| Documental Research | https://doi.org/10.21041/ra.v10i2.476 |

Recommendations for rehabilitation and corrosion protection of a 100-year-old steel bridge (Durgadee) across heavily polluted river near Mumbai, India

Recomendações para reabilitação e proteção contra a corrosão de uma ponte metálica de 100 anos de idade (Durgadee) sobre um rio fortemente poluído perto de Mumbai, Índia

Recomendaciones para la rehabilitación y protección contra la corrosión de un puente de acero de 100 años de antigüedad (Durgadee) sobre un río muy contaminado cerca de Mumbai, India

S. S. Bhonge1 , P. Dalwi2 , J. K. Kulkarni3 , S. K. Manjrekar4

1 The Superintending Engineer, Designs Circle (BR), P.W.D., Govt of Maharashtra, India..

2 Executive Engineer, PW Division Thane, India..

3 Retired Executive Engineer, MIDC, Govt of Maharashtra, Mumbai, India..

4 Director, Sunanada Speciality coatings, Mumbai, Hon. Member ACI India, India..

*Contact author: bhongess@gmail.com

Reception: December 09, 2019.

Acceptance: April 15, 2020.

Publication: April 30, 2020.

| Cite as: Bhonge, S. S., Dalwi, Pradeep, Kulkarni, J. K., Manjrekar, S. K. (2020), "Recommendations for rehabilitation and corrosion protection of a 100-year-old steel bridge (Durgadee) across heavily polluted river near Mumbai, India", Revista ALCONPAT, 10 (2), pp. 259 – 273, DOI: http://dx.doi.org/10.21041/ra.v10i2.476 |

Abstract

This paper describes the rehabilitation proposal, methodology of evaluation of distress and likely remedial measures for 100 years old steel bridge on Ulhas river, near Mumbai. The bridge is constructed in year 1914 during British era apparently now heritage bridge as it was constructed with unique structural arrangement of jack arch decking and warren truss girder with verticals. After structural audit in 2000, it revealed the deterioration of steel parts and concrete initiated long back because of humid atmosphere and pollution in the area. Durgadee bridge showed various signs of bridge distress like major cracks in masonry abutments, heavy corrosion of Mild Steel (MS) structural members, non -functioning of expansion joints and bearings, failure of jack arch roof plates, de-bonding of concrete and exposed reinforcement etc. Paper discusses recommendations for rehabilitation and corrosion protection.

Keywords:

corrosion protection,

rehabilitation,

distress,

steel structure,

LCNR

Resumo

Este artigo descreve a proposta de reabilitação, metodologia de avaliação de perda de capacidade resistente e prováveis medidas corretivas para uma ponte metálica de 100 anos de idade no rio Ulhas, perto de Mumbai. A ponte foi construída no ano de 1914, durante a era britânica, agora como ponte histórica, uma vez que foi construída com arranjo estrutural exclusivo de decks em arco e viga vertical treliçada. Após uma inspeção estrutural em 2000, foi revelada a deterioração dos elementos de aço e concreto iniciadas há muito tempo por causa da atmosfera úmida e da poluição na área. A ponte Durgadee mostrou vários sinais de deterioração da sua estrutura, como grandes fissuras nos pilares de alvenaria, corrosão avançada dos elementos metálicos estruturais, não funcionamento das juntas de dilatação e aparelhos de apoio, falha das chapas metálicas do deck em arco, desplacamento do concreto e armadura exposta. O documento discute recomendações para reabilitação e proteção contra corrosão.

Palavras-chave:

proteção contra corrosão,

reabilitação,

perda de capacidade resistente,

estrutura de aço,

LCNR.

Resumen

Este artículo describe la propuesta de rehabilitación, metodología de evaluación de daño y las posibles medidas correctivas para el puente de acero de 100 años en el río Ulhas, cerca de Mumbai. El puente se construyó en el año 1914 aparentemente durante la era británica, ahora puente patrimonio ya que se construyó con una disposición estructural única de cubierta de arco plano y vigas de celosía con verticales. Después de una auditoría estructural en el año 2000, se reveló el deterioro de las piezas de acero y concreto iniciado desde hace mucho tiempo debido a la atmósfera húmeda y la contaminación en el área. El puente Durgadee mostró varios signos de daño como grietas importantes en los pilares de mampostería, corrosión intensa de los miembros estructurales de acero dulce (MS), disfuncionalidad de las juntas de expansión y los cojinetes, falla de las placas de techo del arco plano, desprendimiento de concreto y refuerzo expuesto, etc. El artículo discute recomendaciones para rehabilitación y protección contra la corrosión

Keywords:

protección contra la corrosión,

rehabilitación,

daño,

estructura de acero,

LCNR.

