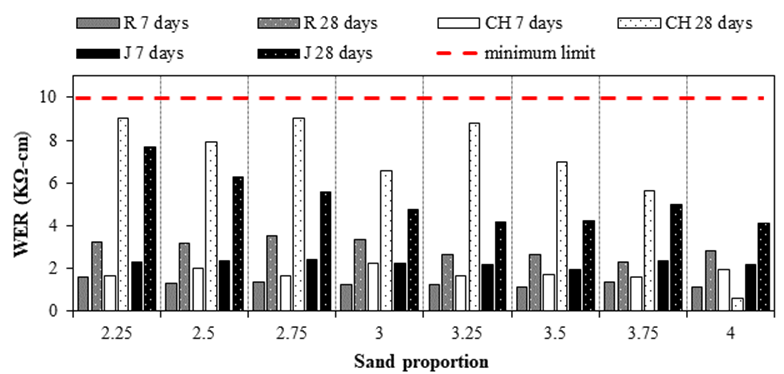

Figures 8 and 9 display the results of the WER test at 7 and 28 days for B1 and B2 mortars. We can also find the behavior of the three different FA employed and how they work with the different cementitious materials. The minimum limit suggested by the standard NMX-C-514-ONNCCE-2019 is 10 kΩ-cm; a higher value might suggest an excessive porosity of the mortars.

All the samples complied with the standard, being able to be utilized as Type II mortars for building construction; nevertheless, we can find higher results for the B2 mortars, which are closer to the minimum limit. For both B1 and B2, the CH sand was the one that presented higher electrical resistivity values, which could be related with the higher content of coarse material and the lower density obtained.

|

||||

| Figure 8. Wet electrical resistivity of B1 mortars as a function of the sand proportion. | ||||

|

||||

| Figure 9. Wet electrical resistivity of B2 mortars as a function of the sand proportion. | ||||

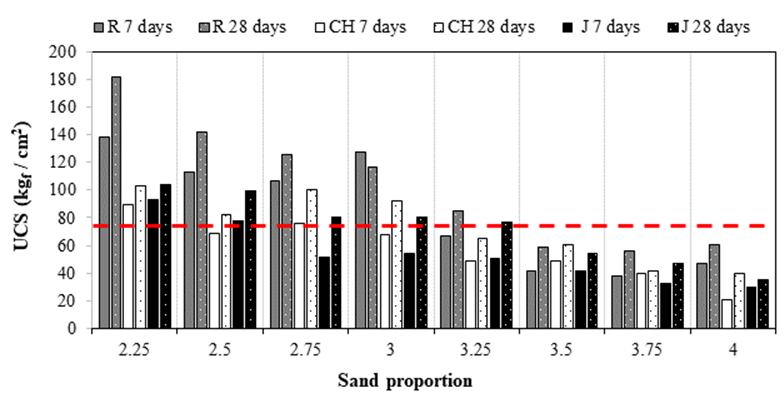

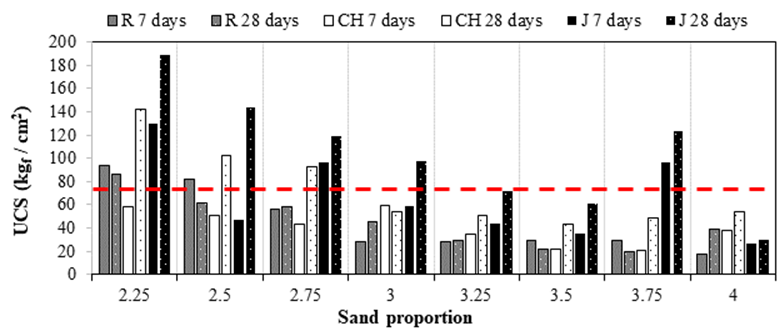

Figures 10 and 11 show the UCS of B1 and B2 mortars in function of the sand proportions utilized (from 2.25 to 4), at 7 and 28 days respectively. The minimum individual compressive strength required is fj = 75 kg/cm2 (7.5 MPa), according to the standard N-CMT-2-01-004/02, considering the utilization and application of these mortars.

