| Documental Research | https://doi.org/10.21041/ra.v13i2.637 |

Sustainability strategies for increased competitiveness in the Mexican cement industry

Estratégias de sustentabilidade para maior competitividade na indústria cimenteira do México

Estrategias de sostenibilidad para la mayor competitividad en la industria cementera de México

1 Fundación Universitaria Iberoameticana, Ciudad de México, México.

*Contact author: tapy_angulo@hotmail.com

Reception:

September

06,

2022.

Acceptance:

April

14,

2023.

Publication: May 01, 2023.

| Cite as:Angulo, P., Ochoa, C. (2023),“Sustainability strategies for increased competitiveness in the Mexican cement industry”, Revista ALCONPAT, 13 (2), pp. x-x, DOI: https://doi.org/10.21041/ra.v13i2.637 |

Abstract

The objective of this research is to identify and discuss the most eco-efficient sustainable strategies for utilizing or reducing emissions of NOx, SOx, and SiO2 dust in cement manufacturing, in order to improve competitiveness in the Mexican cement industry. The research design was qualitative, observational, and deductive. Results showed that SOx waste bioreactors have greater eco-efficiency, followed by domes for capturing and utilizing SiO2 and bag filters. These strategies are effective for specific contaminants derived from cement production. This study delves into a scarcely addressed topic in Mexico: cement sustainability. By applying these strategies, the Mexican cement sector would boost its business competitiveness.

Keywords:

business competitiveness,

competitiveness indicators,

sustainability,

cement industry.

1. Introduction

Competitiveness aligned with environmental sustainability regimes guarantees any business organization productive success, a stable economy, and business survival. It also enables the adoption of transformations required by the changes in the globalized world. Scientific innovation and technological development provide the necessary tools and means for designing better and eco-efficient production strategies, thus helping in making more objective decisions (Jaramillo, 2017).

This study focuses on the cement industry, a sector that releases a large amount of greenhouse gases and other polluting compounds into the environment. This situation represents a significant challenge that must be addressed to ensure the health of future generations (León-Velez & Guillén-Mena, 2020; Rodgers, 2018; Kumar, 2018). In this context, developing competitiveness implies an analysis of the viability and applicability of sustainable and eco-efficient strategies in the cement production process. The study of these strategies strengthens quality control in the manufacturing of this material. It also provides a better understanding and mastery of topics such as the environment, legal aspects, ethics, costs, and safety management in the construction sector. The results of international and local cement companies contribute to improving the use and preservation of resources in the Mexican cement industry.

1.1 Business competitiveness from a sustainable perspective

Business competitiveness from a sustainable approach aims to achieve greater stability, market competition, and productivity based on sustainable processes. In this way, the life of a company is guaranteed in the long term. The adoption of more eco-efficient production strategies is in line with the prerogatives outlined in the 2030 Agenda to meet the Sustainable Development Goals (SDGs). These goals were proposed by the United Nations (UN) in 2016 (Rivera-Hernández et al., 2018; UN, 2018).

Sustainability refers to the appropriate use, development, and recovery of all tangible, intangible, material, and natural resources available to a business or industrial organization. Consequently, it enables long-term stability and productivity (Roy, 2021). At this point, it is important not to confuse the concepts of sustainability and sustainability. The former deals with the care and use of natural resources, while the latter refers to development related to environmental care (Rivera-Hernández et al., Ruggerio, 2021).

The SDGs that are directly related to a sustainable industrial sector are responsible production and consumption, climate action, preservation of underwater life and terrestrial ecosystems, clean water and sanitation, as well as access to non-polluting energy. These SDGs are linked to community human development at local, regional, and global levels. In addition, they converge with environmental sustainability and promote optimal community development and health (UN, 2018; Balanzátegui et al., 2019; The Cement Sustainability Initiative or CSI, 2019).

An industrial corporation that operates under the terms of Sustainability, Corporate Social Responsibility (CSR), and Corporate Environmental Responsibility (CER) can obtain certain benefits. It improves its development, social reputation, business image, and generates long-term economic returns. This effect is enhanced if their actions go beyond legal interests and obligations (González & Cuesta, 2018). The general process to develop greater business competitiveness in sustainable terms involves:

- Identifying suitable objectives and goals for each organization's characteristics.

- Defining strategic action plans.

- Generating a system of indicators that show the information derived from business activity.

- Applying evaluations of their behavior.

It is important to note that the design of strategies and actions is different in each company because it depends on the results of a previous diagnosis that shows its deficiencies, potentialities, resources, etc. (Vega, 2017). Some actions that strengthen the CER of any industry are reusing industrial waste as raw material in production processes or implementing innovative production based on other eco-efficient strategies. Experience shows that their implementation reduces production costs, gas emissions, and the generation of polluting compounds (Bravo & Arroyo, 2018; Pérez et al., 2016; Lin et al., 2017).

1.2 Competitiveness indicators applicable in the cement industry

Productivity and economic performance are basic indicators of competitiveness in the cement industry. Pérez et al. (2013) proposed other potential indicators that can be addressed at the organizational level. These indicators promote business competitiveness in this sector and include:

- Participation in the global market and a strong international position. Generates greater growth and integration of the domestic market.

- Development of CSR and CER. Maximizes functions and improves corporate image.

- Price competitiveness. Drives attractive prices for the market.

- Technological competitiveness. Increases productivity by offering differentiated products.

