| Basic Research | https://doi.org/10.21041/ra.v13i1.608 |

Potential alkali reactivity of aggregates for concrete in Uruguay. Correlation between mortar bar test and concrete prism test (accelerated and traditional)

Potencialidad reactiva de agregados para hormigón en Uruguay. Correlación entre la metodología de la barra de mortero y el prisma de hormigón (acelerada y tradicional).

Reatividade potencial de agregados para concreto no Uruguai. Correlação entre a metodologia da barra de argamassa e o prisma de concreto (acelerado e tradicional)

P. E.

Vila1

*

![]() ,

H. L.

Bonjour1

,

H. L.

Bonjour1

![]() ,

L. J.

Díaz1

,

L. J.

Díaz1

![]() ,

M. N.

Pereyra1

,

M. N.

Pereyra1

![]()

1 Departamento de Construcción, Instituto de Estructuras y Transporte, Facultad de Ingeniería, Universidad de la República, Montevideo, Uruguay.

*Contact author: pvila@fing.edu.uy

Reception:

May

11,

2022.

Acceptance:

December

21,

2022.

Publication: January 01, 2023.

| Cite as: Vila, P. E., Bonjour, H. L., Díaz, L. J., Pereyra, M. N. (2023),“Potential alkali reactivity of aggregates for concrete in Uruguay. Correlation between mortar bar test and concrete prismtest (accelerated and traditional)”, Revista ALCONPAT, 13 (1), pp. 45 –60, DOI: https://doi.org/10.21041/ra.v13i1.608 |

Abstract

The correlation between the international criteria to define the reactivity degree in the mortar bar expansion test and the expansion in concrete prism test (accelerated and traditional methodology) was analyzed. The three test methods were applied experimentally to 19 aggregates samples used for concrete in Uruguay. There were aggregates of different reactivity degree, but no consensus was found in the interpretation by the different techniques. The results are only for the lithologies evaluated and provided background for a relatively new assay methodology. No correlation was observed between the expansion of the mortar bar test and the concrete prism-traditional test, but an adequate correlation was observed between both concrete test method (accelerated and traditional).

Keywords:

expansion,

durability,

alkali-aggregate reaction,

tests

1. Introduction

Portland cement concrete is constituted between 60 and 75% of its volume by aggregates. In the case of aggregates containing low crystallinity or amorphous silica (such as quartz with reactive silica, phtanite, chert, chalcedony, tridymite, cristobalite, opal and volcanic glass) together with the presence of alkalis (sodium and potassium oxide), hydroxyl ions (OH-) and moisture, produce a deleterious chemical reaction in concrete called the alkali-silica reaction (ASR). This reaction, once triggered, can cause serious problems in concrete structures, mainly in civil infrastructures such as bridges, pavements, foundations, and dams (Fanijo et al., 2021; Godart et al., 2013; Sims and Poole, 2017).

The main deleterious effect on concrete is due to the expansive nature of the reaction products, which can lead to edge breaks in joints, differential movement at wall edges, classic crackle crack mapping of the RAS in pavement slabs or massive elements, longitudinal crack mapping in columns, pop-outs, discoloration and leaching on surfaces (Fournier et al., 2010; Méndez, 2019).

For the design of a new structure it is important to know the risk of being affected by this pathology so that the necessary preventive measures are taken to minimize the damage. These measures are of a prescriptive or performance nature, but the first step is always to know the reactive potential of the aggregate to be used, which will allow it to be classified by its degree or level of reactivity. This degree of reactivity, together with the design lifetime, the risk associated with the failure, the type of element and the environment, determines the level of prevention required to control the ASR. Prescriptive measures may include limiting the alkali content of the concrete or the use of supplementary cementitious material (IRAM, 2016; IRAM, 2012; ABNT, 2008; ASTM, 2020; Nixon and Sims, 2016).

The degree of reactivity is determined using one of the existing standardized laboratory expansion test methods: accelerated mortar bar test (AMBT) (IRAM, 1997), accelerated concrete prism test (CPT-60) (IRAM, 2013) or the traditional concrete prism test (CPT-38) (IRAM, 2013).

Uruguay has a great lithological variety, represented by rocks of different nature, age and geological history (Veroslavsky Barbe et al., 2004a; Veroslavsky Barbe et al., 2004b). These rocks have been widely used as aggregates in the construction industry, especially granitic rocks, granodiorites, basalts, and pebbles. Additionally, natural sands of fluvial origin are used. To date, there is no national regulation that indicates the procedure to evaluate the reactive potential of an aggregate source. Traditionally, the evaluation of the reactive potential of the aggregate was carried out only with the mortar bar method (AMBT).

