| Applied Research | https://doi.org/10.21041/ra.v10i1.426 |

Polymeric fiber reinforced concrete exposed to fire

Concreto reforçado com fibras poliméricas exposto ao fogo

Hormigón reforzado con fibras poliméricas expuesto al fuego

D. M.

Dias1

*

![]() ,

J. L.

Calmon1

,

J. L.

Calmon1

![]() ,

G. L.

Vieira1

,

G. L.

Vieira1

![]()

1 Federal University of Espírito Santo, Vitória-ES, Brazil.

*Contact author: dainerdias@gmail.com

Reception:

July

01,

2019.

Acceptance:

November

27,

2019.

Published: 30 December 2019.

| Cite as: Dias, D. M., Calmon, J. L. Vieira, G. L. (2020), “Polymeric fiber reinforced concrete exposed to fire”, Revista ALCONPAT, 10 (1), pp. 36 – 52, DOI: http://dx.doi.org/10.21041/ra.v10i1.426 |

ABSTRACT

The aim of this work was to investigate the influence of the addition of polypropylene, polyester, polyamide, aramid and aramid pulp fibers on the behavior of concretes subjected to high temperatures. For that, test specimens with fiber additions were made at a rate of 2 kg/m3 and submitted to temperatures in furnace, as well as to high temperatures through direct fire test. Columns were also built and subjected to a live fire simulator belonging to the Espírito Santo Fire Department - Brazil. Microstructural and mechanical properties were analyzed. It has been observed that the fibers may influence the properties of the concrete and that fire tests with standard fire load may be an alternative or complementary analysis of concrete subjected to elevated temperatures.

Keywords:

Reinforced concrete,

polymeric fibers,

high temperatures,

fire,

mechanical properties.

RESUMO

O objetivo desse trabalho foi investigar a influência da adição de fibras poliméricas de polipropileno, poliéster, poliamida, aramida e polpa de aramida no comportamento de concretos submetidos a temperaturas elevadas. Para tanto, corpos de prova com adições de fibras a uma taxa de 2kg/m3 foram produzidos e submetidos a mufla, bem como a altas temperaturas através de teste de fogo direto em grelha. Protótipos também foram construídos e submetidos a simulador de incêndio real pertencente ao Corpo de Bombeiros do Espírito Santo - Brasil. Propriedades microestruturais e mecânicas foram analisadas. Observou-se que as fibras podem influenciar as propriedades do concreto e que os ensaios de teste de fogo com carga de incêndio padrão podem ser uma alternativa ou complementar análise de concreto submetido a temperaturas elevadas.

Palavras-chave:

Concreto reforçado,

fibras poliméricas,

altas temperaturas,

incêndio,

propriedades mecânicas.

RESUMEN

El objetivo de este trabajo fue investigar la influencia de la adición de fibras poliméricas de polipropileno, poliéster, poliamida, aramida y pulpa de aramida en el comportamiento de hormigones sometidos a temperaturas elevadas. Las probetas con adiciones de fibras a una tasa de 2 kg/m3 fueron producidas y sometidas a altas temperaturas a través de pruebas en horno y de fuego directo. También se construyeron columnas y se sometieron a un simulador de incendios en vivo perteneciente al Departamento de Bomberos de Espírito Santo - Brasil. Se analizaron las propiedades microestructurales y mecánicas. Se observó que las fibras pueden influir en las propiedades del concreto y que los ensayos de fuego con carga de incendio estándar pueden ser una alternativa o complemento para el análisis de hormigón sometido a temperaturas elevadas.

Palabras clave:

hormigón reforzado,

fibras poliméricas,

altas temperaturas,

fuego,

propiedades mecánicas.

1. Introduction

Large fires have already severely compromised various structures throughout history (Metha and Monteiro, 2008). Structural fire safety is one of the most important considerations that should be applied in constructions (Khalaf and Huang, 2016). The behavior of concrete under the action of aggressive agents has long been the subject of studies in the fields of technology and durability of concretes (Petrucci, 1981).

