| Casos de Estudio | https://doi.org/10.21041/ra.v12i2.585 |

Non-destructive evaluation of the wooden beams from the Narciso López building in the Historic Center of Havana for reuse in its restoration

Evaluación no destructiva de las vigas de madera del edificio Narciso López del Centro Histórico de La Habana para reúso en su restauración Avaliação não destrutiva das vigas de madeira do edifício Narciso López no Centro Histórico de Havana para reutilização em sua restauração

Alberto Hernández

Oroza1

*

![]() ,

Edrey Berreo

Alayo1

,

Edrey Berreo

Alayo1

![]() ,

Raúl Expósito

Mendez1

,

Raúl Expósito

Mendez1

![]()

1 Departamento de Diagnóstico y Levantamiento. Empresa Filial RESTAURA, Oficina del Historiador de La Habana, La Habana Vieja, Cuba.

*Contact author: ahernandez@proyectos.ohc.cu

Reception:

February

01,

2022.

Acceptance:

April

08,

2022.

Publication: May 01, 2022.

| Cite as: Hernández Oroza,A., Berreo Alayo, E., Expósito Mendez, R. (2022),“Non-destructive evaluation of the wooden beams of the Narciso López building in the Historic Center of Havana for reuse in its restoration”, Revista ALCONPAT, 12 (2), pp. 263 – 278, DOI: https://doi.org/10.21041/ra.v12i2.585 |

Abstract

The objective of the study was to evaluate, through visual classification and non-destructive tests, the state of conservation of 32 wooden beams for reuse as a restoration project for a historic building. For this, measurements of the moisture content, penetrometer, estimation of the modulus of elasticity and breaking stress by ultrasonic pulse velocity were made. The results showed that 66% of the beams were affected by rot, defibration and cracking. The tests carried out on the deteriorated beams made it possible to determine that, for a reliability of 95%, of the remaining 21 beams it was possible to reuse 17 of them with an average density of 0.4 g/cm3.

Keywords:

restoration,

wooden beams,

decay,

penetrometer,

ultrasound

1. Introduction

The use of wood as a construction material has its origins in the first human settlements, with the formation of primitive shelters. The benefits of its properties in terms of handling, durability, hardness, resistance and color have led to its use throughout the history of mankind, both for artistic and constructive creation. In buildings where the use of this material has a structural performance, which influences the safety of the building and its tenants, it is necessary to carry out periodic evaluations of the integrity of the wood through inspections and tests (Szostak et al., 2020; Zielińska and Rucka, 2021). Factors such as the low global availability of structural timber, the decrease in the diameter of the trunks of wood species that makes them less industrially usable, together with the need to preserve the historical memory of buildings, have led to the development of regulations, methodologies and assessment techniques for the evaluation of the quality and state of conservation of this material (Documento Básico SE-M, 2019; Manavella et al., 2019; Salazar et al., 2018; UNE 56544, 2011).

To make the intervention on timber structures as less invasive as possible, the application of ultrasonic pulse velocity tests (UPV), resistography, screw extraction or penetrometer allow reliable results to be obtained from in-situ measurements, and the evaluation of the state of conservation of wooden structural elements. Their application makes it possible to estimate parameters such as density, breaking stress, and modulus of elasticity for reuse or replacement in accordance with project requirements. Although the use of these techniques offers advantages in terms of classification safety based on their results, the visual evaluation of timber, as an acceptance criterion, remains currently the most widely used method, fundamentally due to its low cost compared to the use of equipment, and the ease that wood offers to show its characteristics and damages on its surface.

The buildings of the Historic Center of Havana constructed before the 20th century have in common the use of wood as a structural element to support floors and roofing, where beam and plank systems are combined, with beam and slab by plank. These woods, at the time they were sawn for exploitation as a structural element, were not classified by their characteristics due to the lack of regulations in this regard, so criteria such as the width of the growth rings, cracks, resin bags, gems, deformations and biological alterations were not taken into account in a standardized way. In this sense, current valid standards DIN EN 338:2016-07, 2016; (ISO 9709:2018, 2018; UNE 56544, 2011), establish rejection criteria that would lead to the total or partial substitution of timber elements that, after having been used for more than a century, have demonstrated their durability and bearing capacity, since this standards are designed for new wood.