Between 2018 and 2021, an experimental campaign was carried out to evaluate the alkaline reactivity of aggregate samples belonging to the main sources of aggregates for concrete located in different areas of the country. The degree of reactivity was evaluated by applying the expansion test methods mentioned above.

The objective of this work was to analyze the correlation between the international criteria to define the degree of reactivity that arises from the mortar bar or the concrete prism test (accelerated or traditional methodology) applied to 19 samples of aggregates belonging to different quarries in Uruguay.

2. Degree of alkali-silica reactivity of aggregate

International standards define the degree of alkali-silica reactivity of an aggregate by applying one of the following test methods: expansion in a mortar bar test (AMBT), expansion in a concrete prism-accelerated test (CPT-60) or expansion in a concrete prism-traditional test (CPT-38). From the results, the aggregate is classified on a scale from R0 to R3, as shown in Table 1 (R0 corresponds to the non-reactive aggregate and R3 very high reactive aggregate) (ASTM, 2020; ABNT, 2008; IRAM, 2016; Giovambattista et al., 2020).

Table 1. Degree of reactivity of aggregate according to the expansion (E, in %) in the mortar bar and in concrete methods

Reactivity Degree

Description

14-days expansion in AMBT1)

28-days expansion in AMBT2)

13-weeks expansion in CPT-603)

1-year expansion in CPT-384)

R0

Non-reactive

E<0,10

E<0,19

E<0,04/0,085)

<0,04

R1

Moderately reactive

0,10≤E< 0,30

0,19 ≤E< 0,40

0,04/0,085) ≤E<0,12

0,04≤E< 0,12

R2

Highly reactive

0,30≤E< 0,45

0,40≤E< 0,60

0,12≤E<0,24

0,12≤E< 0,24

R3

Very highly reactive

E≥0,45

E≥0,60

E≥0,24

≥0,24

Notes 1): ASTM C1778 and Bases for an Argentine Model Code Código 2)NBR 15577; 3) IRAM 1531, IRAM 1512 and Bases for an Argentine Model Code; 4)ASTM C1778, NBR 15577 y Bases for an Argentine Model Code; 5): for aggregates whose reactivity is exclusively due to some variety of quartz (microcrystalline or strained), the limit of 0.08% is adopted.

The AMBT is adopted by all standards to define the degree of reactivity. This methodology usually adopts an expansion limit of 14 or 28 days. The American and Argentine standards adopt an expansion limit of 14 days, while the Brazilian regulations adopt an expansion limit of 28 days.

CPT-60 is the accelerated expansion test in concrete prisms and is adopted by Argentine standards. CPT-38 is the traditional test for concrete prisms and is adopted by all standards. In case of discrepancy between the different methods, the latter have priority over the rest, since being the least aggressive, the behavior of the aggregate is the most similar to that of in-service aggregate (on site).

The AMBT involves the preparation of mortar bars of 25 mm x 25 mm x 285 mm with the aggregate in the fractions smaller than 4.75 mm and greater than 0.150 mm, in the proportions indicated in Table 2. The specimens are cured by 24 h at 20 °C and 100 % RH and then immersed in water for 24 h at 48 h, the initial reading is recorded, and they are immersed in 1 N NaOH solution at 80 °C for a period of 14 or 28 days. This test methods is also used to evaluate the pessimum effect and the ability to inhibit the reaction of a reactive mineral addition (ASTM International, 2020).

Table 2.

Mortar dosage in AMBT method

Inserta titulo aqui!!

Particle size of aggregate, % in mass

Total aggregate (kg)

Cement (kg)

Water (kg)

4,75-2,36, mm

2,36-1,18, mm

1,18-0,60, mm

0,60-0,30, mm

0,30-0,15, mm

10

25

25

25

15

0,99

0,44

0,207

In the concrete expansion test methods (CPT-60 and CPT-38), prismatic specimens of 75 mm x 75 mm x 285 mm of concrete are produced in the proportions indicated in Table 3. In the accelerated test method, the prisms are kept at 60 °C and 100 % RH for 13 weeks and in the traditional test method at 38 °C and 100 % RH for 1 year.

| Table 3. Concrete dosage in CPT-60 and CPT-38 methods (kg/m3) | ||||||||||||||

| Particle size of coarse aggregate | Particle size of fine aggregate | Cement (Kg) | Water (kg) | Admixtures | NaOH (g) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 19-12,5 mm | 12,5-9,5 mm | 9,5-4,75 mm | 4,75-2,36 mm | 2,36-1,18 mm | 1,18-0,60 mm | 0,60-0,15 mm | Sikament 290N (%) | |||||||

| 354 | 354 | 354 | 71 | 142 | 142 | 354 | 420 | 198,4 | 0,20% | 535,7 | ||||

Prior to the expansion tests, the petrographic evaluation of the aggregate is carried out to determine the reactive components (ASTM, 2019).

