| Basic Research | https://doi.org/10.21041/ra.v13i2.643 |

Study of waterproofed concrete panels with silicate-based permeability reducing admixtures

Estudo de painéis de concreto impermeabilizados com aditivo redutor de permeabilidade a base de silicato

Estudio de paneles de hormigón impermeabilizado con aditivo reductor de permeabilidad a base de silicatos

F. E. Z.

Alves1

![]() ,

R. P.

Gurkewicz1

2

3

*

,

R. P.

Gurkewicz1

2

3

*

![]() ,

E. C.

Zancan1

2

,

E. C.

Zancan1

2

![]() ,

L. J. J.

Nieves1

2

,

L. J. J.

Nieves1

2

![]() ,

E. G. P.

Antunes1

2

,

E. G. P.

Antunes1

2

![]()

1 Departamento de Engenharia Civil, UNESC, Criciúma, Santa Catarina, Brasil.

2 GPDECC, Grupo de Pesquisa em Desempenho de Estruturas e Construção Civil, UNESC, Criciúma, Santa Catarina, Brasil.

3 Programa de Pós-Graduação em Ciências e Engenharia de Materiais, UNESC, Criciúma, Santa Catarina, Brasil.

*Contact author: rafaelpgurkewicz@unesc.net

Reception:

February

28,

2022.

Acceptance:

April

11,

2023.

Publication: May 01, 2023.

| Cite as: Alves, F. E. Z., Gurkewicz, R. P., Zancan, E. C., Nieves, L. J. J., Antunes, E. G. P. (2023), "Study of waterproofed concrete panels with silicate-based permeability reducing admixtures", Revista ALCONPAT, 13 (2), pp. 175 –191, DOI: https://doi.org/10.21041/ra.v13i2.643 |

Abstract

This research studies the water absorption capacity of concrete panels and its self-healing process, using the incorporation of admixtures to the concrete or its application on the surface. Through permeability tests, water absorption by immersion and by capillarity, after the wet curing, the panels with crystalline admixtures applied superficially showed lower absorption capacity, followed by those without admixtures and those with the admixtures incorporated into the concrete, which showed greater absorption. Microscopy characterization was performed on the panels split in half, it was observed that the crystallization of the panels with superficial admixtures was more advanced compared to those with the incorporated admixtures. The induced fissures did not reach full pore filling after curing in both types of application.

Keywords:

crystalline admixtures,

fissure,

self-healing,

waterproofing,

concrete.

1. Introduction

In recent years, with the decrease in demand and the increase in competitiveness in the civil construction market, companies have begun to pay more attention to the materials used in their buildings, to minimize costs, rework and, in this way, remain competitive in the market. In addition to economic factors, the performance standard, as NBR 15575:2013 is known, with an emphasis on meeting user requirements, provides opportunities for the search and use of new materials and construction methods in buildings.

Among the many materials used in a building, those used for waterproofing deserve special attention, given that their cost is 1% to 3% of the value of the building (VEDACIT, 2019).

Currently, the products used in the waterproofing process are divided into 2 groups according to NBR 9574:2008, rigid and flexible materials. Thus, they must be applied in locations consistent with their technical characteristics to ensure the efficiency of the system. Within the rigid group, there are the crystallizing additives. Composed of silicates, which when mixed with water and in contact with the alkalinity of the concrete, become hydrosilicates, an insoluble crystal. Crystals can fill pores and fissures in concrete, making it waterproof.

The ability to fill fissures, also called self-healing, is a great advantage of the system, especially in structures that need to be impermeable to negative pressures, according to the process described by the NBR 9574:2008 standard. Through the self-healing capacity of concrete, these fissures, if they do not exceed the limit of 0.6 mm of opening, can be automatically filled.

According to Takagi, Almeida Júnior and Oliveira (2007), the crystallization treatment is a physical-chemical process where the active ingredients of the crystallizer trigger catalytic reactions, compatible with the cement hydration reactions, in which the formation of non-soluble crystals occurs and non-toxic in the concrete structure. In this way, ensuring that there is no penetration of water by capillarity, supporting both positive and negative hydrostatic pressures of up to 0.7 MPa.

As they are added to fresh concrete, after hardening, the crystallizers prevent the passage of water in the liquid phase, but do not completely prevent the passage when in the gaseous phase. This behavior can be validated by the authors Pazderka and Hájková (2016), who, after testing with two different crystallizers, obtained percentages of only 16% and 20% of reduction in the absorption of water steam.

Recently studies conducted by Huang et al. (2016), with the aid of magnetic resonance, pointed out that in concrete with permeability-reducing additives, after a few hours, the non-chemically bound water content decreased in areas adjacent to the fissures, proving that the water that had penetrated the fissure was used in hydration processes, making these areas denser.