However, when it comes to reusing structural timber elements for rehabilitation and heritage conservation, the combined use of visual and analytical criteria is important, since the latter can provide better success criteria compared to visual classification, as was proven by (Rello et al., 2007) where they obtained that through UPV it is possible to reach up to 72% with respect to the 53% of success in wood quality. Over the years of exploitation, construction materials suffer different forms of deterioration that, in the case of wood, begin fundamentally due to the presence of humidity since it is a hygroscopic and porous material. In this sense, several researchers (Bratasz et al., 2010; Sotomayor Castellanos, 2015) have shown the influence of water content on the conservation of wood and its properties. According to (Arriaga et al., 2006), the modulus of elasticity, might vary by 2% for humidity ranges between 5% and 30%.

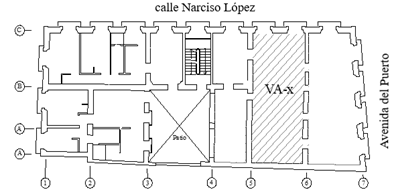

Based on the aforementioned considerations and the need to evaluate the possible reuse of wooden beams in historic buildings, this work aims to present the results of the evaluation of the state of conservation of the wooden beams of the first level support between the axes 5-6:A-C of the Narciso López building (Figures 1 and 2), located in the Historic Center of Havana. It was built in 1858 and has 4 levels, of which the ground floor and mezzanine are made of stone walls, while the upper floors are made of masonry. The floors are supported by pine wood beams (pinus sp.). The restoration processes started in 2019 required a pathological diagnosis, for the first time since the construction of the property, to determine its possible use and thus preserve, as far as possible, the original elements of the building.

|

||||

| Figure 1. Narciso López Building. Source: Arch. Fernando Salinas Documentation Center, Restaura, OHCH | ||||

|

||||

| Figure 2. Plan view of the first level of the building. Signage of the study area. Own elaboration | ||||

2. Experimental procedure

The study began with the removal of the floor and the dismantling of all the beams. This enables detailed inspection on all sides (Figures 3 y 4), fundamentally in the area of the heads, which, being embedded in the walls, show greater deterioration due to rot by increase of moisture inside the joints (Figures 5 y 6). This first stage makes it possible to record the position, length, direction and sense of each fissure, crack, rot and/or defibration present in the beams, for which the distance of the lesion with respect to the head was taken as a reference (Figure 7). Additionally, the test areas that have the ideal conditions for carrying out the measurements were identified. In areas where there are cracks or deterioration due to different forms of rot (brown, soft, etc.) it is not possible to carry out measurements because a correct transmission or confinement of the signal is not achieved from the emitter to the receiver, or the results obtained are altered by the presence of microbial films that affect the physical-chemical composition of the wood, degrading its structure and density. On the other hand, impact or penetration techniques have the drawback that they should not be applied on irregular surfaces that influence the moment of impact of the drill bit, either due to its deformation, alteration in the angle of entry or lack of wood to offer a density value representative of the real properties of the structural element. For the preparation of the test areas, two sections were selected for each beam, free of surface lesions.

Subsequently, each beam was identified using the code (VA-x), where x represents a consecutive number, starting from 1. The local has a total of 32 wooden beams, which support each other axes 5-6. To determine the dimensions, a tape measure was used, and the measurements of width, depth and length were recorded (Table 1). The heads of the beams were identified with the letters A and B (Figure 8).

|

||||

| Figure 3. Stage of detailed inspection in beam mounted on wood supports | ||||

|

||||

| Figure 4. Inspection and visual classification of disassembled beams | ||||

|

||||

| Figure 5. State of the beam heads | ||||

|

||||

| Figure 6. Disassembled beams with different pathological manifestations | ||||

|

||||

| Figure 7. Measure of the affected beam section with Steel tape | ||||

|

||||

| Figure 8. Identification of wooden beams | ||||

2.1 Non-destructive test applied

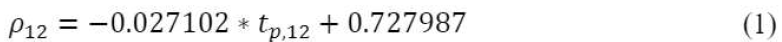

The tests applied consisted of estimating the density (ρ), breaking stress (fk) and dynamic modulus of elasticity (MOE), by combining the penetrometer and UPV techniques. For both it is necessary to make adjustments with respect to the moisture content, for which the value of 12% is taken as a reference. In the case of the penetrometer, to determine the density at 12% humidity, the adjustment equation used was (Kuklík, 2007):

