| Applied Research | https://doi.org/10.21041/ra.v11i1.509 |

Comparative analysis of the effectiveness and efficiency of three waterproofing systems

Análise comparativa da eficácia e eficiência de três sistemas impermeabilizantes

Análisis comparativo de la efectividad y eficiencia de tres sistemas de impermeabilización

R. S.

Kmick1

![]() , M. G. Gazolla1

, M. G. Gazolla1

![]() , R. M. da Silva1

, R. M. da Silva1

![]() , A. P. B. Capraro*

2

, A. P. B. Capraro*

2

![]() , K. A. W. Moreira1

, K. A. W. Moreira1

![]()

1 Engenharia Civil, Centro Universitário Araucária, Araucária, Brasil..

2 Departamento de Construção Civil, Universidade Federal do Paraná, Curitiba, Brasil.

* Contact author: anapcapraro@gmail.com

Reception: September 11, 2020.

Acceptance: October 30, 2020.

Publication: January 01, 2021.

| Cite as: Kmick, R. S., Gazolla, M. G., da Silva Junior, R. M., Capraro, A. P. B., Moreira, K. A. W. (2021), "Comparative analysis of the effectiveness and efficiency of three waterproofing systems", Revista ALCONPAT, 11 (1), pp. 34 – 47, DOI: https://doi.org/10.21041/ra.v11i1.501 |

Abstract

The objective of this study was to comparatively analyze waterproofing systems used in Brazil. The evaluated products were: asphalt emulsion, acrylic resin and thermoplastic resin. In order to evaluate the effectiveness of the systems the tests measured the tightness and the absorption by immersion and capillarity, the last one was also analyzed by thermographic images. For the systems efficiency analysis an accelerated aging pattern was adopted, which consisted of alternating the samples in wet and dry cycles. The results indicate a good performance for the studied systems, in comparison to the non-impermeable series, it presented lower absorbance (approximately 300%). The accelerated aging test indicated, after 140 days of age, a reduction in the performance of the waterproofed series.

Keywords:

waterproofing systems,

effectiveness,

efficiency,

accelerated aging,

yield reduction

Resumo

O objetivo desse estudo foi analisar comparativamente sistemas de impermeabilização empregados no mercado brasileiro. Os produtos avaliados foram: emulsão asfáltica, resina acrílica e resina termoplástica. Para avaliação da eficácia dos sistemas foram realizados os ensaios de estanqueidade, absorção por imersão e capilaridade, sendo esse último também analisado por imagens termográficas. Para a análise da eficiência dos sistemas foi adotado um padrão de envelhecimento acelerado, o qual consistiu na alternância das amostras em ciclos de molhagem e secagem. Os resultados indicam um bom desempenho para os sistemas estudados, que quando comparados a série não impermeabilizada apresentaram absorções inferiores (aproximadamente 300%). Já o ensaio de envelhecimento acelerado indicou, posteriormente aos 140 dias de idade, redução do desempenho das séries impermeabilizadas.

Palavras-chave:

sistemas de impermeabilização,

eficácia,

eficiência,

envelhecimento acelerado,

redução de desempenho.

Resumen

El objetivo de este estudio fue analizar comparativamente los sistemas de impermeabilización empleados en el mercado brasileño. Los productos evaluados fueron: emulsión de asfalto, resina acrílica y resina termoplástica. Para evaluar la efectividad de los sistemas, se realizaron pruebas de estanqueidad, absorción por inmersión y capilaridad, siendo este último también analizado por imágenes termográficas. Para el análisis de eficiencia de los sistemas, se adoptó un patrón de envejecimiento acelerado, que consistía en alternar las muestras en ciclos húmedos y secos. Los resultados indican un buen desempeño para los sistemas estudiados, que en comparación con las series no impermeables presentaron absorbancias más bajas (aproximadamente 300%). La prueba de envejecimiento acelerado indicó, después de 140 días de edad, una reducción en el rendimiento de la serie impermeabilizada.

Palabras clave:

sistemas de impermeabilización,

efectividad,

eficiencia,

envejecimiento acelerado,

reducción de rendimiento.