Ma et al. (2015), Haddad et al. (2008), Cree et al. (2013) and Park and Yim (2016) showed that the high temperature is known to seriously damage the micro and the mesostructure of the concrete, what causes a general mechanical decay and even harmful effects at the structural level due to the cracking of the concrete and the exposure of the steel to the flames in case of fire.

The behavior of a real fire is very different from most furnace tests. In a performance-based approach, a more realistic representation of fire can be used, what consists of a heating phase followed by a cooling phase until it returns to room temperature (Gernay and Franssen, 2015). Real fire tests are important to understand the true behavior of concrete in fires, since conventional laboratory tests do not always reflect the behavior of this pathological situation. Just as the fire resistance of constructed structures is greater than that predicted from tests on individual element (Lennon et al., 2007), it is observed that traditional methods of testing materials are more conservative than fire tests.

The use of fibers in concrete has become popular, mainly because of the resistance to cracking, plastic retraction and increased tenacity, and, more specifically, the polymeric fibers give the concrete a better post-cracking behavior, prevent and control the formation and propagation of cracks and also avoid the phenomenon of spalling (Alhozaimy et al., 1996; Kurtz and Balaguru, 2000; Ezziane et al., 2015; Poon et al., 2004). Already Pai and Chandra (2013) said a better understanding of the concepts behind fiber reinforcement, new manufacturing methods and new types of organic fibers have led researchers to conclude that synthetic and natural fibers can reinforce concrete.

In a fire, the fibers melt at a certain temperature, which assists in the release of water vapor through the pores (Pliya et al., 2011). The additional porosity and the small channels created by the melting of the polypropylene fibers can decrease the internal vapor pressure in the concrete and reduce the probability of spalling (Noumowe, 2005), especially in high strength concrete.

Lee et al. (2012) remember that the addition of fibers to concrete has been suggested by several researchers since the first documents discussed the fire resistance of concrete, like the ACI report in 1919 (ACI, 1919). However, the discussion about the positive influence of polymer fibers on the mechanical properties of concrete is not yet finalized because, although some studies indicate that fibers do not significantly influence or worsen the properties of a reference concrete, other studies have shown the opposite, before and after. After being subjected to high temperatures, the fibers can improve the mechanical properties of concrete, as demonstrated by Shihada (2011) and Drzymala et al. (2017).

Studies have shown that polypropylene fibers are effective in mitigating spalling in concretes exposed to high temperatures (Ezziane et al., 2015; Xiao and Falkner, 2006; Behnood and Ghandehari, 2009; Bangi and Horiguchi, 2012; Akca and Zihnioǧlu, 2013) and that the addition of polypropylene fibers is the most widely used method in preventing spalling in high strength concrete. Song et al. (2005) evaluated the effects of addition of nylon and polypropylene fibers and showed that the compressive strength of the concretes increased, respectively, 12.4% and 5.8% when compared to the concrete without fibers. Regarding to polyester fibers, and depending on the percentage used, the addition of fibers may contribute to the increase of the compressive strength of the concrete, as Suresh et al. (2014) concluded. In an ideal dosage, the polyester fibers improved the compressive strength and flexural tensile strength of the concrete exposed to high temperatures in the range of 150-250°C during intervals of 1,2 or 3 hours (Sekhar and Raju, 2017). The addition of polyester fibers in the concrete can contribute to a failure delay of normal concrete when subjected to a sustained temperature range of 25 to 400 ° C (Suresh et al., 2014). Aramid fiber is still uncommon for the construction industry (Çavdar, 2013), showing that it can be better studied.

Therefore, due to the existing gaps and the importance of the theme, the objective of this work was to investigate the influence of the addition of polypropylene, polyester, polyamide, aramid and aramid pulp fibers in the behavior of concretes subjected to elevated temperatures through different tests. For that, test specimens with fiber additions were made at a rate of 2 kg/m3. The samples were submitted to temperatures of 300°C, 500°C and 700°C in furnace, as well as at high temperatures through direct fire test. Short columns were also built and subjected to fire through a live fire simulator belonging to the Espírito Santo Fire Department - Brazil. Compressive strength, flexural tensile strength, splitting tensile strength, mass loss and ultrasonic pulse velocity tests were subsequently performed.

