| Review | https://doi.org/10.21041/ra.v10i2.477 |

Use of supplementary cementitious materials (SCMs) in reinforced concrete systems - Benefits and limitations

Uso de materiais cimentícios suplementares (SCMs) em sistemas de concreto armado - Benefícios e limitações

Uso de materiales cementicios suplementarios (SCM) en sistemas de concreto armado - Beneficios y limitaciones

R. G. Pillai1

![]() , R. Gettu1

*

, R. Gettu1

*

![]() , M. Santhanam1

, M. Santhanam1

1 Department of Civil Engineering, Indian Institute of Technology Madras, Chennai, India..

*Contact author: gettu@iitm.ac.in

Reception: January 07, 2020.

Acceptance: April 08, 2020.

Publication: April 30, 2020.

| Cite as: Pillai, R. G., Gettu, R., Santhanam, M. (2020), "Use of supplementary cementitious materials (SCMs) in reinforced concrete systems – Benefits and limitations", Revista ALCONPAT, 10 (2), pp. 147 – 164, DOI: https://doi.org/10.21041/ra.v10i2.477 |

Abstract

About a decade of research carried out at IIT Madras on cementitious systems has shown that the partial replacement of portland cement with supplementary cementitious materials (SCMs) has benefits as well as limitations. The SCMs do not adversely affect the long-term compressive strength and drying shrinkage of concretes, though there may be some compromise in workability and the resistance against plastic shrinkage cracking. Through the assessment of the chloride ingress rate in concrete and chloride threshold of steel, it is evident that the use of SCMs could significantly enhance the service life under chloride attack, though there is a reduction of the carbonation resistance. More importantly, SCMs can lead to significant reduction of the carbon footprint of concrete, and hence, are essential to achieve sustainability.

Keywords:

supplementary cementitious materials,

limestone calcined clay,

mechanical properties,

microstructure,

durability.

Resumo

Cerca de uma década de pesquisa realizada no IIT Madras em sistemas cimentícios mostrou que a substituição parcial do cimento Portland por materiais cimentícios suplementares (SCMs) traz benefícios e limitações. Os SCMs não afetam adversamente a resistência à compressão a longo prazo e a retração por secagem dos concretos, embora possa haver algum comprometimento na trabalhabilidade e na resistência contra fissuras por retração plástica. Através da avaliação da taxa de penetração de cloretos no concreto e considerando o patamar limite de cloreto no concreto, é evidente que o uso de SCMs poderia melhorar significativamente a vida útil sob ataque de cloretos, embora haja uma redução da resistência à carbonatação. Mais importante, os SCMs podem levar a uma redução significativa da pegada de carbono do concreto e, portanto, são essenciais para alcançar a sustentabilidade.

Palavras-chave:

materiais cimentícios suplementares,

argila calcificada calcária,

propriedades mecânicas,

microestrutura,

durabilidade.

Resumen

Alrededor de una década de investigación realizada en IIT Madras sobre sistemas cementicios ha demostrado que el reemplazo parcial de cemento portland con materiales cementicios suplementarios (SCM) tiene beneficios y limitaciones. Los SCM no afectan negativamente la resistencia a la compresión a largo plazo y la contracción por secado de los hormigones, aunque puede haber algún compromiso en la trabajabilidad y la resistencia contra el agrietamiento por contracción plástica. A través de la evaluación de la tasa de ingreso de cloruro en el hormigón y el umbral de cloruro de acero, es evidente que el uso de SCM podría mejorar significativamente la vida útil bajo ataque de cloruro, aunque hay una reducción de la resistencia a la carbonatación. Más importante aún, los SCM pueden conducir a una reducción significativa de la huella de carbono del hormigón y, por lo tanto, son esenciales para lograr la sostenibilidad.

Palabras clave:

materiales cementicios suplementarios,

arcilla calcinada,

caliza,

propiedades mecánicas,

microestructura,

durabilidad.

1. Introduction

Since the 1990s, many leading researchers started advocating the use of supplementary cementitious materials (SCMs), such as fly ash (PFA) and ground granulated blast-furnace slag (GGBS) due to their ability to partially substitute cement and even make it a more effective binder in concrete (Dhir and Jones, 1994; Malhotra and Ramezanianpour, 1994; Mehta, 1994, 2001). The benefits that were initially demonstrated in reinforced concrete structures included the (i) reduction of the carbon footprint by using the SCMs that are waste products, (ii) enhancement of the strength of the aggregate-paste interfaces and concrete; (iii) decrease in the permeability; (iv) increase in electrical resistivity; (v) lowering of the risk of alkali-silica reaction; (vi) reduction of the heat evolution during hydration; (vii) enhancement of the resistance to chlorides and sulphates; and (viii) reduction in the cost of concrete. Many research findings over the past couple of decades have also shown that the incorporation of SCMs, with a concurrent decrease in the ordinary portland clinker content in concrete, is perhaps the most viable way towards sustainability, especially when a long corrosion-free service life is expected. This is mainly brought about by the enhanced durability, reduced carbon footprint and lower raw material demand - all without sacrificing strength (Chatterjee, 2018; Scrivener et al., 2018). Also, the use of SCMs can increase the ratio between the tensile or flexural strength and the compressive strength of concrete. Regarding corrosion resistance, the use of SCMs can tremendously increase the resistance to the ingress of chlorides and the enhancement of the electrical resistance of concrete can reduce the rate of corrosion of the embedded steel. Nevertheless, simple substitution, by weight, of cement with a SCM without any appropriate modification of the mix-design, and/or the processes of making and placing the concrete may lead to some limitations. These include (i) the higher potential for plastic shrinkage cracking (due to higher paste content, less bleeding and lower early strength gain), (ii) slower evolution of strength (due to slower hydration), (iii) leaching of heavy metals, (iv) undesired thixotropy, (v) lower surface hardness, (vi) lower chloride threshold, and (vii) faster carbonation (due to lower carbonatable material content). These issues have raised concerns about the problems that could occur if the material and structural designs are not done adequately. At present, more than 75% of cement available in India is made by blending ground clinker or intergrinding the ordinary portland clinker with PFA, GGBS, limestone, calcined clay or other SCMs. Moreover, the clinker content is expected to decrease further in the years to come - mainly due to the advantages associated with the long list of engineering properties, and those associated with the economics and climate change. Therefore, it is important that the benefits of using the SCMs are emphasized appropriately, along with the limitations and measures for their mitigation.

