| Basic Research | https://doi.org/10.21041/ra.v11i3.542 |

Durability of concrete with pozzolanic admixtures and recycled aggregates

Desempenho do concreto com adições pozolânicas e agregado reciclado

Comportamiento de hormigones con adiciones puzolánicas y árido reciclado

H.

Gurdián1, P. Garcés1

![]() , E. Zornoza1

, E. Zornoza1

![]() , E. García Alcocel1

, E. García Alcocel1

![]()

1 Dpto. de Ingeniería Civil, Universidad de Alicante, Alicante, España..

*Contact author: pedro.garces@ua.es

Reception: June 18, 2021.

Acceptance: August 04, 2021.

Publication: September 01, 2021.

| Cite as: Gurdián, H., Garcés, P., Zornoza, E., García Alcoce, E. (2021), "Durability of concrete with pozzolanic admixtures and recycled aggregates", Revista ALCONPAT, 11 (3), pp. 17 – 30, DOI: https://doi.org/10.21041/ra.v11i3.542 |

Abstract

Mechanical and durability properties of concrete with a reduced environmental impact have been evaluated. This approach consist of replacing 50% of Portland cement by fly ash (35%) and spent catalytic cracking catalyst (15%), and also substituting a 20% and 100% of natural coarse aggregates by recycled aggregates. The performance of the prepared concrete consisted of mechanical tests, porosity, air permeability and chloride penetration. The obtained results show that the mechanical performance is significantly reduced in concretes with recycled aggregates and pozzolanic binder, but durability-related properties are only affected by the use of recycled aggregates. Nevertheless, all the tested formulations are suitable for their use as structural concretes.

Keywords:

recycled aggregate,

spent catalytic cracking catalyst,

fly ash,

concrete,

mechanical properties,

durability.

Resumo

As propriedades mecânicas e de durabilidade de concreto com baixo impacto ambiental são avaliadas com substituições de cimento por subprodutos industriais (35% cinzas volantes e 15% catalisador de craqueamento catalítico) e de agregados graúdos por agregados reciclados (20% e 100%). Os concretos estudados foram submetidos a ensaios de caracterização mecânica, porosidade, permeabilidade ao ar e nível de penetração do íon cloreto. Os resultados obtidos mostram que as propriedades mecânicas são reduzidas com o aumento das proporções de agregado reciclado e de resíduos usados como substituição na matriz cimentícia, enquanto as propriedades de durabilidade são afetadas apenas pelo aumento na porcentagem de agregados reciclados. Todos os concretos estudados são adequados para uso como concreto estrutural.

Palavras-chave:

agregado reciclado,

resíduo de catalisador do craqueamento de petróleo,

cinzas volantes,

concreto,

propriedades mecânicas,

durabilidad.

Resumen

Se evalúan las propiedades mecánicas y de durabilidad de hormigones de bajo impacto ambiental con sustituciones de cemento por subproductos industriales (35% cenizas volantes y 15% catalizador de craqueo catalítico) y de áridos gruesos por áridos reciclados (20% y 100%). Los hormigones estudiados se han sometido a ensayos de caracterización mecánica, porosidad, permeabilidad al aire y nivel de penetración del ion cloruro. Los resultados obtenidos muestran que las propiedades mecánicas se ven reducidas con el incremento en las proporciones de árido reciclado y de los residuos utilizados como sustitución en la matriz cementante, mientras que las propiedades de durabilidad se ven únicamente afectadas por el aumento en el porcentaje de áridos reciclados. Todos los hormigones estudiados son aptos para ser utilizados como hormigón estructural.

Palabras clave:

árido reciclado,

residuo de catalizador del craqueo del petróleo,

ceniza volante,

hormigón,

propiedades mecánicas,

durabilidad.

