| Articulos | https://doi.org/10.21041/ra.v12i3.630 |

Flexural behavior of reinforced concrete beams with electrochemical parameters associated with high level of corrosion

Comportamiento a flexión de vigas de concreto reforzado con parámetros electroquímicos asociados con un nivel de corrosión alto

Comportamento à flexão de vigas de concreto armado com parâmetros eletroquímicos associados a um alto nível de corrosão

Joel Alberto

Moreno Herrera1

*

![]() ,

Jorge

Varela-Rivera1

,

Jorge

Varela-Rivera1

![]() ,

Rebeca Visairo

Méndez2

,

Rebeca Visairo

Méndez2

![]() ,

Pedro

Castro-Borges2

,

Pedro

Castro-Borges2

![]()

1 Facultad de Ingeniería, Universidad Autónoma de Yucatán, México.

2 Centro de Investigación y de Estudios Avanzados, IPN, Unidad Mérida, México.

*Contact author: joel.moreno@correo.uady.mx

Reception:

July

16,

2022.

Acceptance:

August

17,

2022.

Publication: September 01, 2022.

| Cite as: Moreno Herrera, J. A., Varela Rivera, J. L., Visairo Méndez, R., Castro Borges, P. (2022),“Flexural behavior of reinforced concrete beams with electrochemical parameters associated with high level of corrosion”, Revista ALCONPAT, 12 (3), pp. 422 – 432, DOI: https://doi.org/10.21041/ra.v12i3.630 |

Abstract

In this work the change in the flexural behavior of reinforced concrete beams was evaluated. Beams without corrosion and beams with electrochemical parameters associated with high level of corrosion were considered. The electrochemical parameters considered were the corrosion rate, the electrical resistivity, and the concentration of chlorides. Beams were subjected to vertical incremental loads until failure. Cracking pattern, yielding load, maximum load, yielding stiffness, and displacement ductility of beams are presented. Based on the analysis of these structural parameters it is concluded that the flexural behavior of beams with and without corrosion was similar.

Keywords:

reinforced concrete beams,

corrosion,

sustained loads,

structural behavior,

electrochemical behavior

1. Introduction

Reinforced concrete (RC) is one of the most used materials in the construction industry around the world. Concrete global production per year is about 11000 million cubic meters (Ceballos, 2016). Corrosion is one of the main problems that affects safety and durability of reinforced concrete structures (Rodríguez, 2014). Corrosion can initiate when different agents such as chlorides, sulfates and carbon dioxide penetrate into the concrete (Castro, 1988). Corrosion induces a degradation in the physical and mechanical properties of steel reinforcement. This degradation is associated with changes in the chemical composition related to the chemical reaction of steel with the corrosion agents in the surrounding environment (Maldonado-López, 1996). Corrosion can cause damage in RC elements such as cracking and loss of the concrete cover of the steel reinforcement. These damages are associated with losses in the strength and the deformation capacity of RC elements. These losses produce a reduction in the safety of RC structures. Damage in structures associated with corrosion generates expenses and economic loses in many countries (Vázquez-Castillo, 1998). The annual cost of repairments of RC structures in the UK it is approximately 755 million pounds (Rodríguez, 2014). Rodríguez, 2014cost of maintenance and repairment of coastal infrastructure in the USA its around 600 million dollars (Xianming et al. 2012). Therefore, prevention, evaluation, and control of corrosion in RC structures are very important.

Current Mexican regulations on durability of reinforced concrete structures focus mainly in two aspects: prevention and evaluation. The specifications in the Mexican Complementary Technical Norms for the Design and Construction of Concrete Structures (NTCC-2017) focus on prevention of corrosion. In these technical norms, minimum requirements are specified for the compressive strengths of concrete and the thickness of the concrete cover as a function of different exposed environments. On the other side, there are some standards mainly based on the electrochemical behavior of reinforced concrete beams. For example, in the Mexican standard NMX-C-514-ONNCCE-2016, levels of corrosion are proposed as a function of the corrosion rate. In the same sense, in the Mexican standard NMX-C-523-ONNCCE-2015, corrosion risk levels are proposed as a function of the electrical resistivity of concrete. These standards are not explicitly related to the structural behavior of reinforced concrete elements.