3. Experimental methodology

3.1 Materials

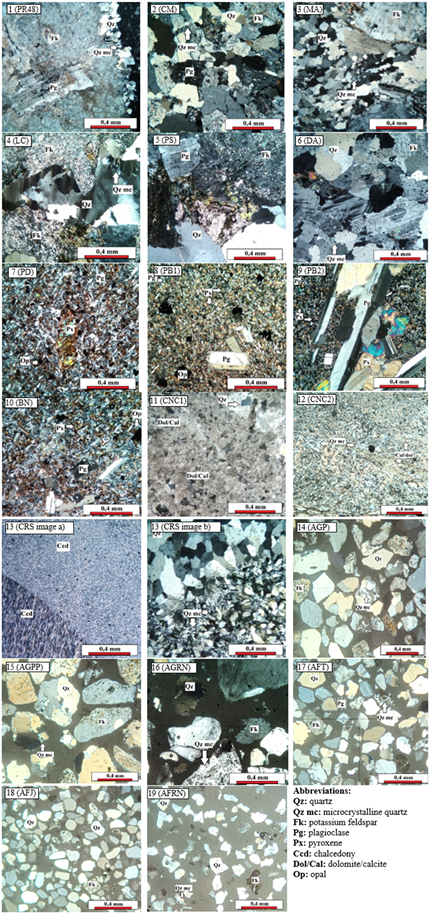

In the evaluation, 19 aggregate samples were used (13 of coarse aggregate, 3 of coarse sand and 3 of fine sand), all considered suitable for concrete (UNIT, 2005) from quarries located in different areas of the country (Table 4). Additionally, the mineralogical composition and the alkali reactive components are indicated according to IRAM 1531 (IRAM, 2016) and IRAM 1512 (IRAM, 2012). The samples from ordinal 1 to 6 were samples of coarse aggregate called “granites”, which presented microcrystalline quartz and strained quartz (Qz/mc and Qz/t) as reactive components. Ordinals 7 to 10 were basalt samples and presented altered volcanic glass (Vg) as a reactive component (also sample 10 presented opal). Samples 11 and 12 were metadolomite, and sample 12 presented microcrystalline quartz (Qz/mc). Sample 13 was a pebble with the presence of microcrystalline quartz (Qz/mc) and chalcedony (Ccd) as reactive components. Samples 14 to 19 are fluvial deposit sands with microcrystalline quartz (Qz/mc) as a reactive component (also sample 16 presented chalcedony). In Figure 1, photomicrographs with crossed polarized light of the samples are shown.

| Table 4. Aggregate samples used in the experimental evaluation. | |||||||||||||||||||

| Ordinal | Sample id. | Type | Location | Geological origin | Reactive components | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | PR48 | Coarse | Las Piedras, Canelones | Granito La Paz | Qz/mc | ||||||||||||||

| 2 | CM | Coarse | Cno. Carrasco, Montevideo | Granodiorita Cañada de las Canteras | Qz/mc | ||||||||||||||

| 3 | MA | Coarse | Mal Abrigo, San José | Granito Mal Abrigo | Qz/mc | ||||||||||||||

| 4 | LC | Coarse | San Carlos, Maldonado | Granito Aiguá | Qz/mc y Qz/t | ||||||||||||||

| 5 | PS | Coarse | Soca, Canelones | Granito Soca | Qz/mc y Qz/t | ||||||||||||||

| 6 | DA | Coarse | Durazno, Durazno | Franja Granito-Gnéisica Terreno Piedra Alta | Qz/mc y Qz/t | ||||||||||||||

| 7 | PD | Coarse | Ruta 5 Km 480, Tacuarembó | Basalto Arapey | Vv | ||||||||||||||

| 8 | PB1 | Coarse | Centenario, Durazno | Basalto Arapey | Vv | ||||||||||||||

| 9 | PB2 | Coarse | Centenario, Durazno | Basalto Arapey | Vv | ||||||||||||||

| 10 | BN | Coarse | Paso de los Toros, Tacuarembó | Basalto Arapey | Vv and Op | ||||||||||||||

| 11 | CNC1 | Coarse | Pan de Azúcar, Maldonado | Metadolomía – Complejo Zanja del Tigre | Qz | ||||||||||||||

| 12 | CNC2 | Coarse | Pan de Azúcar, Maldonado | Metadolomía – Complejo Zanja del Tigre | Qz/mc | ||||||||||||||

| 13 | CRS | Coarse | Salto, Salto | Canto Rodado Salto | Qz/mc y Ccd | ||||||||||||||

| 14 | AGP | Coarse Sand | Aguas Corrientes, Canelones. | Depósito actual – Sedimento Río Santa Lucía | Qz/mc | ||||||||||||||