- Authentic or genuine competitiveness. Increases quality and productive efficiency by taking advantage of economies of scale and product differentiation.

- Spurious competitiveness. Generates a system of protected industrialization, reduces excessive local competition, and leads to financial stability. Additionally, it allows companies to receive government subsidies arising from currency devaluation and wage depression.

Authors such as López (2018) and the Future Cities group of Siemens (2018) point out that technological innovation also contributes to improving productive efficiency and massive data processing. These innovations include the use of drones, automated computer systems with real-time functions, adoption of the internet of things, maintenance 4.0, and the use of advanced materials. Likewise, eco-industrial technologies minimize the emission of residual gases and lead to lower consumption of renewable energies. The CSI also establishes practices and performance indicators for sustainable development, focusing on safety, climate protection, air emissions, use of fuels and raw materials, communications, and local impacts on land and communities. It should be noted that the CSI brings together companies from around the world (CSI, 2012).

In summary, the implementation of sustainable and eco-efficient strategies in cement production is a necessity for the industry worldwide because it contributes to reducing its harmful effect on the environment and promotes the competitiveness of companies. For these reasons, this research aims to identify the most sustainable and eco-efficient strategies to exploit or reduce the emission of NOX, SOX, and SiO2 dust in the manufacture of cement, in order to improve the competitiveness of the Mexican cement industry.

2. Problem statement

Currently, the application of technological strategies focused on the care and preservation of the environment is an almost obligatory prerogative in the entire business productive sector because it benefits their technological and innovative competitiveness. Likewise, its application is aligned with the UN SDGs (2018).

Business competitiveness in the cement industry is reflected in its economic performance and level of competition in the market, as well as in its results on the emission of polluting waste. In this sense, technologies adopted to reduce the emission of sulfur oxides (SOx), nitrogen oxides (NOx), and SiO2 dust can improve their business competitiveness because it is the industrial sector that pollutes the most and damages the environment.

Portland cement (“gray cement”) mainly consists of a fine powder or clinker containing compounds such as calcium silicates and calcium aluminates. These compounds set and harden at room temperature or underwater when mixed with water. Cement types vary in formulation depending on their use and the desired strength (Sanjuán & Chinchón, 2014).

Industrial cement production includes the phases of cooking and cooling that stand out for their adverse ecological implications. Most of it is produced during the burning of fuels such as coal, petroleum coke, heavy fuel oil, among others. The chemical transformation that produces the clinker is called "decarbonation" and consists of the decomposition of calcium carbonate (CaCO3) at 900 °C. This reaction produces calcium oxide (CO) and releases significant amounts of carbon dioxide (CO2). In addition, CO reacts at high temperatures with SiO2 dust, alumina or aluminum oxide (Al2O3), and iron oxide (Fe2O3). The result of this process is the formation of compounds that harm the environment such as calcium silicates, aluminates, and ferrites. All of these are clinker-forming elements (Sanjuán & Chinchón, 2014; Ashby, 2024).

The cooling of the clinker also has adverse environmental consequences (León-Velez & Guillén-Mena, 2020; Sanjuán & Chinchón, 2014). During this phase, electric fans are used that generate a secondary waste of air-energy that is released at a temperature of 800 °C. During cooling, polluting gases are also emitted into the atmosphere. Mainly CO, nitrogen monoxide (NO), and sulfur dioxide (SO2). These gases are released especially when an adequate mechanism for their treatment is not available.

According to recent data, the cement industry consumes approximately 40% of the planet's primary energy. This percentage is due to the high use of petroleum, natural gas, coal, biomass, wind, and solar radiation. This industry also consumes 60% of the raw materials extracted from the earth's lithosphere (silicates, crust, and mantle) and produces 5% to 8% of global CO2 emissions (León-Velez & Guillén-Mena, 2020; Rodgers, 2018).

A study conducted by the Dutch Environmental Assessment Agency during the years 2010 to 2017 addressed the relationship between the amount of cement produced and the total CO2 emissions. Its results showed that China is the largest cement producer and CO2 emitter globally. Behind it are India, the European Union, the United States, Vietnam, Turkey, Egypt, and other producing countries (Rodgers, 2018).

According to several 2020 studies conducted by the Global Cement and Concrete Association (GCCA), cement is the most consumed material in the world. Its production process generates the highest CO2 emissions (around 150 tons per second) and a total of 14 billion cubic meters of concrete is used each year (France 24, 2021). As can be seen, the environmental damage caused by the massive production of cement represents an obstacle to strengthening business competitiveness, as its environmental effects violate the SDGs (UN, 2018). Therefore, it is not possible to consider it as a sustainable sector in real terms.

More actions are needed in addition to the commitment to reduce the ravages of climate change adopted by cement industry leaders. For example, each company needs to apply eco-efficient strategies that lead to the transformation of their production processes and demonstrate a reduction in their polluting emissions. This can be accredited through evaluations backed by scientific evidence (Rodgers, 2018).

The application of systematic models to evaluate polluting emissions before, during, and after the implementation of sustainable strategies represents an objective reference framework that goes beyond a simple commitment speech. According to some experts, this approach stands out as the main tool for a real estimation of possible scenarios. In this way, it is possible to make decisions based on the results provided by scientific evidence. All of this leads to designing viable alternative solutions oriented towards better future actions (Gessa, 2016).