1. Introduction

Waterproofing systems are essential to ensure the durability of any construction, and neglecting them can result in infiltration, which provides pathological mechanisms such as leaching, concrete degradation, corrosion of reinforcement and deficiency in renderings (Aldea and Shah, 1999).

A material considered waterproof is one that prevents water from passing from one plane to the other. It is also understood as a substrate that does not absorb more than 2.5% moisture when compared to a reference sample (Basheer et al., 2001).

The lack of information about the techniques and the use of inappropriate materials, among other factors, for a long time were responsible for the failures in waterproofing (PICCHI, 1986). The cost of a good design and a good execution waterproofing can represent 1% to 3% of the value of a work. Furthermore, damage and maintenance of waterproofing systems cost between 5% to 10% of the value of the project (Bauer et al., 2010).

New standards, such as the case of NBR 15575 (ABNT, 2013), and updates of existing standards recommend meeting the needs and performance of buildings, requiring that all housing systems meet a minimum level of performance throughout of the useful life determined in the project.

Currently, the most used waterproofing system is the one that uses asphalt emulsion (Menezes, 2018), however, suppliers have invested a lot in new products development researches, expanding the options and bringing benefits such as durability of the buildings and costs reduction.

According to Andrello and Takagi (2017), applying a product with higher performance saves costs on the application and maintenance of the building. In addition, as claimed by Andrello and Takagi (2017), companies have products with the same purpose, however, the characteristics from each product change. If the consumer or the applicator do not pay attention to this, they can apply a product in the same way in different cases not reaching the expected performance.

Taking into consideration the facts above, the present study aimed to compare the effectiveness and efficiency of three waterproofing systems, provided and recommended by national suppliers for use in non-transitable roof slab. For the analysis of the effectiveness of the waterproofing systems, which implies the success of the system as a waterproof layer, the waterproofing test (NBR 15575-3, 2013), immersion absorption (NBR 9778, 2005) and capillary absorption were performed (NBR 9779, 2012) at an early age, shortly after the curing of the applied systems. For the analysis of the system efficiency, expressing the performance over time, the same immersion absorption tests (NBR 9778, 2005) and capillarity absorption (NBR 9779, 2012) were performed, however, after the exposure of the samples in wetting and drying cycles, aiming to represent an accelerated aging cycle of the systems.

2. Experimental procedure

This study included the development of an experimental program, with the production of concrete samples and protection thereof with the waterproofing material to be evaluated.

2.1 Waterproofing materials

To choose the three waterproofing products it was taken into account: (i) the application site, which is recommended for the same purpose among the three products, a recommendation made by the suppliers; (ii) the products are standardized; (iii) and the classification, regarding the useful life, by the Brazilian Institute of Waterproofing (BIW), with three intervals of expected useful life being chosen.

Three membranes were then chosen, which met the criteria for manufacturing and applying the standards NBR 9685 (ABNT, 2005), NBR 13321 (ABNT, 2008), NBR 15885 (ABNT, 2010) and the BIW service life criteria, cited by Morgado et al. (2018). The products, their respective standards and useful lives are shown in Table 1.

| Table 1. Waterproofing products used in research. | ||||||||||||||

| Product group | Membranes | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Standard (ABNT, NBR) | 9685:2005 | 13321:2008 | 15885:2010 | |||||||||||

| Product | Asphalt emulsion | Acrylic resin | Polymeric resin | |||||||||||

| Useful life | 8 | 16 | 26 | |||||||||||

The asphalt emulsion membrane is based on asphalt modified with polymers and is emulsified in water, ready for use and non-aggressive to the environment. According to the supplier, kept confidential for ethical reasons, its characteristics are: good performance in elasticity and flexibility, adherence, easy handling and application. The product can be applied indoors, forming a continuous and seamless membrane, with resistance and durability. Its uses can be in terraces, flower boxes, retaining walls, cold rooms, gutters, small slabs, walls and cold floors.