| 15 | AGPP | Coarse Sand | Paso Pache, Canelones. | Sedimento Río Santa Lucía | Qz/mc | ||||||||||||||

| 16 | AGRN | Coarse Sand | Centenario, Durazno | Depósito actual fluvial – Río Negro | Qz/mc y Ccd | ||||||||||||||

| 17 | AFT | Fine Sand | Delta del Tigre, San José | Formación Chuy | Qz/mc | ||||||||||||||

| 18 | AFJ | Fine Sand | Jaureguiberry, Canelones | Depósito actual- Dunas Costeras | Qz/mc | ||||||||||||||

| 19 | AFRN | Fine Sand | Centenario, Durazno | Depósito actual fluvial – Río Negro | Qz/mc | ||||||||||||||

| Qz/mc: microcrystalline quartz. Qz/t: strained quartz. Vv: volcanic glass. Ccd: chalcedony. Op: opal | |||||||||||||||||||

|

||||

| Figure 1. Photomicrographs with crossed polarized light of the samples | ||||

The cement used for the mortars and concretes is a Portland cement containing only clinker as the main component, without mineral additions and for general use in concrete (Table 5), identified as CPN 40 according to UNIT 20. (UNIT, 2017).

| Table 5. Characterization of Portland cement CPN 40 | ||||||||||||||

| CaO (%) | SiO2 (%) | Al2O3 (%) | Fe2O3 (%) | SO3 (%) | Na2O (%) | K2O (%) | Na2O+0,658K2O (%) | C3A (%) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 62,99 | 19,93 | 4,42 | 2,76 | 3,06 | 0,34 | 1,23 | 1,15 | 6,5 | ||||||

| Insoluble residue (%) | Calcination loss (%) | Retained at sieve 75 µm (%) | Blaine (m2/kg) | Autoclave expansion (%) | Specific weight (kg/dm3) | Initial setting time (h:min) | Final setting time (h:min) | Strength at 28 days (MPa) | ||||||

| 0,11 | 2,46 | 3,1 | 356 | No record | 3,15 | 01:56 | 02:56 | 46,6 | ||||||

Mortars and concretes were manufactured using the standard IRAM 1674 (IRAM, 1997) and IRAM 1700 (IRAM, 2013) procedures, respectively. The proportions are shown in Tables 2 and 3.

3.2 Methodology

Three expansion test methods were applied (AMBT, CPT-60 and CPT-38). In the AMBT test, the length of the mortar bars was recorded at 0 days (initial length, prior to immersion in the 1 N NaOH solution at 80 °C), 14 days, and 28 days after immersion. In the accelerated concrete prism test, (CPT-60), the length was recorded initially at 0 days (prior to conditioning at 60 °C and 100% RH) and at 13 weeks. Finally, in the concrete prism, traditional test method (CPT-38), the length was recorded initially at 0 days (prior to conditioning at 38 °C and 100 % RH) and at 52 weeks. For each test method, the expansion E(ti) of each of the bars was determined according to (1):

|

Where:

E (ti): expansion to test age t i

ti: test age, expressed in days for the AMBT and in weeks for the CPT-60 and CPT-38 test methods.

Lti: bar length between pins at age ti, in mm

Lt0: bar length between pins at time 0, in mm

Ln: effective bar expansion length, in mm

The expansion at age t i per aggregate sample was obtained as the mean expansion of three bars of the same mortar tested simultaneously, previously calculating the coefficient of variation per sample to verify the precision between bars according to ASTM C1260 (ASTM, 2014) for the AMBT and according to IRAM 1700 (IRAM, 2013) for concrete prisms.

After calculating the expansion and adopting the limits of Table 1, the degree of reactivity for each sample was determined, and the correlation between the results by applying the three test methods was analyzed. Each sub-sample of aggregate included to evaluate the expansion at three test methods was extracted from the same sample by quartering and fractionation.

4. Results and discussion

4.1 Degree of reactivity according to the applied test method

Table 5 shows the reactivity degree of the aggregates according to the expansion in the mortar bars (AMBT) at 14 and 28 days, the expansion in concrete prisms, accelerated test (CPT-60) at 13 weeks and expansion in concrete prisms, traditional test (CPT-38) at 52 weeks (1 year).