Where:

ρ12 = wood density at 12% humidity; g/cm3

tp,12 = depth of penetration in the wood with 12% humidity; mm

tp = depth of penetration in the tested wood; mm

w= wood moisture at the time of measurement; %

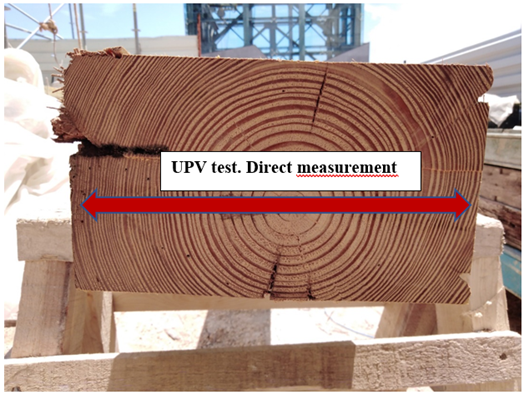

For the measurement of UPV, the equipment used was Proceq Pundit Lab+, with 54 KHz conical transducers (Figure 9). They were placed perpendicular to the fibers (Figure 10) and the distance between them was programed in the equipment for each beam. The adjustment was made at 12% humidity using the following equation (Liñán et al., 2011):

Where:

UPV12= ultrasonic pulse rate referred to 12% humidity; m/s

w= wood moisture at the time of measurement; %

UPV= measured ultrasonic pulse velocity; m/s

|

||||

| Figure 9. Application of UPV tests on wooden beams | ||||

|

||||

| Figure 10. UPV application diagram perpendicular to the fiber | ||||

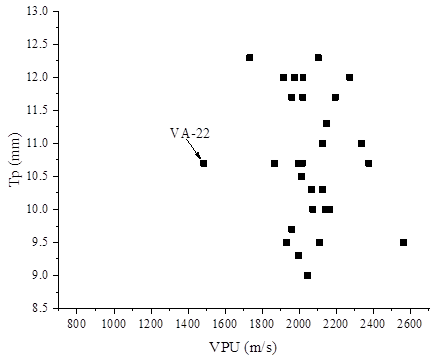

Based on the same criteria, the basic breaking stress (fk) and the limit for determining the state of conservation of the wooden beams were calculated:

Where:

fk= breaking strain; MPa

UPV12= ultrasonic pulse rate referred to 12% humidity; m/s

From the UPV measurements and the density estimation values obtained, the dynamic modules were calculated by applying the equation used by (Alquicira and Castellanos, 2021; Ettelaei et al., 2018):

Where:

MOE= dynamic modulus of elasticity; N/m2

ρ= density; Kg/m3

VPU122= ultrasonic pulse rate referred to 12% humidity; m/s

To measure the humidity on the timbers, the Delmhorst's TotalCheck thermo-hygrometer was used (Figure 11).

|

||||

| Figure 11. Surface moisture measurement with Delmhorst's TotalCheck thermo-hygrometer equipment | ||||

3. Results and discussion

3.1 Visual Assessment

Of the 32 beams inspected, eleven of them did not show any type of injury (Table 1). In accordance with the visual classification requirements of the standard (UNE 56544, 2011), 4 beams categorized as ME-1 and 7 as ME-2 (Table 2). The rest of the beams are classified as Rejected considering the recurring damage from cracks and longitudinal fissures, rotting and splintering, mainly in the area of the heads up to a distance of approximately 40 cm. However, as it is a rehabilitation project that intends to use the original beams, with the exception of VA-18, all of them need to be re-evaluated through the proposed tests.