1. Introduction

The growing demand of materials for use in construction has led the industry to direct its efforts towards recycling and reusing stone materials and other waste derived from the industry itself. In this sense, the main focus of this research has been the replacement of natural aggregate by recycled aggregate, and Portland cement by industrial by-products in different concretes. This has been to demonstrate their viability to be used in the manufacture of structural concrete. This would make it possible to minimize the impacts of quarries and waste dumps. To this end, numerous authors have investigated the influence of pozzolanic materials on the mechanical properties and durability of concrete, showing that these materials can offer important improvements in their properties (Hooton, 2015, Paris et at., 2016, Yin et al., 2018). One of the supplementary materials that has generated more research in its characterization as pozzolanic material is fly ash. In general, the use of fly ash is considered viable due to its high pozzolanic properties, with its notable advantages over the long-term mechanical properties and durability of concrete (Bijen, 1996, Herath et al., 2020). Another supplemental material that has generated great interest is petroleum cracking catalyst (FCC) residue. Different studies have shown that this residue can lead to improvements in compressive strength of 20-30% in the short term, and its significantly positive influence on the durability of concrete, which places it as an effective substitute for cement, at a level equivalent to other more commonly used pozzolans such as metakaolin or silica fume (García de Lomas et al., 2016, Garcés et al., 2011, Borrachero et al., 2021).

On the other hand, numerous research works have been carried out with the aim of characterizing the effect of the use of recycled concrete aggregates on the resistant characteristics and durability of concrete (Chaofeng et al., 2021, Hoai-Bao et al. 2020).

In recent years, various investigations have been developed where supplementary materials have been used with a partial or total replacement of aggregates with recycled aggregates (Corinaldesi and Moriconi, 2009, Sim and Park, 2011, Kou, 2011). Thus, Corinaldesi and Moriconi experimented with concretes made entirely with coarse and fine recycled aggregate and substitutions of Portland cement by fly ash and silica fume, and found that optimal properties can be developed in concretes if the substitution percentages are studied and planned correctly.

However, it is hardly possible to find studies that combine fly ash and FCC residue as substituent pozzolanic materials for Portland cement in the cementitious matrix of recycled concretes (Payá et al., 2016, Zornoza et al., 2008).

The objective of this research is to evaluate the mechanical and durability properties of concretes with low environmental impact that combine substitutions of 20% and 100% of natural aggregate by recycled aggregate, and 50% of Portland cement by pozzolanic materials (35% fly ash and 15% % catalytic cracking catalyst).

2. Materials and experimental procedure

2.1 Materials

Two types of cementitious arrays have been used for the preparation of the specimens: one composed entirely of Portland cement (CP); and an alternative one (MA) composed of 50% CP, 35% fly ash (CV) and 15% of catalytic cracking catalyst (FCC).

The cement used has been Portland type CEM I 52.5 R designated according to the European Standard UNE-EN 197-1: 2000. The CVs used to replace cement in concrete come from Holcim Spain and have been used as supplied, without applying any treatment before use. The FCC was supplied by BP Oil España (Castellón). The chemical composition of the cement and the pozzolans used, obtained by X-ray fluorescence, are shown in Table 1.

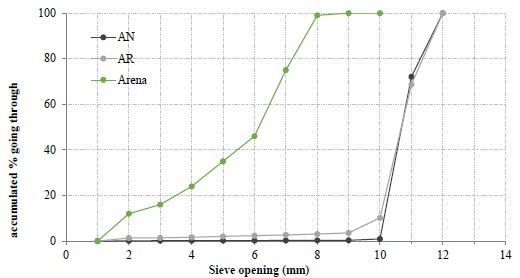

Two types of coarse aggregate have been used in the manufacture of concrete: limestone aggregate (AN), from crushing, and recycled aggregate (AR), from the demolition and crushing of mass concrete waste, both supplied by Holcim Morteros S. A. The supplier certifies the following percentages of impurities present in recycled aggregates: Clays <5%, light particles <1%, asphalt <1%, other impurities <1%; thus complying with the limits established in the Spanish Structural Concrete Instruction (EHE-08) on the properties of recycled aggregates for concrete. The sand used to make the test tubes is limestone crushing sand from the Fontcalent quarry (Alicante), supplied by the company Holcim Morteros S. A. The properties of the aggregates and sand used in the mixes and their granulometric curves are shown in Table 2 and Figure 1 respectively. As additive, a Sikament 200R superplasticizer was used, free of chlorides and which allows to obtain very fluid concretes, even in hot weather.