Researchers at IIT Madras have worked on several projects related to the behaviour and properties of cementitious systems with SCMs and have studied their workability, mechanical properties, dimensional stability, durability and corrosion resistance, among other aspects. These studies have enhanced the knowledge about the short- and long-term performance of concretes with blended binders, as well as the confidence to guide their applications in the Indian and other contexts. Major real-scale applications of SCMs that have stemmed from this experience include the construction, over the past 15 years or so, of various reinforced concrete buildings, on the IIT Madras campus, with a cumulative built-up area of about 126,000 m2 with concrete containing fly ash, and fibre-reinforced concrete road stretches of more than 1 km length with high volumes of fly ash (see Figure 1a). Also, the recently completed complex of four 10-storey commercial buildings (in the IIT Madras Research Park Phase II) with about 80,000 m2 of built-up area used GGBS in the normal and self-compacting fair-faced concrete façades (see Figure 1b). The remaining sections of this paper provide previews of findings from the relevant research projects conducted by the authors and their research group on various SCMs, such as fly ash, slag and limestone calcined clay.

Figure 1.

FRC pavement on IIT Madras campus, and (b) the SCC building in the IIT Madras Research.

2. Fresh concrete properties

The presence of SCMs could increase the superplasticizer demand to achieve the required flow or workability. They could also affect the evolution of the various rheological characteristics as a function of time. Consequently, the flow responses of the blended binder system would differ significantly from that of an ordinary portland cement (OPC) system with the same water-binder ratio (w/b), depending mainly on the particle size distribution and particle shape of SCMs. A simple method such as Marsh Cone test has been used extensively to assess the variations in the behaviour of cement pastes with various superplasticizers and SCMs (Jayasree and Gettu, 2008, 2012; Jayasree et al., 2011; John and Gettu, 2014). Figure 2 shows the flow time (in log scale) versus the superplasticizer/binder dosage for pastes with (i) OPC, (ii) OPC with 30% replacement with fly ash (i.e., FA30), and (iii) limestone calcined clay cement (LC3) pastes; all with w/b = 0.40 and a PCE based superplasticizer (Nair, 2018). The flow times corresponding to the saturation dosage of superplasticizers (indicated by vertical lines in Figure 2b) for the pastes with FA30 and LC3 pastes are higher than that for OPC paste. These results show that the mortars and concretes made with fly ash and limestone calcined clay systems would exhibit differences in flow response and workability (Jayasree and Gettu, 2010; Nair 2018). However, such challenges can be mitigated with the appropriate corrections in the mixture proportioning - i.e., by adjusting the paste, superplasticizer, and water content.

Figure 2.

Marsh cone test setup and flow time curve (Nair, 2018; Mohan, 2019)

The increase in cohesiveness of the paste due to the higher fineness of the SCMs reduces the rise of bleed water. This is generally beneficial because bleeding produces defects within the concrete, typically at the interfaces between the coarse aggregates or steel reinforcing bars and the paste. However, the absence of bleed water leads to the evaporation of water from the concrete surface when it is subjected to drying, resulting in plastic shrinkage. Preventing plastic shrinkage cracking is a major challenge in many construction sites - although covering/curing of concrete is generally practiced. Sirajuddin and Gettu (2018) studied the susceptibility to cracking during the first few hours after placing the concrete using the restrained plastic shrinkage test (ASTM C1579, 2013) and found that the partial replacement of OPC with SCMs can increase the tendency for plastic shrinkage cracking in concrete, especially when replacement levels are high. This is attributed to the significant less replenishment of moisture at the surface subjected to drying leading to higher capillary stresses. If the gain in strength is slow during the early hours, the tensile stresses induced due to moisture loss could be higher than the tensile strength of the concrete - leading to cracking of concrete during the early hours. It was seen that 15% replacement with fly ash and slag increased the crack area by about 20 and 100%, respectively. At 30% replacement with fly ash and slag, the crack area increased by about 40 percent and four-fold, respectively. Other results can be seen in Table 1, where OPC is the control concrete; FA15 and FA30 are concretes with 15 and 30% replacement with fly ash, respectively; and SG15 and SG30 are concretes with 15 and 30% replacements with slag (Sirajuddin and Gettu, 2018). This study strongly suggests that curing should be initiated earlier in mortars and concretes with SCMs and/or appropriate mitigation measures must be adopted, such as the incorporation of about 1 kg/m3 of short polypropylene fibres or shrinkage reducing admixtures in concrete.

| Table 1. Data from tests for plastic shrinkage cracking potential | ||||||||

| Mix ID | Crack initiation time (min) | Crack parameters | % increase in crack area | % increase in mean crack width | ||||

| Crack area (mm2) | Crack length (mm) | Maximum crack width (mm) | Mean crack width (mm) | |||||