| Table 1. Results of the inspection to the wooden beams. | ||||||||||||||

| ID | Wide (cm) | Timber cant (cm) | Length (cm) | Damages | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| VA-1 | 15 | 19.5 | 312 | Splintered by UND at 70 cm from head A. | ||||||||||

| VA-2 | 16 | 20 | 320 | Discontinuous longitudinal cracks in the middle of the depth of the LAS, from head B to a length of 250 cm. | ||||||||||

| VA-3 | 18 | 20 | 309 | Longitudinal discontinuous cracks in the middle of the depth. | ||||||||||

| VA-4 | 17.5 | 20 | 295 | Shredded in TOE throughout the length of the beam. | ||||||||||

| VA-5 | 17.5 | 20 | 310 | Discontinuous longitudinal cracks and fissures by LAS, in the middle of the depth. Shredded by TOS from head B to a length of 70 cm. | ||||||||||

| VA-6 | 14 | 20 | 304 | Crack in the LAS, from head B to a length of 20 cm in the middle of the superelevation. | ||||||||||

| VA-7 | 12.5 | 20 | 304 | Longitudinal crack in the middle of the depth of both lateral faces, from head A to a length of 90 cm. | ||||||||||

| VA-8 | 12.5 | 20 | 310 | Longitudinal cracks from head B to a length of 60 cm in the upper half of the LAS. LAS rot from head A, up to a length of 70 cm. | ||||||||||

| VA-9 | 14.5 | 20 | 309 | No damages were observed. | ||||||||||

| VA-10 | 15.5 | 20 | 310 | Longitudinal fissure in the upper half of the LAS, along the entire length. Superficial shredding by LAS, 90 cm from head B. | ||||||||||

| VA-11 | 17.5 | 21 | 310 | No damages were observed. | ||||||||||

| VA-12 | 17 | 20 | 310 | |||||||||||

| VA-13 | 11.5 | 21.5 | 476 | Shredded by the TOS affecting 5 cm of the width of the LAS and 2-3 cm of the height. | ||||||||||

| VA-14 | 11.5 | 21.5 | 475 | No damages were observed. | ||||||||||

| VA-15 | 11.5 | 21.5 | 472 | Longitudinal fissure in the middle of the depth of the LAS throughout the length. | ||||||||||

| VA-16 | 12 | 22 | 480 | No damages were observed. | ||||||||||

| VA-17 | 13 | 21.5 | 480 | Shredded by TOS at 30 cm from head B, up to a length of 60 cm. | ||||||||||

| VA-19 | 13 | 21 | 480 | No damages were observed. | ||||||||||

| VA-18 | Widespread decay | |||||||||||||

| VA-20 | 12 | 20 | 480 | No damages were observed. | ||||||||||

| VA-21 | 11.5 | 20 | 480 | |||||||||||

| VA-22 | 11.5 | 21 | 480 | Discontinuous longitudinal cracks and fissures by LAS throughout the span of the beam in the lower half of the depth. Shredded by TOS from 160 cm from head A, up to a length of 200 cm. | ||||||||||

| VA-23 | 15 | 20 | 299 | Superficial defibration in the upper third of the LAS, from head B to a length of 40 cm. | ||||||||||

| VA-24 | 14 | 19.5 | 297 | No damages were observed. | ||||||||||

| VA-25 | 15.5 | 20 | 306 | |||||||||||

| VA-26 | 18 | 20 | 305 | Shredded throughout the upper edge of the LAS. | ||||||||||

| VA-27 | 17 | 20 | 305 | Longitudinal cracks by TOS throughout the light. | ||||||||||

| VA-28 | 15 | 20 | 310 | Softening and defibering by TOS, throughout the length. Discontinuous longitudinal fissures by the LAS. | ||||||||||

| VA-29 | 14.5 | 20 | 310 | Shredded in head A and B by the TOS up to a length of 40 cm respectively. | ||||||||||

| VA-30 | 14.5 | 20 | 310 | Shredded by TOS affecting 3 cm of the depth along the entire length. | ||||||||||

| VA-31 | 16.5 | 20 | 362 | Chipped by UND at 60 cm from head B. Superficial defibration in TOE of the LAS. | ||||||||||

| VA-32 | 11 | 21 | 361 | No damages were observed. | ||||||||||

| Abbreviations used: | ||||||||||||||

| UND: underside | ||||||||||||||

| LAS: lateral side | ||||||||||||||

| TOS: top side | ||||||||||||||

| TOE: top edge | ||||||||||||||

The visual inspection allowed to determine the extension of the damage on the surface, but not its depth in the mass of the wood, except in cases where the rot is very advanced. Injuries due to rot or deep cracks towards the interior of the beams can lead to the loss of the bearing capacity of the element and cause its fracture.