According to the company that manufactures the product used in the present work, concrete with additives can fill fissures of up to 0.6 mm, this value being 0.2 mm higher than the maximum allowed by the NBR 6118:2014 standard, for reinforced concrete inserted in the class of environmental aggressiveness I.

This research studies and evaluates the water absorption capacity of concrete panels and their self-healing process, through two methods of application of permeability-reducing additives.

2. Procedure

In order to verify the impermeability and the self-healing effect in concrete panels, an experimental procedure was elaborated that consists in the execution of 2 groups of panels with 3 subgroups each. The distinction between the first and second groups refers to the presence of induced fissures, that is, one group had two induced fissures across the entire thickness of the panel, while the second group did not. The subgroups are distinguished according to the waterproofing treatment used, with the first subgroup not having any type of waterproofing treatment, while the second and third subgroups were waterproofed, but in a different way between them. The second subgroup was waterproofed by incorporating the crystallizing additive into the concrete and in the third subgroup the crystallizing additive was applied on one of the panel faces. For this, 18 panels were produced (9 for each group, 3 for each subgroup). Table 1 presents the groups and subgroups developed, in addition to the nomenclature adopted for each subgroup of panels.

| Table 1. Models de painéis. | ||||||||||||||

| GROUP | SUBGROUP | NOMENCLATURE | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NO FISSURE | (IMAGEN) | Control Panel Without Crystallizing Additive | S CRI | |||||||||||

| (IMAGEN) | Panel With Crystallizing Additive Mixed To Concrete Still Fresh | C CRI | ||||||||||||

| (IMAGEN) | Panel With Crystallizing Additive Applied Superficially After Curing Time | C CRI SOB | ||||||||||||

| WITH FISSURE | (IMAGEN) | Control Panel Without Crystallizing Additive | S CRI+F | |||||||||||

| (IMAGEN) | Panel With Crystallizing Additive Mixed To Concrete Still Fresh | C CRI+F | ||||||||||||

| (IMAGEN) | Panel With Crystallizing Additive Applied Superficially After Curing Time | C CRI SOB+F | ||||||||||||

The panels produced measure 50 x 25 x 5 cm (length x width x thickness) and 2 cm thick wooden molds were used for their execution. The concrete used was dosed in a machined plant with an average strength of 10 MPa, with a slump of 10 ± 2 cm, in accordance with NBR 16889:2020. The filling of the molds was done manually.

The application of the crystallizing additive on the panels of the subgroups “C CRI SOB” and “C CRI SOB+F” occurred after 28 days of curing the panels. Figure 1(a) illustrates the casting of concrete into the molds and Figure 1(b) the mold filled with concrete.

|

||||

| Figure 1. Molds: (a) concreting of a panel, (b) mold filled with concrete | ||||

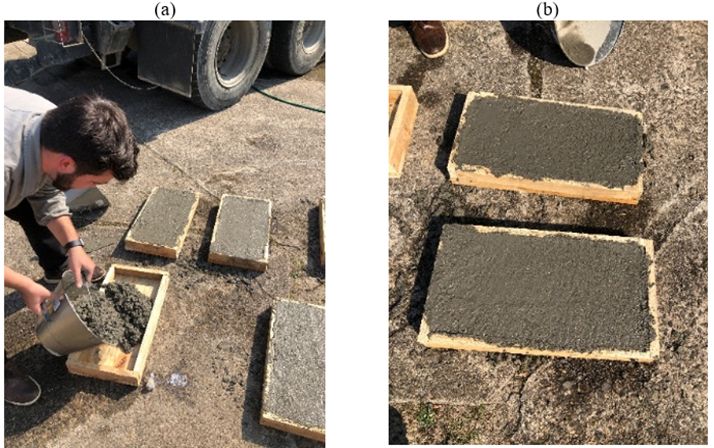

The fissures were induced in the panels by inserting two 0.4 mm thick aluminum sheets, which were introduced into each panel shortly after concreting and removed after 48 hours of concreting, when its fluidity was not able to cause closure from the fissure. The thickness of the sheets was determined following NBR 6118:2014, which limits the value of 0.4 mm as the largest permissible dimension of fissures in structural elements of reinforced concrete and the manufacturer's recommendation on the maximum dimension of clogging of the product.