There are some studies about the structural behavior of reinforced concrete elements with corrosion. The main variables studied were the level of corrosion (Gu et al., 2010; Ou et al., 2016; Ye et al., 2018), the diameter of the longitudinal steel reinforcement (Gu et al., 2010; Ou et al., 2016; Shaikh, 2018), and the magnitude of sustained loads (Tachibana et al., 1990; Castel et al., 2000; Vidal et al., 2007; Torres et al., 2007; Juárez et al., 2011; Ye et al., 2018). On the other side, there are studies about the electrochemical behavior of reinforced concrete beams with corrosion (Andrade and González, 1978; Andrade et al., 1993; Elsener et al., 2003). In the above studies, it was observed that, in general, the structural and electrochemical behavior of concrete elements are studied independently. Only one study was found where the relationship between the structural and electrochemical behavior was considered (Yu et al., 2015. However, in that study only two beams with corrosion were considered. The only variable studied was the corrosion rate. Therefore, it is observed that more experimental studies are still needed. In these studies, it is important to consider the relationship between the structural and electrochemical behavior of reinforced concrete beams. The main parameters used to define the structural behavior of RC beams are the strength, stiffness, and deformation capacity. The main parameters used to define the electrochemical behavior are the corrosion rate, electrical resistivity, and concentration of chlorides in concrete. The relationships between those parameters will allow a better evaluation of structures damaged by corrosion.

The objective of this work it is to evaluate the change in the flexural behavior of reinforced concrete beams. Beams without corrosion and beams with electrochemical parameters associated with high level of corrosion were considered. The beams were obtained from the study carried out by Moreno-Herrera et al. (2022).

2. Methodology

2.1 Properties of existing beams

Eight existing reinforced concrete beams were considered, four control beams and four beams with corrosion (Moreno-Herrera et al., 2022). The dimensions of beams were 15 x 30 x 350 cm (width x height x length). Beams were design to induce flexural behavior. Longitudinal steel reinforcement of beams consisted of two #4 bars (13 mm diameter) in the tension zone and two #3 bars (9.5 mm diameter) in the compression zone. Deformed steel bars with nominal yield strength of 411.88 MPa (4200 kg/cm2) were used. Transverse steel reinforcement consisted of #2 hoops (6.4 mm diameter) at every 130 mm. Plain steel bars with nominal yield strength of 227.51 MPa (2320 kg/cm2) were used. Clear cover of the longitudinal reinforcement was 25 mm. The average compressive strength of concrete was 17.53 MPa (178.75 kg/cm2). Portland cement and calcareous aggregates with high absorption were used in the concrete mixture. The nominal maximum size of coarse aggregate was 19 mm. A water/cement ratio of 0.62 and a slump of 100 mm were considered. Beams were constructed by an experimented worker. The transverse steel reinforcement was painted with an anticorrosive alkyd enamel. This paint was used to induce the corrosion only in the longitudinal steel reinforcement. For the case of the control beams, the concrete was placed in a traditional way. For the case of the beams with corrosion, the concrete was placed in two layers of 150 mm heigh. The first layer with concrete contaminated with chlorides (1.5% of the cement weight) and the second layer with regular concrete. Beams were cured with drinking water for a period of 28 days.

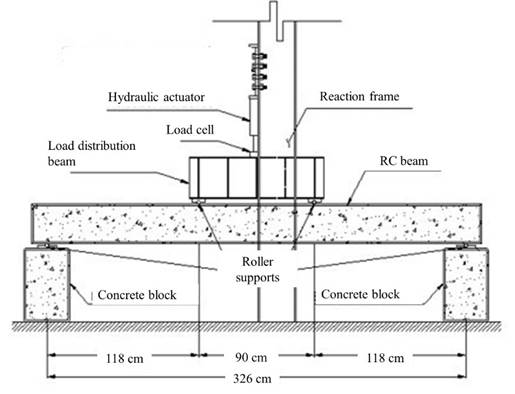

Beams were subjected to incremental vertical loads until the target tensile stresses in the longitudinal steel reinforcement were reached (Table 1). Loads were applied using a traditional four-point load system (Figure 1). With this loading system, a constant bending moment with no shear force was induced in the central third of the beam length. In Table 1, VC refers to control beams, VCC to beams with corrosion, 0.4 and 0.8 refer to the target tensile stresses in the longitudinal steel reinforcement (40% and 80% of fy). In Table 1, P cr refers to the cracking load associated with flexural cracking strength and ∆cr refers to the corresponding displacement, Pm1 refers to the load associated with the target tensile stress and ∆m1 refers to the corresponding displacement. In that table, the initial stiffness ( K0 ) and the post-cracking stiffness ( Kcr ) of beSams are included. The initial stiffness was calculated using Pcr and ∆cr . The post-cracking stiffness was calculated using both Pcr and Pm1.