The acrylic resin membrane is a one-component material ready for use. Due to its characteristics, mentioned by the supplier, also kept confidential, it is considered an excellent waterproofing and has good durability, easy application, good elasticity, is resistant to UV rays, with good adhesion on cementitious substrates and fiber cement and reflects sun rays, reducing part of the heat absorbed by the structure. Its application can be in arched and inclined roofs, concrete slabs, concrete gutters, balconies and terraces, reservoir roofs and fiber cement tiles.

Thermoplastic resin is a flexible, two-component waterproofing agent based on acrylic polymers with cement and reinforced with fibers, especially suitable for structures subject to movement. It is recommended to use it in hydraulic structures that have contact with drinking water, wet areas such as bathrooms, balconies and facades, roof slabs with occasional passage and with their appropriate expansion joints, pools and reservoirs, flower boxes, among others. It presents high flexibility and elongation, being able to be exposed to the weather (resistant to U.V) and resistant to high positive hydrostatic pressures. Additionally, conforming to the supplier, it is easy and quick to apply and can be applied manually or designed, without the need for curing.

The description of the waterproofing products that were used in this research is shown in Table 2.

| Table 2. Characteristics of waterproofing products used. | ||||||||||||||

| Product | Component | Characteristics | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Asphalt emulsion | Asphalt (40-70% concentration) | Density: 0.95 to 1.05 g/cm3 Viscosity: 9000 to 12000 Cps Black color | ||||||||||||

| Acrylic resin | Water, mineral fillers, acrylic emulsion, pigment, stabilizers, defoamer, biocide. | Density: 1.2 g/cm3 Viscosity: 1000 to 2500 Cps White color | ||||||||||||

| Thermoplastic resin | Acrylic Polymers (Thermoplastic Resin), Portland Cement (25 -50% concentration) | Density: 1.60 g/cm3 Gray color | ||||||||||||

2.2 Study samples

The samples used in the study were made with Portland cement concrete CPV-ARI, 35 MPa of strength, mixture proportion of 1: 1: 6 with a water/cement ratio of 0.495. The cement used has a specific mass of 3.13 g/cm³, the fine aggregate has a maximum dimension of 2.4 mm and a specific mass of 2.62 g/cm³ and the coarse aggregate used was a gravel 1, with a specific mass equal to 2.65 g/cm³.

For the analysis of product performance, 32 cylindrical specimens 0.10x0.20m and 4 slabs, with dimensions of 0.6 x 0.6 x 0.07 m, were molded. After the concrete was cured for 28 days of the samples, the products were applied, according to the guidelines of the technical sheets (Table 3).

| Table 3. Application of waterproofing products used. | ||||||||||||||

| Product | Specification | Intervals between layers | Drying time | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Asphalt emulsion | 2 to 3 layers | 12 hours | 5 days | |||||||||||

| Acrylic resin | 3 to 4 layers | 6 hours | 1 days | |||||||||||

| Thermoplastic resin | Thickness between 2 to 4 mm | 6 hours | 7 days | |||||||||||

2.3 Experimental analysis

The concrete samples were subjected to experimental tests, which aimed to evaluate the effectiveness and efficiency of the product used as waterproofing.

For the analysis of the systems effectiveness, which is the initial performance of the products when compared to the reference series, the tests of waterproofing, absorption by immersion and absorption by capillarity were performed without any protection.

The results of the tests of absorption by immersion and absorption by capillarity, which are qualitative because they present percentage differences in absorption, were analyzed statistically, using the Tukey test, with 95% confidence. The purpose of the test was to indicate the smallest statistically significant difference between the analyzed results. Therefore, with the 95% confidence interval, the series (reference and the three waterproofed) were compared, in order to evaluate the statistical difference between them in the quantitative tests performed.