Logically, the mortars increased their resistance over time, as the samples at 28 days reported higher values. In general, the sand proportions from 2.25 to 3 worked better, since from the 3.25 value, the mixtures did not comply with the standard. We can see how the B1 lime mortars functioned better, with more specimens reaching the minimum strength required of 75 kgf/cm2, according to the results reported by other authors (Beng Wei et al., 2021; HAMMAT et al., 2021; Souza et al., 2020). For B1 mortars the best aggregate was R; while for the B2 mortars, the best one was J.

|

||||

| Figure 10. Compressive strength of B1 mortars as a function of the sand proportion. | ||||

|

||||

| Figure 11. Compressive strength of B2 mortars as a function of the sand proportion. | ||||

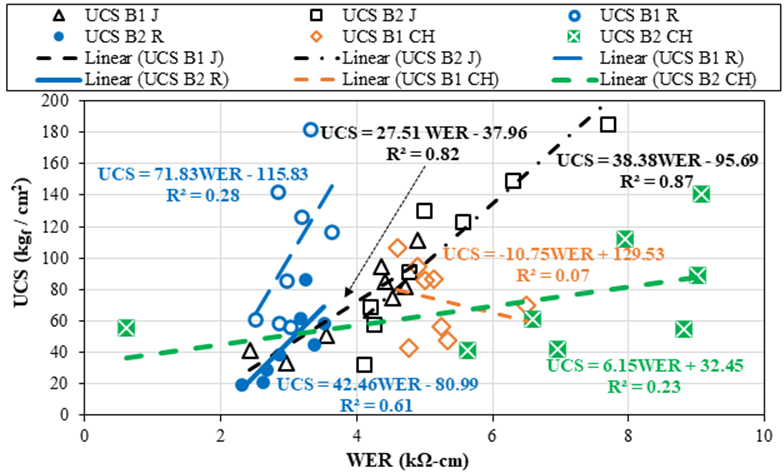

The figure 12 shows the correlation of the designed mortars between the UCS and the WER results at 28 days. The aggregate J presented the best trend line with a correlation coefficient of R2 = 0.87 for the B2 type mortars and R2 = 0.87 for the B1 mixtures. This great correlation of the two method tests could be related to the low absorption and high density of the material, in addition to its granulometric curve with a good distribution according to the standard ASTM C-91. On the other hand, the R and CH sands evidenced a worst correlation, especially the last. These mortars presented higher water absorption and more fine material during the sieve analysis, which increased the water demand and consequently the water/CM ratio, as it was reported before by Haach et al. (2011).

|

||||

| Figure 12. Correlation between UCS and WER of the mortars at 28 days. | ||||

4. Discussion

The Joyitas sand (J) historically has been the most employed material by the builders and artisans in the region near Morelia, in Michoacan. This dark volcanic sand, according to the sieve analysis presented fewer fine materials and a slightly excess of coarse grains, which were retained in the meshes nº 16 and 30, providing a greater mechanical behavior compared to the two other quarries. Furthermore, J presented greater density values and the lowest water absorption, justifying the choice of the local users in the region.

The characterization process allowed to assess the three FA and determine how they work with each type of mortar (B1 and B2) and which proportions obtain the best results. It is important to understand that other than the compliance with the minimum requirements, each mixture could be useful under specific conditions. The WER test is a great NDT to assess the durability of concretes and mortars, and infer the porosity, while all this data can be related to the sieve analysis and particle size of the studied sands. To this effect, the CH sand presented the higher electrical resistivity values, while it contained great amounts of fine material retained in the meshes #100 and #200, and they act as fillers, sealing the porosity of the mixtures and impeding the permeability of depassivating ions, which could reduce the durability of reinforced concrete and mortar structures, as some researchers reported (Durán Ramos, 2021; Giordani & Masuero, 2019; Haach et al., 2011; Ren et al., 2021).

The lower sand proportions achieved the better mechanical behavior, at the same time that they complied with the fluency required values for mortar design. Regarding the WER, all the specimens remained under the limit of 10 kΩ-cm imposed by the standard NMX-C- 514-2019. Even though this parameter is associated to concrete mixtures, the mortars were designed with high ratios of water/CM, as it is displayed in the figures 8 and 9. Due to the desired fluency requirements to achieve a good workability, the mortars need good adherence either for its use as joining elements or coatings.