2.1 Context of the problem in Mexico

In Mexico, the cement industry is strong, highly productive, and profitable. Cement production contributes 1% of the national Gross Domestic Product (GDP). According to data from the International Trade Center, this industry was in first place as a cement marketer in Latin America, ranked 19th as a cement exporter worldwide, and ranked 22nd as a cement importer in 2018. However, more recent data from 2020 revealed that the Mexican cement industry currently ranks second in Latin America. The reason for this decline is due to competition from the Chinese cement industry (Clavijo & Guevara, 2020; Aguilar, 2019; Martínez & Alexandre, 2020).

According to the National Chamber of Cement (2020), the Mexican cement industry is made up of the following companies: Grupo Cemex, Cementos de Chihuahua (GCC) Group, CYCNA, Cement and Concrete Moctezuma, Holcim Cement, Cementos Fortaleza, and Cementos Cruz Azul. These companies make up the National Chamber of Cement (CANACEM). According to this organization, the Mexican cement sector produces a total of 40 million tons of cement per year and generates more than 170,000 direct and indirect jobs in the country. Some of these companies have adopted the following strategies to reduce their pollutant emissions:

- Grupo Cemex. Implementación de un modelo de sustentabilidad en sus operaciones que incluye infraestructura energéticamente sustentable (Grupo Cemex, 2021).

- GCC. Promotion of environmental responsibility and protection of the climate for economic sustainability (GCC, 2023).

- Cemento y Concreto Moctezuma. Development of technology and modernization of cement plants to reduce environmental impacts (Cemento y Concreto Moctezuma, n.d.).

- Cementos Cruz Azul. Some of its plants have water treatment and rainwater harvesting systems for use. They also use alternative sources of energy such as biomass obtained through the nopal plant (Cooperativa La Cruz Azul, 2016).

In 2020, the CANACEM reported the main strategy to improve CSR in this sector: to seek better management of the co-processing or incineration of urban solid waste. These waste come from different states of the Republic, such as Colima, Baja California Sur, Mexico City, Michoacán, Nayarit, Quintana Roo, and Sinaloa. To comply with the strategy, this organization intervenes through the installation of transfer, reception, separation, crushing, compaction, composting, and biodigestion centers for waste. Additionally, it subjects them to adequate treatment for their inclusion in the industrial production of cement (National Chamber of Cement, 2020).

Even with the implementation of these measures, it cannot be affirmed that the Mexican cement sector is a sustainable industry. This sector shows clear deficiencies in scientifically demonstrating the eco-efficiency of its production processes. For example, among Mexican companies, only CEMEX has reported a 30% reduction in its carbon footprint in its production processes. Similarly, it claims to have reduced its water consumption by 10.2% in the last 10 years (García-Muñoz & Pérez-Sánchez, 2020). Regarding this, it is necessary to emphasize that such data lacks clear information on the evaluation model that supports them.

Companies such as CEMEX and Cementos Cruz Azul have implemented strategic actions that demonstrate their intention to align with the UN's 2030 Agenda goals (García-Muñoz & Pérez-Sánchez, 2020). But there is no data that fully supports their results. That is why the Mexican cement industry needs to more systematically demonstrate the eco-efficiency in the implementation of its sustainable strategies (León-Velez & Guillén-Mena, 2020).

In the context of the above, international and national scientific evidence shows that the application of eco-efficient analysis allows quantifying the environmental impact of cement production, mainly when seeking to take advantage of the substitution of raw materials for savings in non-renewable natural resources such as fuel and water. It is also useful when it comes to using waste from the production process itself to reduce the emission of polluting gases (Pérez et al., 2013; Sanjuán & Chinchón, 2014; Ruiz et al., 2017).

During the cement production process, CO2, NOx, SOx gases, and SiO2 dust are released into the atmosphere (Kumar, 2018; Semarnat, n.d .; Cooperativa La Cruz Azul, n.d.). The NOx and SOx gases diminish the air quality and contribute to the greenhouse effect. On the other hand, SiO2 dust represents a significant risk to the lung health of workers inside a cement production plant. In Mexico, there are no studies that scientifically demonstrate the eco-efficiency of sustainable strategies applied to residual emissions of SOx and NOx gases and SiO2 dust. Although some companies such as CEMEX and Cementos Cruz Azul claim to apply strategies that seem to align with the SDGs of the UN's 2030 Agenda. This research aims to know these strategies, which also allow improving the business competitiveness of the cement sector.

3. Research method

A qualitative-observational-deductive research design was used (Hernández et al., 2014). Research strategies such as information search and selection, document analysis, and data interpretation were also applied.

Literature search was conducted through online scientific research platforms such as Redalyc, Dialnet, Google Scholar, and Scielo. Keywords such as “cement production and gases”, “greenhouse gases”, “sustainable cement production”, and “industrial waste utilization” were used in the search engines. An approximate body of 35 documents was selected, consisting mainly of indexed and academic journal articles written in Spanish and English.

Document analysis consisted of identifying key concepts and innovative ideas about the methods and analysis of the processes of interest. The visualization of viable solutions to the problem was based on finding new data for the Mexican context. The main document analysis tools used were:

- Classification of the literature that makes up the state of the art of the addressed problem.

- Elaboration of informative tables.

- Construction of schemes, diagrams, or conceptual maps.

- Elaboration of study cards (Hernández et al., 2014).