| Table 1. Initial structural parameters of beams (Moreno-Herrera et al., 2022) | ||||||||||||||

| Beam | Pcr (kN) | ∆cr (mm) | Pm1(kN) | ∆m1 (mm) | Ko (kN/mm) | Ker(kN/mm) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| VC1-0.4 | 7.69 | 0.83 | 18.17 | 4.32 | 10.30 | 3.00 | ||||||||

| VC2-0.4 | 5.20 | 0.45 | 18.29 | 4.25 | 12.90 | 3.44 | ||||||||

| VC1-0.8 | 8.03 | 0.80 | 35.8 | 10.63 | 11.18 | 2.82 | ||||||||

| VC2-0.8 | 5.40 | 0.68 | 35.31 | 11.77 | 8.86 | 2.70 | ||||||||

| VCC1-0.4 | 7.61 | 0.80 | 17.88 | 4.38 | 10.55 | 2.87 | ||||||||

| VCC2-0.4 | 9.74 | 0.98 | 18.37 | 4.09 | 11.21 | 2.78 | ||||||||

| VCC1-0.8 | 9.11 | 1.00 | 36.11 | 10.93 | 10.20 | 2.72 | ||||||||

| VCC2-0.8 | 7.93 | 0.92 | 36.37 | 11.17 | 9.56 | 2.78 | ||||||||

2.2 Sustained loads and accelerated corrosion in existing beams

Beams were subjected to sustained loads for a period of 166 days (Moreno-Herrera et al., 2022). Sustained loads associated with target tensile stresses were considered (Table 1). Applied loads induced the same distribution of bending moments and shear forces in the beams as described before for the four-point load system. To induce the corrosion in the steel reinforcement, wetting and drying cycles were applied during this period. Beams were moistening every 12 hours, a first time with drinking water and a second time with a 3.5% saline solution. This concentration of chlorides is similar to the average concentration of chlorides of sea water. Table 2 shows the maximum values observed for the corrosion rate in the longitudinal steel reinforcement, electrical resistivity, and concentration of chlorides in concrete of beams. Corrosion rate and electrical resistivity of concrete were measured with a corrosimeter (James Instruments, 2010). Concentration of chlorides were determined according with the Mexican Standard NMX-C-523-ONNCCE-2015.

| Table 2. Electrochemical parameter of beams (Moreno-Herrera et al., 2022) | ||||||||||||||

| Beam | Corrosion rate (μAmp/cm2) | Electrical resistivity of concrete (kΩ ∙ cm) | Concentration of chlorides (% per weight of cement) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| VC1-0.4 | 0.45 | 11.97 | 0.3034 | |||||||||||

| VC2-0.4 | ||||||||||||||

| VC1-0.8 | 0.65 | 11.08 | 0.3295 | |||||||||||

| VC2-0.8 | ||||||||||||||

| VCC1-0.4 | 7.01 | 1.37 | 2.5853 | |||||||||||

| VCC2-0.4 | ||||||||||||||

| VCC1-0.8 | 5.66 | 2.47 | 3.2038 | |||||||||||

| VCC2-0.8 | ||||||||||||||

Table 2 shows that the maximum corrosion rate of control beams (CV) was associated with a low to moderate level of corrosion (0.1 a 0.5 μAmp cm 2 ) (NMX-C-501-ONNCCE-2015). The electrical resistivity of concrete was associated with a low to moderate risk of corrosion (10 a 50 kΩ∙cm) (NMX-C-514-ONNCCE-2016). The concentration of chlorides was smaller than the threshold value of 0.52 proposed for concrete made of calcareous aggregates and a water/cement ratio of 0.6 (Castro et al., 1993). On the other side, Table 2 also shows that the corrosion rate of beams with corrosion (VCC) was associated with a high level of corrosion (larger than 1 μAmp⁄cm2). The electrical resistivity of concrete was associated with high risk of corrosion (less than 10 kΩ∙cm). The concentration of chlorides was at least five times larger than the proposed threshold value. Therefore, based on the electrochemical behavior, the VCC beams have parameters associated with a high level of corrosion.

For beams with the same target tensile stress, the cracking pattern was in general similar. For beams with target tensile stress of 0.8 fy, larger and wider cracks were observed compared with beams with tensile stress of 0.4 fy. This was related to the larger loads applied on beams with tensile stress of 0.8 fy. After the corrosion technique was applied, the cracking pattern of beams was similar to that observed prior to the application of the corrosion technique.