Additionally, it was corroborated how the sand proportion has a direct correlation with the water demand, resulting in an increase of the water/CM ratio. Therefore, the better and more adequate mortars are the ones with lower sand proportions without taking account of their typology or cementitious products employed, like other authors have stated (Hafid et al., 2016; Stolz & Masuero, 2018). It is interesting to prove how the B1 mortars achieved a satisfactory performance for all the test methods, considering that they were elaborated with lime, a material which is known for its low strength (Souza et al., 2020), and commonly substituted by Portland cement (Navarro-Mendoza et al., 2023). Notwithstanding the lower mechanical behavior of the B1 mixtures, they had a considerably lower water demand than B2, while they achieved the same fluency requirements, being this a great attribute to consider.

The WER technique has demonstrated to be really useful to characterize materials and components while assessing their durability. The higher correlation values of R2 for J sands indicate how the density, the electrical resistivity and the mechanical resistance are related. The correlation coefficient between UCS and WER is strongly related with the absorption and density of the FA. When these two variables increase, the coefficient will considerably alter, with a dispersion of the data. For this reason, it is important to combine the NDT with the mechanical test methods to have a better understanding of the construction and building materials.

According to the regulations, the fineness modulus (FN) of the FA employed in mortars for construction and building processes must range between 1.6 and 2.5. The three sands analyzed met this parameter: CH presented the lower FM value, with 2.06; also presenting a slight excess of fine material, as it was shown in figure 2. These particles can act as fillers, shuttering the porosity and consequently increasing the electrical resistivity of mortars B1 and especially B2, compromising the durability of the mortars at 28 days.

5. Conclusions

The results showed how the water demand of the studied mortars increases at the same time than the relation FA/CM. For both mixtures, B1 and B2, the reduction of the volumetric proportion of FA/CM, increased the UCS, while the fluency remained in the expected range of 105 to 130 %. Regarding the water/CM relation, it increased with the sand proportion from 1.10 to 1.80 for the B1 mixtures, and from 1.10 to 2.60 for the B2 mixtures; noting that the incorporation of lime improves this relation, especially for the higher sand proportions.

Regarding the WER, at early ages of 7 days both mixtures B1 and B2 presented a similar behavior, with slight advantage of J over CH and R; however, at 28 days CH standed out for B2 mixtures, with a closer value to 10 kΩ-cm for the FA/CM ratio of 2.25 (the minimum WER required for the elaboration of hydraulic concrete mixtures considering the corrosion velocity).

With the results obtained in this research, it is confirmed that is necessary to study and characterize properly the construction materials, especially the compound ones like the construction and building mortars. An inadequate utilization of the FA and the CM could affect hugely their mechanical resistance. These research works enhance the technical and scientific knowledge of construction mortars, allowing the builders and workers to make better decisions based in these formal studies.

6. Acknowledgements

Authors want to acknowledge the sponsor by CIC Projects of the Universidad Michoacana de San Nicolas de Hidalgo (UMSNH); and also the funding by Consejo Nacional de Ciencia y Tecnología (CONACYT), through the Project PRONACE 321260: Desarrollo de un modelo de producción social replicable de vivienda y habitat, and the Project CF-2023-G-985, Concretos y morteros auto degradantes de biota y compuestos contaminantes presentes en la atmósfera, para su aplicación en vivienda digna de interés social, en ciudades medias mexicanas; the SEP-Prodep program; and the technical support of the Laboratory “Ing. Luis Silva Ruelas”, in the Faculty of Civil Engineering of UMSNH. Finally, the authors thank the civil engineering students Ana Miriam Duran Ramos and Saul Mondragon-Martinez for their support during the laboratory tests.

References

Álvarez Galindo, J. I., Martín Pérez, A., García Casado, P. J. (1995). Historia de los morteros. Revista PH, 13, 52. https://doi.org/10.33349/1995.13.263

ASTM International. (2017). ASTM C29/C29M 17a. Standard Test Method for Bulk Density (“Unit Weight”) and Voids in Aggregate. ASTM International.