| Table 1. Chemical composition of cement and pozzolans. | ||||||||||||||

| % | CaO | SiO2 | Al2O3 | MgO | Fe2O3 | SO3 | Na2O | K2O | P.F.* | S.D.* | Density (g/cm3) | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CP | 62,87 | 20,21 | 4,94 | 1,05 | 2,85 | 3,37 | 0,10 | 0,95 | 2,34 | 1,32 | 3,1 | |||

| FCC | 0,11 | 46,04 | 47,47 | 0,17 | 0,58 | 0,02 | 0,30 | 0,02 | 1,50 | 3,79 | 2,7 | |||

| CV | 9,83 | 40,94 | 24,65 | 1,59 | 13,59 | 1,60 | 0,34 | 1,40 | 2,44 | 3,62 | 2,8 | |||

| * P.F.: Loss to fire. S.D.: Not determined. | ||||||||||||||

| Table 2. General properties of aggregates. | ||||||||||||||

| Property | Normative | AN | AR | Sand | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Granulometric modulus | UNE-EN 933-1 | 8,3 | 8,0 | 3,1 | ||||||||||

| Apparent density | UNE-EN 1097-6 | 2700 | 2490 | 2690 | ||||||||||

| Water absorption | UNE-EN 1097-6 | 0,6 | 4,5 | 0,6 | ||||||||||

| Los Angeles coefficient | UNE-EN 1097-2 | 21,1 | 30,3 | - | ||||||||||

|

||||

| Figure 1. Granulometry of the aggregates used. | ||||

2.2 Experimental procedure

Six different compositions were elaborated (Table 3) in order to evaluate the influence that recycled aggregates and complementary cementitious materials (CV and FCC) have on the durability properties of concrete:

In order to be able to compare the different concretes with each other, the substitutions of natural aggregate by recycled aggregate are carried out by volume. The effective water / cementitious material ratio of 0.50 remains constant. This is achieved by adding the aggregate absorption water to the total mixing water for 10 minutes, the time that the mixing process lasts. The settlement value, obtained by the Abrams cone method (UNE-EN 12350-2: 2009), remains constant in all cases with the use of additive, which allows starting from the same workability in all concretes.

A total of 60 cylindrical specimens of Ø150x300 mm were kneaded to carry out the compression failure and air permeability tests at 28 and 365 days, and 6 cylindrical specimens of Ø100x250 mm for the tests of resistance to the penetration of chlorides at 28 days. The specimens were made according to the procedure described in the ASTM C192/C192M-07 standard. The mixing water is added in two stages; 1/3 is added with the coarse aggregates and the rest after introducing the sand and cement, reserving a little to add the additive at the end. The mixing time is 10 minutes. Once kneaded, the specimens were cured in a humid chamber (95% HR, 23 ºC) until they were tested.

| Table 3. Dosages used in this work. | ||||||||||||||

| 0%AR-CP | 0%AR-MP | 20%AR-CP | 20%AR-MA | 100%AR-CP | 100%AR-MA | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CP (kg/m3) | 380 | 190 | 380 | 190 | 380 | 190 | ||||||||

| CV (kg/m3) | 0 | 133 | 0 | 133 | 0 | 133 | ||||||||

| FCC (kg/m3) | 0 | 57 | 0 | 57 | 0 | 57 | ||||||||

| atotal (kg/m3) | 195 | 195 | 200 | 200 | 216 | 216 | ||||||||

| aef (kg/m3) | 187 | 187 | 187 | 187 | 187 | 187 | ||||||||

| Arena (kg/m3) | 934 | 934 | 934 | 934 | 934 | 934 | ||||||||

| AN (kg/m3) | 981 | 981 | 785 | 785 | 0 | 0 | ||||||||

| AR (kg/m3) | 0 | 0 | 173 | 173 | 865 | 865 | ||||||||

| Aditivo* (%) | 1,6 | 1,8 | 1,6 | 1,8 | 1,6 | 1,6 | ||||||||

| Consistency (mm) | 100 | 100 | 90 | 90 | 95 | 100 | ||||||||

| * The amount of additive is taken as a percentage of the amount of cementitious material. atotal is the total amount of water used in mixing. aef: it is the difference between the total water present in the fresh concrete and the water absorbed by the aggregates. It takes part in the hydration reaction of the cement and the workability of the concrete. | ||||||||||||||

2.2.1 Compressive strength

Four Ø150x300mm cylindrical specimens were used for each dosage for compression failure tests at 28 and 365 days, following the procedure described by the UNE-EN 12390-3: 2009 standard.