| OPC | 207 | 97 | 263 | 0.68 | 0.37 | - | - | |

| FA15 | 180 | 121 | 303 | 0.93 | 0.40 | 24 | 7 | |

| FA30 | 167 | 138 | 333 | 1.03 | 0.42 | 42 | 12 | |

| SG15 | 197 | 225 | 427 | 1.25 | 0.53 | 132 | 42 | |

| SG30 | 183 | 402 | 444 | 1.73 | 0.91 | 313 | 144 | |

3. Compressive strength and elastic modulus

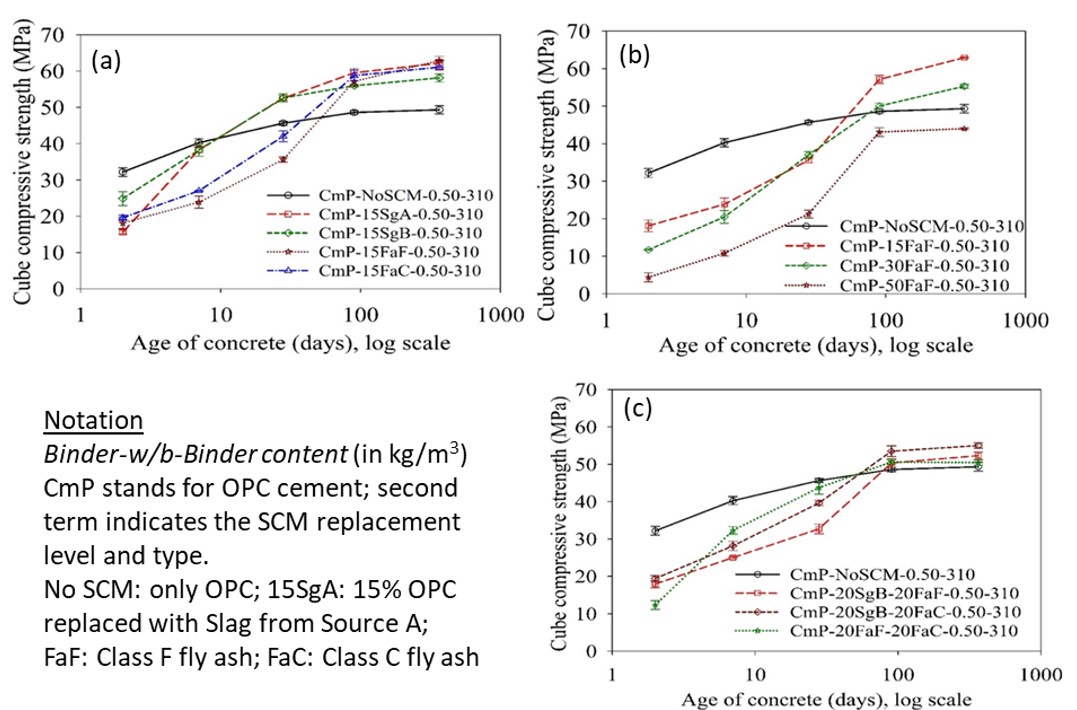

Compressive strength is probably the most important parameter influencing the structural performance of concrete systems. Hence, many researchers have investigated the effect of SCMs on the compressive strength of concrete. However, there are still negative perceptions and restrictions on the use of SCMs for major infrastructure projects, mainly because of the lack of awareness on the advantages of such materials and the possible variations in the quality and type of SCMs available from various sources. To address such issues, experimental data has been obtained for concretes that are typically used in the Indian construction sector to quantify the evolution of their strengths (Dhandapani et al., 2018; Sakthivel, 2019; Sakthivel et al., 2019). Though the early-age compressive strength of blended binder concretes could be lower than that of OPC concrete, Figure 3 shows that the eventual values can be much higher, especially for replacement levels of 15% of fly ash and slag (see Figure 3a & Figure 3b). Figure 3c shows that ternary blends with 60% OPC, 20% slag and 20% fly ash can exhibit higher compressive strengths at later ages than concretes without SCMs. This indicates a need for appropriately planning the schedule for curing and formwork removal while using concretes with SCMs. Figure 4 shows that the concretes with various SCMs exhibit adequate elastic modulus, as predicted by various standards and codes. Altogether, it can be concluded that the performance of SCM based concretes is good in terms of the mechanical properties.

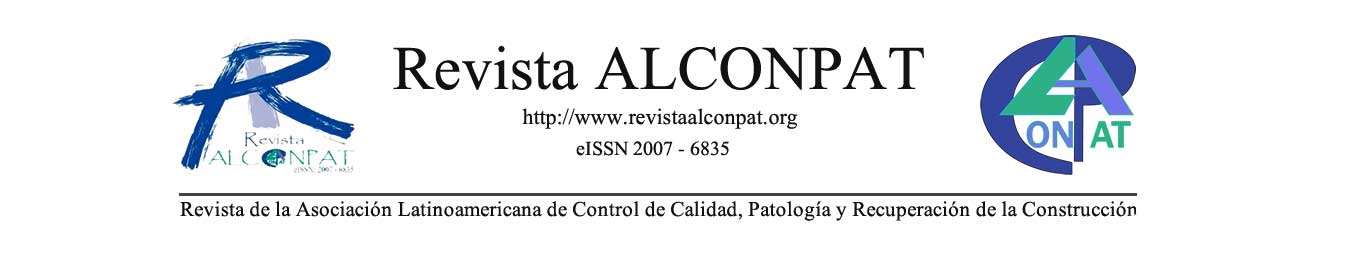

4. Evolution of shrinkage

Ongoing tests at IIT Madras on the shrinkage of concretes with blended binders indicate that the incorporation of SCMs does not alter the drying shrinkage strain evolution significantly (see 4-year data in Figure 5). It can be concluded that replacement of OPC by ≤ 30% of slag and fly ash, at the same w/b, will not change the ultimate strains due to drying shrinkage. This is of considerable relevance to design practices because most shrinkage models do not directly give provisions for the estimating shrinkage in concretes with SCMs. The findings also indicate that the shrinkage models calibrated for OPC concretes (i.e., without SCMs) can be used for concretes with SCMs, with some recalibration, if needed

Figure 3.

Compressive strength evolution in concretes with blended binders

Figure 4.