1. Introduction

This paper describes the need for rehabilitation proposal, methodology of evaluation of distress and likely remedial measures for 100 years old steel bridge (also known as Durgadee bridge) on Ulhas River at km 1/ 800 on Bhiwandi road, Kalyan, near Mumbai.

The bridge is constructed in year 1914 during British era apparently now heritage bridge as it was constructed by British engineers with unique structural arrangement of jack arch decking and warren truss girder with verticals. The bridge is a steel structure with two columns filled with concrete with Steel superstructure consisting of jack arch type deck support sheet.

Steel structures in severe atmosphere must face a variety of environmental forces. Although several deteriorating processes, chemical attack still represent severe challenges and problems to many important steel structures. Rapid development in technology in recent years has made easier to control such deteriorating processes.

Structural steel offers several advantages:

High strength: the yield stress of steel in tension and compression is almost the same which helps us in the use of steel as long span bridges and tall structures.

Durability: this property of steel allows successive deformation without significant loss of strength and stiffness including resistance to weathering action.

Prefabrication: steel parts are manufactured at factory under strict supervision and quality control due to which there is a very less variation in material properties. The material can be transported at site and assembled which helps in speedy construction ensuring better quality.

Demountability: steel structure can be disassembled and reused if required. It can be recycled easily reducing the wastage. Even the repairs and retrofitting of steel structure and their strengthening is much simpler and easier than the concrete structure.

Limitations: steel structure are susceptible to corrosion when exposed to air and water.

Although structural Steel are not combustible, they lose their strength rapidly during fire. Aesthetically, steel structure does not give pleasing appearance. The cost of steel structure is more than that of concrete

The choice of section in steel structure is governed by:

2. General- indian scenario

India is home to various geographical features such as rivers, mountains, valleys, tablelands, long seashores, deserts, and flat terrains. India is the seventh largest country in the world and covers a total area of 3,287,263 sq km. The shoreline of the country extends for 7,517 km.

India has one of the largest road networks in the world with about 59 lakh km of road length including National Highways (NHs), Expressways, State Highways, District roads, Other District Road and Village roads. In India, road infrastructure is used to transport over 60% of total goods and 85% of total passenger traffic. India has inventoried more than 4 lakh bridges/structures constructed through various Government bodies.

The bridges in coastal areas were constructed in the face of several adverse factors, such as difficulty of fixing water way, navigational requirements, approach alignments, foundation problems, saline conditions, difficulty of construction of superstructure and approach banks, Navigational requirements. These in turn, sometimes required bridges having long spans involving sophisticated construction procedures. Foundations were usually deep in the creek bridges and standing water posed major problem in construction.

Due to extraordinary increase in traffic densities, particularly in and around main cities of the state, the Government has undertaken a program of constructing flyovers, underpasses and bye-pass roads. But before a decision of new construction, priority to rehab and retro fitting of existing bridge is given. As the Durgadee bridge has outperformed and proved its durability because of its robust structural arrangement. Bridge after rehabilitation, can act as bypass for LMV (light and medium vehicles) and city users in the city of Kalyan.

3. Present scenario of durgadee bridge

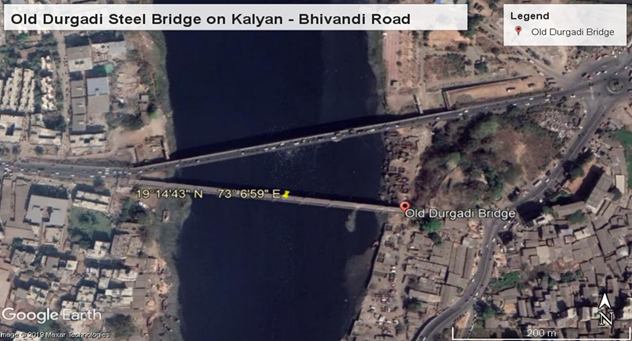

Kalyan is near Mumbai and is historical place and was famous Trade Centre due to Kalyan creek coast. There exists one fort known as Durgadee fort along the side of the bridge which is around 400 years old. Similarly, Bhiwandi is a Taluka place and equally important historical Trade Centre. In early parts of 19th century the British Government decided to connect Kalyan and Bhiwandi by steel bridge across Ullas river near Durgadee fort. The construction of bridge started somewhere in 1908 and was commissioned in 1914. (Bridge site location: 19°14'43" N 73° 6'59" E)

In addition, above, general causes of distress in structure, following have played major role in damaging the structure and reduction in service life.