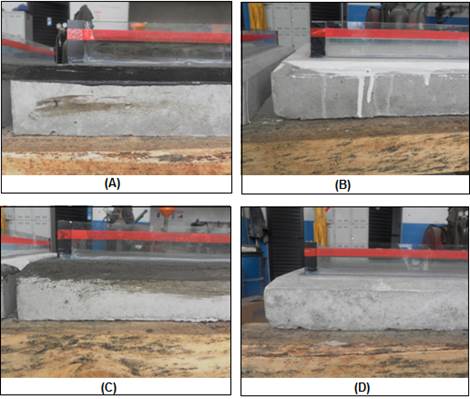

For the waterproofing test, four slabs were used, three of them with the products selected for the research and one for the comparison of unprotected behavior, the reference sample. The slabs were subjected to the waterproofing test, which consists of exposing the samples to a 0.03 m water slide for 72 hours, through a transparent and sealed container, as recommended by Annex C NBR 15575-3 (ABNT, 2013), Figure 1.

|

||||

| Figure 1. Waterproofing test performed in the laboratory. | ||||

In addition, 12 10 x 20 cm specimens were used to perform the immersion absorption test, according to NBR 9778 (ABNT, 2005), 3 for each product applied and 3 for the reference series, without application. After the application and drying of the products, the specimens remain in an oven for 72 hours, at 40ºC. This drying temperature was adopted to prevent the deterioration of the material. After drying, the masses of the dried samples were obtained and, after the immersion periods (24, 48 and 72 hours), the masses of the immersed samples were also obtained.

In addition, the capillarity water absorption test was performed, according to NBR 9779 (ABNT, 2012). Twenty specimens were used, 5 of which were waterproofed in half, with each product and 5 as a reference, without product application. Only the lower part was waterproofed, because it was the only sample part in contact with the water during the test. After the drying time of the products, the specimens remained in an oven at a temperature of 40ºC for 72 hours and cooled to room temperature for 24 hours. After the determination of the dry mass, the specimens were exposed to a 10 mm constant water layer. During the test, the saturated mass of the specimens was determined at intervals of 3 h, 6 h, 24 h, 48 h and 72 h. After determining the masses, the specimens were broken by diametrical compression, to allow measurement of the water distribution inside using infrared thermography.

To evaluate the efficiency of the products, that is their performance over time, an accelerated aging condition was adopted, which consisted of the weekly cycling of the cylindrical specimens used in the immersion absorption test. The adopted cycle alternated the samples between a condition of wetting (immersion) and drying (exposure to the sun and the outdoor weather). The aging pattern was adopted because it has already been used in other studies that sought to accelerate aging (Gao et al., 2013; Gong et al., 2016; Jiang and Niu, 2016).

The samples used in the analysis of accelerated aging were subjected to three sets of cycles, each consisting of 8 cycles (8 weeks), with the ages of analysis being 84, 140 and 196 days. At the ages mentioned, the specimens were subjected to the procedures mentioned in the immersion absorption test.

3. Results

3.1 Waterproofing test

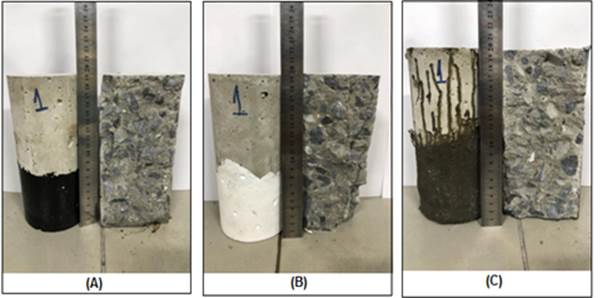

After submitting the slabs to the waterproofing test, they were observed for 72 hours. However, in the evaluated period, recommended by NBR 15575 (ABNT, 2013), the appearance of bubbles, infiltration in the lower part of the slabs and the lowering of the water level in the reference of 0.03 m was not observed. Figure 2 shows part of the four slabs studied, indicating the tightness of all systems.

As all the slabs were considered watertight, no behavioral difference that could be identified by this test was verified between the reference sample (without protection) and the waterproofed samples.

|

||||

| Figure 2. Waterproofing test result after 72 hours. A - Slab with asphalt emulsion; B - Slab with acrylic membrane; C - Slab with thermoplastic resin; D - Reference slab. | ||||