Elastic modulus of various concretes with SCMs (Sakthivel et al., 2019)

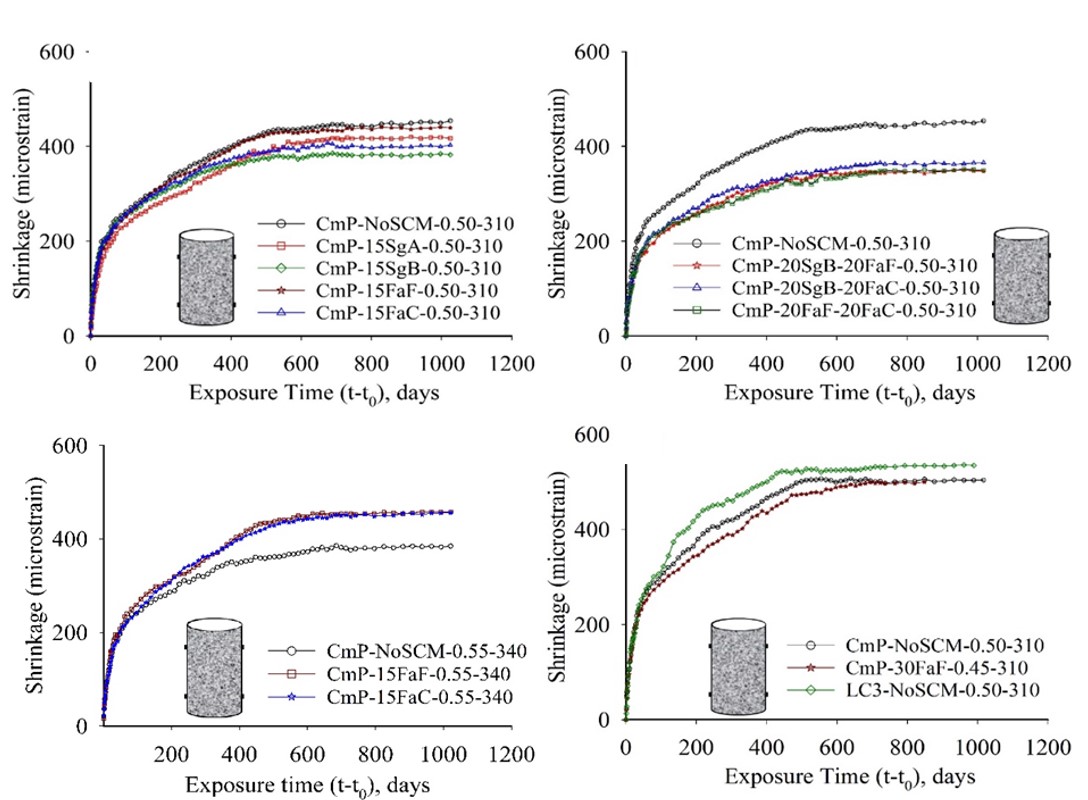

5. Toughness and crack resistance

Concrete pavements are being used more extensively in many parts of the world, and this type of application is promising for the use of high volumes of fly ash in concrete. However, there could be problems (see Figure 6) of significant cracking due to the shrinkage and fatigue loading. Such problems cannot be resolved by just increasing the compressive strength of concrete and require targeted enhancement of the toughness, which is the key influencing parameter in providing adequate crack resistance. The incorporation of (steel, polymer, amorphous metal and glass) fibres for improving the toughness has been studied extensively at IIT Madras (see the image on the right in Figure 6), leading to guidelines for testing and design (Nayar and Gettu, 2015, 2018, 2020). Further work has also shown that steel fibres can dramatically prevent crack propagation in cracked concrete under a range of loading conditions (Jose et al., 2018; Stephen and Gettu, 2019a, 2019b).

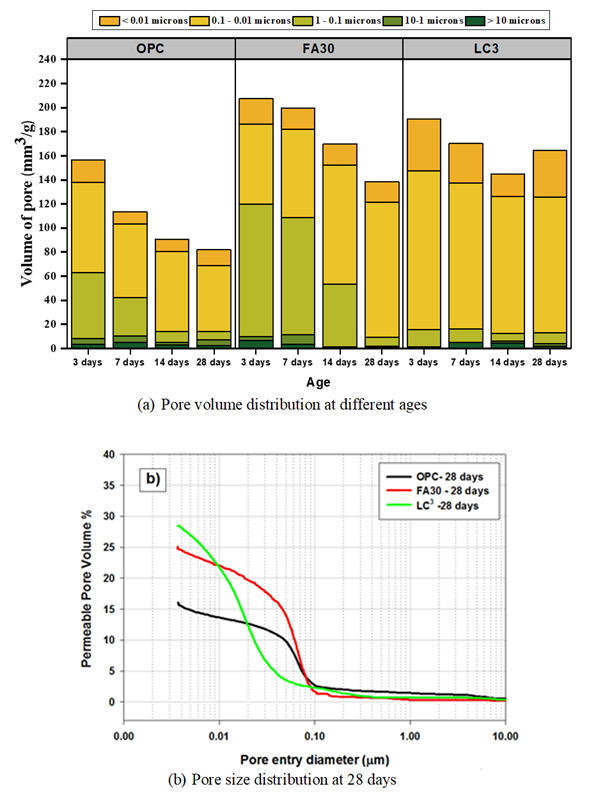

6. Evolution of microstructure and permeability

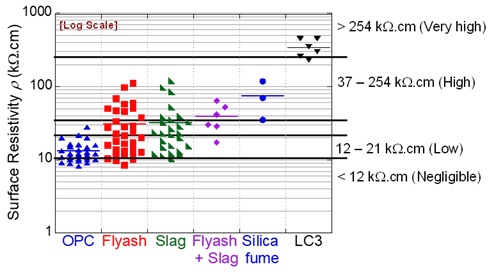

Concretes with blended binder systems exhibit a more refined pore structure than OPC systems because of the additional/prolonged hydraulic and pozzolanic reactions. Dhandapani and Santhanam (2020) performed extensive studies on the evolution of microstructure in binders with various SCMs, especially LC3 systems. Figure 7(a) shows the evolution of pore sizes in hardened cement pastes with a w/b ratio of 0.35 and prepared with (i) OPC, (ii) OPC with fly ash (at 30% replacement dosage), and (iii) LC3. The results clearly indicate that slower reacting SCMs, like fly ash, result in a retardation of about 14 days to exhibit significant refinement of pores, whereas the faster reacting SCMs, like limestone-calcined clay, exhibit much finer pores even as early as 3 days. Figure 7(b) shows the pore size distributions in OPC, FA30 and LC3 systems at 28 days of curing. One important lesson is that the concretes with fly ash will require prolonged curing to exploit the full potential. More refinement of pores will improve the resistivity of the system, as seen in Figure 8 for concretes with SCMs, in particular LC3 systems. Consequently, the resistivity higher will lead to better chloride resistance and lower corrosion rates.