Interpretation of qualitative design study data consisted of “isolating portions of discourse” (Schettini & Cortazzo, 2015). This process involved a particular selection of information that the researchers made by inferring some aspects of their research. During this procedure, not only the hypothesis and objectives influence but also the sociocultural world, intuition, and life experience of the interpreter.

4. Results, discussion and proposal

4.1 Results

The literature review yielded the following results it was identified that during the base processing of cement, a myriad of chemical reactions occur, such as exothermic reactions. They are called exothermic because they release energy in the form of heat, light, or sound during the formation of clinker. These reactions are a source of residual compounds such as molecular nitrogen (N2), amino radical (NH2), and water (H2O). The greatest amount of polluting emissions of SO2 is generated during this phase of the process, as well as in grinding, cooling, and packaging of the finished product. The maximum allowable level of emissions for this type of waste is around 400 mg/m3. This indicator is measured annually using the “non-dispersive infrared NMX-AA-55-1979” method, as stipulated by the Mexican Ministry of Environment and Natural Resources (Semarnat, n.d.).

SiO2 is part of the raw material used in cement production, although it can also be released as waste from the process, even in the storage phase. The dust generated from the production of clinker is a mixture of silica + oxygen + carbon + aluminum + calcium microparticles. It has been observed that this mixture affects the health of workers inside a cement production plant. Inhalation of the mixture can cause irritation in the respiratory tract and skin and can cause severe eye damage. These effects are related to the development of chronic diseases such as silicosis, tuberculosis, lung cancer, or chronic obstructive pulmonary disease (COPD) (Kumar, 2018; Cobo & Estébanez, 2021).

To minimize NOx, SOx, and SiO2 waste during industrial cement processing, the chemical properties of the raw material used must be considered. The application of eco-efficient strategies is also required, such as the substitution of fossil fuels, the design of systems for waste capture, the use of nanotechnology (Poudyal & Kushal, 2021), and other strategies that lead to this objective in the short, medium, and long term. Table 1 analyzes strategies that have been applied in Mexico and other countries to reduce the emission of these wastes.

| Table 1. International and national strategies to reduce NOx, SOx, and SiO2 dusts derived from the cement production process | |||||||||||||||||||

| Author, country, and year | Objective | Strategy to take advantage of or reduce the emission of NOX, SOX, and SIO2 | Demonstrated ecoefficiency | Conclusions | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| European Commission, Europe, 2010 | Keep low emissions of SOx residues during the clinker manufacturing phase. | Best Available Techniques (BAT): | Daily average emission value obtained from SO2: <50 mg/Nm3 when the sulfur content in the material is <0.10% mg/Nm3. 250-400 mg/Nm3, if the sulfur content is >0.25% mg/Nm3. | Emission margins depend on the sulfur content in the raw material used. Therefore, the strategy is to select raw materials with the lowest concentrations of this chemical. | |||||||||||||||

| 1.- Allows reducing combustion gases in two phases: preheating and precalcination of the kiln. Achieved through the addition of absorbent material or a wet scrubber. | |||||||||||||||||||

| 2.- Optimizes raw material grinding processes for dry processes. | |||||||||||||||||||

| CEMEX, Mexico, 2012 and 2016. CSI, 2014. | Replace fossil fuels and gas with urban or organic solid waste during clinker formation. | Use of urban solid waste: used tires, waste solvent residue, used oils, among others. | CEMEX reduced its carbon footprint by 22.7% in 2012. In 2016, it reported obtaining 26.6% of the energy for its kilns from biomass and waste. No data was found on the eco-efficiency of these strategies. They also did not present results for NOx, SOx, and SiO2 residues. | Publishing data on the eco-efficiency of these strategies can help support the reduction of the carbon footprint. | |||||||||||||||

| Use of organic waste: rice husk, coffee, sediment from wastewater, among others. | |||||||||||||||||||

| Rocha et al., Bolivia and Brazil, 2022. | Use of energy and raw materials with lower ecological | 85% of Clinker was produced with conventional fuels in 1990. In 2014, that percentage was reduced to 23%. | |||||||||||||||||

| Sagástegui, Peru, 2012. | Captar la mezcla de polvos fugitivos en una planta productora de cemento. | Capture the fugitive powder mixture in a cement production plant. Installation of domes for capturing fugitive dust. These domes have an air filtration system from the outside that helps minimize fugitive dust emissions. They are installed on temporary storage or in the clinker yard. | · Directly benefits the health of workers. | Micro-particles of SiO2 do not have a significant environmental impact. But they can harm the health of those who inhale their dust. For this reason, it is also recommended that workers use special protective equipment with a mask. | |||||||||||||||

| · Maintenance does not have excessive costs. | |||||||||||||||||||

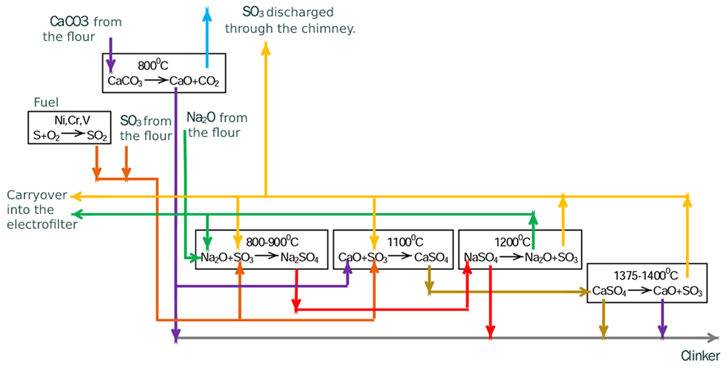

| Sanjuán and Chinchón, Spain, 2014 | Reduce the particles of dust and polluting gases emitted by localized sources. | Use of electrostatic precipitator or bag filters | Generally, emissions are <50 mg/Nm3. | Both the precipitator and the bag filters work at loading, unloading, and transportation points. They have shown to reduce NOX and SOX gases. | |||||||||||||||