After structural audit in 2000, it revealed the deterioration of steel parts and concrete initiated long back because of humid atmosphere in the Kalyan area, carbonation of concrete, chloride ingress, leaching, sulphate attack, which all lead to the corrosion and ultimately reduction in life of structure. Bridge is closed for traffic since 2001. Figure 1 shows Google map of bridge.

Any bridge structure in service life will be subjected to chemical and physical changes. A durable structure is one in which these changes occur at a slower rate which does not detrimentally affect its performance within its intended lifespan. As per Indian codes and other contemporary codes, the steel structures are designed for a maintenance-free operating life of 60 to 100 years. However, the various structures in and around Mumbai area show severe deterioration (or failure in many cases) within a very short span due to aggressive environment and humidity in atmosphere. In present case generally aggressive environment added by polluted water of Ulhas river is playing major role for deterioration.

Based on the studies, the water from river cannot be considered safe even for irrigation purpose. The chloride content in the wastewater effluent was with an average value of 1,377 mg/L. The results indicate that the chloride content is very much above the acceptable limit of 200 mg/L set by WHO. The results indicated high level of pollution due to toxic heavy metals like chromium (Cr), cadmium (Cd), nickel 6 (Ni), zinc (Zn), copper (Cu), lead (Pb) and iron (Fe). The concentration of all these heavy metals were found to be much above the acute toxicity level.

Because of heavy pollution in Ulhas river, water and the humidity due to nearness to seashore, the bridge condition is very dilapidated. There is heavy corrosion of steel parts used in the structure. The structure must have been designed for normal river water in 1914. It is however seen that the color of river water is blackish which may be due to mixing of wastewater of surrounding urban areas and industrial waste. River water contains both organic and inorganic chemicals in addition to various gases like H2S, CO2, CH4, and NH3 etc., that are formed due to the decomposition of sewage. This leads to faster deterioration of steel structure and concrete.

Figure 1.

Google map of bridge.

4. Distresses noticed in durgadee bridge

Durgadee bridge showed various signs of distress as under:

State Transport Department (called as PWD) has already stopped the vehicular traffic on the bridge since 2001.

5. Draft policy/ proposed stages of rehabilitation and repair

The whole program of restoration of this bridge can be divided into the following parts.

1. Study of old records related to bridge

2. Inspection

Steel bridge will be inspected with the purpose of identifying any defects that may be present in the structure and to establish causes for these defects. Defects that are likely to affect the strength, safety or serviceability of a bridge are planned to attend as part of the remedial and maintenance work cycle.

3. Study of corrosion parameters related to various bridge components that is corrosion mapping.

4. Various types of NDT (Non-Destructive Testing) to assess the damage

5. Testing of river water.

6. Planning for working platform for working of labor and machinery

Suspended or hanging platform will be needed for working below the soffit. Detailed drawings will be prepared for above cases considering site situation and methodology of repair. Ideally floating pontoon with small boat along with winch machine will be very useful for speedy execution of work. Figure 2 is a photo of bridge showing bearing and expansion joint location.

7. Underwater assessment of the part of the substructure and foundation

Special types of cameras and certified divers will be needed as water due to turbid due to pollution. It will involve underwater videography and taking photographs and Submission survey details in soft copies and status report of underwater survey. Total number of piers to be survey will be 9 piers of bridge.

Figure 2.

Photo of bridge showing bearing and expansion joint location

8. Evaluation of defects

All observed defects will influence the strength or serviceability of the bridge. Defects which reduce the capacity or durability of the bridge do require remedial action. The purpose of evaluation is to determine the relative significance of each defect so that the load-carrying capacity of the bridge can be reassessed and so that any remedial work required can be given proper priority. Evaluation will also assist in determining future strategies for maintenance or replacement.