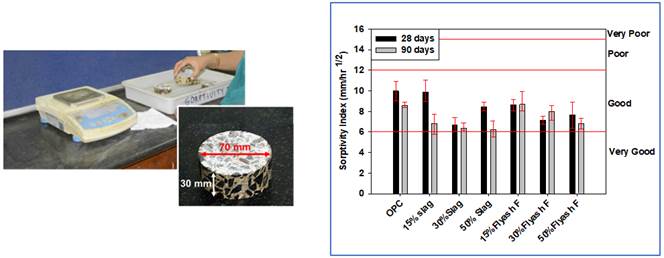

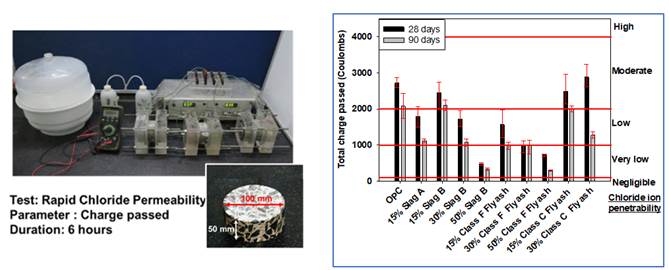

Due to the refined pore structure, concretes with SCMs also exhibit lower permeability (Dhanya and Santhanam, 2017). The charge passed in the rapid chloride penetration test is a good indicator of the permeability of concrete; Figure 9 indicates the significant resistance to charge transfer, especially when the replacement levels of slag and Class F fly ash are more than 30%. On the other hand, the performance of calcareous (Class C) fly ash is rated less than that of Class F fly ash and slag. Note that at 15% replacement level, both slag and Class C fly ash exhibit similar performance. Figure 10 shows data from water sorptivity tests, indicating that SCM based concretes show only marginally lower sorptivity than OPC concretes. The literature does not also provide any consensus on the water sorptivity and chloride penetration of concretes with SCMs. The authors believe that with appropriate mix-design, placement and curing practices, the positive aspects of SCMs can be exploited to enhance the durability of reinforced concrete systems.

Figure 7.

Pore size distribution of different binder systems (Dhandapani and Santhanam, 2017)

Figure 8.

Wenner 4-probe surface resistivity of concretes with various SCMs

(binder content.

of 310 kg/m3, w/b of 0.5) (Dhanya, 2015)

7. Chloride resistance, chloride threshold and service life

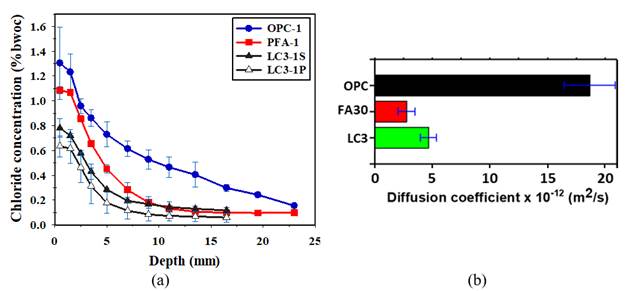

Many reports suggest that the resistance of concretes against chloride ingress can be greatly enhanced by using SCMs. The refined pore structure and enhanced chloride binding capacity are the major reasons for this. Figure 11a shows chloride profiles (ASTM C1556 tests) of concretes moist cured for 1 year; the curves for FA30 and LC3 systems exhibit steeper slopes than that for the OPC system - indicating lower chloride diffusion coefficients and better chloride binding capacity, which can be attributed to higher concentration of reactive alumina in the SCMs. Also, fly ash and LC3 systems exhibit about 75% in the chloride diffusion coefficients (see Figure 11b), with the LC3 systems possessing better chloride binding capability than those with fly ash. Pillai et al. (2018), and Dhandapani and Santhanam (2020) showed that the SCM type greatly influences the ageing factor or decay constant for the chloride diffusion coefficient. The appropriate choice of ageing factor is important to obtain more realistic service life estimates. See Table 2 for the recommended ranges of ageing factors for various binder systems; to be conservative, one may choose a lower value in the range given. For example, for systems with OPC, Class F fly ash, Class C fly ash, slag and LC3, it is recommended to use ageing factors of 0.1, 0.6, 0.4, 0.4 and 0.4, respectively, for the initial estimation of service life. The service life estimates can be refined by collecting field samples to obtain chloride profiles, and then determining the chloride diffusion coefficients and ageing factors at later ages.