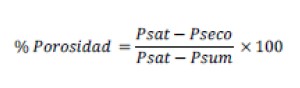

2.2.2 Porosity

The water-accessible porosity of hardened concrete is obtained from (1), following the ASTM C642-13 standard.

|

(1) | ||||

The saturated weight is obtained by vacuum saturating a piece of each of the test specimens under compression, following the ASTM C3652-05 standard since it is the most appropriate method according to the comparative study carried out by Safiuddin and Hearn (Safiuddin and Hearn, 2005) on the different techniques of saturation of concrete. A pump is connected to the desiccator and a vacuum is carried out for three hours. After that time, the distilled water tap is opened and the vacuum continues for another hour. The pump is stopped and the vacuum is maintained for 20 ± 2 hours. The samples are taken out and weighed on a hydrostatic balance and superficially dry. They are then dried at 110 ° C for 24 hours, allowed to cool, and the dry weight is obtained.

2.2.3 Air permeability

The air permeability tests are carried out at 28 and 365 days on central sections of cylindrical specimens of Ø150mm that were cut with a height of 50mm. As a conditioning method, the one proposed by Antón et al. (Antón et al., 2013) that allows reaching a specific interior humidity inside the specimen, thus guaranteeing that the six concretes studied are at the same degree of saturation (65% in this case) to be able to be compared with each other.

The procedure consists firstly in obtaining the absorption capacity of the concrete to be tested by means of the ASTM C642-13 standard. Knowing the absorption, it is possible to determine the mass of the specimen corresponding to a specific degree of saturation. The test tubes are then saturated with distilled water under vacuum, according to the ASTM C3652-05 standard. The next step is to protect the lateral surfaces of the test tubes with insulating tape to avoid the formation of humidity gradients in them and they are dried at 50ºC until the objective degree of saturation is achieved. Drying at 50 ° C minimizes microstructural modifications by exposure to elevated temperatures. When the specimens reach the target degree of saturation (GS), they are sealed with a polyethylene film that is impervious to water vapor, which guarantees their watertightness, and they are reintroduced into the oven at 50ºC for 7 days in the case of the concretes studied. . This is done to redistribute the moisture inside the concrete, according to the work developed by Parrott (Parrot, 1994).

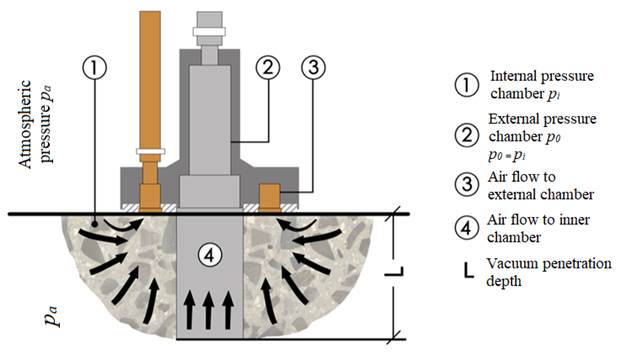

The air permeability coefficient (kT) in concretes with a GS of 65% is obtained with the Proceq Torrent Permeability Tester equipment. This equipment consists of a cell with a double vacuum chamber and a pressure regulator that ensures that the air flows at the correct angle from the surface to its internal chamber (see Figure 2). This allows the calculation of kT through a rapid and non-destructive test that can be carried out both in the laboratory and on site. Measurements are made on 3 specimens on both sides for each dosage studied.

|

||||

| Figure 2. Permeability test with the Torrent Permeability Tester equipment and the equipment's operating diagram. | ||||

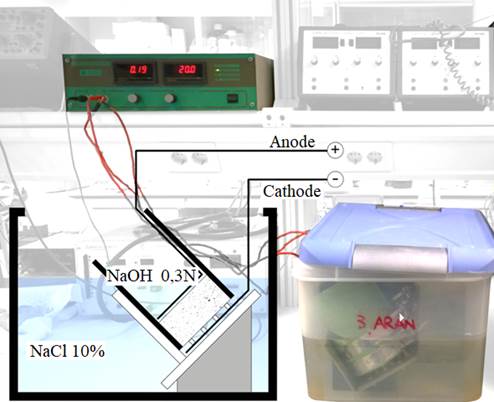

2.2.4 Resistance to chloride penetration

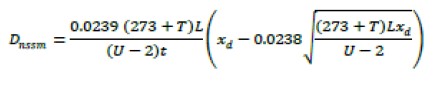

An accelerated method based on the migration of chlorides by electric field is used following the Nordic Standard NT Build 492 that allows a comparative approximate evaluation of the resistance to chloride penetration. The test is carried out on Ø100x50mm test tubes that have been saturated in a saturated Ca(OH)2 solution, following the procedure described in the standard. In this procedure, an external electrical potential is applied axially through the sample that forces the chloride ions to migrate towards the interior of the sample, as shown in Figure 3. After a certain test time, the graduated cylinder and a silver nitrate solution is sprayed onto one of the newly divided sections. Chloride penetration depth can be measured from the formation of the white silver nitrate precipitate and with this penetration depth the non-steady state chloride migration coefficient (Dnssm) is calculated, through the following simplified formula (2)