2.3 Load system and instrumentation for testing of beams

Control beams and beams with corrosion were subjected to incremental vertical loads until failure. Beams were tested after the period of application of the corrosion technique. Loads were applied using the same four-point load system described before (Figure 1). Loads were applied using a hydraulic actuator and were measured with a load cell. Vertical displacements at the mid-length of beams were measured using two linear potentiometers. Strains of the longitudinal steel reinforcement were measured using strain-gages. The strain-gages were attached to the longitudinal steel reinforcement prior to pouring of concrete (Moreno-Herrera et al., 2022).

|

||||

| Figure 1. Four-point load system | ||||

3. Results y discusion

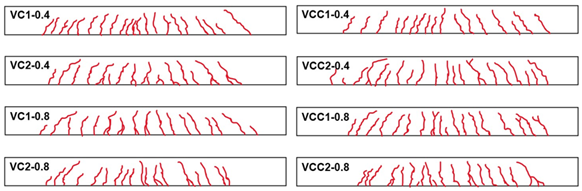

The final cracking pattern of tested beams are presented in Figure 2. The final cracking pattern of control beams and beams with corrosion was similar. This cracking pattern was defined by the formation of vertical flexural cracks at the beam center and diagonal flexure-shear cracks at beams ends.

|

||||

| Figure 2. Final cracking pattern of beams | ||||

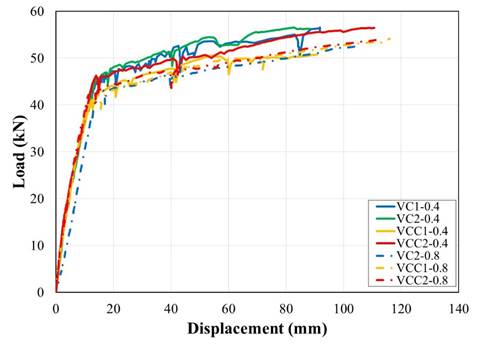

The load - displacement curves of beams are presented in Figure 3. Table 3 shows the yielding load ( P 푦 ) and corresponding yielding displacement ( ∆ 푦 ), the maximum load ( P 푚2 ) and corresponding displacement ( ∆ 푚2 ) of beams. Yielding loads were determined using the strains measured with the strain-gages. Initial yielding stiffness ( K 푦 ) and displacement ductilities (휇) of beam are presented in Table 3. Initial yielding stiffness was calculated using the yielding load. Displacement ductility was calculated as the ratio between the maximum displacement and the yielding displacement of corresponding beams. For beam VCC1-08, only the maximum load and corresponding displacement are presented because of problems with the measurements with the strain-gages.

|

||||

| Figure 3. Load - displacement curves | ||||

| Table 3. Structural parameters of beams tested until failure | ||||||||||||||

| Beam | Py (kN) | ∆y (mm) | Pm2 (kN) | ∆m2 (mm) | Ky (kN/mm) | μ (∆m2/∆y) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| VC1-0.4 | 43.47 | 13.08 | 56.54 | 91.79 | 3.32 | 7.02 | ||||||||

| VC2-0.4 | 44.09 | 13.24 | 54.45 | 88.18 | 3.33 | 6.66 | ||||||||

| VC1-0.8 | -- | -- | 52.93 | 119.30 | -- | -- | ||||||||

| VC2-0.8 | 42.52 | 14.35 | 52.56 | 105.87 | 2.96 | 7.38 | ||||||||

| Average | 43.36 | 13.56 | 54.12 | 101.28 | 3.21 | 7.02 | ||||||||

| CV | 0.02 | 0.05 | 0.03 | 0.14 | 0.07 | 0.05 | ||||||||

| VCC1-0.4 | 42.63 | 14.11 | 50.70 | 90.72 | 3.02 | 6.43 | ||||||||

| VCC2-0.4 | 46.13 | 15.59 | 56.48 | 110.66 | 2.96 | 7.10 | ||||||||

| VCC1-0.8 | 41.92 | 16.54 | 54.10 | 116.03 | 2.53 | 7.02 | ||||||||

| VCC2-0.8 | 42.93 | 14.44 | 53.92 | 112.79 | 2.97 | 7.81 | ||||||||

| Average | 43.30 | 15.17 | 53.80 | 107.55 | 2.87 | 7.09 | ||||||||

| CV | 0.04 | 0.07 | 0.04 | 0.11 | 0.08 | 0.08 | ||||||||

Table 3 shows that the average yielding loads and the average maximum loads together with corresponding average displacements were similar for all beams, respectively. The ratio between the average yielding load of beams with corrosion and the average yielding load of control beams was 0.99. On the other hand, the ratio between the average maximum load of beams with corrosion and the average maximum load of control beams was 1.01.