In the samples of coarse “granite” aggregate (sample ordinal from 1 to 6) in the AMBT, mortars 1, 2, 3 and 6 presented an expansion at 14 days of less than 0.10% and at 28 days of less than 0.19%. Therefore, under this test method, these samples are classified as having a degree of reactivity R0 (non-reactive). Granites 4 and 5 exceeded the limit of 0.10% at 14 days, both being classified with the degree of reactivity R1 for this age. However, adopting the expansion at 28 days, sample 4 would be classified as non-reactive (R0) and sample 5 as R1. In the concrete methods CPT-60 and CPT-38, sample 1 presented an expansion of less than 0.08% and 0.04% (limits of both methods, respectively) and was classified as R0 (non-reactive) applying these methods. The concrete prepared with sample 2 and that prepared with sample 6 presented an expansion above the limit, being classified as R1. The concrete with sample 3 presented the highest expansion of all and was classified with a degree of reactivity R2 in CPT-60 and with R1 in CPT-38.

In the basalt samples (sample ordinal from 7 to 10), according to the AMBT method, the expansion at 14 and 28 days classified sample 7 as R1, sample 8 as R3 and R2 (14 and 28, respectively) and samples 9 and 10 as R3. In the last two, expansions that exceeded 1% at 14 days were obtained. However, in the concrete evaluation, basalt samples 7, 8 and 9 were classified as non-reactive (R0), and sample 10 was classified as R1.

In the metadolomite samples (11 and 12), all the evaluation methods classify sample 11 as non-reactive (R0) and sample 12 as R1. The pebble (sample 13) was classified as R1 by all methods.

In the sands, samples 14 and 15 presented the same behavior, in the AMBT and in CTP-38, both were classified with reactivity degree R1 and by CPT-60 as non-reactive (R0). Both samples came from sediments the Santa Lucía river, although they were extracted from different areas.

The sand samples 16 and 19 presented a very similar behavior in the expansion, being classified with reactivity degree R1, except in the expansion at 28 days in AMBT of the sample 16, which was slightly less than 0.19% what classifies it as non-reactive. Both samples were from the same origin (Rio Negro sediments).

Samples 17 and 18 were classified as non-reactive (R0) except for CPT-38 in sample 17 which exceeded the expansion of 0.04 % (at 52 weeks) and was classified as R1.

Adopting the CPT-38 test method as the most reliable and considering the non-coincident results obtained according to the other methods (“no” cells of Table 6), it is observed that erroneous interpretations known as false-positives and false-negatives are reached. False-positives are identified as reactive by the method used, while the expansion in CPT-38 is less than 0.04% (which is associated with a non-deleterious in-service behavior). False-negatives, on the other hand, are aggregates of negligible expansion due to the test method used but which present an expansion greater than 0.04% in the CPT-38 (associated with deleterious in-service behavior).

| Table 6. Expansion and reactivity degree according to the test methods. | ||||||||||||||

| Sample | Reactivity degree | Matches with CPT-38? | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ordinal | Id. | AMBT -14d | AMBT -28d | CPT-60 | CPT-38 | AMBT -14d | AMBT -28d | CPT-60 | ||||||

| 1 | PR48 | R0 | R0 | R0 | R0 | yes | yes | yes | ||||||

| 2 | CM | R0 | R0 | R1 | R1 | no | no | si | ||||||

| 3 | MA | R0 | R0 | R2 | R1 | no | no | no | ||||||

| 4 | LC | R1 | R0 | R0 | R1 | yes | no | no | ||||||

| 5 | PS | R1 | R1 | R0 | R1 | yes | yes | no | ||||||

| 6 | DA | R0 | R0 | R1 | R1 | no | no | yes | ||||||

| 7 | PD | R1 | R1 | R0 | R0 | no | no | yes | ||||||

| 8 | PB1 | R3 | R2 | R0 | R0 | no | no | yes | ||||||

| 9 | PB2 | R3 | R3 | R0 | R0 | no | no | yes | ||||||

| 10 | BN | R3 | R3 | R1 | R1 | no | no | yes | ||||||

| 11 | CNC1 | R0 | R0 | R0 | R0 | yes | yes | yes | ||||||

| 12 | CNC2 | R1 | R1 | R1 | R1 | yes | yes | yes | ||||||

| 13 | CRS | R1 | R1 | R1 | R1 | yes | yes | yes | ||||||

| 14 | AGP | R1 | R1 | R0 | R1 | yes | yes | no | ||||||

| 15 | AGPP | R1 | R1 | R0 | R1 | yes | yes | no | ||||||

| 16 | AGRN | R1 | R0 | R1 | R1 | yes | no | si | ||||||

| 17 | AFT | R0 | R0 | R0 | R1 | no | no | no | ||||||

| 18 | AFJ | R0 | R0 | R0 | R0 | yes | yes | yes | ||||||

| 19 | AFRN | R1 | R1 | R1 | R1 | yes | yes | yes | ||||||

| R0: green color. R1: orange color. | Total "yes": | 11 | 9 | 13 | ||||||||||

| R2 y R3: pink color. “yes”: green color. “no”: pink color. | Total "no": | 8 | 10 | 6 | ||||||||||

Analyzing the results that did not match with those obtained in the CPT-38, in the AMBT at 14 days, eight samples yielded erroneous results (42% of the samples), and considering the expansion at 28 days, ten results were erroneous (53%). In the coarse aggregates, the false-negatives of this method belonged to the granite samples (CM, MA, LC, DA) that presented microcrystalline quartz (Qz/mc) as a reactive component. In the sand samples, it was in AGRN where a false-negative was observed (with Qz/m as a reactive component). Regarding the false-positives of the AMBT, they were in four basalt samples of the five samples tested. Both false-positives and false-negatives of this test method have been reported in the literature (Madsen et al., 2018; Torres, 2014; Garber et al., 2005).