Figure 2(a) shows the aluminum sheets inserted in a panel and Figure 2(b) the fissure induced by the aluminum sheet, both 48 hours after concreting, that is, when it was already possible to remove the sheets of concrete panels.

|

||||

| Figure 2. Sheets for fissure induction: (a) panel with two sheets, (b) sheet in detail. | ||||

| Table 2. presents the characteristics of the crystallizing additive used in the research. | ||||||||||||||

| Density | 1.200 Kg/m3 | |||||||||||||

| Base | Silicate | |||||||||||||

| Dosage | 200 ml for every 50 kg of cement or 1.2 l for every m3 of concrete | |||||||||||||

| Appearance | Yellow liquid | |||||||||||||

| pH | 11 | |||||||||||||

| Viscosity (Ford 4 at 25ºC) | 12 seconds | |||||||||||||

| Validity | 24 months from fabrication date | |||||||||||||

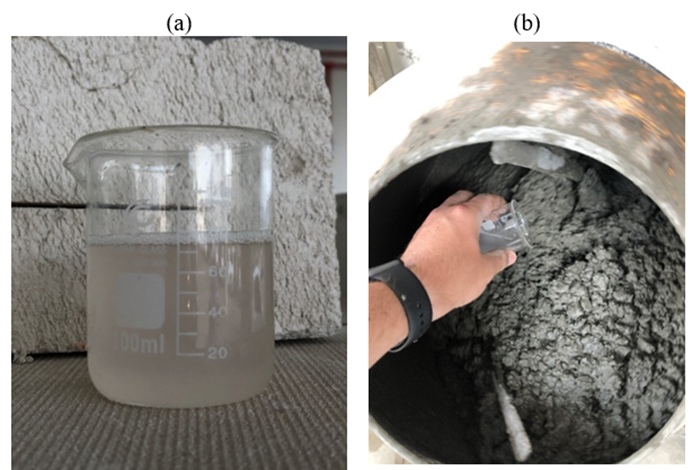

To mix the additive to the concrete, a concrete mixer was used. It should be noted that such action was necessary in order not to contaminate the concrete of the panels without the use of the additive. Figure 3(a) shows the amount of product used for concreting and Figure 3(b) the process of incorporating the additive into the concrete.

|

||||

| Figure 3. Crystallizer mixing process: (a) required amount of crystallizer, (b) mixing process in the concrete mixer. | ||||

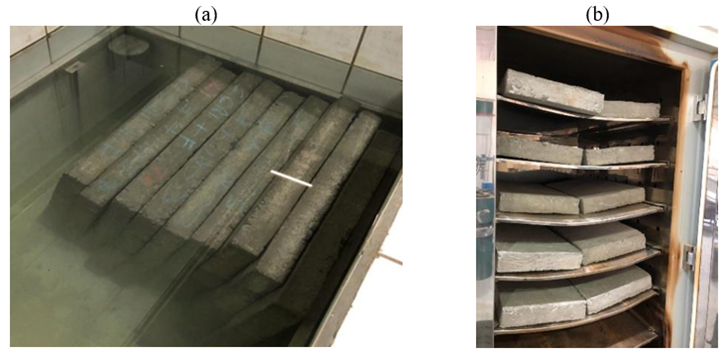

After the execution and deforming of the panels, which took place on the third day, the panels were submitted to submerged curing for a period of 28 days. To avoid contamination of the samples not yet waterproofed, the panels with waterproofing incorporated into the concrete were separated into different tanks. After 28 days of curing, the panels were oven-dried for 72 hours at a temperature of 40 ± 5 ºC. Figure 4(a) shows the panels during submerged curing and Figure 4(b) the panels after the curing and drying process.

|

||||

| Figure 4. Panels during submerged curing and drying: (a) panels in tank, (b) panels in oven. | ||||

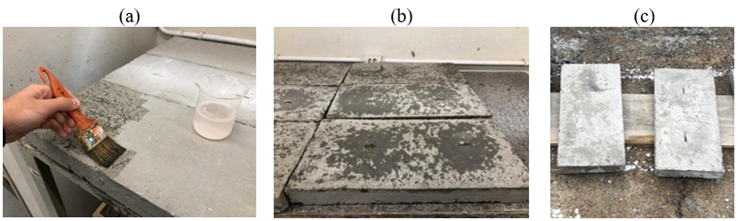

Once the panels were dry, the crystallizing additive was applied to the panels of the subgroups “C CRI SOB” and “C CRI SOB+F”. The application was performed through 2 coats of the product with the aid of a brush. The surface of these panels was completely saturated with the crystallizing additive and it took approximately 3 hours for the additive to be completely absorbed by the panels. Subsequently, these panels were stored outdoors for 3 days, and during these days they were exposed to rain, which aids in the hydration of the crystallizing additive. Figure 5(a) shows the surface application of the additive on one side of the plates, Figure 5(b) the plates during the product absorption process and Figure 5(c) the curing process of the panels with surface application.