|

(2) | ||||

where U is the absolute value of the applied voltage, in volts; T is the mean value of the temperature in the anode solution in ºC, measured at the beginning and end of the test; L is the thickness of the specimen in mm; x 푑 is the mean value of the penetration front in mm; and t is the duration of the test in hours.

|

||||

| Figure 3. Chloride migration in concrete. Test scheme according to the NT Build 492 standard. | ||||

3. Results and discussion

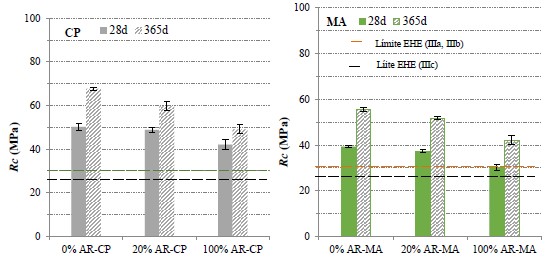

Regarding the mechanical characterization of the concretes, the mean value of four specimens has been used for the analysis of the compressive strength. Figure 4 shows the values obtained for compressive strength, where the expressed percentage, followed by AR, refers to the amount of recycled aggregate present in the mixture; CP, refers to the cementitious matrix composed of CEM I 52.5 R; and MA to the alternative cementitious matrix (35% fly ash, 15% catalytic cracking catalyst and 50% CP). In general, it is observed that all concretes exceed the limits established by the EHE-08 to be used as structural concrete (25 MPa) and as concrete in atmospheric areas exposed to a marine environment (30 MPa), although it is notable that the values compressive strength are lower in all concretes with respect to the pattern (0% AR-CP), both at 28 and 365 days. The results show that as the percentage of substitution of natural aggregate for recycled aggregate increases, there is a decrease in resistance, coinciding with the results obtained by other authors (Hansen, 1992, Poon, 2004, Etxebarria et al., 2007, Corinaldesi, 2010). This happens in both, concrete with CP and in those made with MA. The use of recycled aggregates affects this property due to its greater porosity and the weak behavior of the microstructure, due to the existence of different interface zones. In addition to the paste-aggregate junction that the recycled aggregate presents, another contact zone appears between the recycled aggregate paste and the new paste.

|

||||

| Figure 4. Compressive strength values at 28 and 365 days for the different concretes studied. | ||||

In the different percentages of substitution of AN by AR (0%, 20% and 100%) it is clear that the resistance of concretes with CP is higher than those made with MA (Safiuddin and Hearn, 2005), since the contribution of these pozzolanic materials to compressive strength is more relevant in the long term. It is also observed that at 365 days the compressive strength increases in all cases, this increase being more significant in those concretes with 0% and 20% substitution of NA by AR made with the alternative cementing matrix (0% AR-MA and 20% AR-MA), with a 25% increase compared to 28-day resistance in both cases.

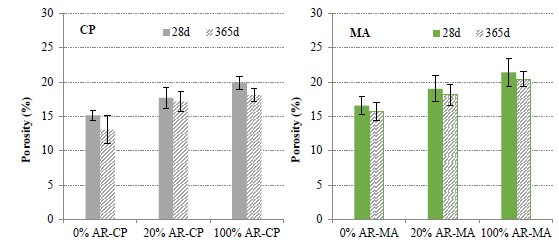

Regarding porosity (Figure 5), it increases as the substitution of AN by RA increases (Chaofeng et al., 2021, Kou et al., 2011). This increase is due in large part to the greater porosity of the recycled aggregate (Etxebarria et al., 2006). It is clearly observable in the results at 28 days that the most porous concretes are those with total replacement of natural aggregate by recycling (100% AR-CP and 100% AR-MA) and that the porosity remains practically constant in both cases, without distinction of the cementitious matrix.