In the expansion in the concrete prism, accelerated test method CPT-60, six samples yielded results that did not match with the traditional test method (32% of the samples). Five correspond to false-negatives, two in coarse granite aggregate (LC and LS) and three in sands (AGP, AGPP and AFT). All these samples presented microcrystalline quartz (Qz/mc) and strained quartz (Qz/s) as reactive constituents; for these, the limit of 0.08% should be adopted instead of 0.04% (Table 1).

If the limit of 0.04% was considered instead of 0.08%, there would be three non-coincident results, samples PR48, MA and AFJ (PR48 and AFJ, both exceeded the limit of 0.04% in CPT-60 but not in CPT-38).

4.2 Correlation between expansion results

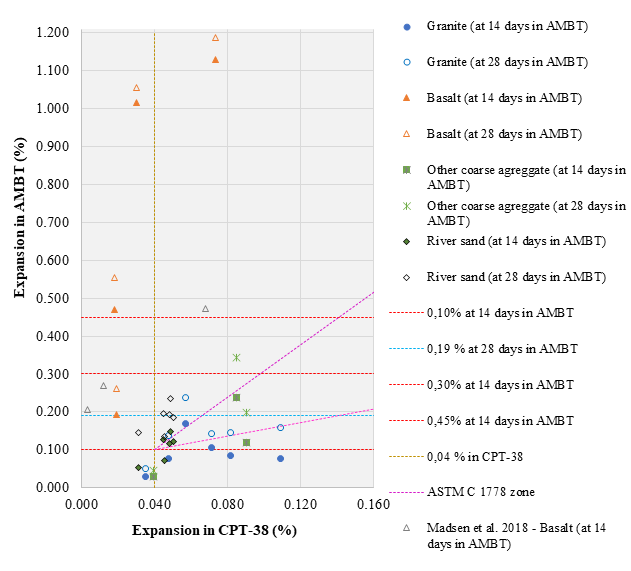

In Figure 2, the expansion in the AMBT was plotted at 14 and 28 days of testing vs. the expansion in CPT-38, which allowed us to observe the weak correlation between both test methods. Both the points close the abscissa axis and the points close the ordinate axis show results that deviate from the correlation. The first ones are due to granite samples (with Qz/mc and Qz/t as reactive components) and the latter to basalt samples (with the presence of Vv). The results in basalts reported by Madsen et al. (2018) were included, observing that two of the three samples presented weak correlation (points close to the ordinate axis).

ASTM C 1778 standard (ASTM, 2020) defines a zone on the chart for reactive aggregates where there is good correlation between both tests. Among the reactive aggregates, only three remained in the zone of good correlation (AGRN, AFRN, CNC), and only three aggregates were classified as non-reactive by both methods (AFJ, PR48 and CNC1).

Therefore, the mortar bar test method (AMBT) resulted in low reliability to evaluate the potential reactivity of the aggregate, although it is considered adequate to evaluate the uniformity of an aggregate quarry or to evaluate the ability to inhibit the reaction of a preventive measure taken (ASTM, 2020).

|

||||

| Figure 2. Expansion at 14 and 28 days in AMBT vs. expansion at 52 weeks in CPT-38. | ||||