3.2 Immersion absorption test

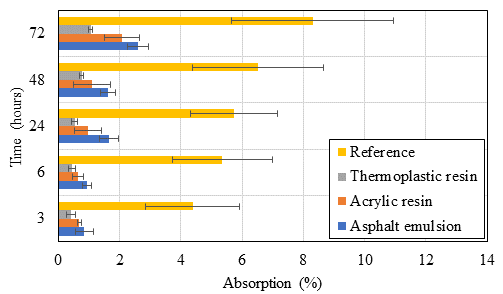

Figure 3 presents the results obtained for the immersion absorption rate. The initial average rate, in 24 hours, of waterproofed specimens was 0.3%, against 5.17% of reference specimens. After the 72-hour period, a small increase in rates was observed, with the average absorption rate of waterproofed specimens being 0.4%, and 5.23% for the reference series. Considering the 2.5% reference absorption mentioned by Basheer et al. (2001), it is noted that only waterproofed samples can be considered as watertight substrates.

By comparatively analyzing the results obtained for the waterproofed series, a very similar behavior was noted between them, and a satisfactory one if compared to the reference series. By the standard deviation obtained, the asphalt emulsion and thermoplastic resin series could be considered statistically equivalent, by the Tukey test, in all readings performed. At the final age evaluated, 72 hours of testing, the acrylic membrane revealed the lowest value statistically validated, among all series evaluated, indicating the best performance during this test.

|

||||

| Figure 3. Result of the immersion absorption test. | ||||

3.3 Capillary absorption test

In the first periods of the test, 3 and 6 hours, the behavior of the specimens with the waterproofing products can be considered similar, since the average absorption rate in these periods was approximately 0.659%, all of which are considered statistically equivalent by the statistical test applied. However, in the last reading interval of the test, 72 hours, the specimens of the thermoplastic resin series had the lowest absorption rate of 1.05%, against an average of 2.34% of the other products. At the end of the test, the reference series had an absorption 7.9 times greater than the series of thermoplastic resin, indicating the best behavior. The asphalt emulsion and acrylic membrane remained statistically equivalent, considering the greater variability of standard deviation between them, as shown in Figure 4.

|

||||

| Figure 4. Result of the capillarity absorption test. | ||||

The better performance of the thermoplastic resin in the capillary absorption test confirms the indication of Pezzolo (2013) for the use of the material for waterproofing in baseboards of drywall walls.

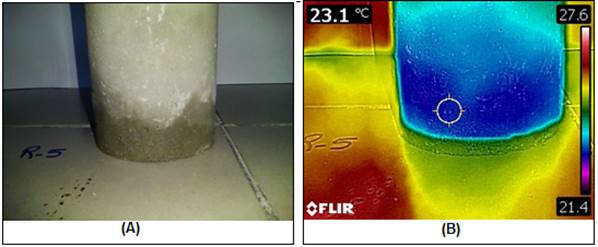

The visual analysis of the specimens that was submitted to the diametrical compression test and later to the analysis by infrared thermography, allowed the confirmation of the inferior performance of the reference series and the similar performance between the waterproofed series.

Figure 5 shows the specimens of the reference series that were submitted to the diametrical compression test. For the case of this series an average capillary rise height of 4.3 cm was noted.

|

||||

| Figure 5. Specimens of the reference series after the diametrical compression test. | ||||

The thermographic images for the reference series, Figure 6, confirm the percolation of water into the specimen, since the temperature obtained in the test was the lowest among the series studied (23.1 ºC).

|

||||

| Figure 6. Thermographic image for the reference series. A - Specimen after the diametrical compression test; B - Specimen during the thermography test. | ||||