|

||||

| Figure 5. Porosity values at 28 and 365 days in the concretes studied. | ||||

In the case of concretes with substitutions of 20% and 0% of NA by RA, this is lower than that of the previous ones and an apparent relationship between porosity and cementing matrix is observed, since, although it decreases, the highest values are observed for concretes with alternative matrix (20% AR-MA and 0% AR-MA). At 365 days, porosity decreases in concretes with only one type of aggregate, either natural or recycled (substitutions of 0% and 100%) and no significant increase is observed in those with a combination of aggregates (20% AR-CP and 20% AR-MA). This is due to a greater complete development of the hydration reactions, with the consequent decrease in capillary porosity. At this age, it is also observed that porosity increases as the amount of recycled aggregate in the mix increases and that, for the same percentage of substitution, the value is higher in the concretes made with the alternative matrix, even in those with 100% of substitution.

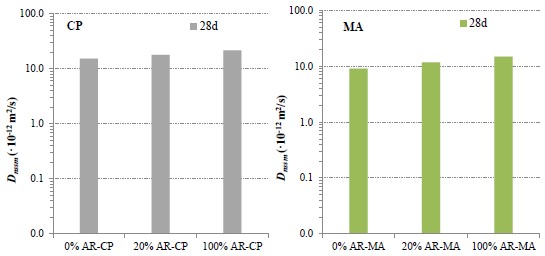

Figure 6 shows the chloride migration coefficient values obtained in concrete cured for 28 days and measured according to NT Build-492.

|

||||

| Figure 6. Chloride migration coefficient at 28 days. | ||||

The plot shows that there is an increase in the migration coefficient when the amount of AR in the mixtures increases, regardless of the type of cementitious matrix used, due to the higher porosity of the AR, coinciding with what was found by Kou and Poon (Kou and Poon, 2010) and Kou et al. (Kou et al., 2011). The migration coefficient is lower in all concrete with MA, so it can be stated that the presence of CV and FCC in the cementitious matrix leads to important improvements in the porous structure, both for concrete with AR and with AN. In cases where there are no substitutions of recycled aggregate (0%), the migration coefficient increases when the matrix is composed only of CP, which means that the alternative matrix combined with natural aggregate (0% AR-MA), behaves even better than the standard (0% AR-CP).

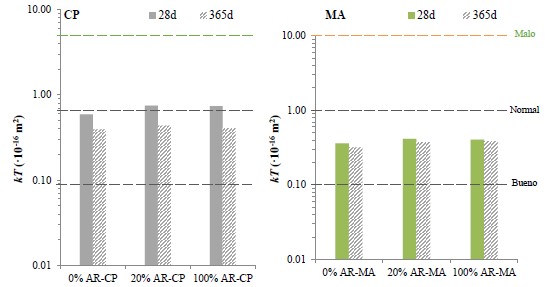

The air permeability coefficient of concrete (kT) was obtained using the Torrent method (Torrent, 1999), allowing the quality of the coating to be classified as good (0,01<kT<0,1), normal (0,1<kT<1) and bad (kT>1).

The results obtained are presented in Figure 7. These represent the mean value of three samples for each type of concrete.

In general terms, the results obtained indicate that air permeability tends to increase with the degree of substitution of the aggregates in both cementitious arrays. In addition, it can be observed that the alternative matrix presents a greater resistance to oxygen than the cement matrix, both at short and long term. This behavior is due to the fact that a part of the CVs that do not react act as fillers in the alternative matrix. However, all concretes present air permeability coefficients lower than 1, therefore, they fall within the “normal” classification, both at 28 and 365 days.

Regarding the results obtained at 28 days, in concrete with CP matrix, the substitution of 20% and 100% of the aggregate produces increments in permeability of 27% and 25% with respect to the standard; while in concrete with MA matrix the increments are 15% and 13% with respect to its pattern. At 365 days, the trend for all concretes is the same, that is, the permeability coefficient tends to increase with the amount of recycled aggregate in the mix.

Regarding the evolution of this property, it is observed that the permeability values of all the concretes decrease with the curing time, due to the complete development of the microstructure.

|

||||

| Figure 7. Air permeability coefficients at 28 and 365 days. | ||||

The results of this research indicate that all the changes applied to the concretes with respect to the pattern (substitutions of AN for AR and of CP for MA) reduce their mechanical behavior. This is due, in the case of aggregate substitutions, to the high porosity of the recycled aggregate and to the substitution percentages; while in the case of the cementitious matrix, it is attributed to the high degree of substitution of CP for CV and FCC, which can limit the development of the pozzolanic reaction. Regarding porosity, two trends are observed: porosity depends on the cementing matrix when the AR substitutions are low; and when these substitutions are high, the influence of the porosity of the aggregate over the total porosity of the concrete prevails.