| Table 2. Recommended ranges of ageing factors for different binders | ||||||||

| Binder type | Recommended range of ageing factor | |||||||

| OPC | 0.1-0.3 | |||||||

| Class F fly ash | 0.6-0.8 | |||||||

| Class C fly ash | 0.4-0.6 | |||||||

| Slag | 0.4-0.6 | |||||||

| Calcined clay | 0.4-0.5 | |||||||

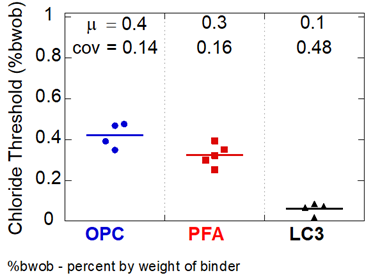

Service life can be defined primarily as the time taken to initiate corrosion (say, the corrosion free service life) for assessing the influence of SCMs, though it has been shown that fly ash can be beneficial in the propagation phase even in cracked concretes (Sangoju et al., 2011, 2015). For obtaining such service life estimates, in addition to the chloride diffusion coefficient and its decay constant, quantitative estimates of chloride threshold are essential. The test procedures adopting teelell corrosion measurements do not adequately detect the corrosion initiation in highly resistive concrete systems (such as those with LC3 and with SCMs and low w/b ratios). In such systems, corrosion initiates with macrocells or microcells forming on the same steel rebar, which is not detected in typical teelell test methods like ASTM G109 (Rengaraju et al., 2018). Also, linear polarization resistance techniques have limitations in detecting corrosion in highly resistive concrete systems (Rengaraju et al., 2019). Hence, an accelerated chloride threshold test method (hr-ACT test method) was developed to accommodate chloride threshold tests in highly resistive (hr) concrete systems (Pillai et al. 2018, Rengaraju, 2019). This test uses a lollipop-type steel-mortar specimen, the linear polarization resistance and/or the electrochemical impedance spectroscopy technique, and a statistical procedure to detect corrosion initiation. Consequently, probabilistic estimates of chloride threshold of various steel-cementitious systems could be developed (see Table 3). As seen in Table 3 and in Figure 12, there is a noticeable reduction in the chloride threshold from OPC to fly ash (i.e., PFA) to LC3 systems (from about 0.4 to 0.1 % by weight of binder), which can be attributed to the lower pH in the PFA and LC3 systems.

| Table 3. Chloride thresholds of various steel-cementitious systems (determined using hr-ACT test) | ||||||||

| Water-binder ratio | Type of binder | Type of steel | Chloride threshold (%bwob) | |||||

| Mean | Coefficient of variation | |||||||

| 0.4 | OPC | Uncoated TMT/QST steel | 0.47 | 0.10 | ||||

| OPC + fly ash | 0.30 | 0.10 | ||||||

| 0.5 | OPC | Uncoated TMT/QST steel | 0.40 | 0.14 | ||||

| OPC + fly ash | 0.31 | 0.16 | ||||||

| OPC | Prestressing teel – Unstressed | 0.40 | 0.17 | |||||

| OPC + fly ash | 0.23 | 0.15 | ||||||

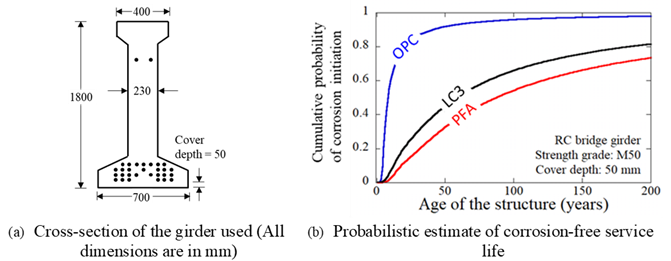

Nevertheless, one should note that achieving long service life is a consequence of the synergistic effect of many parameters (primarily the chloride diffusion coefficient, ageing factor and chloride threshold). In order to demonstrate the potential to enhance the service life of reinforcement concrete structures under chloride exposure through the incorporation of blended binders, a bridge girder (see Figure 13a) having a cover depth (d) of 50 mm, and exposed to a surface chloride concentration of 0.8% by weight of binder, is considered. The cumulative probabilities of corrosion initiation were obtained using the solution of Fick’s 2nd Law of Diffusion, in a MATLAB® programme SL-Chlor, considering d, D cl and Cl th as random variables (Pillai et al. 2018; Rengaraju, 2019). Figure 13a shows that SCM based systems can generally yield much longer service lives than the OPC systems.

8. Carbonation resistance

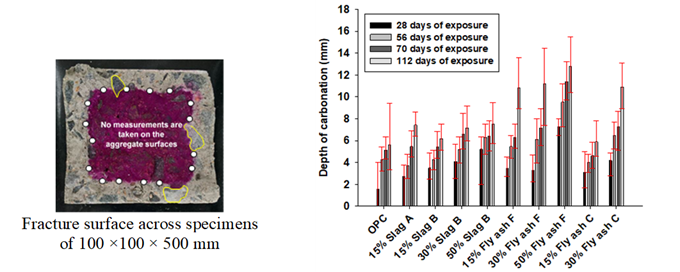

The resistance to the penetration of CO2 is generally good in OPC systems because of the high calcium hydroxide buffer. However, due to prolonged pozzolanic reactions, SCM-based concretes exhibit lower calcium hydroxide buffers and consequently, lower resistance to carbonation. Due to less availability of Ca(OH)2 in SCM based systems, the CO2 is able to carbonate the CSH at an earlier time - leading to rapid progression of the carbonation front. Dhanya (2015) showed, from accelerated carbonation studies under 1% CO2, that carbonation depths in concretes having more than 15% of the OPC replaced with Class F fly ash could be much higher than with only OPC as the binder (see Figure 14). On the other hand, the increase in carbonation for slag-substituted mixes was not significant. Natural carbonation results from recent studies have also shown greater penetration depths for SCM blended concretes. Therefore, corrosion initiation due to carbonation can be expected to occur earlier in concretes with SCMs, if exposed without any coating. However, the propagation of corrosion would still depend on the availability of moisture and oxygen, as well as on the conductivity (or conversely, resistivity) of the medium - these factors are expected to compensate and yield a situation favourable to the SCMs. Considering all these aspects it is possible to effectively design an SCM based concrete for situations where carbonation could govern the durability. Hence, it is cautioned not to refrain from using concretes with SCMs - rather engineers could adopt mitigation measures, such as anti-carbonation coatings, to compensate for the adverse effects due to potentially faster carbonation.