In addition, Table 3 shows that the average initial yielding stiffness was similar for all beams. The ratio between the average initial yielding stiffness of beams with corrosion and the average initial yielding stiffness of control beams was 0.90. Table 3 also shows that the average displacement ductility of all the beams was similar. The ratio between the average displacement ductility of beams with corrosion and the average displacement ductility of control beams was 1.01.

Even though the electrochemical parameters of the beams with corrosion indicates a high level of corrosion, the flexural structural behavior of beams with corrosion compared with the behavior of control beams was similar. The difference between each behavior was not significant. Yielding load, maximum load, initial yielding stiffness and displacement ductility of beams were in general similar. Even though from a structural point of view the parameters observed are acceptable, the electrochemical parameters suggested a risk for the durability of the beams. Therefore, from the electrochemical point of view preventive actions should be taken for the beams with corrosion.

4. Conclusions y recomendations

Eight reinforced concrete beams were subjected to incremental loads until failure. Beams had electrochemical parameters associated with high level of corrosion. Based on the experimental result of these beams the following conclusion and recommendations are presented:

- The final cracking pattern of control beams and beams with corrosion was similar. This cracking pattern was defined by the formation of vertical flexural cracks at the beam center and diagonal flexure-shear cracks at beams ends.

- Even though the electrochemical parameters of the beams with corrosion indicates a high level of corrosion, the flexural structural behavior of beams with corrosion compared with the behavior of control beams was similar. The difference between each behavior was not significant. Yielding load, maximum load, initial yielding stiffness and displacement ductility of beams were in general similar.

- Even though from a structural point of view the parameters observed are acceptable, the electrochemical parameters suggested a risk for the durability of the beams. Therefore, from the electrochemical point of view preventive actions should be taken for the beams with corrosion.

- It is recommended to study beams with electrochemical parameters associated with higher level of corrosion than that considered in this work. Physical parameter such as cracking of concrete and stains due to corrosion must be considered. These physical parameters were not observed in the beams studied. The parameters will help to stablish a relationship between different levels of corrosion and corresponding structural damage in reinforced concrete beams. Levels of corrosion can be defined as a function of structural parameters such as loss of strength, stiffness, or deformation capacity. By the other side, physical parameters can be assessed as a function of the width and length of cracks developed parallel to the longitudinal steel reinforcement. This kind of cracks are typically observed in beams with high level of corrosion.

5. Acknowledgments

R. Visairo Méndez thanks the National Council of Science and Technology for the master's scholarship received. Similarly, he thanks the Faculty of Engineering of UADY and Cinvestav Mérida for the facilities provided for structural and corrosion measurements.

References

Andrade F., y González J.A. (1978). Quantitative measurements of corrosion rate of reinforcing steels embedded in concrete using polarization resistance measurements. Materials and Corrosion. 29(8): 515-519.

Andrade, C. (1993), Calculation of chloride diffusion-coefficients in concrete from ionic migration measurements. Cement and Concrete Research, 23 (3): 724-742. https://doi.org/10.1016/0008-8846(93)90023-3.

Castro P. (1998). “Corrosión en Estructuras de Concreto: teoría, inspección, diagnóstico, vida útil y reparaciones”. 1ª Edición. Instituto Mexicano del Cemento y del Concreto A.C., México, DF.

Castel A., François R., Arliguie G. (2000). Mechanical behaviour of corroded reinforced concrete beams-Part 1: Experimental study of corroded beams. Materials and Structures, 33: 539-544, https://doi.org/10.1007/BF02480533

Ceballos, M. (2016). “El concreto, material fundamental para la infraestructura.” Centro de Innovación Tecnológica para la Construcción. pp. 24-25.

Elsener, B., Andrade, C., Gulikers, J., Polder, R y Raupach, M. (2003). Half-cell potential measurements-Potential mapping on reinforced concrete structures. Materials and Structures. 36: 461-471, https://doi.org/10.1007/BF02481526

Gu X., Zhang W., Shang D., Wang X. (2010). “Flexural Behavior of Corroded Reinforced Concrete Beams.” Earth and Space 2010: Engineering, Science, Construction, and Operations in Challenging Environments, ASCE, 2, 3545-3552. https://doi.org/10.1061/41096(366)339

Juárez, C. A., Guevara, B., Fajardo, G., & Castro-Borges, P. (2011). Ultimate and nominal shear strength in reinforced concrete beams deteriorated by corrosion. Engineering Structures, 33(8): 3189-3196. https://doi.org/10.1016/j.engstruct.2011.08.014

Maldonado López, L. (1996). “Corrosión del acero de refuerzo: revisión del estado del arte en México.” En F. d. Yucatán (Ed.), VII Seminario de Investigación, (pág. 18). Mérida, Yucatán, México.