|

||||

| Figure 5. Crystallizer application process: (a) application with a brush, (b) waterproofed panels, (c) panels during the curing process. | ||||

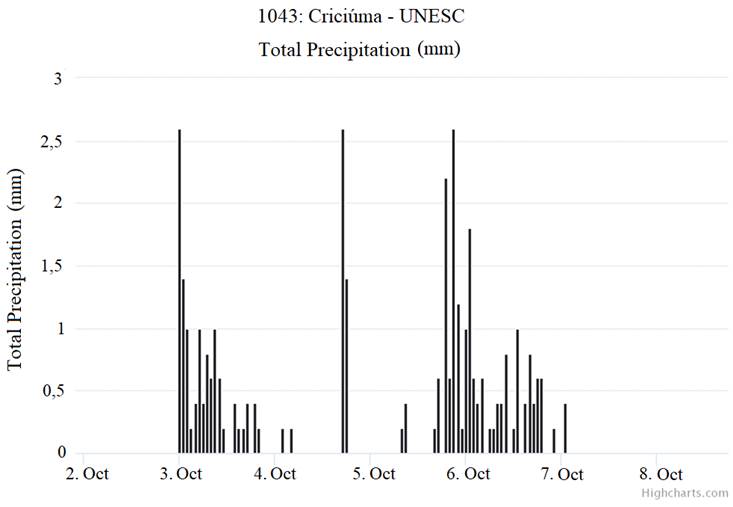

The “C CRI SOB” and “C CRI SOB+F” panels received a total of 14.4 mm of rain, as shown in Figure 6, taken from the meteorological station close to the test site.

|

||||

| Figure 6. Pluviometric index graph (Source: EPAGRI). | ||||

Once the stage of execution, waterproofing and curing of the panels was over, tests were started to verify the permeability of the panels. The tests carried out were: determination of water absorption by immersion, water absorption by capillarity with calculation of the void ratio and water absorption by the Karsten Tube.

The first test performed was the test to determine permeability using the Karsten tube. This test was carried out in accordance with NBR 14992:2003, which specifies such verification for Portland cement-based mortars for grouting ceramic tiles. The Karsten tubes were placed on the concrete panels, and their lateral bases, which were in contact with the face of the panels, were sealed with polyurethane. Each tube was fixed 10 cm away from the edges and 30 cm spacing between the tubes, thus, two tubes per panel. The Karsten tubes were filled with water up to the predefined volume of 3.5 ml and later the level measurements were performed after 60, 120, 180 and 240 minutes. Each panel had two points of permeability measurement.

Figure 7(a) shows the test being performed on the panel with crystallizer and Figure 7(b) the Karsten tube over the fissure of a plate with crystallizer applied on the concrete.

|

||||

| Figure 7. Karsten tubes fixed on the panels: (a) Panel tube without fissure, (b) Panel tube with fissure. | ||||

The second test carried out was the determination of the panel's water absorption and the calculation of the void ratio, as described by NBR 9778:2005, using three panels per condition. The panels were initially dried in an oven at 105 ± 5 ºC for 72 hours and the dry mass was measured, then immersed in water for another 72 hours, for complete saturation. After removing the saturated panels, the saturated sample was weighed and another weighing was carried out using a hydrostatic balance, as shown in Figure 8. From these values, it was possible to determine the water absorption, the voids ratio, dry specific mass and saturated specific mass.

|

||||

| Figure 8. Hydrostatic weighing. | ||||

The percentage of water absorption can be calculated with Equation 1.

Wherein

A is the absorption rate, expressed in percentage;

msat is the mass of the sample saturated in water after immersion and boiling;

ms is the mass of the sample dried in the oven.

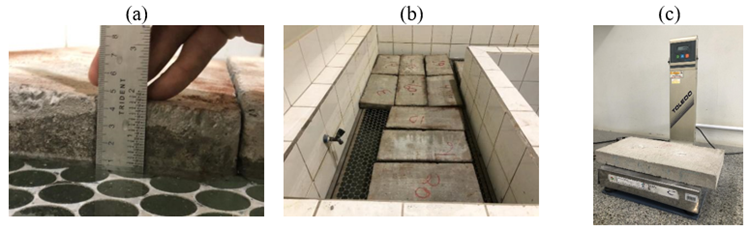

The last test carried out was the determination of water absorption by capillarity, described by the NBR 9779:1995 standard. To carry out this test, the panels were placed in a water depth of 0.5 cm for a period of 72 hours, in order to verify the absorption of water by capillarity. In order to be able to observe variations in absorption between the panels, the waterproofed upper faces were submerged. Mass measurements were taken after 3, 6, 24, 48 and 72 hours.