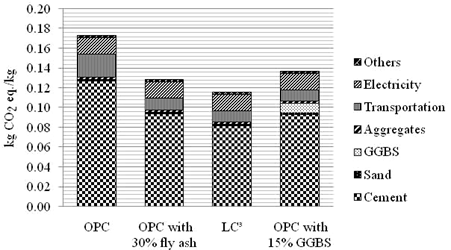

9. Carbon footprint

Partial substitution of OPC with SCMs can lead to significant reduction in the CO2 emissions associated with the production of cement; and hence, the production of concrete. In order to quantify the positive aspects related to the carbon footprint and environmental impact of concretes with blended binders, extensive investigations have been undertaken at IIT Madras using life cycle assessment (LCA) performed with data from various cement plants in India (Gettu et al., 2016, 2018, 2019). Figure 15 shows the CO2 emissions obtained for one of the case studies considering M50 concretes. These values are in the ranges reported in the literature; e.g., Flower and Sanjayan (2007) gave values of about 0.13 kg/kg for OPC concrete, and the embodied carbon values given by Hammond and Jones (2008) yield CO2 emissions of 0.13-0.16 kg/kg. More importantly, the plots indicate that in concretes with only OPC, more than 75% of the CO2 emissions are associated with the cement, while the majority of the remaining 25% of the CO2 emissions is associated with the transportation and electricity. This is also in agreement with the observations of Flower and Sanjayan (2007) and Marceau et al. (2007). Upon replacement of OPC with SCMs or blended binders, significant reduction in emissions is observed. It is seen that the use of fly ash and GGBS decreases the CO2 emissions by about 26% and 21% - similar to ranges reported by Flower and Sanjayan (2007). The LC3 concretes are very promising in terms of CO2 emissions, with a 30-35% reduction compared to OPC concretes with similar compressive strengths. In general, the use of locally available SCMs at higher dosages leads to significant reduction in the carbon footprint of concrete industry.

Figure 15.

Carbon dioxide emissions for M50 concretes with different binders (Gettu et al., 2016)

10. Conclusions

For more than a decade, researchers at IIT Madras have been working on several aspects of SCMs and their performance in reinforced concrete systems. Various aspects related to fresh properties, hardened properties and durability (corrosion and transport) properties have been studied. Based on such studies with relevance to the Indian context, the following conclusions can be drawn:

11. Acknowledgements

Many researchers have been cautioning against unrestricted use of SCMs in concrete construction and drawing attention to possible negative repercussions of using them. On the other hand, it is evident that the SCMs provide, debatably, the most viable option for sustainable concrete technology. This work is an acknowledgement of the arguments given by these researchers over the years, and an attempt to provide a balanced view, based on extensive experimental studies carried out over more than a decade. The authors express deep gratitude to their research scholars, students and project staff for their dedication and hard work that has led to the many interesting and important results obtained, such as those summarised in this paper. They have made possible the many projects, which have been taken to successful completion. These works have been carried out mainly in the Construction Materials Research Laboratories of the Department of Civil Engineering, including the IIT Madras-Lafarge Laboratory for Durability and Long-term Performance of Concrete; the help of the staff of these facilities is gratefully acknowledged. Thanks are also due to the sponsors and funding agencies for their generous support in the various phases of our research work over the years. This paper is a revised version of that corresponding to a keynote lecture at the 3rd RN Raikar Memorial International Conference on Advances in Science & Technology of Concrete, Mumbai, 2018, and appearing in its proceedings. The previous version was also adapted and translated to Spanish for the Revista Hormigón, (ISSN-0325-8947) in 2019.

References

Chatterjee, A. K. (2018). Cement production technology: Principles and practice. CRC Press, Boca Raton, USA, 419 p.

Dhandapani, Y., Santhanam, M. (2017). Assessment of pore structure evolution in the limestone calcined clay cementitious system and its implications for performance. Cement and Concrete Composites, 84:36-47. https://doi.org/10.1016/j.cemconcomp.2017.08.012

Dhandapani, Y., Sakthivel, T., Santhanam, M., Gettu, R., Pillai, R. G. (2018). Mechanical properties and durability performance of concretes with limestone calcined clay cement (LC3). Cement and Concrete Research, 107:136-151. https://doi.org/10.1016/j.cemconres.2018.02.005

Dhandapani, Y., Santhanam, M. (2020), Investigation on the microstructure-related characteristics to elucidate performance of composite cement with limestone-calcined clay combination, Cement and Concrete Research, 129, 22 p. https://doi.org/10.1016/j.cemconres.2019.105959

Dhanya, B. S. (2015). Study of the influence of supplementary cementitious materials on selected durability parameters of concrete, Doctoral Thesis, IIT Madras, Chennai, India, 361 p.

Dhanya, B. S., Santhanam, M. (2017). Performance evaluation of rapid chloride permeability test in concretes with supplementary cementitious materials, Materials and Structures, 50:67, 9 p. https://doi.org/10.1617/s11527-016-0940-3

Dhir, R. K., Jones, M. R., Eds. (1994). Euro-cements: Impact of ENV 197 on concrete construction, Proc. National Seminar (Dundee, UK). E&FN Spon, London, 240 p.

Flower, D. J. M., Sanjayan, J. G. (2007). Green house gas emissions due to concrete manufacture. The International Journal of Life Cycle Assessment, 12:282. https://doi.org/10.1065/lca2007.05.327

Gettu, R., Patel, A., Rathi, V., Prakasan, S., Basavaraj, A. S., Maity, S. (2016). Sustainability assessment of cements and concretes in the Indian context: Influence of supplementary cementitious materials, Proc. Fourth Intnl. Conf. on Sustainable Construction Materials and Technologies (Las Vegas, USA), Eds. N. Ghafoori, P. Claisse, E. Ganjian and T.R. Naik, paper S299, 142-1150.

Gettu, R., Pillai, R. G., Santhanam, M., Basavaraj, A. S., Rathnarajan, S., Dhanya, B. S. (2018). Sustainability-based decision support framework for choosing concrete mixture proportions. Materials and Structures, 52 (122), 17 p. https://doi.org/10.1617/s11527-019-1425-y

Gettu, R., Patel, A., Rathi, V., Prakasan, S., Basavaraj, A. S., Palaniappan, S., Maity, S. (2019). Influence of supplementary cementitious materials on the sustainability parameters of cements and concretes in the Indian context, Materials and Structures, 52:10, 11 p. https://doi.org/10.1617/s11527-019-1321-5 .

Hammond, G. P., Jones, C. I. (2008). Embodied energy and carbon in construction materials. Proceedings of the Institution of Civil Engineers, Energy 161(2): 87-98. https://doi.org/10.1680/ener.2008.161.2.87

Jayasree, C., Gettu, R. (2008). Experimental study of the flow behaviour of superplasticized cement paste. Materials and Structures, 41:1581-1593. https://doi.org/10.1617/s11527-008-9350-5

Jayasree, C., Gettu, R., (2010). Correlating properties of superplasticized paste, mortar and concrete. Indian Concrete Journal, 84(7):7-18.