| SO2 absorbents. They are applied in dry kilns. | |||||||||||||||||||

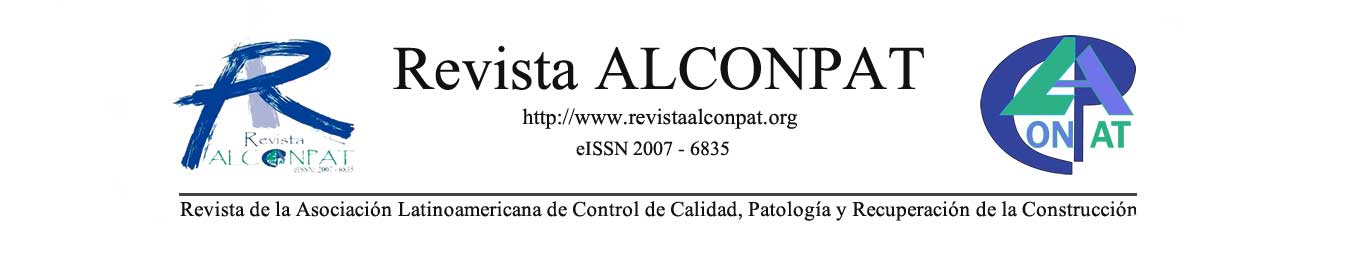

| Feijoó et al., Cuba, 2016. CSI, 2012. | erform a balance of the main chemical reactions that sulfur undergoes during cement processing. | Stoichiometric chemical monitoring system.Based on the calculation of the molar mass of sulfur and its chemical reactions. | Detects standard reference values of SO3 and Na2O, necessary for cement processing to occur optimally. | This system allows knowing when strategies should be applied to avoid sulfur rings in the furnace. | |||||||||||||||

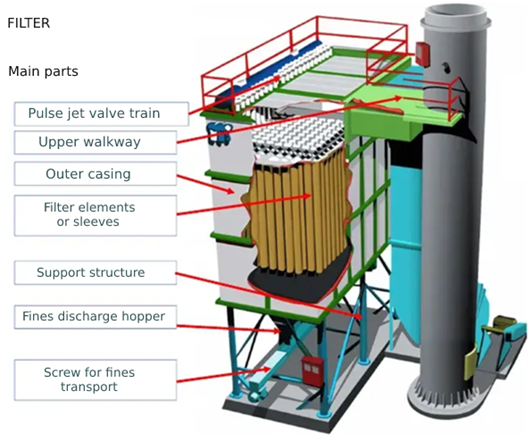

| Veana et al., Mexico, 2019. | Producing bioenergy in the form of pure methane biogas. | using a bioreactor that processes agro-industrial waste. The process involves a biochemical interaction of organic compounds with biogas, carbon dioxide, water vapor, hydrogen, and hydrogen sulfide. | t is based on biochemical reactions of chemolithotrophic bacteria. The processing guarantees lower emission of gases and contaminating waste. | This bioreactor stands out for its dual functionality in the cement production process. On the one hand, it allows for the processing of waste generated by SOX. On the other hand, it produces methane biogas that can be used instead of fossil fuels. | |||||||||||||||

| Badillo et al., Mexico, 2020. | Thermal valorization in the separation of waste to produce alternative sources of fuel for the cement sector. | Tharmal valorization and its utilization. Textile waste, among others, is processed as fuel in the production of clinker. | There is no specificity for waste types such as NOX, SOX, and SiO2 dust. | his method could promote a change in behavior among the population by encouraging waste separation. It requires joint collaboration between the population and the cement sector. | |||||||||||||||

| Poudyal and Kushal, United Statess, 2021. | Integrated approach for sustainable cement production. | Capturing CO2 to produce CaCO3 that can be used as input. | Integration of three strategies: emissions capture, substitution of materials and fuel, and the use of nanotechnology. | Adopting these strategies can have benefits for the environment and society. | |||||||||||||||

| Source: own elaboration based on data collected from the European Commission (2010), CEMEX (2012), CEMEX (2016), CSI (2014), Rocha et al. (2022), Sagástegui (2012), Sanjuán & Chinchón (2014), Feijoó et al. (2016), CSI (2012), Veana et al. (2019), Badillo et al. (2020), and Poudyal & Kushal (2021). | |||||||||||||||||||

4.2 Discussion

When comparing these strategies with other studies or documentary reviews, some similarities were found. Regarding the substitution of fossil fuels, CEMEX stated that 26% of its kilns operated with biomass or waste in 2016 (CEMEX, 2016). This figure is consistent with that reported by Teja et al. (2022), which ranged from 20% to 30%. It should be noted that it is possible to substitute 3% to 80% of clinker with biomass ashes. In contrast, Huh et al. (2018) reported that the major problem for substituting fossil fuels with biomass is that the latter is still more expensive. In their study, they compared the marginal utilities of Korean companies using different types of fuels in their processes. They found that coal is still cheaper than other alternative energy sources, which makes it difficult to use in many companies.