Figure 9(a) shows the verification of the water depth of 0.5 cm, Figure 9(b) the panels arranged in the tank during the absorption process and Figure 9(c) the weighing of one of the panels.

|

||||

| Figure 9. Capillarity absorption test: (a) Submerged panel 0.5 cm deep, (b) Panels in the tank, (c) Panel being weighted. | ||||

The water absorption by capillarity can be calculated with Equation 2.

Wherein

C is the water absorption by capillarity, expressed in grams per square centimeter;

msat is the saturated mass of the specimen that remains with one side in contact with the water during a specified period, expressed in grams;

ms is the mass of the dry specimen, as soon as it reaches a temperature of 23 ± 2 ºC, expressed in grams.

S is the cross-sectional area, expressed in square centimeters.

The data from the results were analyzed using analysis of variance (ANOVA) and the Tukey test, when necessary, with a significance of 95%.

After finishing the tests, a microscopy of the plates was performed for a better observation of the state of crystallization of the pores. For this purpose, 3 plates were broken, “S CRI”, “COM CRI” and “C CRI SOB”, and a digital microscope with 1600x magnification capacity.

3. Results and discussion

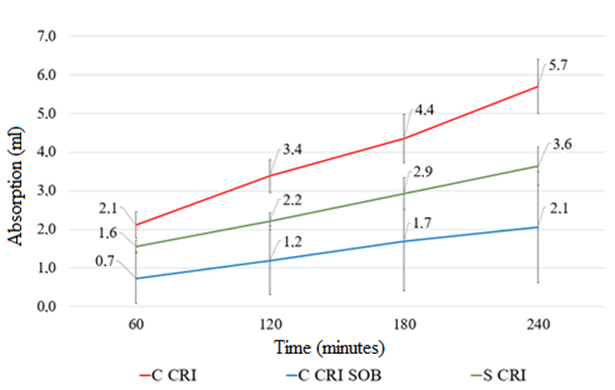

The results of the permeability test with a Karsten Tube, represented by Figure 10, indicate the permeability values obtained over time (60, 120, 180 and 240 min). As can be seen, the panels with the highest permeability at 240 minutes, the final measurement time, were the panels with crystallizer additive incorporated into the concrete, followed by panels without crystallizer and, finally, by the panel with crystallizer applied on its surface.

|

||||

| Figure 10. Average absorption over time. | ||||

Through the analysis of the permeability values presented graphically, it was possible to observe that both the initial absorption and the absorption speed of the panels with the incorporation of the crystallizing additive were superior to those of the other panels. The highest permeability, since the first measurement of the “C CRI” panels in relation to the other panels reached 171.43% more absorption in comparison to the “C CRI SOB” and 58.33% more in relation to the “S CRI” panel.

The higher water absorption speed of the “C CRI” panels can be visualized by their steeper inclination in relation to the other panels, as well as by the greater difference between the initial and final absorption, which was 171.34%, being that for the “C CRI SOB” panels it was 200% and for the “S CRI” panels it was 125%.

After statistical analysis, through analysis of variance (ANOVA), it was possible to conclude that the panels present a significant difference between them in the permeability test through the Karsten tube, that is, the type of waterproofing treatment influenced the results of this verification. Through the Tukey Test (p= 4.13477E-05) it can be stated that the “C CRI” panels were the most permeable, followed by the “S CRI” panels and, finally, by the “C CRI SOB” panel.

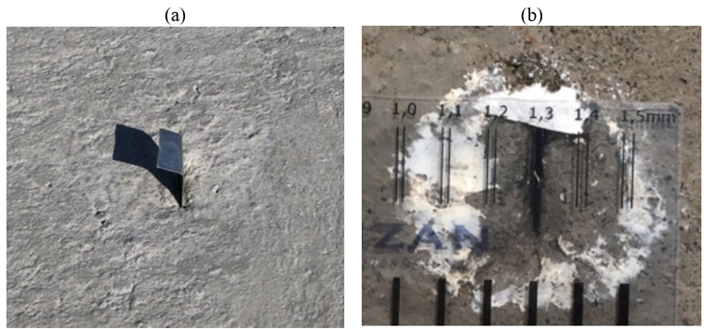

It is important to mention that it was not possible to analyze the permeability by the Karsten tube method of the “C CRI + F”, “S CRI + F” and “C CRI SOB + F” panels, with induced fissures, due to the final dimension of the fissure opening, approximately 1.3 mm. Even so, it should be noted that an attempt was made to carry out the test, however, given the thickness of the opening, the water from the Karsten tube, which was inserted exactly over the fissure, completely drained through it in seconds. Figure 11(a) shows the sheet after 48 hours of concreting the panels and Figure 11(b) the fissure after the panels curing process.

|

||||

| Figura 11. Fissuras: (a) Fissura ainda com a lâmina, (b) Fissura após a retirada da lâmina | ||||

The induced fissure, which had been planned for 0.4 mm, exceeded its opening by 0.9 mm, as it ended at 1.3 mm (Figure 11), extrapolating the 0.6 mm presented by the company as the maximum dimension for clogging fissures.