Moreno-Herrera, J., Visairo-Méndez, R., Varela-Rivera, J., Balancan-Zapata, M., y Castro-Borges, P. (2022, enviado para su posible publicación). Corrosion, The Journal of Science and Engineering.

NMX-C-501-ONNCCE-2015. (2015). “Industria de la Construcción - Durabilidad de Estructuras de Concreto Reforzado - Medición de Velocidad de Corrosión en Campo - Especificaciones y Método de Ensayo.” Organismo Nacional de Normalización y Certificación de la Construcción y Edificación, S.C.

NMX-C-514-ONNCCE-2016. (2016). “Industria de la Construcción - Resistividad Eléctrica del Concreto Hidráulico - Especificaciones y métodos de ensayo.” Organismo Nacional de Normalización y Certificación de la Construcción y Edificación, S.C.

NMX-C-523-ONNCCE-2016. (2016). “Industria de la construcción - Durabilidad de estructuras de concreto reforzado - Concentración de cloruros solubles en agua y ácido - determinación en concreto hidráulico - Método de extracción y método de determinación por ión selectivo.” Organismo Nacional de Normalización y Certificación de la Construcción y Edificación, S.C.

NTCC-2017 (2017). “Normas Técnicas Complementarias para Diseño y Construcción de Estructuras de Concreto.” Órgano del Gobierno del Distrito Federal, Jefatura de Gobierno. México, D.F.: Administración Pública del Distrito Federal.

Ou Y., Susanto Y., Roh H. (2016). Tensile behavior of naturally and artificially corroded steel bars. Construction and Building Materials, 103: 93-104, https://doi.org/10.1016/j.conbuildmat.2015.10.075

Rodriguez-Rodriguez, A. (2014). Las pérdidas económicas causadas por el fenómeno de la corrosión atmosférica del acero de refuerzo embebido en el hormigón armado. CENIC: Ciencias Químicas, 45: 52-59.

Shaikh, F.U.A. (2018). Effect of Cracking on Corrosion of Steel in Concrete. International Journal of Concrete Structures and Materials, 12(3), https://doi.org/10.1186/s40069-018-0234-y

Tachibana Y., Maeda K., Kajikawa Y., Kawuamura M. (1990). Mechanical behavior of RC beams damaged by corrosion of reinforcement. Corrosion of Reinforcement in Concrete Construction, 178-187.

Torres Acosta, A., Navarro Gutiérrez, S., & Terán, C. (2007). Residual flexure capacity of corroded reinforced concrete beams. Engineering Structures, 1145-1152. https://doi.org/10.1016/j.engstruct.2006.07.018.

Vázquez Castillo, C. D. (1998). “Diagnóstico de la corrosión del puente de Celestún.” Tesis. Mérida, Yucatán, México: Facultad de Ingeniería, Universidad Autónoma de Yucatán.

Vidal T., Castel A., François R. (2007). Corrosion process and structural performance of a 17 year old reinforced concrete beam stored in chloride environment. Cement and Concrete Research, 37(11): 1551-1561, https://doi.org/10.1016/j.cemconres.2007.08.004

Xianming, S., Ning, X., Keith, F., Jing, G. (2012) Durability of steel reinforced concrete in chloride environments: An overview. Construction and Building Materials, 37: 36-40, https://doi.org/10.1016/j.conbuildmat.2011.12.038

Ye, H., Fu, C., Jin, N., Jin, X. (2018). Performance of reinforced concrete beams corroded under sustained service loads: A comparative study of two accelerated corrosion techniques. Construction and Building Materials, 162: 286-297, https://doi.org/10.1016/j.conbuildmat.2017.10.108

Yu, L., François, R., Hiep, V., L’Hostis, V., Gagné, R. (2015). Development of chloride-induced corrosion in pre-cracked RC beams under sustained loading: Effect of load-induced cracks, concrete cover, and exposure conditions. Cement and Concrete Research, 67: 246-258, https://doi.org/10.1016/j.cemconres.2014.10.007