In accordance with (Nuere, 2007), in cases in which the deterioration can lead to the invalidation of the element to fulfill the structural function assigned to it in the whole, the decision must be made whether to replace or reinforce the beams. The application of these criteria to each beam will depend on the combined analysis of the visible lesions, and the results obtained by non-destructive techniques (Table 3). The removal of a wooden element will necessarily require its replacement by another of similar dimensions that meets the requirements of visual classification and resistance class, so as not to affect the load requirements for the project.

3.2 Application of non-destructives assays

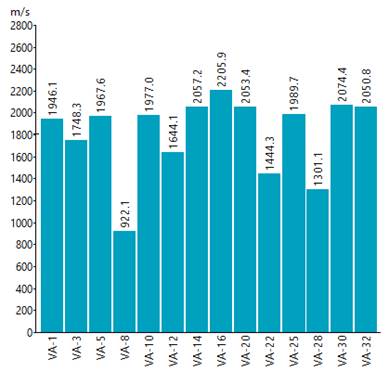

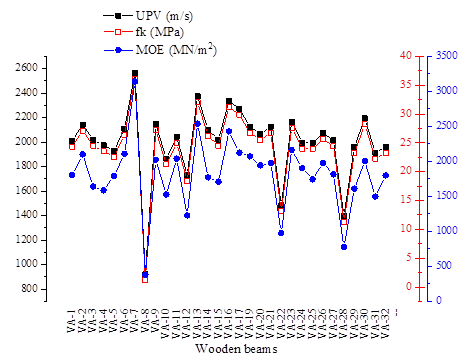

To carry out the penetrometer and UPV tests, two points were prepared on each beam. In each one, 5 readings were recorded, for a total of 10 results for each element. Figure 12 shows a summary of values in some of the beams tested.

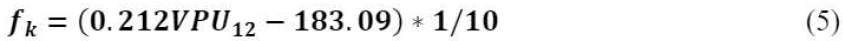

The criteria for estimating wood deterioration based on UPV results were established in accordance with (Liñán et al., 2011), in which it is established that:

UPV > 1400 m/s: sound wood (SW)

UPV < 1400 m/s: damaged wood (DW)

In the UPV results obtained, only two beams (VA-8 and VA-28) show values below the established limit of 1400 m/s, being classified as "deteriorated wood". This may be due to fungal infestation from rotting, softening and spalling in the wood having spread into the beams, which is reflected in the wave transmission velocity output between the transducers. With the years of exploitation of the building it is not possible to determine the causes for which these beams suffered a deterioration considerably higher than the rest. It is possible that its location coincided with that of humid areas such as bathrooms or kitchens, although the registered humidity contents do not show extreme values that support this hypothesis. The statistical analysis of the data (Table 4), in which beams VA-8 and VA-28 were excluded, show a dispersion for UPV of less than 10%, with a reliability of 95%, so that for the rest of the values the population of data obtained is accepted.

The minimum density of the beams was 0.4 g/cm3. This corresponds to a resistance class classification higher than C35, according to (Documento Básico SE-M, 2019). The UPV results of less than 1400 m/s obtained for VA-8 and VA-28 infer that the deterioration due to rot and cracks extends towards the interior of the element. However, their penetration depth results were not significant compared to the other beams.