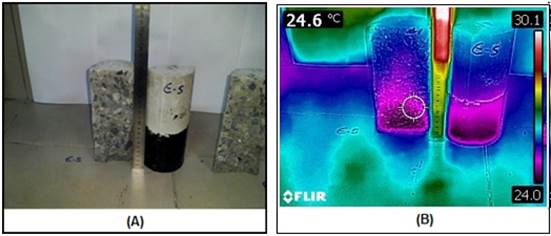

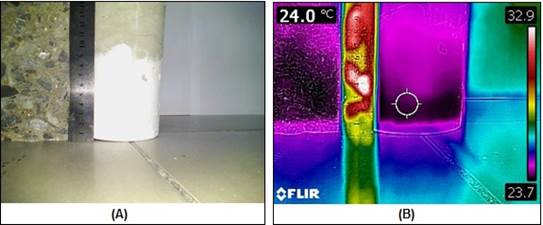

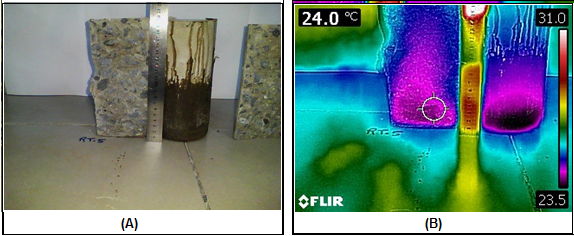

Figure 7 presents the specimens of the waterproofed series after the diametrical compression test. For these series, the difficulty of obtaining readings of capillary rise was greater and the analysis was performed using thermographic images, presented in Figures 8, 9 and 10. The temperatures recorded in the thermographic images are close to the minimum indicated in the reference scale, on the right side of each image, indicating the water absorption region.

|

||||

| Figure 7. Specimens of the waterproofed series after the diametrical compression test. A - Sample with asphalt emulsion; B - Sample with acrylic resin; C - Sample with thermoplastic resin. | ||||

|

||||

| Figure 8. Thermographic image for the series with asphalt emulsion. A - Specimen after the diametrical compression test; B - Specimen during the thermography test. | ||||

|

||||

| Figure 9. Thermographic image for the series with acrylic resin. A - Specimen after the diametrical compression test; B - Specimen during the thermography test. | ||||

|

||||

| Figure 10. Thermographic image for the series with thermoplastic resin. A - Specimen after the diametrical compression test; B - Specimen during the thermography test. | ||||

The thermography test indicated among the waterproofed series the best performance for the asphalt emulsion series, which had the highest temperature of 24.6 ºC. The series of acrylic membrane and thermoplastic resin showed the same temperature indicating a similar behavior of 24 ºC.

According to the literature, the variation from 1 ºC to 2 ºC is considered an indication of problems (Cortizo, 2007; Freitas et al., 2014). Therefore, the temperature difference observed between the reference series and the waterproofed series is sufficient to indicate better performance of these series.

Despites the small temperature variation observed, the studied thermographic images proved to be adequate for the detection of absorption, since the visual analysis in the broken specimens confirmed the capillary rise. In addition, regarding the small variation, the literature still reports that variations in the order of 1ºC are already susceptible to identification of infiltration in concrete elements (Maldague, 2001; Merlrinho, Matias e Farias, 2015; Lourenço, Matias e Faria, 2017; Rocha, Santos, Oliveira, Albuquerque e Póvoas, 2018).

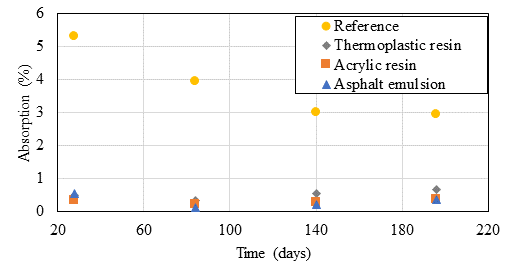

3.4 Immersion absorption after accelerated aging

The absorption test after the accelerated aging process, shown in Figure 11, indicates reduced absorption for the reference series over time. The result was expected whereas the continuous hydration of Portland cement causes pores filling, consequently decreasing the permeability of the material (Rossignolo, 2005). Moreover, once the specimens were subjected to time, the influence of the carbonation phenomenon is possible, which may have contributed to the filling of the pores with calcium carbonate (CaCO3), and reduction of the materials absorbent capacity, as reported by Ngala and Page (1997). The absorption results of the reference series were from 5% at the initial age to 3% at the final age studied, confirming the pore filling.

All waterproofed series showed lower absorption at 84 days than that presented at 28 days, also explained by the drying and fixing of the products in the period. However, after 140 days it was possible to notice a behavioral inversion, the series started to show greater absorptions when compared to the age of 28 days.