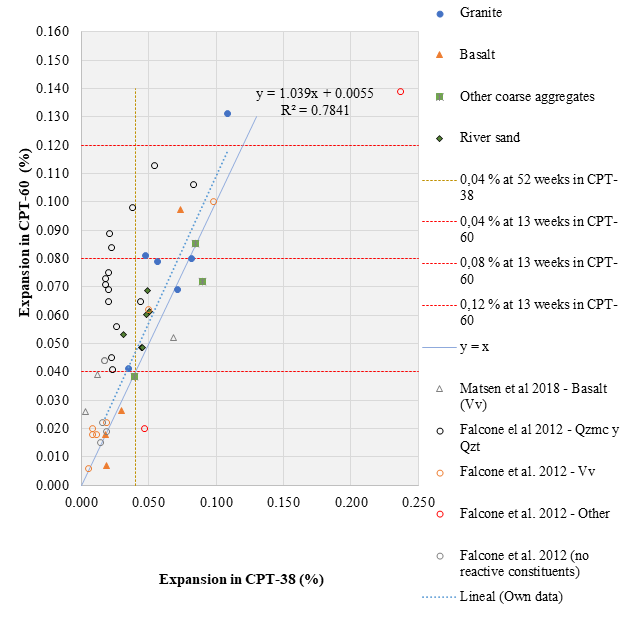

In Figure 3, the expansion of the CPT-60 accelerated test method vs. the expansion using the traditional CPT-38 test method was plotted, including all the samples evaluated. An adequate correlation between the two was obtained (R2 = 0.78). The number of samples per type of aggregate was limited, so it was not possible to make a correlation line for each type. The data reported in the literature grouped by reactive constituents (Qz/mc, Qz/t, Vv and others) were added to the same graph.

The aggregates with the presence of volcanic glass (Vv) (identified as basalts) presented an adequate correlation both in own and in the literature data (Madsen et al. 2018 y Falcone et al. 2012).

Falcone et al. (2012) showed that the aggregates with the presence of Qz/mc and Qz/t were grouped closer to the ordinate axis (points in black outline, unfilled), and therefore, they recommended a limit of 0.08% for aggregates with these reactive constituents in the CPT-60 methodology (Table 1). However, our own results did not show a similar trend for this type of aggregate.

|

||||

| Figure 3. Expansion at 13 weeks in CPT-60 vs. expansion at 52 weeks in CPT-38. | ||||

The CPT-60 method is relatively new, with limited evidence of correlation with the rest of the methods and of correlation with the be havior of the in-service aggregate. A greater number of studies should be available to analyze whether the limit of 0.08 % in the CPT-60 at 13 weeks for aggregates with the presence of microcrystalline or strained quartz is correlated with the limit of 0.04 % in the CPT-38 at 52 weeks. In this sense, there is another method of analysis proposed by RILEM (Nixon and Sims, 2016). In this analysis, by applying the mathematical model known as the Kolmogorov-Avrami-Mehl-Johnson model (abbreviated KAMJ model), the kinetic parameters of the reaction (ln (k) and M) specific to the material under study and to the expansion methodology used are obtained. These parameters are linked to the expansion limits of Table 1, and the reactivity of the sample is obtained (Gowripalan and Sirivivatnanon, 2017; Mangialardi, 2002; Vila et al., 2020; Johnston and Fournier, 2000).

5. Conclusions

Applying the expansion test method in mortar bars (AMBT) and in concrete prisms (CPT-60 and CPT-38) in 19 samples of aggregates of different rocks used to produce concrete in Uruguay and adopting the limits to define the grade of reactivity existing in international standards, the following can be concluded:

The conclusions apply to the Uruguayan materials used in this work. Therefore, its extrapolation to other conditions must be carefully analyzed.

6. Acknowledgments

Thanks to the Structures and Transport Institute (IET) of the Engineering University (Facultad de Ingeniería-UdelaR) for the equipment and laboratory necessary to carry out the tests, as well as the CSIC (Science Investigation Committee - UdelaR) and Concrexur S.A. for the financial support within the framework of the CSIC project: “Estudio de la reacción álcali-sílice en agregados para hormigón en Uruguay”.

References

Associação Brasileira de Normas Técnicas. (2008). ABNT NBR 15577-1. Agregados - Reatividade álcali-agregado Parte 1: Guia para avaliação da reatividade potencial e medidas preventivas para uso de agregados em concreto.

ASTM International. (2014). ASTM C 1260: Standard Test Method for Potential Alkali Reactivity of Aggregates (Mortar-Bar Method). http://doi.org/10.1520/C1260-07

ASTM International. (2019). ASTM C 295: Standard Guide for Petrographic Examination of Aggregates for Concrete. http://doi.org/10.1520/C0295-08

ASTM International. (2020). ASTM C 1778: Standard Guide for Reducing the Risk of Deleterious Alkali-Aggregate Reaction. http://doi.org/10.1520/C1778-22

Falcone, D y Milanesi, C. (2012). Método acelerado del prisma de hormigón. evaluación de la ras con agregados de diversas regiones de la Argentina. V Congreso Internacional - 19º Reunión técnica de la AATH.

Fanijo, E., Kolawole, J., y Almakrab, A. (2021). Alkali-silica reaction (ASR) in concrete structures: Mechanisms, effects and evaluation test methods adopted in the United States. Case Studies in Construction Materials. n° 15. http://doi.org/10.1016/j.cscm.2021.e00563

Fournier, B., Bérubé, M.-A., Folliard, K., y Thomas, M. (2010). Report on the diagnosis, prognosis and mitigation of ASR in transportation structures. Federal Highway Administration.