The evaluation of the effect of some defects requiring a thorough understanding of the behaviour of the structure concerned. The interaction of primary and secondary load-carrying members, the effect of imperfectly pinned joints and the possible presence of alternative load paths need to be appreciated. A basic understanding of metal fatigue and crack mechanics is necessary to evaluate problems of this nature.

9. Analysis of factors to decide methodology of rehabilitation/ strengthening

Structural repair and maintenance of steelwork includes the replacement and maintenance of protective coatings, repair of corroded members, replacement of damaged members and defective fastenings, and remedial work associated with fatigue cracking. These problems have been identified during the inspection and evaluation process.

Fatigue behavior is very much influenced by the presence of stress concentrations such as holes, welds, abrupt changes of shape, cracks or other defects.

10. Residual life Assessment and bridge rating

11. Action plan for Corrosion Protection

The detailed evaluation of corroded material is to be carried out by laboratory testing in ICT (Institute of Chemical Technology), Matunga Mumbai, India and Metallurgical testing of steel at Metallurgical Department, IIT (Indian Institute of Technology) Powai Mumbai, India.

Plan on the various technology and material available for repair and its methodology with reference to economic consideration. Corrosion protection system to protect the bridge for further 25 years including sacrificial anode system to prevent the further corrosion and its damaging action.

12. Selection of appropriate repair, restoration and rehabilitation measures to various structures.

6. Methodology proposed: salient features and parameters to be considered

6.1 Steel girder repair

Figure 3 is a photo of the bridge showing the warren truss type structure. The work of repairing built-up steel girders by restoring or replacing damaged or deteriorated elements include, but is not limited to, providing temporary supports for jacking; modifying girders to accept jacking loads; temporarily supporting or reducing loads carried by girders; disconnecting or removing elements from girders by removing bolts or rivets; drilling and reaming holes; grinding to provide required finish or tolerances on steel surfaces; making minor repairs to decks within the work area; erecting repaired or replaced elements and incidental items by welding or high tensile strength bolting; and preparing surfaces damaged or left bare by the work and applying a prime coat of paint.

Figure 3.

Photo of bridge showing warren truss type structure.

6.2 Protective coating failure

It is rare for a protective coating to outlast the life of the structure. Breakdown of paint or loss of any coating is inevitable and should be anticipated. This usually results from condensation and may be increased by absorption of moisture by wind-borne salts on areas not subject to rain washing. Accumulation of debris, bird droppings, flaking paint etc. will all retain moisture and promote corrosion.

In addition to eventual failure of a coating system by weathering, premature failure may result from:

6.3 Loss of section

Where the protective coating has not been maintained or an area of damaged coating not been repaired, corrosion resulting in a loss of section usually follows. The corrosion rate largely depends on the proximity of the bridge to the coast.

Corrosion can also be accelerated by the following situations:

6.4 Loose or defective fastenings

Whether operating in shear or in a friction grip joint, fastenings must be properly installed to function correctly. Sometimes, because of excessive vibration, over-straining, corrosion or improper installation, fastenings can become loose and should be replaced.

Specific problems typically associated with various types of fastenings are:

6.5 Cracks

Cracking of any bridge component is potentially serious and needs to be thoroughly investigated. Cracks in steel bridge members can be caused by metal fatigue, embrittlement, impact damage or manufacturing defects such as rolling flaws, and can extend with time. Structural cracks are most likely to have started at obvious stress concentrations such as a bolt or rivet hole, extremities of welds, abrupt changes of section, or at nicks and notches.

Fatigue cracks might not become obvious until a member has been subject to many stress reversals or fluctuations.

6.6 Impact damage

Accidental damage to bridge members through vehicle impact is a serious matter and one which needs to be investigated promptly. Obvious damage will usually be in the form of bent and distorted members and overstrained fastenings.

6.7 Deformation and distortion

A structural member's resistance to compressive forces is considerably reduced if components are buckled or distorted out of plane. Tensile members can act unpredictably. Deformation and distortion can occur as a result of:

Deformations cause members designed for tension being forced to take compressive loads.

6.8 Manufacturing defects

Despite the rigorous specifications and the tight manufacturing tolerances to which structural components are rolled and formed, manufacturing and fabrication defects can and do find their way into completed structures.