During the hardening process of concrete, reactions occur that cause plastic shrinkage. According to Marin, Brasil (2016) plastic shrinkage occurs by evaporation of water on the surface of freshly compacted concrete and is influenced by climatic conditions to which the concrete is exposed. Therefore, it was not possible to evaluate the clogging of the induced fissures through the permeability test using the Karsten tube method, considering that the induced fissures had a final opening thickness of approximately 1.3 mm. In addition, the clogging process by the “self-healing” effect is slow, since, as presented by Venquiaruto (2017), after 91 days of wet curing, there was a partial recovery of the micro fissures, in relation to the analyzes after 3 and 28 days. After 3 days of healing, the fissures ranged from 2,294 µm to 5,410 µm, and at 91 days they had dimensions from 1,204 µm to 3,077 µm.

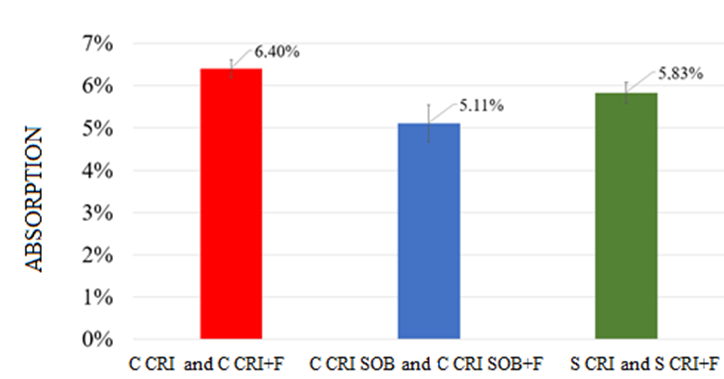

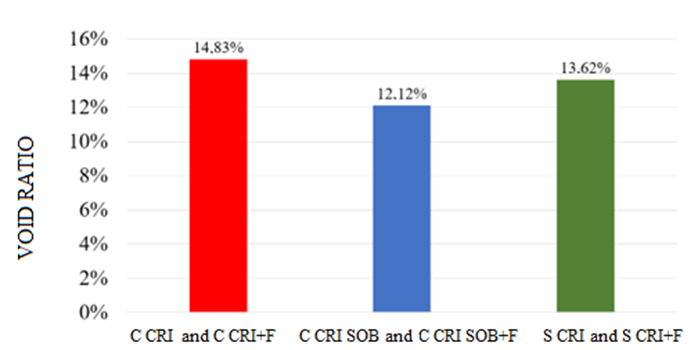

Through the results of the water absorption test by immersion, presented from Figures 12 and 13, it can be concluded that again the panels with crystallizer incorporated into fresh concrete showed a higher void rate and, consequently, a greater absorption after 72 hours submerged. Panels with superficially applied crystallizer had the lowest void ratio and an average of 1.29% lower than panels with crystallizer mixed with concrete.

The results were condensed into “C CRI and C CRI+F” (with crystallizer and with crystallizer + induced fissure), “C CRI SOB and C CRI SOB+F” (with crystallizer superficially and with crystallizer superficially + induced fissure), “S CRI and S CRI + F” (without crystallizer and without crystallizer + induced fissure).

|

||||

| Figure 12. Absorption after 72 hours. | ||||

|

||||

| Figure 13. Void ratio. | ||||

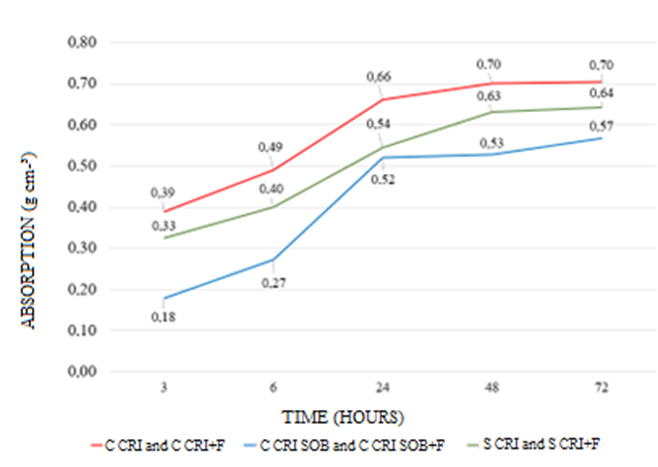

The results of the water absorption by capillarity test can be seen in Figure 14. Again, it was found that the “C CRI” and “C CRI + F” panels showed values that demonstrated greater permeability of these panels in relation to the others.