Garber, S., Ideker, J., Ley, T., Williams, S., Juenger, M., Fournier, B., and Thomas, M. (2005). Preventing ASR/DEF in New Concrete: Final Report.

Giovambattista, A., Zerbino, R., Giaccio, G., Fava, C., Milanesi, C., Traversa, L., Iloro, F. (2020). Bases de un código modelo para la tecnología de las obras de hormigón: Anales LEMIT, Serie IV, año 6, n° 13. (L. Tecnológica, Ed.) La Plata, Argentina. https://digital.cic.gba.gob.ar/handle/11746/11068

Godart, B., De Rooij, M., y Wood, J. (2013). RILEM State-of-the-Art Reports Guide to Diagnosis and Appraisal of AAR Damage to Concrete in Structures. http://www.springer.com/series/8780

Gowripalan, N., y Sirivivatnanon, V. (2017). Kinetic based approach for Alkali Silica Reaction-Comparison of laboratory and field tests Fibre Optic sensors for bridge monitoring View project Applications of FRP mesh as reinforcement View project. https://www.researchgate.net/publication/320620011

Instituto Argentino de Normalización y Certificación. (1997). IRAM 1674: Determinación de la reactividad alcalina potencial. Método acelerado de la barra de mortero. Buenos Aires.

Instituto Argentino de Normalización y Certificación. (2012). IRAM 1512. Agregado fino para hormigón de cemento. Buenos Aires.

Instituto Argentino de Normalización y Certificación. (2013). IRAM 1700: Métodos para la determinación del cambio de largo en prismas de hormigón, debido a la reacción álcali-agregado. Buenos Aires.

Instituto Argentino de Normalización y Certificación. (2016). IRAM 1531: Agregado grueso para hormigón de cemento Pórtland. Buenos Aires.

Instituto Uruguayo de Normas Técnicas. (2005). UNIT 1050:2005. Proyecto y ejecución de estructuras de hormigón en masa o armado. Montevideo, Uruguay.

Instituto Uruguayo de Normas Técnicas. (2017). UNIT 20: Cementos pórtland para uso general - Definiciones y requisitos. Montevideo, Uruguay.

Johnston, D., y Fournier, B. (2000). A kinetic-based method for interpreting accelerated mortar bar test (ASTM C1260) data. 11th ICAAR:355-364.

Madsen, L., Falcone, D., Locati, F., Marfil, S., y Rocco, C. (2018). Estudio de barras de mortero y prismas de hormigón elaborados con basaltos de la provincia de corrientes. VIII Congreso Internacional - 22a Reunión técnica de la AATH, págs. 211-218.

Mangialardi, T. (2002). Reconsideration of ASTM C1260 test results in the light of a recent kinetic model. Advances in Cement Research. 14(2):51-60.

Marfil, P., Falcone, D., Locati, F., y Marfil, S. (2018). Evaluación de la potencialidad reactiva de agregados pétreos de las Sierras Septentrionales de la provincia de Buenos Aires. VIII Congreso Internacional - 22a Reunión técnica de la AATH:211-218.

Méndez, E. (2019). Estrategia integral de prevención de la reacción árido-álcali. (Consejo Superior de Investigaciones Científicas, Ed.) Gobierno de España. https://editorial.csic.es/publicaciones/libros/13219/978-84-00-10516-7/estrategia-integral-de-prevencion-de-la-reaccion-a.html

Nixon, P., y Sims, I. (2016). RILEM Recommendations for the Prevention of Damage by Alkali-Aggregate Reactions in New Concrete Structures (Vol. 17). http://doi.org/10.1007/978-94-017-7252-5

Sims, I., y Poole, A. (2017). Alkali-Aggregate Reaction in Concrete: A World review.

Torres, A. (2014). Estudio Experimental sobre la reacción álcali-sílice en el hormigón producida por áridos de reacción lenta. Tesis doctoral, Universidad Politécnica de Madrid.

Veroslavsky Barbe, G., Ubilla Gutierrez, M., y Martinez Chiappara, S. (2004a). Cuencas sedimentarias de Uruguay: geología, paleontología y recursos naturales: Mesozoico. Montevideo, Uruguay.

Veroslavsky Barbe, G., Ubilla Gutierrez, M., y Martinez Chiappara, S. (2004b). Cuencas sedimentarias de Uruguay: geología, paleontología y recursos naturales: Cenozoico. Montevideo, Uruguay.

Vila, P., Bonjour, H., y Pereyra, M. (2020). Análisis cinético para la interpretación de los resultados de expansión por reacción álcali-sílice en barras de mortero y de hormigón. IX Congreso Internacional y 23ª Reunión Técnica, págs. 221-228.