2. Experimental program

2.1 Materials and mix proportions

For the preparation of the concrete, Portland cement CP III 40 RS, according to classification in standard (ABNT, 2018) was used. Natural sand of fineness modulus of 1.92 and maximum dimension of 2.4 mm was used as fine aggregate. Two types of granitic aggregate were used in the concrete as coarse aggregate, one of maximum size of 19 mm and one with 9 mm. A superplasticizer was used in the preparation of the concretes. Fibers were used at a dosage of 2 kg/m3. Such a dosage was mainly aimed at reducing the possibility of spalling and followed a tendency extracted from the study of the state-of-the-art of better fiber consumption (Poon et al., 2004; Behnood and Ghandehari, 2009; Kim et al., 2013; Lourenço et al., 2011; Bei and Zhixiang, 2016), where the best results were obtained with rate at or very close to it. Typical fiber properties are shown in Table 1.

Table 1.

Properties of fibers

Fiber

Diameter (μm)

Length (mm)

Modulus of elasticity (GPa)

Tensile strength (GPa)

Density (g/cm3)

Melting point (°C)

Polypropylene

12

12

9.0

0.5

0.91

160

Polyester

20-25

15

8.2

0.3 – 0.5

1.34

235

Polyamide

(Nylon 6.6)30

12

5.0

0.9

1.14

260

Aramid

(Kevlar 29/49)14

12

65/125

2.8

1.44

427-482

Aramid pulp Kevlar

2-13

0.5-1.0

65/125

2.8

1.45

423

2.2 Specimen preparations

The proportion of the materials used to concrete mixtures is show in Table 2. Six concretes were produced, the reference without fibers (NF), polypropylene fiber reinforced concrete (PP), polyester fiber reinforced concrete (POL), polyamide fiber reinforced concrete (NY), aramid fiber reinforced concrete (AR) and aramid pulp fiber reinforced concrete (AP).

| Table 2. Mix proportions | ||||||||||

| Material | NF | PP | POL | NY | AR | AP | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| Cimento (kg/m3) | 340 | 340 | 340 | 340 | 340 | 340 | ||||

| Agregado miúdo (kg/m3) | 770 | 770 | 770 | 770 | 770 | 770 | ||||

| Agregado graúdo 9 mm (kg/m3) | 300 | 300 | 300 | 300 | 300 | 300 | ||||

| Agregado graúdo 19 mm (kg/m3) | 842 | 842 | 842 | 842 | 842 | 842 | ||||

| Água (l/ m3) | 170 | 170 | 170 | 170 | 170 | 170 | ||||

| Superplastificante (l/ m3) | 2,85 | 2,85 | 2,85 | 2,85 | 2,85 | 2,85 | ||||

| a/c | 0,5 | 0,5 | 0,5 | 0,5 | 0,5 | 0,5 | ||||

| Fibra (kg/m3) | 0 | 2 | 2 | 2 | 2 | 2 | ||||

| Abatimento (mm) | 190 | 30 | 50 | 70 | 60 | 20 | ||||

| Densidad (kg/m3) | 2471 | 2439 | 2455 | 2457 | 2460 | 2452 | ||||

Cylindrical and prismatic specimens were molded according to NBR 5738 (ABNT, 2015a). The fresh concrete mixtures were tested for workability by slump test according to NBR NM 67 (ABNT,1998). Reinforced concrete short columns with cross section of 20x20cm and height of 1.35m were made soon after.

The specimens remained in moist cure for 28 days. After this period, the specimens were kept in a controlled environment (climatic chamber) for 7 days more with a constant temperature of 23°C and a relative humidity of 77%, close to the reality found in the state of Espírito Santo - Brazil. As the tests of high temperatures are influenced by the humidity and considering that the goal was to test the concrete as close to reality as possible, temperature and humidity control was performed. Conditioning specimens with the objective of providing the internal moisture condition similar to constructed buildings is indicated by ASTM E119 (ASTM, 2018).