In terms of durability, the results obtained from the air permeability and chloride migration tests show that concretes with an alternative matrix are the ones that present the greatest resistance to attack by external aggressive agents; behaving even better than standard concrete. Its effectiveness against the attack of external agents is associated with the porosity reductions produced by the pozzolanic additions used (CV and FCC). However, these results cannot be conclusive at an early age, so they need to be completed with long-term data that allow the complete development of the microstructure.

In addition to the porosity values studied, the presence of other factors that influence the permeability and resistance to the passage of chlorides of the concretes is detected, such as the influence of the size and connectivity of the pores, whose study will be carried out through tests of mercury intrusion porosimetry (PIM). In addition, the study of the influence of the matrix-aggregate interface on the migration of chlorides by means of the X-ray diffraction technique (XRD) will be studied in depth in order to determine the existence of Friedel's salt.

It can be stated that, although there are variations in the properties of the concretes studied that depend on the type of substitution (aggregate or matrix), they are all suitable to be used as structural concrete since they exceed the limits set by the EHE.

4. Conclusions

Once the influence of the partial replacement of cement by additions (CV and FCC) and of natural aggregates with recycled aggregates on the physical, mechanical and durability properties of concrete has been evaluated, the following conclusions can be established:

References

Antón, C., Climent, M. A., de Vera, G., Sánchez, I., Andrade, C. (2013), An improved procedure for obtaining and maintaining well characterized partial water saturation states on concrete samples to be used for mass transport tests. Materials and Structures, 46, 1389-1400. https://doi.org/10.1617/s11527-012-9981-4

Borrachero, M. V., Payá, J., Monzó, J., Soriano, L., Tashima, M. M. (2021), Inorganic binders from petrochemical industry waste: The case of fluid catalytic cracking catalyst residue. Waste and Byproducts in Cement-Based Materials (Innovative Sustainable Materials for a Circular Economy), Woodhead Publishing Series in Civil and Structural Engineering. Pages 283-334. https://doi.org/10.1016/B978-0-12-820549-5.00003-6

Chaofeng, L., Zhedong, C., Huixia, W., Jianzhuang, X., Yuming, Z., Zhiming, M. (2021), “Chloride transport and induced steel corrosion in recycled aggregateconcrete: A review”. Construction and Building Materials, vol 282, 122547. https://doi.org/10.1016/j.conbuildmat.2021.122547

Corinaldesi, V. (2010), “Mechanical and elastic behaviour of concretes made of recycled-concrete coarse aggregates”. Construction and Building Materials, 24 (9), pp. 1616-1620. https://doi.org/10.1016/j.conbuildmat.2010.02.031

Corinaldesi, V., Moriconi, G. (2009), “Influence of mineral additions on the performance of 100% recycled aggregate concrete”. Construction and Building Materials, 23 (8), pp. 2869-2876. https://doi.org/10.1016/j.conbuildmat.2009.02.004

Garcés, P., Glasser, F.P., Brew, D.R.M., Zornoza, E., Payá, J. (2011), “Pozzolanic activity of a spent fluid catalytic cracking catalyst residue”. Advances in Cement Research, vol. 23, pp. 1-7. https://doi.org/10.1680/adcr.9.00036

García de Lomas, M., Sánchez de Rojas, M.I., Frías, M., Mújika, R. (2006), “Comportamiento científico-técnico de los cementos portland elaborados con catalizadores FCC. Aplicación de la norma vigente”. Monografía Materiales, No. 412, editado por el CSIC, Madrid, pags. 46.