|

||||

| Figure 14. Absorption by capillarity. | ||||

In this test, the “C CRI” and “C CRI+F” panels had an absorption of 9.38% higher than the reference panels, while the “C CRI SOB” and “C CRI SOB+F” panels showed a decrease of 10.94%. It is also possible to observe that during the periods of 3 and 24 hours there was the highest absorption by the panels, after these periods the plates had low absorptions.

After statistical analysis using analysis of variance (ANOVA) and Tukey test, with a significance of 95% (p=0.000142449), it was possible to conclude that the panels present a significant difference in their absorption by capillarity results in 72 hours.

Based on the results obtained in the three tests (Karsten tube, absorption by immersion and absorption by capillarity) it can be concluded that the incorporation of the permeability-reducing additive caused a significant increase in permeability and water absorption in relation to the other types of treatments. Meanwhile, the “C CRI SOB” and “C CRI SOB + F” panels had a significant decrease in their permeability compared to untreated panels (“S CRI” and “S CRI + F”). This behavior can be explained by the process of crystallization of the permeability-reducing additive. For the reaction of the silicate additive to occur, it is necessary to hydrate it, similarly to the hydration reactions of cement grains. Therefore, the water initially made available in the mixture ends up being necessary for both actives in the first days, causing a slower formation of concrete crystals and the crystals that fill the pores.

The presence of the additive mixed with the concrete during the curing process can cause internal reactions that divide the crystallization power, since both use water for the process. Thus, the crystallization of the product combined with the crystallization of calcium hydroxide may be responsible for the greater initial absorption. The slow formation of crystals, when the additive is incorporated into the concrete, is due to the gradual formation of crystals in the cement, created during the curing process, since the product reacts both with the cement and with the water for its crystallization. In this way, the crystals of the additive and the concrete begin to hydrate more slowly than with the panels without the crystallizer.

This behavior was also observed by Araújo, Saviatto (2018), who, after an absorption and compression test, observed an increase in permeability and a decrease in resistance in the plates with the additive mixed with the concrete, after 28 days of submerged curing.

The surface application on the panels after the curing process presents a better initial performance due to the higher surface concentration of the product and the calcium hydroxide crystals in the concrete being mostly hydrated at the time of application of the permeability-reducing additive.

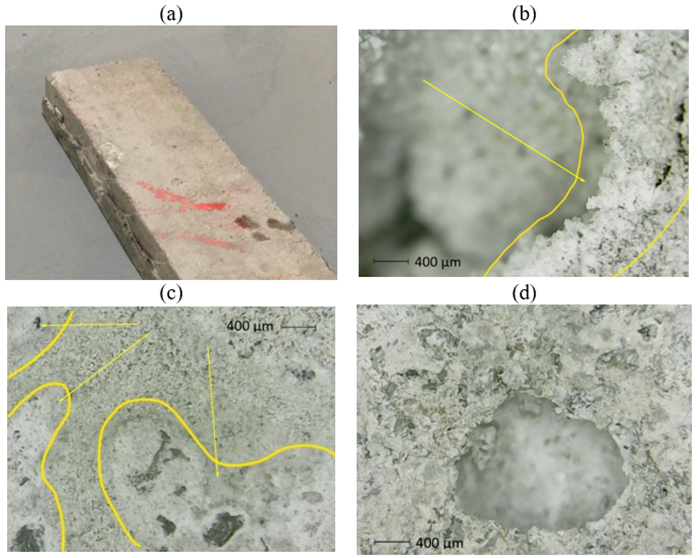

For a better visualization of the crystalline processes in the 3 types of panels, microscopies were performed with a digital microscope that has a 1600x magnification capacity. These images are represented in Figure 15(a) which illustrates the panel after the cutting process, Figure 15(b) microscopy of the “C CRI” panel, Figure 15(c) panel “C CRI SOB” and Figure 15(d) “S CRI” panel. The cut on the panel was performed with a diamond saw and water cooling at the cutting site, minimizing vibrations, in accordance with NBR 7680: 2015.

|

||||

| Figure 15. Microscopy: (a) Panel cut in half, (b) Panel with crystallizer mixed with concrete, (c) Panel with crystallizer applied over it, (d) Reference panel. | ||||

In the panels with the application of the additive incorporated into the concrete (C CRI), it was possible to observe few crystals on the pore surfaces, which may indicate an initiating crystallization process. In the panels with superficial application of the crystallizer (C CRI SOB), it was possible to observe a greater clogging, with many being completely obstructed by the crystals.