Rolling flaws may show up as delamination, cracks, blisters, pits or inclusions as well as out-of- tolerance straightness or lack of squareness.

6.9 Faults in detailing

Regrettably, defects can be built into a bridge structure through poor design, detailing and specification. In this category are found such details as:

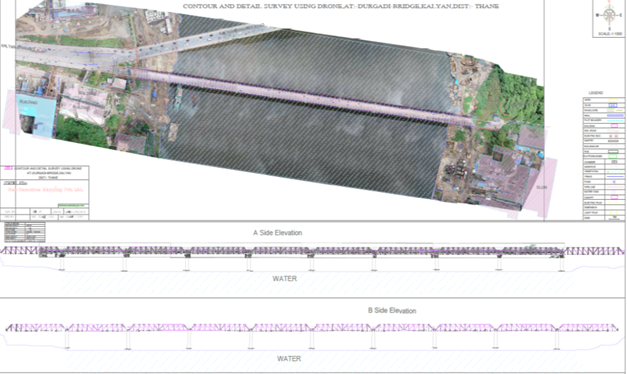

Manufacturing defects as well as design flaws can sometimes be noticed through a drone tour as illustrated in figure 4.

Figure 4.

Drone survey map of bridge

7. Proposed methodology and procedure for corrosion protection

7.1. The Composite Treatment of LCNR (Long Chain Nylon Reticulant) UV (Ultraviolet) Resistant Coating along with Electrochemical Protection by sacrificial anodes

It will be necessary to evolve ‘State of the Art’ corrosion removal, highly adhesive, UV resistant coating system and include electro-chemical protection to further prolong the life of protective system. This paper attempts to choose such composite system based on test parameters and past track records of innovative systems.

The points to be considered for rendering new protective systems:

7.2. Procedure of rectifications

As a result of sand blasting, the corrosion products and residual paint are removed fully, however it also leads to creating a very vulnerable steel surface which is susceptible for ‘flash corrosion’ due to moisture and oxygen in the ambient conditions. This layer of flash rust can be visible within even 2 to 3 hours of sand blasting in the form of reddish iron oxide layer. This layer then onward creates compromise to some extent in the loss of adhesion of subsequent polymer/epoxy/polyurethane coatings.

Rusticide can be applied by cotton waste, soft brush etc. Rusticide not only removes the residual rust but also reacts with corrosion products to convert them to a stable passivating nano film on the surface of the steel and return the steel back to its original grayish white color the steel from flash rusting. As a result of application of Rusticide, the steel surface turns into whitish-black colour.

Epoxy coatings are not to be given as finishing layers as it easily gets disintegrated by ultraviolet rays or any form of external energy.

Sunepoxy 358 is a specially made epoxy primer which has longer chain nylon reticulant molecule which enhances its performance as compared to ordinarily available general epoxy coatings.

After 24 hours of application of Sunepoxy 358, provide and apply 2 coats of Sungard APR using soft paint brush / spray gun, etc. Polyurethane coatings are resistant to attack of ultraviolet rays. However, in case of Sungard APR the normal polyurethane molecule has been added with the characteristics of acyclic polyisocyanate reticulantness, making the matrix more complex due to additional cross linking and hence added denseness of the cured polymer. This adds to the robustness and protection to a higher degree.

There will be need of Rollers with long handles (metal sticks), spike shoes on horizontal surfaces.

The placement of sacrificial anodes shall be more focused at gusset plate weld joints and at major junctions etc. Where the possibility of proper protective coating will be difficult.

8. Preventive maintenance

8.1 The preventive maintenance of a steel bridge starts after completion of rehabilitation as proposed above.

Provision of access to facilitate future inspections and maintenance should also be considered. Other practices which will assist in minimizing maintenance of an in-service bridge include:

8.2 Bridge instrumentation systems for dynamic monitoring of bridge.

Baseline model development of a bridge is essential for structural health monitoring which can play an important role in securing system integrity, minimizing maintenance cost, and maintaining longevity of bridges. Structural health monitoring and baseline model are required periodically, especially after damaging earth quacks, degradation of a structure due to aging or environmental actions or if there is a damage-causing event such as impact due to accident or natural disaster.