2.3 Heating procedures

Before the mechanical tests, the specimens were submitted to high temperature tests in furnace and direct fire. In the furnace, the maximum temperatures reached for analysis were 300, 500 and 700°C. These temperature ranges analyzed (intervals where important transformations take place in concrete) follow a trend found in the state-of-the-art like, for example, Xiao and Falkner (2006), Shihada (2011), Suresh et al. (2014) and Yermak et al. (2017). In a previous study Dias et al. (2017) observed that at higher temperatures concretes lost their structural capacity.

Regarding spalling, a phenomenon that occurs with concrete subjected to high temperatures, factors such as aggregate type, samples size, presence of additives, strength concrete and, mainly, heating rate, influence the appearance or not of spalling. In most cases a temperature higher than 700°C is required to spalling. However, temperatures above 500°C, added to other characteristics, are enough. For example, Akca and Zihnioglu (2013) said that explosive spalling was observed especially in nonfibrous specimens and began after 500°C.

As the real fires in compartments, within its phases, presents an apex point and soon after the decay comes (Hartin, 2018), in the tests performed, after reaching the maximum stipulated temperature, the furnace was turned off. The heating rate used was 10°C/min and the cooling was at room temperature for 24 hours. The furnace tests followed methodologies commonly found in the state-of-the-art for this type of laboratory tests (Ezziane et al., 2015; Poon et al., 2004; Pliya et al., 2011; Shihada, 2011; Pai and Chandra, 2013; Xiao and Falkner, 2006; Behnood and Ghandehari, 2009; Akca and Zihnioǧlu, 2013; Suresh et al., 2014; Sekhar and Raju, 2017; Bei and Zhixiang, 2016; Choumanidis et al., 2016; Srikar et al., 2016; Yermak et al., 2017).

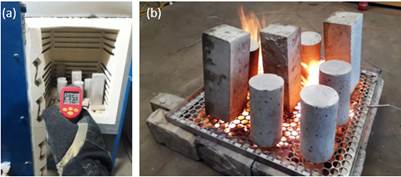

In order to obtain results that could be compared with furnace heating, direct fire tests were also performed according to ISO 834-R (ISO, 2015). To perform the test, the specimens were placed vertically on a steel grill of dimensions of (500x500) mm in a height of 100mm of the combustible material, leaving space between them to have direct contact with the fire. In the tests with real fire, as found in (Shihada, 2011), the fuel material used was wood. The amount of wood used in each test was calculated based on a standard low-risk fire load of 300 MJ/m2 commonly found in apartments in Brazil (CBMES, 2009; Polícia militar do estado de São Paulo, 2011; ABNT, 2000), considering the caloric potential of 19 MJ/kg of wood in each burn. To start the burning, alcohol was used. Two K-type thermocouple sensors were placed in the device to gauge the temperature evolution. The Espírito Santo Fire Department - Brazil (CBMES) supported with knowledge and protective equipment in the realization of the real fire test. This test lasted 80 min, which practically coincided with the end of the combustible material, and the cooling was ambient. The furnace test and the fire test can be seen in Fig. 1

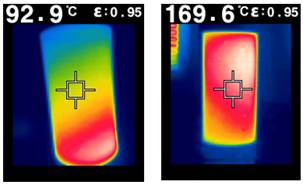

An imaging infrared thermometer was used before, during and after the high temperature tests. Mechanical tests of compressive strength, flexural tensile strength, splitting tensile strength were performed after the high temperature tests. Ultrasonic pulse velocities and mass loss were performed before and after the submission to high temperature.