Bijen, J. “Benefits of slag and fly ash”. Construction and Building Materials, 1996, 10 (5), pp. 309-314. https://doi.org/10.1016/0950-0618(95)00014-3

Etxeberria Vázquez, M. E., Marí, A. 2006, “Microstructure analysis of hardened recycled aggregate concrete”. Magazine of Concrete Research, 58 (10), pp. 683-690. https://doi.org/10.1680/macr.2006.58.10.683

Etxeberria, M., Marí, A. R., Vázquez, E. (2007), “Recycled aggregate concrete as structural material”. Materials and Structures, vol. 40, pp. 529-541. https://doi.org/10.1617/s11527-006-9161-5

Hansen, T. C. (1986), Recycled aggregates and recycled aggregate concrete second state-of-the-art report developments 1945-1985. Materials and Structures 19, 201-246. https://doi.org/10.1007/BF02472036

Herath, C., Gunasekara, C., Law, D. W., Setunge, S. (2020), “Performance of high-volume fly ash concrete incorporating additives: A systematic literature review”. Construction and Building Materials, vol. 258, 365606. https://doi.org/10.1016/j.conbuildmat.2020.365606

Hoai-Bao, L., Quoc-Bao, B. (2020), “Recycled aggregate concretes - A state-of-the-art from the microstructure to the structural performance”. Construction and Building Materials, Vol. 257, 119522. https://doi.org/10.1016/j.conbuildmat.2020.119522

Hooton, R. D. (2015), “Current developments and future needs in standards for cementitious materials”. Cement and Concrete Research, vol. 78, pp. 165-177. https://doi.org/10.1016/j.cemconres.2015.05.022

Kou, S.; Poon, C. (2010), “Properties of concrete prepared with PVA-impregnated recycled concrete aggregates”. Cement and Concrete Composites, 32 (8), pp. 649-654. https://doi.org/10.1016/j.cemconcomp.2010.05.003

Kou, S., Poon, C., Agrela, F. (2011), “Comparisons of natural and recycled aggregate concretes prepared with the addition of different mineral admixtures”. Cement and Concrete Composites, 33 (8), pp. 788-795. https://doi.org/10.1016/j.cemconcomp.2011.05.009

Kou, S., Poon, C., Etxeberria, M. (2011), “Influence of recycled aggregates on long term mechanical properties and pore size distribution of concrete”. Cement and Concrete Composites, 33 (2), pp. 286-291. https://doi.org/10.1016/j.cemconcomp.2010.10.003

Paris, J. M., Roessler, J. G., Ferraro, C. C., DeFord, H. D., Townsend, T. G. (2016), “A review of waste products utilized as supplements to Portland cement in concrete”. Journal of Cleaner Production, vol. 121, pp.1-18. https://doi.org/10.1016/j.jclepro.2016.02.013

Poon, C. S., Shui, Z. H., Lam, L., Fok, H., Kou, S. C. (2004), “Influence of moisture states of natural and recycled aggregates on the slump and compressive strength of concrete”. Cement and Concrete Research, 34 (1), pp. 31-36. https://doi.org/10.1016/S0008-8846(03)00186-8

Safiuddin, M.; Hearn, N. (2005), “Comparison of ASTM saturation techniques for measuring the permeable porosity of concrete”. Cement and Concrete Research, 35 (5), pp. 1008-1013. https://doi.org/10.1016/j.cemconres.2004.09.017

Sim, J., Park, C. 2011, “Compressive strength and resistance to chloride ion penetration and carbonation of recycled aggregate concrete with varying amount of fly ash and fine recycled aggregate”. Waste Management, 31 (11), pp. 2352-2360. https://doi.org/10.1016/j.wasman.2011.06.014

Soriano, L., Payá, J., Monzó, J., Borrachero, M.V., Tashima, M.M. (2016), “High strength mortars using ordinary Portland cement-fly ash-fluid catalytic cracking catalyst residue ternary system (OPC/FA/FCC)”. Construction and Building Materials, Volume 106, pp. 228-235. http://dx.doi.org/10.1016/j.conbuildmat.2015.12.111

Torrent, R. J. (1999). Un método rápido y no-destructivo para medir la permeabilidad al aire del hormigón. Materiales de Construcción, 49 (254), 51-56. https://doi.org/10.3989/mc.1999.v49.i254.450

Yin, K., Ahamed, A., Lisak, G. (2018), “Environmental perspectives of recycling various combustion ashes in cement production - A review”. Waste Management, vol.78 pp. 401-416. https://doi.org/10.1016/j.wasman.2018.06.012

Zornoza, E., Payá, J., Garcés, P. (2008), “Carbonation rate and reinforcing steel corrosion rate of OPC/FC3R/FA mortars under accelerated conditions”. Advances in Cement Research, 20 (1), pp. 15-22. https://doi.org/10.1680/adcr.2007.00008