Guo et al. (2023) also conducted a documentary review to identify strategies to reduce the ecological impact of cement production. Their results showed that some focus on improving process efficiency and reducing energy consumption, mainly in Asian countries such as China and India. These strategies coincide with the substitution of fossil fuels with alternative fuels identified in this review (Badillo et al., 2020; CEMEX, 2016). Similarly, they agree with some strategies that contribute to maintaining adequate levels of pollutant emissions. An example is the stoichiometric chemical monitoring system or the bag filters (Figure 1 and Figure 2).

|

||||

| Figure 1. Stoichiometric chemical monitoring system. Source: Feijoó et al. (2016). | ||||

|

||||

| Figure 2. Bag filter used in the cement industry. Source: Camargo (n.d.). | ||||

Another type of strategy reported by Guo et al. (2023) is related to the development of technologies to capture, utilize, and store carbon emissions. In this case, their implementation occurs mainly in European countries. In this study, strategies of this type adopted in Mexico and other Spanish-speaking countries were found. Some examples are domes to capture SiO2 (Sagástegui, 2012) or the transformation of SOX waste into bioreactors through sulfur oxidation processes (Figure 3).

|

||||

| Figure 3. Example of the cycle generated in a bioreactor. Source: Veana et al. (2020). | ||||

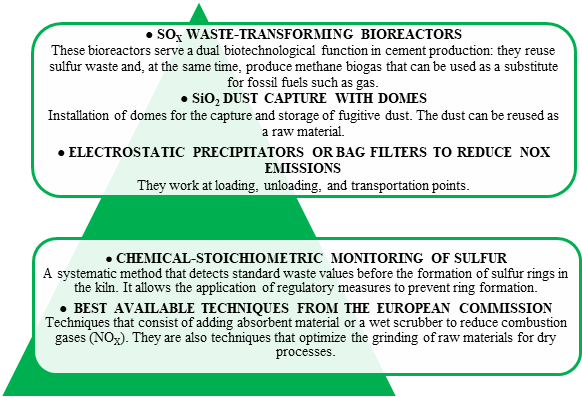

4.3 Proposal

Figure 4 presents the sustainable strategies analyzed in this study arranged according to their feasibility of implementation in the cement industry sector in Mexico. This allows visualizing their priority and importance. The options located at the top of the pyramid showed greater eco-efficiency and benefits, according to the scientific evidence that supports them.

|

||||

| Figure 4. Hierarchical diagram of eco-efficient strategies that have proven to reduce the emission of NOx, SOx, and SiO2 dust residues to the maximum during cement production. | ||||

5. Conclusions

The SOx bioreactors exhibit higher eco-efficiency since they reuse sulfur waste and produce methane biogas which can be used as fuel. The domes capture SiO2 dust that can be reused as raw material. Finally, the bag filters were able to reduce the emission of NOx residual gases. The adoption of these strategies would allow the Mexican cement sector to demonstrate the eco-efficiency of their production processes with scientific evidence.

As of the writing of this article, only CEMEX and Cementos Cruz Azul have adopted strategies such as replacing fossil energy sources with biomass or waste. However, they do not refer to the application of other strategies considered in this proposal to mitigate emissions.

Likewise, Mexican cement companies would obtain added value in their production processes and finished cement by applying eco-efficient processes. This would contribute to strengthening their business competitiveness. Furthermore, the benefits of this strengthening go beyond simply obtaining the environmental certifications required by law.

It will be necessary to double efforts to review more thoroughly whether the strategies adopted by cement companies in Mexico are truly sustainable and aligned with the UN SDGs. Again, CEMEX and Cementos Cruz Azul are the only cement companies that appear to align with these objectives through their fossil fuel substitution strategies. The rest of the Mexican cement companies express a commitment to sustainable development, but do not present strategies or indicators to reduce their environmental impact.

Finally, it is suggested to implement better methods to evaluate the results before, during, and after the application of sustainable strategies in this sector. This would provide greater certainty about their eco-efficiency. It is reiterated that the great challenge facing this sector is to demonstrate the eco-efficiency of the sustainable methods they apply with scientific evidence.

References

Aguilar, J. D. (2019), Cemento, el oro gris mexicano. Consultado el 23 de marzo de 2023. https://www.milenio.com/especiales/cemento-el-oro-gris-mexicano

Ashby, M. F. (2024), “Materials and Sustainable Development”. Elsevier, España, pp. 377-390. https://doi.org/10.1016/B978-0-323-98361-7.00016-6

Badillo, M. M., Martínez, L. A., Flores, J. R., y Flores, J. I. (2020), “La termovaloración de combustibles alternativos y materias primas (AFR) en hornos para la producción de cemento Portland: una opción sostenible ”. Academia Journals, Hidalgo, México.

Balanzátegui, R. I., Coba, L. M. y Vega, J. G. (2019), Desarrollo sostenible de proyectos productivos sobre la base de la ley de Economía Popular Solidaria. Revista Espacios. 40(22): 4-21.