It should be noticed that the three waterproofing products tested, according to their suppliers, could be applied outdoors, such as roof slabs. Therefore, no matter how much they were subjected to wetting and drying cycles, the performance should not have been impacted. According to Silveira and Granato (2013), the waterproofing system must be able to withstand all types of request during its useful life, whether mechanical or chemical. Therefore, the choice of the system must always take into account the active requests, so that the applied material meets the proposed demand.

The values obtained in this test still confirm the greatest performance of the waterproofed series, with the average absorption between them, at 196 days, 0.52%, against 3.0% of the reference series. However, the necessity to observe the performance of these materials over time is highlighted, once their inefficiency would lead to a direct loss in the useful life of concrete structures. Since the proposal of the work is the evaluation of application of the systems in roof slabs, it is expected that the systems resist the action of UV rays, as well as the hygroscopic request for constant wetting and drying.

|

||||

| Figure 11. Result of the immersion absorption test after accelerated aging. | ||||

4. Conclusions

The results obtained in this study allowed to present the conclusions listed below:

- The waterproofing test indicated similar behavior among all the series studied, and infiltration, percolation or any other indication of failure in the three series observed cannot be observed in the period indicated by NBR 15575 (ABNT, 2013);

- The immersion absorption test once again indicated similar behavior among the products studied. However, in this case, to indicate at the end of the test the best performance of the acrylic membrane, with the absorption of the material equal to 0.35% was possible;

- The capillary absorption test indicated a better performance for the thermoplastic resin, confirming its indication for use in baseboards;

- Thermographic images helped to visualize the percolation of water into the specimens, confirming the better performance (higher temperatures) for the waterproofed series;

- Finally, accelerated aging was sensitive to indicate a behavioral change between the waterproofed series. However, at the end of the test their performance was still much higher (about 6 times) than the reference series. It is recommended to monitor these materials for a longer period of study, in order to verify their efficiency and confirm their useful life time in service.

5. Acknowledgments

The authors thank the support of the Brazilian agencies CNPq, Capes and Fundação Araucária for their financial support, the Federal University of Paraná (UFPR), the Graduate Program in Civil Construction Engineering (PPGECC), the UNIFACEAR University Center and the concrete company NOVAMIX for the aid given to the study.

6. References

Aldea, C., Shah, S. P., Karr, A. (1999) “Permeability of cracked concrete” Materials and Structures, 32, pp. 370-376. https://doi.org/10.1007/BF02479629

Andrello, J. M., Takagi, E. (2017)“Debate técnico: impermeabilização in loco”Construção Mercado - Téchne, PINI.

Associação Brasileira de normas Técnicas. (2005). NBR 9685: Emulsão Asfáltica para Impermeabilização. Rio de Janeiro.

Associação Brasileira de normas Técnicas. (2005). NBR 9778: Argamassa e concreto endurecidos - Determinação da absorção de água, índice de vazios e massa específica. Rio de Janeiro.

Associação Brasileira de normas Técnicas. (2008). NBR 13321: Membrana acrílica para impermeabilização. Rio de Janeiro.

Associação Brasileira de normas Técnicas. (2010). NBR 15885: Membrana de Polímero Acrílico com ou sem Cimento para Impermeabilização. Rio de Janeiro.

Associação Brasileira de normas Técnicas. (2012). NBR 9779: Argamassa e concreto endurecidos - Determinação da absorção de água por capilaridade. Rio de Janeiro.

Associação Brasileira de normas Técnicas. (2013). NBR 15575: Edificações habitacionais - Desempenho. Rio de Janeiro.

Basheer, I., Kropp, J., Cleland, D. J. (2001) “Assessment of the durability of concrete from its permeation properties: a review” Construction and Building Materials, 15 (2-3), pp. 93- 103. https://doi.org/10.1016/S0950-0618(00)00058-1

Bauer, E., Vasconcelos, P. H. C., Granato, J. E. (2010) “Sistemas de impermeabilização e isolamento térmico” In: ISAIA, G. C. Materiais de construção civil e princípios de ciência e engenharia dos materiais. São Paulo: Ed. IBRACON.