This shows that the estimation of the state of conservation of wood based on the density calculated by penetrometer, can lead to false positives if it is not combined with other measurement techniques. The hardness of the wood at the point of impact of the needle can result in a high value that does not reflect the deterioration inside the material. Figure 13 shows the general analysis of results that correlate the moisture content/penetration/calculated density. In the cases of VA-9 and VA-16, it is identified how they reach a penetration value ≥ 11.0 mm for humidity close to 20%, in which a softening of the wood would be expected that result in greater penetration, as happens with the VA-28. The moisture content comparison between these beams is very similar but with opposite results. In the case of VA-9 and VA-16 they do not present any lesions and they maintained a UPV higher than 2000 m/s, while in VA-28 the progression of the damages towards the interior of the beam was confirmed with UPV results less than 1400m/s.

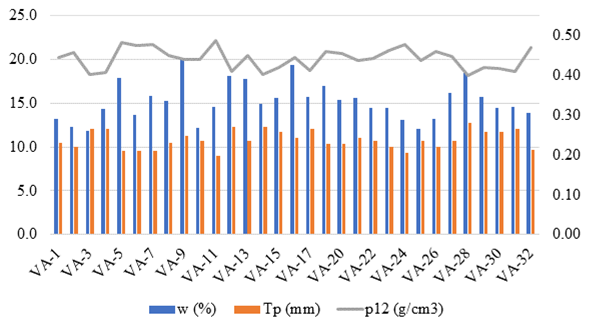

Of the total UPV measurements made, 82% fluctuated in a penetration depth between 9.0 mm and 12.0 mm. In the graphical analysis (Figure 14) it can be seen how the majority set of results occupies the range between 1800 m/s and 2400 m/s for the aforementioned interval. The graph allowed to identify beam VA-22 as a variable distant from the population mean with a result of UPV= 1485.10 m/s. If the calculated standard deviation and the damages present in the beam are taken into account, it would be reasonable for structural safety reasons to replace it with a new one. The values obtained from the proposed equations for estimating the fk and the MOE show a high correlation between them (Figure 15), characterizing the beams in structural class ME-2 (UNE 56544, 2011), on which they must apply all the restoration and consolidation actions necessary for its reuse.

4. Conclusions

Of the 32 beams diagnosed to evaluate their possible reuse as structural timer in the rehabilitation of the property, the following conclusions are reached:

The most recurrent injuries found during the visual inspection were the deterioration of the heads due to excess moisture in the joints, by the development of rotting fungi, as well as fissures and discontinuous cracks on the faces and edges. Among the most common restoration and reinforcement techniques for these types of deterioration are the use of metal caps and brackets to guarantee the fastening of the beams at the support points. Pickling or brushing of the faces and edges until reaching a surface with the fewest possible number of injuries. The fissures, on the other hand, can be sealed using resins, or from the preparation of a paste of carpenter's glue mixed with sawdust. Fumigation and treatment with biocide products, and finally the structural recalculation for the new dimensions of the beams.

The combined study of visual evaluation and non-destructive tests made it possible to identify that beams VA-8, VA-18, VA-22 and VA-28 must be replaced due to advanced lesions and poor density to be reused as a structural element.

The current regulations for visual classification of sawn wood for structural use is very conservative with regard to deterioration, which can result in the total replacement of old wooden elements. In rehabilitation and conservation projects of patrimonial assets, the evaluation of the state of conservation is more effective through the application of measurement tests on the pieces of wood.

According to the results obtained in this study, the UPV technique showed more accurate results with respect to the density condition of the wood compared to the penetrometer technique, in which, through the equations used, no affectations were reflected in the densities for moisture content variations between 11.8% and 19.9%.

5. Aknowledgment

This study was financed by the Investment Group Avenida del Puerto, belonging to the Directorate of Investments of the OHCH under contract S-No. 4DG /2021 to Contract 6DG/2020. The authors wish to thank the support of the technicians Lázaro Y. Martínez García and Raúl de Jesús Expósito Mendez, as well as acknowledge the work and collaboration of the workers and carpenters on the site.