|

||||

| Fig. 1. Temperature rise through furnace (a) and grill fire test (b). | ||||

Aiming to complement the analysis, especially of the spalling, tests were carried out with real fire in the short columns through one of the CBMES’s live fire simulators. The chosen module provides extreme fire behavior within the first few minutes of fire. Ventilation was controlled through the front doors. The fire load stipulated was also low risk using plywood and pallets. The arrangement of the fire load and the columns in the simulator can be seen in Fig. 2. The mounting followed firing patterns of the fire brigades and aimed to provide reality in the evolution of fire and uniformity of firing. Type k thermocouple sensors were inserted at 0.8m and 1.6m high in the container to gauge the internal temperature and a sensor was monitoring the external temperature. A firefighter with all the necessary personal protective equipment started this simulation. See Fig. 3 for a sequence of photos of the test run.

|

||||

| Fig. 2. Chosen simulator (a), device assembly (b) and sensor arrangement (c). | ||||

|

||||

| Fig. 3. Real fire simulation in columns | ||||

2.4 Test procedures

Compressive strength, flexural tensile strength, splitting tensile strength, mass loss and ultrasonic pulse velocity (UPV) tests were subsequently performed. Macro and microscale analysis were also performed on the specimens.

The verification of the concrete submitted to high temperatures began with visual analysis, observing spalling, cracks and changes of color. Images of fragments of specimens at a depth of 1cm were generated through a scanning electron microscope (SEM), aiming to verify the interfacial transition zone between the aggregate and the mortar matrix, and especially the interaction of the fibers in the concrete and the permanence or not of them in relation to the high temperatures.

The concrete specimens were subjected to the compressive strength test following the procedure of NBR 5739 (ABNT, 2007) after being submitted to high temperatures. The flexural tensile strength was carried out in accordance with the standards found in NBR 12142 (ABNT, 2010), in which it this test method covers the determination of the flexural strength of concrete by the use of a simple beam with third-point loading. In order to complement the analysis of the destructive mechanical tests, the splitting tensile strength test was also carried out. The test followed the regulations of NBR 7222 (ABNT, 2011).

The mass loss was obtained by the ratio between the difference of the mass of the test specimen before and after being subjected to high temperature and the mass before burning, the result being presented in percentage. The non-destructive tests to determine the propagation velocity of longitudinal waves obtained by ultrasonic pulses through concrete specimens were performed based on NBR 8802 (ABNT, 2013), where direct transmission between the transducers was used.

3. Results

It was performed a statistical analysis of the results obtained in the tests to verify if there is a statistical difference in a 95% confidence interval, which reflects a level of significance of 0.05. The analysis of variance (ANOVA) was used, followed by the Tukey’s multiple comparisons test. At first, the results of high temperatures in the furnace were analyzed separately and in a second moment the comparison with the fire test was carried out.

There was no spalling in any test specimens tested. As temperature and humidity were controlled in the cure, it was verified that under normal climatic conditions found in Espírito Santo - Brazil the spalling was mitigated, even in the case of concretes with strengths greater than 50 MPa - concrete class II (ABNT, 2015b).

From an overall analysis, as will be seen in the following topics, greater percentage losses were observed after the 500°C range. This is explained by the fact that heat passes through the interior of the test specimen and by the transformations of the microstructure of the concrete occurring during heating and are more damaging after this range (Ma et al., 2015; Castellote et al., 2004; CEN, 2004; Khoury , 1992).

3.1 Microstructure of the concrete

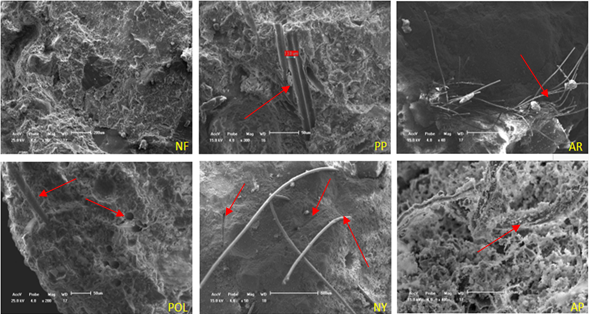

From the generated images, the interaction of the fibers was considered satisfactory. In the furnace tests in the range of 700°C it was not observed the presence of fibers in any concrete, which was to be expected, since the melting point of the all fibers did not exceed 500°C, as seen in Table 1.