Cortizo, E. C. (2007) “Avaliação da técnica de termografia infravermelha para identificação de estruturas ocultas e diagnóstico de anomalias em edificações: Ênfase em edificações de Patrimônio Histórico” 178f. Tese (Doutorado) - Universidade Federal de Minas Gerais, Escola de Engenharia, Departamento de Engenharia Mecânica. Belo Horizonte.

Freitas, J. G., Carasek, H., Cascudo, O. (2014) “Utilização de termografia infravermelha para avaliação de fissuras em fachadas com revestimento de argamassa e pintura”. Ambiente Construído, Porto Alegre, v. 14, n. 1, p. 57-73. http://dx.doi.org/10.1590/S1678-86212014000100006

Gao, J., Yu, Z., Song, L., Wang, T., Wei, S. (2013) “Durability of concrete exposed to sulfate attack under flexural loading and drying-wetting cycles” Construction and Building Materials. v. 39, pp. 33-38. https://doi.org/10.1016/j.conbuildmat.2012.05.033

Gong, J., Cao, J., Wang, Y. (2016) “Effects of sulfate attack and dry-wet circulation on creep of fly-ash slag concrete” Construction and Building Materials. v.125, pp.12-20. https://doi.org/10.1016/j.conbuildmat.2016.08.023

Jiang, L., Niu, D. (2016) “Study of deterioration of concrete exposed to different types of sulfate solutions under drying-wetting cycles” Construction and Building Materials. v. 117, pp. 88-98. https://doi.org/10.1016/j.conbuildmat.2016.04.094

Lourenço, T., Matias, L., Faria, P. (2017) “Anomalies Detection in Adhesive Wall Tiling Systems by Infrared Thermography.” Construction and Building Materials, v. 148, p. 419-428. https://doi.org/10.1016/j.conbuildmat.2017.05.052

Maldague, X. (2001) “Infrared and Thermal Testing: nondestructive testing handbook.” 3. ed. Columbus, OH: Patrick O. Moore.

Melrinho, A., Matias, L., Faria, P. (2015). Detecção de anomalias em impermeabilizações de coberturas em terraço através da termografia de infravermelhos. Tech ITT by Construlink, 13(37), 29-38. https://run.unl.pt/bitstream/10362/16576/1/RI%20-%20Melrinho%20et%20al_RIT%2037_2015.pdf

Menezes, M. (2018) “Influência da umidade do substrato na aderência de sistema de impermeabilização com manta asfáltica aderida à maçarico”IBI - Instituto Brasileiro de Impermeabilização, 16 p, São Paulo.

Morgado, J. M., et al. (2018) “Guia de aplicação da norma de desempenho para impermeabilização. Especificação, aplicação e contratação com foco no atendimento à ABNT 15575/2013” IBI - Instituto Brasileiro de Impermeabilização, Rio de Janeiro.

Ngala, V. T., Page, C. L. (1997) “Effects of carbonation on pore structure and diffusional properties of hydrated cement pastes”. Cement and Concrete Research, V. 27, n.7, pp. 995-1007. https://doi.org/10.1016/S0008-8846(97)00102-6

Pezzolo, V. (2013)“Conheça os tipos de impermeabilizante” Equipe Obra Prima, PINI.

Picchi, F. A. (1986)“Impermeabilização de coberturas” Editora Pini, São Paulo.

Rocha, J. H. A., Santos, C. F. dos, Oliveira, J. B. de, Albuquerque, L. K dos S., Póvoas, Y. V. (2018) “Detecção de infiltração em áreas inerenas de edificações com termografia infravermelha: estudo de caso” Ambiente Construído, Porto Alegre, V. 18, n.4, pp. 329-340. https://doi.org/10.1590/s1678-86212018000400308

Rossignolo, J. A. (2005) “Avaliação da porosidade e do teor de CH de pastas de cimento Portland com Sílica Ativa e Látex SRB” Revista Matéria, V.10, n.3, pp. 437-442. http://www.materia.coppe.ufrj.br/sarra/artigos/artigo10654

Silveira, M. A., Granato, J. E. (2013) “Diretrizes de desempenho para produtos de impermeabilização”. 13º Simpósio Brasileiro de Impermeabilização.