ASTM International. (2018). ASTM C33-C33M-18. Standard Specification for Concrete Aggregates. ASTM International. https://doi.org/10.1520/C0033_C0033M-18

ASTM International. (2019a). ASTM C1876-19. Standard Test Method for Bulk Electrical Resistivity or Bulk Conductivity of Concrete. ASTM International. https://doi.org/10.1520/C1876-19

ASTM International. (2019b). ASTM D75/D75M-19. Standard Practice for Sampling Aggregates. ASTM International.

ASTM International. (2020a). ASTM C305-20. Standard Practice for Mechanical Mixing of Hydraulic Cement Pastes and Mortars of Plastic Consistency. ASTM International. https://doi.org/10.1520/C0305-20

ASTM International. (2020b). ASTM E1266-20. Standard Practice for Processing Mixtures of Lime, Fly Ash, and Heavy Metal Wastes in Structural Fills and Other Construction Applications. ASTM International. https://doi.org/10.1520/E1266-20

ASTM International. (2021). ASTM C109/C109M-21. Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50 mm] Cube Specimens). ASTM International. https://doi.org/10.1520/C0109_C0109M-21

ASTM International. (2022a). ASTM C31/C31M-22. Standard Practice for Making and Curing Concrete Test Specimens in the Field. ASTM International. https://doi.org/10.1520/C0031_C0031M-22

ASTM International. (2022b). ASTM C128-22. Standard Test Method for Relative Density (Specific Gravity) and Absorption of Fine Aggregate. ASTM International.

ASTM International. (2022c). ASTM C150-C150M-22. Standard Specification for Portland Cement. ASTM International. https://doi.org/10.1520/C0150-07

Beng Wei, C., Othman, R., Yee Ying, C., Putra Jaya, R., Shu Ing, D., Ali Mangi, S. (2021). Properties of mortar with fine eggshell powder as partial cement replacement. Materials Today: Proceedings, 46, 1574-1581. https://doi.org/10.1016/j.matpr.2020.07.240

Brazão Farinha, C., de Brito, J., Veiga, R. (2021). Incorporation of high contents of textile, acrylic and glass waste fibres in cement-based mortars. Influence on mortars’ fresh, mechanical and deformability behaviour. Construction and Building Materials, 303, 124424. https://doi.org/10.1016/j.conbuildmat.2021.124424

Danish, A., Ozbakkaloglu, T. (2023). Impact of nano-silica on the mechanical properties of mortar containing e-waste plastic as fine aggregates. Materials Today: Proceedings. https://doi.org/10.1016/j.matpr.2023.03.182

Durán Ramos, A. M. (2021). Diseño de mezclas plásticas aglomerantes y su consideración de proporcionamiento por medio del ensayo de fluidez (Bachelor’s Degree Thesis). Universidad Michoacana de San Nicolás de Hidalgo.

Gao, X., Yao, X., Xie, R., Li, X., Cheng, J., Yang, T. (2022). Performance of fly ash-based geopolymer mortars with waste cathode ray tubes glass fine aggregate: A comparative study with cement mortars. Construction and Building Materials, 344, 128243. https://doi.org/10.1016/j.conbuildmat.2022.128243

Giordani, C., Masuero, A. B. (2019). Blended mortars: Influence of the constituents and proportioning in the fresh state. Construction and Building Materials, 210, 574-587. https://doi.org/10.1016/j.conbuildmat.2019.02.077

Haach, V. G., Vasconcelos, G., Lourenço, P. B. (2011). Influence of aggregates grading and water/cement ratio in workability and hardened properties of mortars. Construction and Building Materials, 25(6), 2980-2987. https://doi.org/10.1016/j.conbuildmat.2010.11.011

Hafid, H., Ovarlez, G., Toussaint, F., Jezequel, P. H., Roussel, N. (2016). Effect of particle morphological parameters on sand grains packing properties and rheology of model mortars. Cement and Concrete Research, 80, 44-51. https://doi.org/10.1016/j.cemconres.2015.11.002