The Fig. 4 shows the concretes after being subjected to a temperature of 500°C in furnace.

|

||||

| Fig. 4. SEM of concretes after being subjected to a temperature of 500°C | ||||

It is observed that PP and POL did not contain more fibers after 500°C, that the AR and AP did not lose the fibers in their totality and in the NY there was the partial fusion of the fibers. The temperature applied was 500°C, but it is worth remembering that the heat in the concrete goes through conduction and that is the reason why some fibers of the inner part of the NY remained and others not, that is, at the analyzed point the internal temperature of the concrete was close to 260°C. The arrows in Fig. 4 show this information.

Later it will be seen that NF and AP were the concretes that presented spalling in the live fire simulator test. Correlating with the MEV test it is verified that the lack of porosity to release water vapor influenced the spalling of NF. In the AP, the high fibrillation of the aramid pulp, the surface concentration and the fact that it did not melt were determinant factors for not increasing the porosity of the concrete. More explanations will be given in the topic of Fire test in live fire simulator.

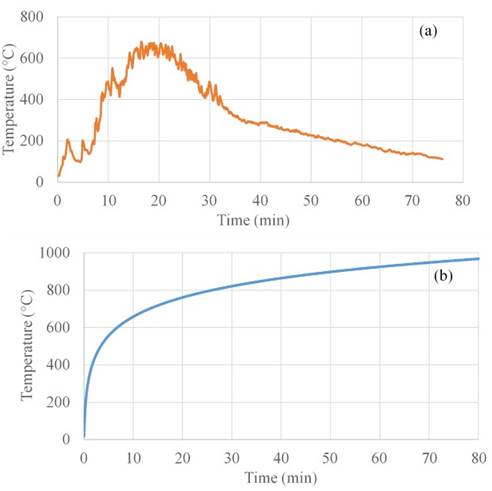

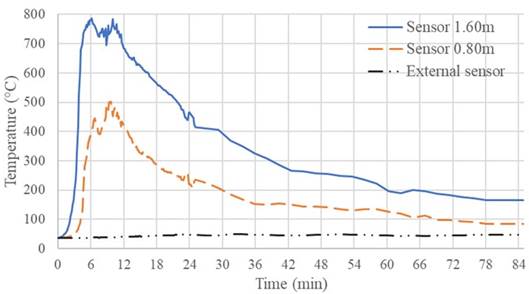

3.2 Fire test

The type K thermocouple sensors gauged the behavior of real temperature evolution over time in the grill fire test and live fire simulator test. It is observed that the behavior is quite different from the standard ISO 834 curve of an electric furnace. Such a difference can be seen in Fig. 5.

|

||||

| Fig. 5. Temperature x time in the grill fire test (a) and ISO 834 (b) curve | ||||

As shown in the graph, in the grill fire test there were the phases of the compartment burning, in other words, the tests showed the ignition point, growth phase, with or without generalized burning, apex and decay due to lack of material fuel. A behavior different from that found in furnace assays. Another divergent point is the heating pattern of the specimen. Heat is passed by conduction to the specimen. In a fire, the fire front most of the time has a pattern. In furnace burning all sides transfer energy equally to the test specimen. In Fig. 6 it is observed in thermograph images how the heat is passed in the two types of tests performed.

|

||||

| Fig. 6. Thermographic images of the specimens in cooling phase, immediately after burning on grill fire test (a) and immediately after being subjected to 500°C in furnace (b) | ||||

The Fig. 6(a) shows a well-defined temperature gradient, showing hotspots in the lower part of the specimen, where the fire load was concentrated. Already Fig. 6(b) shows that the heating of the specimen is almost uniform, which was expected, the furnace heat on all sides. Most real fires have a definite fire front, i.e. grill fire test was most effective in this aspect.