Global structural health monitoring technology consists of two aspects: (1) Instrumentation of bridges with sensors such as accelerometers and strain gauges and more importantly, (2) Methodologies for obtaining meaningful information concerning the structural health conditions, if any, from the measured data.

Advances in sensing, digitizing, recording, and data communications have led to current monitoring systems capable of sensing, recording, and remotely analyzing/displaying dynamic input and response information for bridges and other structures.

The current generation of sensors for earthquake accelerometers has large dynamic ranges, allowing simultaneous measurement of earthquake shaking, low-frequency wind-induced vibration, and ambient vibration.

Proposed baseline model development of this bridge, which will be instrumented for global structural health monitoring. Monitoring systems including accelerometers, strain gauges, pressure sensors, and displacement sensors to be installed.

A structural health monitoring system may detect unusual structural behavior at an early stage, thereby reducing the risk of sudden and catastrophic failure. Appropriate monitoring requires the development of an accurate computer model that effectively characterizes the entire structure, including the continuity and boundary conditions.

9. Conclusion

The steel bridge though has outlived its service life; however, it is still in serviceable condition with Engineered Strengthening and Corrosion protection. It also enjoys status of Heritage structure. Appropriate strengthening of steel and concrete deterioration is brought out. Its service life enhancement can be done with Life 365 Model of ACI since the damage and rectification is focused around with enhanced properties coatings and the attack of chloride and other aggressive pollutants. Major emphasis in corrosion control will be creating long term barriers for protection against heavy pollutants to come in contact of steel. Protective treatment is also suggested considering coastal conditions of Mumbai and around. The protection program is drawn on the basis of successful past track record of similar structure in similar conditions. The restoration will serve purposes like retaining heritage structure at the same time it will be useful for at least LMV for few more years reducing traffic load on the existing bridge.

10. Acknowledgements

The authors acknowledge the support of Designs Circle, PWD, Govt of Maharashtra, Mumbai and PW Division (Thane), Thane in writing of this paper.

References

Malhotra, M. M. (2007), Design od steel structure. Edition: 7, Reprint Publisher: Jain Brothers.

Indian Road Congress (IRC) (1990), IRC: SP:35-1990: Guidelines for Inspection and Maintenance of Bridges. (Reprint-2000), Indian Road Congress Special Publication. New Delhi.

Indian Road Congress (IRC) (1996), IRC: SP:18-1996: Manual for Highway Bridge Maintenance Inspection. Indian Road Congress Special Publication. New Delhi..

Indian Road Congress (IRC) (1999), IRC: SP:52-1999: Bridge Inspector’s Reference Manual. Indian Road Congress Special Publication. New Delhi.

Indian Road Congress (IRC) (2007), IRC: SP:74-2007: Guidelines for Repair and Rehabilitation of Steel Bridges. Indian Road Congress Special Publication. New Delhi.

Indian Road Congress (IRC) (2008), IRC: SP:75-2008: Guidelines for Retrofitting of steel Bridges by Pre-stressing. Indian Road Congress Special Publication. New Delhi.

Indian Road Congress (IRC) (2002), IRC: SP:60-2002: An Approach Document for Assessment of Remaining Life of Concrete Bridges. Indian Road Congress Special Publication. New Delhi.

Indian Road Congress (IRC) (2004), IRC SP 61-2004: An Approach Document on Whole Life Costing for Bridges in India. Indian Road Congress Special Publication. New Delhi.

Indian Road Congress (IRC) (1993), IRC: SP:40-1993: Guidelines on Techniques for strengthening and Rehabilitation of Bridges. Indian Road Congress Special Publication. New Delhi.

Indian Road Congress (IRC) (2010), IRC: SP:37-2010: Guidelines Evaluation of Load Carrying Capacity of Bridges. Indian Road Congress Special Publication. New Delhi.

MPCP (2019), Maharashtra State Pollution Control Board (MPCP), URL: http://www.mpcb.gov.in/node

Maharashtra Pollution Control Board (2015), Comprehensive Study on Polluted River Stretch of Ulhas River - Downstream of Mohane, Kalyan, MPCB Kalyan.

Karve, S. R., Shah, V. I. (1998), Structural Design Databook Steel Structures, Structures Publications.

NZ Transport Agency (2001), Bridge Inspection and Maintenance Manual. URL: https://www.nzta.govt.nz/resources/bridge-inspection-maintenance-manual/