Hammat, S., Menadi, B., Kenai, S., Thomas, C., Kirgiz, M. S., Sousa Galdino, A. G. de. (2021). The effect of content and fineness of natural pozzolana on the rheological, mechanical, and durability properties of self-compacting mortar. Journal of Building Engineering, 44, 103276. https://doi.org/10.1016/j.jobe.2021.103276

Hu, J. (2005). A study of effects of aggregate on concrete rheology [Iowa State University, Digital Repository]. https://doi.org/10.31274/rtd-180813-15380

Jacques, K. T. J., Zengyao, W., Shoude, W., Shifeng, H., Xin, C. (2023). The influence of different fine aggregate and cooling regimes on the engineering properties of sulphoaluminate cement mortar after heating. Case Studies in Construction Materials, 18, e01866. https://doi.org/10.1016/j.cscm.2023.e01866

Li, T., Nogueira, R., de Brito, J., & Liu, J. (2023). Underlying mechanisms of the influence of fine aggregates’ content and properties on mortar’s plastic viscosity. Journal of Building Engineering, 67, 106016. https://doi.org/10.1016/j.jobe.2023.106016

Li, T., Zhou, Y., Zhu, J., Liu, J. (2022). Effect of fine aggregate gradation on the rheology of mortar. Construction and Building Materials, 332, 127362. https://doi.org/10.1016/j.conbuildmat.2022.127362

Martinez-Molina, W., Chavez-Garcia, H. L., Perez-Lopez, T., Alonso-Guzman, E. M., Arreola-Sanchez, M., Navarrete-Seras, M. A., Borrego-Perez, J. A., Sanchez-Calvillo, A., Guzman-Torres, J. A., Perez-Quiroz, J. T. (2021). Effect of the Addition of Agribusiness and Industrial Wastes as a Partial Substitution of Portland Cement for the Carbonation of Mortars. Materials, 14(23), 7276. https://doi.org/10.3390/ma14237276

Navarro-Mendoza, E. G., Alonso-Guzman, E. M., Ruvalcaba-Sil, J. L., Sánchez-Calvillo, A., Martínez-Molina, W., García, H. L. C., Bedolla-Arroyo, J. A., Becerra-Santacruz, H., Borrego-Pérez, J. A. (2020). Compressive strength and ultrasonic pulse velocity of mortars and pastes, elaborated with slaked lime and high purity hydrated lime, for restoration works in Mexico. In Key Engineering Materials: Vol. 862 KEM. https://doi.org/10.4028/www.scientific.net/KEM.862.51

Navarro-Mendoza, E. G., Alonso-Guzman, E. M., Sanchez-Calvillo, A., Bedolla-Arroyo, J. A., Becerra-Santacruz, H., Navarro-Ezquerra, A., Gonzalez-Sanchez, B., Martinez-Molina, W. (2023). Physical and Mechanical Characterization of Lime Pastes and Mortars for Use in Restoration. Heritage, 6(3), 2582-2600. https://doi.org/10.3390/heritage6030136

ONNCCE. (2004). NMX-C-073-ONNCCE-2004. Industria de la construcción - Agregados - Masa volumétrica. Método de prueba. Organismo Nacional de Normalización y Certificación de la Construcción y Edificación.

ONNCCE. (2006). NMX-C-084-ONNCCE-2006. Industria de la construcción - Agregados para Concreto - Partículas más Finas que la Criba 0,075 mm (No. 200) por Medio de Lavado - Método de Prueba. Organismo Nacional de Normalización y Certificación de la Construcción y Edificación.

ONNCCE. (2014). NMX-C-486-ONNCCE-2014. Industria de la construcción-Mampostería - Mortero para uso estructural- especificaciones y métodos de ensayo. Organismo Nocional de Normalización y Certificación de la Construcción y la Edificación.

ONNCCE. (2015a). NMX-C-061-ONNCCE-2015. Building Industry - Hydraulic Cements - Determination of Compressive Strength of Hydraulic Cements. Organismo Nacional de Normalización y Certificación de la Construcción y Edificación.