Bravo, D. N. y Arroyo, F. R. (2018), Innovación sustentable: un camino al desarrollo productivo del Ecuador. Innova Research Journal. 3(5): 29-44. https://doi.org/10.33890/innova.v3.n5.2018.512

Cámara Nacional del Cemento (2020), Co-procesamiento en la industria del cemento: Alternativa de manejo de residuos ambientalmente segura. Consultado el 24 de marzo de 2023. https://comisiones.senado.gob.mx/ambiente/reu/docs/presentacion4_e121020.pdf

Camargo, G. (s. f.), Filtro de Mangas Partes y Funcionamiento . Consultado el 05 de abril de 2023. https://es.scribd.com/document/439978098/Filtro-de-Mangas-Partes-y-Funcionamiento#

Cemento y Concreto Moctezuma (s. f.), Compromiso por contribuir al desarrollo social. Consultado el 05 de abril de 2023. https://www.cmoctezuma.com.mx/desarrollo-sostenible

CEMEX (2016), “La contribución de CEMEX hacia un futuro bajo en carbono. Postura de CEMEX respecto al cambio climático ”. CEMEX, México.

CEMEX. (2012), “Construyendo las ciudades del futuro. Informe de desarrollo sustentable”. CEMEX, México.

Ciudades del Futuro (2018), Cemento 4.0: la disrupción tecnológica llega a la industria cementera. Siemens. Consultado el 20 de marzo de 2023. https://ciudadesdelfuturo.es/cemento-4-0-la-disrupcion-tecnologica-llega-la-industria-cementera.php

Clavijo, P. A. y Guevara, M. M. (2019), “Análisis Sostenible de la Cementera Holcim con Repercusiones de Mercadeo y Finanzas”, Trabajo de Grado, Universidad del Rosario, Bogotá.

Cobo, M. E. y Estébanez, S. (2021), “Guía para el control de la exposición a polvo de sílice ”. Asepeyo prevención, Madrid, España.

Comisión Europea (2017), “Prevención y control integrados de la contaminación. Documento de referencia sobre las mejores técnicas disponibles en la industria de fabricación de cemento, cal y óxido de magnesio ”. Observatorio de la economía circular en la industria cementera, Sevilla, España.

Cooperativa la Cruz Azul (2016), La Cruz Azul y los Objetivos de Desarrollo Sostenible. Consultado el 05 de abril de 2023. https://www.aciamericas.coop/IMG/pdf/apolinarortiz.pdf

Cooperativa La Cruz Azul (s. f.), Medición isocinética a fuentes fijas y perimetral de partículas. Consultado el 18 de marzo de 2023. https://acortar.link/MpNMyg

Feijoó, J. A., Fabelo, J. A. y Rodríguez, I. L. (2017), Evaluación del ciclo del azufre en el horno de la fábrica de cemento de Cienfuegos. Revista Centro Azúcar. 44(2): 1-9.

France 24 (2021), El hormigón, tercer emisor mundial de gases de efecto invernadero. Consultado el 21 de marzo de 2023. https://www.france24.com/es/minuto-a-minuto/20211019-el-hormig%C3%B3n-tercer-emisor-mundial-de-gases-de-efecto-invernadero

García-Muñoz, A. C. y Pérez-Sánchez, B. (2020), La responsabilidad social en CEMEX. Investigación Valdizana. 14(4): 175-87. https://doi.org/10.33554/riv.14.4.728

Gessa, P. A. y Sancha, D. M. P. (2016), Alternativas de reducción de las emisiones de dióxido de carbono (CO2) en la producción de cemento. Propuesta de un modelo de evaluación. Innovar. 26(60): 51-66. https://doi.org/10.15446/innovar.v26n60.55532

González, M. J. y Cuesta, V. P. (2018), De responsabilidad social a sostenibilidad corporativa: una revisión actualizada. Revista Internacional de Investigación en Comunicación. 17(7): 46-71. https://doi.org/10.7263/adresic-017-04

Grupo Cemex (2021), Sostenibilidad. Consultado el 05 de abril de 2023. https://www.cemexmexico.com/sostenibilidad

Grupos de Cemento Chihuahua (2023), Sustentabilidad. Consultado el 05 de abril de 2023. https://www.gcc.com/es/sustentabilidad/#:~:text=La%20estrategia%20de%20sustentabilidad%20de,para%20esta%20y%20pr%C3%B3ximas%20generaciones.

Guo, Y., Luo, L., Liu, T., Hao, L., Li, Y., Liu, P. y Zhu, T. (2024), A review of low-carbon technologies and projects for the global cement industry. Journal of Environmental Sciences. 136: 682-697. https://doi.org/10.1016/j.jes.2023.01.021

Hernández, R., Fernández, C. y Baptista, M. P. (2014), “Metodología de la investigación ”. Mc Graw Hill Education, Distrito Federal, México.

Huh, S.Y., Lee, H., Shin, J., Lee, D. y Jang, J. (2018), Inter-fuel substitution path analysis of the korea cement industry. Renewable and Sustainable Energy Reviews. 82: 4091-4099. https://doi.org/10.1016/j.rser.2017.10.065

Jaramillo, R. A. (2017), Una Mirada a la competitividad. Dictamen libre. 20:87-98.

Kumar, C. A. (2018), “Cement production technology. Principles and Practice”. CRC Press, Florida, Estados Unidos.

León-Velez, A. y Guillén-Mena, V. (2020), Energía contenida y emisiones de CO2 en el proceso de fabricación del cemento en Ecuador. Ambiente Construido. 20(3): 611-25. https://doi.org/10.1590/s1678-86212020000300448

Lin, K.-L., Lo, K.-W., Hung, M.-J., Cheng, T.-W., y Chang, Y.-M. (2017), Recycling of spent catalyst and waste sludge from industry to substitute raw materials in the preparation of Portland cement clinker. Sustainable Environment Research, 27(5). https://doi.org/10.1016/j.serj.2017.05.001

López, N. V. (2018), El papel de la innovación tecnológica industrial y la sustentabilidad. Un acercamiento a la industria cementera. Tekhné Revista de la Facultad de Ingeniería. 21(2): 83-95.