Jayasree, C., Gettu, R. (2012). “Choice of compatible cement-superplasticizer combinations", ICI J. (Indian Concrete Institute), 12(4): 14-31.

Jayasree, C., Murali Krishnan, J., Gettu, R. (2011). Influence of superplasticizer on the non-newtonian characteristics of cement paste, Materials and Structures, 44(5): 929-943. https://doi.org/10.1617/s11527-010-9677-6

John, E., Gettu, R. (2014). Effect of temperature on flow properties of superplasticized cement paste, ACI Materials Journal, 111(1): 67-76.

Jose, S., Gettu, R., Indhuja, S. (2018). Flexural toughness characterization of steel, polymer and glass fibre reinforced concrete based on the notched beam test, The Indian Concr. J., 92(2): 35-50.

Malhotra, V. M., Ramezanianpour, A. A., (1994). Fly ash in concrete, 2nd ed., Canada Centre for Mineral and Energy Technology, Ottawa, 307 p.

Marceau, M., Nisbet, M. A., Van Geem, M. G. (2007). Life cycle inventory of portland cement concrete, Portland Cement Association, Skokie, Illinois, USA, 121 p.

Mehta, P. K., Ed., (1999). Concrete technology for sustainable development in the twenty-first century, Proc. Intnl. Symp. (Hyderabad). Cement Manufacturers’ Association, New Delhi, 538 p.

Mehta, P. K. (2001). Reducing the environmental impact of concrete, Concrete International., 23(10):61-66.

Mohan, M. K. (2019). Flowable, bleed resistant cementitious grouts and performance specifications for applications in post-tensioned concrete systems, MS Thesis, Department of Civil Engineering, IIT Madras, Chennai, 149 p.

Nair, V. G. N. (2018). Experimental study of the flow behaviour of superplasticized pastes and concretes with limestone calcined clay cement (LC3). MS Thesis, Department of Civil Engineering, IIT Madras, Chennai, 119 p.

Nayar, S. K., Gettu, R. (2015). Synergy in Toughness by Incorporating Amorphous Metal and Steel Fibers, ACI Mater. J., 112(6): 821-827. https://doi.org/10.14359/51687857

Nayar, S. K., Gettu, R. (2016). Benefits of using amorphous metallic fibres in concrete slabs-on-grade, RILEM Technical Letters, 122-128. https://doi.org/10.21809/rilemtechlett.2016.20

Nayar, S. K., Gettu, R. (2020). Mechanistic-empirical design of fibre reinforced concrete (FRC) pavements using inelastic analysis, Sādhanā, 45:19, 7 p. https://doi.org/10.1007/s12046-019-1255-1

Pillai, R. G., Gettu, R., Santhanam, M., Rengaraju, S., Dhandapani, Y., Rathnarajan, S., Basavaraj, A. S. (2018). Service life and life cycle assessment of reinforced concrete systems with limestone calcined clay cement (LC3). Cement and Concrete Research, 118: 111-119. https://doi.org/10.1016/j.cemconres.2018.11.019

Rengaraju, S., Godara, A., Alapati, P., Pillai, R. G. (2018), Macrocell corrosion mechanisms of prestressing strands in various concretes, Mag. Concr. Res. (ICE, UK), 72(4): 194-206. https://doi.org/10.1680/jmacr.18.00284

Rengaraju, S. (2019), Electrochemical response and chloride threshold of steel in highly resistive concrete systems, Ph.D. Thesis, Department of Civil Engineering, IIT Madras, Chennai, 252 p.

Rengaraju, S., Neelakantan, L., Pillai, R. G. (2019), Investigation on the polarization resistance of steel embedded in highly resistive cementitious systems-An attempt and challenges, Electrochimica Acta, 308: 131-141. https://doi.org/10.1016/j.electacta.2019.03.200

Sakthivel, T. (2019). Effect of the incorporation of slag, fly ash, and limestone calcined clay on the compressive strength, elastic modulus and shrinkage of concrete, Ph.D. Thesis, Department of Civil Engineering, IIT Madras, Chennai, 194 p.

Sakthivel, T., Gettu, R., Pillai, R. G. (2019). Compressive strength and elastic modulus of concretes with fly ash and slag. J. Institution of Engineers (India): Series A, 10 p. https://doi.org/10.1007/s40030-019-00376-w

Sangoju, B., Gettu, R., Bharatkumar, B. H., Neelamegam, M. (2011). Chloride-induced corrosion of steel in cracked OPC and PPC concretes: Experimental study, Journal of Materials in Civil Engineering, 23(7): 1057-66. https://doi.org/10.1061/(ASCE)MT.1943-5533.0000260

Sangoju, B., Pillai, R. G., Gettu, R., Bharatkumar, B. H., Iyer, N. R. (2015). Use of portland pozzolana cement to enhance the service life of reinforced concrete exposed to chloride attack, Journal of Materials in Civil Engineering, 27(11): 04015031, 8 p. https://doi.org/10.1061/(ASCE)MT.1943-5533.0001293

Scrivener, K., John, V. M., Gartner, E. M. (2017). Eco-efficient cements: Potential economically viable solutions for a low-CO 2 cement-based materials industry. United Nations Environment Programme, Paris, 50 p.

Sirajuddin, M., Gettu, R. (2018). Plastic shrinkage cracking of concrete incorporating mineral admixtures and its mitigation. Materials and Structures, 51(48), 10 p. https://doi.org/10.1617/s11527-018-1173-4

Stephen, S. J., Gettu, R. (2019a). Rate-dependence of the tensile behaviour of fibre reinforced concrete in the quasi-static regime, Materials and Structures, 52:107, 9 p., with Supplementary Material published online, 6 p. https://doi.org/10.1617/s11527-019-1405-2

Stephen, S. J., Gettu, R. (2019b). Fatigue response of cracked fibre reinforced concrete, Proc. Intnl. Conf. on Innovative Materials for Sustainable Civil Engineering, RILEM Week (Nanjing, China), p. 6.