ONNCCE. (2015b). NMX-C-144-ONNCCE-2015. Building Industry - Hydraulic Cement - Specifications for the Apparatus used in the Flow Test for Mortars made of Hydraulic Cements. Organismo Nacional de Normalización y Certificación de la Construcción y Edificación.

ONNCCE. (2019). NMX-C-514-ONNCCE-2019. Building Industry - Electrical Resistivity of Hydraulic Concrete - Specifications and Testing Methods. Organismo Nacional de Normalización y Certificación de la Construcción y Edificación.

ONNCCE. (2020). NMX-C-165-ONNCCE-2020. Industria de la construcción - Agregados para concreto - Determinación de la reactividad potencial. Organismo Nacional de Normalización y Certificación de la Construcción y Edificación.

ONNCCE. (2002). N-CMT-2-01-004/02. Characteristics of Materials. Materials For Structures. Materials For Hydraulic Concrete. Organismo Nacional de Normalización y Certificación de la Construcción y Edificación.

Ren, Q., Tao, Y., Jiao, D., Jiang, Z., Ye, G., De Schutter, G. (2021). Plastic viscosity of cement mortar with manufactured sand as influenced by geometric features and particle size. Cement and Concrete Composites, 122, 104163. https://doi.org/10.1016/j.cemconcomp.2021.104163

Ribeiro, D. V., Oliveira Rey, R. (2019). Avaliação dos agregados utilizados na região metropolitana de Salvador quanto à ocorrência de Reatividade Álcalis-Agregado (RAA). Revista ALCONPAT, 9(2), 185-199. https://doi.org/10.21041/ra.v9i2.326

Sánchez Tizapa, S., Villaseñor Franco, A., Guinto Herrera, E., Barragán Trinidad, R., Mebarki, A. (2017). Propuesta de valores de referencia para la resistencia de diseño a compresión diagonal y compresión de la mampostería en el estado de Guerrero, México. Revista ALCONPAT, 7(3), 231-246. https://doi.org/10.21041/ra.v7i3.159

Senff, L., Barbetta, P. A., Repette, W. L., Hotza, D., Paiva, H., Ferreira, V. M., Labrincha, J. A. (2009). Mortar composition defined according to rheometer and flow table tests using factorial designed experiments. Construction and Building Materials, 23(10), 3107-3111. https://doi.org/10.1016/j.conbuildmat.2009.06.028

Souza, A. T., Barbosa, T. F., Riccio, L. A., Santos, W. J. dos. (2020). Effect of limestone powder substitution on mechanical properties and durability of slender precast components of structural mortar. Journal of Materials Research and Technology, 9(1), 847-856. https://doi.org/10.1016/j.jmrt.2019.11.024

Stolz, C. M., Masuero, A. B. (2018). Influence of grain distribution on the rheological behavior of mortars. Construction and Building Materials, 177, 261-271. https://doi.org/10.1016/j.conbuildmat.2018.05.131

Tena, A., Liga, A., Pérez, A., González, F. (2017). Proposal for improved mixes to produce concrete masonry units with commonly used aggregates available in the Valley of Mexico. Revista ALCONPAT, 7(1), 36-56. https://doi.org/10.21041/ra.v7i1.170

Ullah, Z., Qureshi, M. I., Ahmad, A., Khan, S. U., Javaid, M. F. (2021). An experimental study on the mechanical and durability properties assessment of E-waste concrete. Journal of Building Engineering, 38, 102177. https://doi.org/10.1016/j.jobe.2021.102177

Westerholm, M., Lagerblad, B., Silfwerbrand, J., Forssberg, E. (2008). Influence of fine aggregate characteristics on the rheological properties of mortars. Cement and Concrete Composites, 30(4), 274-282. https://doi.org/10.1016/j.cemconcomp.2007.08.008

Wu, M., Zhao, Q., Shen, W., Zhao, J., Xu, G., Zhao, D., Xiong, X. (2021). Mix design of self-leveling mortar prepared by crushed sand with high flowability and early strengthening. Construction and Building Materials, 283, 122679. https://doi.org/10.1016/j.conbuildmat.2021.122679