References

Alquicira, I. M., Castellanos, J. R. S. (2021), Densidad, velocidad del ultrasonido y módulo dinámico de madera sólida y laminada de Pinus pseudostrobus. Madera y Bosques, 27(3): e2732235-e2732235. https://doi.org/10.21829/myb.2021.2732235

Arriaga, F., Íniguez, G., Esteban, M., Fernández-Golfín, J. I. (2006), Structural Tali timber (Erythrophleum ivorense A. Chev., Erythrophleum suaveolens Brenan.): Assessment of strength and stiffness properties using visual and ultrasonic methods. Holz als Roh-und Werkstoff, 64(5): 357-362. https://doi.org/10.1007/s00107-006-0100-5

Bratasz, L., Rachwal, B., Kozlowsja, A., Kozlowski, R. (2010). Sorption of Moisture and Dimensional Change of Wood Species Used in Historic Objects, Wood science for conservation of cultural heritage-Braga 2008 : proceedings of the international conference held by Cost action IE0601 in Braga (Portugal) 5-7 November 2008. - ( Proceedings e report ; 67). Firenze University Press, Firenze.

DIN EN 338:2016-07. (2016). Structural timber - Strength classes. Germany. https://dx.doi.org/10.31030/2463437.

Documento Básico SE-M. (2019). Seguridad Estructural. Madera.

Ettelaei, A., Layeghi, M., Hosseinabadi, H. Z., Ebrahimi, G., (2018), Prediction of Modulus of Elasticity of Poplar Wood Using Ultrasonic Technique by Applying Empirical Correction Factors. Measurement. https://doi.org/10.1016/j.measurement.2018.11.076

ISO 9709:2018. (2018). ISO 9709:2018(en) Structural timber - Visual strength grading - Basic principles.

Kuklík, P. (2007). Determinación de las propiedades estructurales de la madera, Praha.

Liñán, C. R., Conde, J. M., Hita, P. R. D., Gálvez, F. P. (2011), Inspección mediante técnicas no destructivas de un edificio histórico: oratorio San Felipe Neri (Cádiz). Informes de la Construcción, 63(521): 13-22. http://dx.doi.org/10.3989/ic.10.032

Manavella, R. D., Guillaumet, A. A., Filippetti, M. C., Meyer, L. C. (2019), "Determinación del módulo de elasticidad por ultrasonido y vibraciones en vigas de pino ponderosa". 4to Congreso Latinoamericano de Estructuras de Madera. Montevideo, Uruguay.

Nuere, E., (2007), Madera, en restauración y rehabilitación. Informes de la Construcción, 59(506): 123-130.

Rello, L. A., Barra, R. D., Sanz, M. C., Fernández, A. L., Sánchez, M. T .L., Basterra, A. (2007). Clasificación de madera estructural de P. pinaster Ait. Mediante ultrasonidos, Congreso Iberoamericano de productos forestales - Iberomadera, Buenos Aires, Argentina.

Salazar, D. V., Delgado, J. C., Yoza, L. Y., Mallque, M. A. (2018), Propuesta metodológica para la evaluación de estructuras de madera en monumentos históricos - Caso Hotel El Comercio. Revista Forestal del Perú, 33(2): 117-132. http://dx.doi.org/10.21704/rfp.v33i2.1225

Sotomayor Castellanos, J. R. (2015), Densidad, velocidad del ultrasonido y módulo de elasticidad de la madera de Pinus douglasiana, en relación a su contenido de humedad. Revista de Ciencia y Tecnología(23): 25-30.

Szostak, B., Trochonowicz, M., Kowalczyk, M. (2020), Determination of the strength parameters of pinewood based on the non-destructive sclerometric test with a wood hammer. Civil and Environmental Engineering Reports, 30(1): 43-52. https://doi.org/10.2478/ceer-2020-0004

UNE 56544. (2011). Norma Española UNE 56544:2011 Clasificación visual de la madera aserrada para uso estructural. Madera de coníferas. Madrid. España.

Zielińska, M., Rucka, M. (2021), "Using the ultrasonic tomography method to study the condition of wooden beams from historical building". 12th International Conference on Structural Analysis of Historical Constructions (SAHC). International Institute for Conservation of Historic And Artistic Works.

Table 2. Visual classification of wooden beams.

Visual quality (UNE 56544, 2011)

Amount of wooden beams

ME-1

4

ME-2

7

Rejected

21

Figure 12.