Martínez, L. M. y Alexandre, P. M. (2020), Industria cementera en México: Sin señales de recuperación a pesar de tocar fondo el año pasado. Consultado el 24 de febrero de 2022. https://www.spglobal.com/_assets/documents/ratings/es/2020-01-22-industria-cementera-mexico.pdf

Organización de las Naciones Unidas y Comisión Económica para América Latina y el Caribe. (2018), “La Agenda 2030 y los objetivos de desarrollo sostenible: Una oportunidad para América Latina y el Caribe”. ONU-CEPAL, Santiago de Chile, Chile.

Pérez, E. M. J., Espinoza, C. C. y Peralta, M. B. (2016), La responsabilidad social empresarial y su enfoque ambiental: una visión sostenible a futuro. Revista Universidad y Sociedad. 8(3): 169-78.

Pérez, S. B., Guzmán, S. A., Mayo, C. A. y Heredia, R. H. (2013), Evolución histórica de cementos mexicanos: un grupo económico de capital nacional. Hitos de Ciencias Económico Administrativas. 19(55): 115-30. https://doi.org/10.19136/hitos.a0n55.113

Poudyal, L. y Adhikari, K. (2021), Environmental sustainability in cement industry: An integrated approach for green and economical cement production. Resources, Environment and Sustainability. 4, 100024. https://doi.org/10.1016/j.resenv.2021.100024

Rivera-Hernández, J. E., Alcántara-Salinas, G., Blanco-Orozco, N., et. al. (2017), ¿Desarrollo sostenible o sustentable? La controversia de un concepto. Revista Posgrado y Sociedad. 15(1): 57-67. https://doi.org/10.22458/rpys.v15i1.1825

Rocha, J. H. A., Toledo Filho, R. D. y Cayo-Chileno, N. G. (2022), Sustainable alternatives to CO2 reduction in the cement industry: A short review. Materials Today: Proceedings. 57, 436-439. https://doi.org/10.1016/j.matpr.2021.12.565

Rodgers, L. (2018), La enorme Fuente de emisiones de CO2 que está por todas partes y que quizás no conocías. Consultado el 17 de marzo de 2023. https://www.bbc.com/mundo/noticias-46594783

Roy, M. (2021), “Sustainable Development Strategies”. Elsevier, España, pp. 1-25. https://doi.org/10.1016/B978-0-12-818920-7.00005-0

Ruiz, Y., Domínguez, E. R., Sánchez, S., Castillo, L., Martirena, J. F. y Suppen, N. (2017), Análisis de ecoeficiencia de la producción de cementos de bajo carbono mediante la sustitución de clínker. Revista Centro Azúcar. 44: 77-88.

Ruggerio, C. A. (2021), Sustainability and sustainable development: A review of principles and definitions. Science of The Total Environment, 786. https://doi.org/10.1016/j.scitotenv.2021.147481

Sagástegui, D. A. (2012), “Propuesta para reducir las emisiones de polvo fugitivo en el proceso productivo de una empresa cementera”, Tesis de ingeniería, Universidad Peruana de Ciencias Aplicadas, Santiago de Surco, Perú.

Sanjuán, M. A. y Chinchón, S. (2014), “Introducción a la fabricación y normalización del cemento Portland”. Universidad de Alicante, España.

Schenttini, P. y Cortazzo, I. (2015), “Análisis de datos cualitativos en la investigación social. Procedimientos y herramientas para la interpretación de información cualitativa ”. Editorial de la Universidad Nacional de la Plata, La Plata, Argentina.

Secretaría del Medio Ambiente y Recursos Naturales. (s. f.), “Guía para la elaboración de la cédula de operación anual. Industria del cemento, cal y yeso ”. SEMARNAT, México.

Teja, R., Hiremath, R.B, Rajesh, P., Kumar, B., y Renukappa, S. (2022), Sustainable transition towards biomass-based cement industry: A review. Renewable and Sustainable Energy Reviews, 163. https://doi.org/10.1016/j.rser.2022.112503

The Cement Sustainability Initiative (2012), “The Cement Sustainability Initiative”. World Business Council for Sustainable Development, Washington, DC, Estados Unidos.

The Cement Sustainability Initiative (2014), “Cement Industry Energy and CO2 Performance Getting the Numbers Right (GNR) ”. World Business Council for Sustainable Development.

The Cement Sustainability Initiative (2019), “Indian Cement Sector SDG Roadmap ”. World Business Council for Sustainable Development, Ginebra, Suiza.

Veana, F., González-Purata, P. Y., Wong-Paz, J. E., Aguilar-Zárate, P., Muñiz-Márquez, D. B. (2019), Tendencias de la bioenergía: del metagenoma de hábitats ricos en azufre a la purificación del biogás. Revista Especializada en Ciencias Químico-Biológicas. 22: 1-11. https://doi.org/10.22201/fesz.23958723e.2019.0.190

Vega, L. A. (2017), Sustentabilidad y competitividad en empresas hortícolas de México. Sapientiae. 2(2): 110-26.