4. Conclusions

Through the analysis of the results, a similarity can be portrayed in the data obtained from the tests, which present the same behavior regarding the absorption capacity and permeability of the panels. Pointing out the samples with the crystallizing additive applied superficially, with the lowest water permeability, and the samples with the additive mixed with the concrete, with the highest voids and water absorption ratios.

The superior performance of panels with surface application can be explained by the high concentration of the additive on the face, obtaining a greater crystallization capacity since the crystals from the concrete curing are completely hydrated, in this way the additive manages to have a more effective initial performance.

Panels with additive mixed with concrete showed higher absorption in all tests and higher void ratio after submerged time. This happens because its crystallization process has not ended, as it uses water and crystals from cement hydration, which are being formed simultaneously with the additive crystals, making the process slower, and it is not possible to observe improvements after 28 days of submerged curing.

Despite not having presented clogging of the fissure after the curing time, the crystallization process was present in the fissures, requiring more time in contact for the clogging to possibly end.

For future works, it is recommended to use more resistant concrete, with at least 20 Mpa. Carry out the same tests, but verifying the results after 1, 20, 40, 60 and 90 days after the submerged curing process, in order to verify the evolution of the process and monitor the clogging of the pores over time.

References

Araújo, M. D., Saviattoo, M. S. C. (2018), Estudo da influência de aditivo impermeabilizante em concreto. 83 f. Monografia (Especialização) - Curso de Engenharia Civil, Universidade do Sul de Santa Catarina, Palhoça. Disponível em: https://repositorio.animaeducacao.com.br/handle/ANIMA/4666

ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 14.992: Argamassa à base de cimento Portland para rejuntamento de placas cerâmicas - Requisitos e métodos de ensaio. Rio de Janeiro, 2003.

ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 16889: Concreto - Determinação da consistência pelo abatimento do tronco de cone. Rio de Janeiro, 2020.

ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 9778: Argamassa e concreto endurecido - Determinação de absorção de água por imersão - Índice de vazios e massa específica. Rio de Janeiro, 1987.

ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 15.575: Edificações habitacionais- Desempenho. Rio de Janeiro, 2013.

ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 9574: Execução de impermeabilização. Rio de Janeiro, 2008.

ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 9779: Argamassas e concreto endurecidos - Determinação da absorção de água por capilaridade. Rio de Janeiro, 1995.

ASSOCIAÇÃO BRASILERA DE NORMAS TÉCNICAS. NBR 6118: Projeto de estruturas de concreto - Procedimento. Rio de Janeiro, 2014.

ASSOCIAÇÃO BRASILERA DE NORMAS TÉCNICAS. NBR 7610: Concreto - Extração, preparo, ensaio e análise de testemunhos de estruturas de concreto. Rio de Janeiro, 2015.

Huang, H., Ye, G., Pel, L. (2016), New insights into autogenous self-healing in cement paste based on nuclear magnetic resonance (NMR) tests. Materials and Structures 49, no. 7, p. 2509-2524. DOI: https://doi.org/10.1617/s11527-015-0664-9

Marin, J. S., Brasil, K. F. (2016), Controle da retração plástica em lajes de cobertura de concreto armado. 67f. Trabalho de Conclusão de Curso (Bacharelado em Engenharia Civil) Universidade Tecnológica Federal do Paraná. Pato Branco , 2016. Disponível em: http://repositorio.utfpr.edu.br/jspui/handle/1/14309

Neville, A. M. (2016), Propriedades do concreto. 5 ed. Porto Alegre: Bookman.

Pazderka, J., Hajková, E. (2016), Crystalline admixtures and their effect on selected properties of concrete. Journal of Advanced Engineering. Praga, República Checa. DOI: https://doi.org/10.14311/AP.2016.56.0306

Takagi, E. M., Almeida, W. J., Oliveira, F. S. (2007), Tratamento químico cristalizante para impermeabilização e proteção de estrutura de concreto armado. In: CONGRESSO BRASILEIRO DO CONCRETO, 45, Florianópolis.

VEDACIT (2013), Manual técnico de impermeabilização de estruturas. 7ª edição. Disponível em: https://www.vedanews.com.br/uploads/biblioteca/manual-tecnico-impermeabilizacao-de-estruturas-7.pdf (acesso: 11 de julho de 2019).