Summary of UPV measurements at a test point for wood beams. Data extracted from software Proceq PunditLink

Table 3:. Average results of measurements and applied calculations.

ID

w (%)

Tp (mm)

Tp,12 (mm)

p12 (g/cm3)

UPV12 (m/s)

fk (MPa)

MOE (MN/m2)

Criteria

VA-1

13.3

10.5

10.4

0.45

2011.58

24.34

1804.33

SW

VA-2

12.3

10

10

0.46

2143.33

27.13

2101.57

SW

VA-3

11.8

12

12

0.4

2020.32

24.52

1642.4

SW

VA-4

14.3

12

11.8

0.41

1972.75

23.51

1587.83

SW

VA-5

17.9

9.5

9.1

0.48

1930.15

22.61

1792.52

SW

VA-6

13.7

9.5

9.4

0.47

2108.75

26.4

2105.94

SW

VA-7

15.8

9.5

9.2

0.48

2565

36.07

3140.7

SW

VA-8

15.2

10.5

10.3

0.45

921.2

1.22

381.7

DW

VA-9

19.9

11.3

10.7

0.44

2147.25

27.21

2022.57

SW

VA-10

12.2

10.7

10.7

0.44

1865.8

21.25

1526.17

SW

VA-11

14.6

9

8.8

0.49

2043

25

2038.96

SW

VA-12

18.1

12.3

11.8

0.41

1733.55

18.44

1228.72

SW

VA-13

17.8

10.7

10.3

0.45

2375.5

32.05

2538.05

SW

VA-14

14.9

12.3

12.1

0.4

2101.05

26.23

1771.94

SW

VA-15

15.6

11.7

11.4

0.42

2019.7

24.51

1708.71

SW

VA-16

19.3

11

10.4

0.45

2336.25

31.22

2429.38

SW

VA-17

15.7

12

11.7

0.41

2273.55

29.89

2125.43

SW

VA-18

Beam discarded due to advanced decay

VA-19

17

10.3

9.9

0.46

2126

26.76

2072.85

SW

VA-20

15.4

10.3

10.1

0.46

2066.1

25.49

1944.34

SW

VA-21

15.6

11

10.7

0.44

2126.2

26.77

1977.26

SW

VA-22

14.4

10.7

10.5

0.44

1485.1

13.18

976.75

SW

VA-23

14.4

10

9.8

0.46

2165.1

27.59

2163.45

SW

VA-24

13.1

9.3

9.2

0.48

1995.55

24

1903.02

SW

VA-25

12

10.7

10.7

0.44

1996.2

24.01

1745.33

SW

VA-26

13.2

10

9.9

0.46

2073.9

25.66

1975.23

SW

VA-27

16.2

10.7

10.4

0.45

2015.7

24.42

1814.24

SW

VA-28

18.4

12.7

12.1

0.4

1397.5

11.32

779.66

DW

VA-29

15.7

11.7

11.4

0.42

1960.35

23.25

1610.61

SW

VA-30

14.5

11.7

11.5

0.42

2193.75

28.2

2004.15

SW

VA-31

14.6

12

11.8

0.41

1914.3

22.27

1497.63

SW

VA-32

13.9

9.7

9.6

0.47

1960.15

23.25

1800.43

SW

Table 4:. Statistical calculations of the results obtained in the beams classified as SW.

Statistical parameters

w (%)

Tp,12 (mm)

p12 (g/cm3)

UPV, 12 (m/s)

fk (MPa)

MOE (MN/m2)

xAVG

15.1

10.8

0.4

2059.5

25.4

1898.3

sd

2.1

1.0

0.0

197.3

4.2

400.3

CV(%)

14.0

9.2

5.8

9.6

16.5

21.1

Min.

11.8

9.0

0.4

1485.1

13.2

976.8

Max.

19.9

12.3

0.5

2565.0

36.1

3140.7

Figure 13.

Relationship of results of moisture content, penetrometer and density calculated at 12% for all the wooden beams studied

Figure 14.

Relationship of results of UPV vs Tp for the beams evaluated as Sound Wood

Figure 15.

Correlation of results obtained from UPV, fk and MOE for wooden beams