Another important information is that even the grill reaching temperatures higher than the furnace at 500 ° C, for example, the temperature of the specimen face in furnace was bigger than the specimen in grill, showing that the radiated thermal energy of the furnace is higher.

Tests of concrete submitted to elevated temperatures through electric furnaces can be reproducible, but do not represent the reality of a compartment fire and are much more severe than fire tests with finite charge material.

3.3 Compressive strength

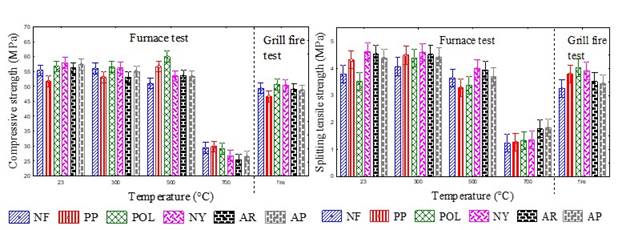

The compressive strength data of the concretes tested in furnace were submitted to ANOVA. It was observed that the isolated effect of the concrete type (NF, PP, POL, NY, AR and AP) and the temperature variation (23, 300, 500 and 700°C) were significant, as well as the interaction between the two variables. Fig. 7a shows the compressive strength as a function of the temperature of the concretes analyzed.

|

||||

| Fig. 7. Compressive strength (a) and splitting tensile strength (b) as a function of the temperature in the furnace and in the grill fire test. | ||||

Analyzing the furnace test, it is observed that from 23°C to the 500°C range there is almost no change in the compressive strength. At 700°C there is an average fall of approximately 50.2% of this mechanical property when compared to ambient temperature. This behavior can be explained by the range of temperature that occurs the important transformations in the concrete, as shown by Castellote et al. (2004).

After ANOVA it is concluded that there is a difference between the concrete groups submitted to different temperatures, however, only with this analysis it is not possible to point out if the difference occurs within the group or between the groups. A multiple comparison test can be used when there is a difference as it completes the analysis by comparing and then showing the result of all combinations of mean pairs. Tukey’s multiple comparisons test was used.

After the Tukey’s multiple comparisons test conclude that:

- The compressive strength of the NF did not change until the 300°C range. The PP presented the same behavior;

- The resistance of the POL did not change until 500°C;

- Up to 300°C the NY compressive strength is the same. Between 300-500°C there was no change in resistance. The AP had the same behavior;

- For the AR between 300-500°C the compressive strength is the same, as the value at room temperature is the same as at 500°C.

Analyzing the grill fire test, the results show that the effect of high temperature through furnace is more severe to concrete. Although the final temperature of the fire test reaches almost 700°C, the obtained values of compressive strength in furnace at 700°C are an average of 55% of the grill fire test results.

3.4 Flexural tensile strength

When performing the ANOVA, it was observed that the fibers and the temperature independently influence the behavior of flexural tensile strength in the concrete. The temperature was the variable of greatest impact followed by concrete type (addition of fibers), but the interaction between these two sources of variation, concrete type and temperature, was not significant, since the P value was higher than 0.05.

3.5 Splitting tensile strength

It was observed that there was no change in the result up to the range of 300°C and after that, when compared to the ambient temperature, the average value of the splitting tensile strength down 12.9% in the range of 500°C and 65.2% at 700°C.

It presented significance when the variation sources of concrete type and temperature were analyzed independently, as well as the interaction between the variables was significant with a 95% of confidence interval. Fig. 7b shows the graph of the splitting tensile strength as a function of temperature.

It was observed that NY, AR and AP had higher averages than NF, PP and POL. Even though it is a test that may present greater variations of results than the other two tests presented previously (compressive strength and flexural tensile strength), it is worth pointing out that the fiber characteristics may have influenced the results. It is verified that over again the temperature was the variable with the greatest impact. After multiple comparisons tests, it is verified that at 700°C there is no difference between the analyzed concretes. It is suggested that the orientation of the fibers may have interfered in the results, because in this test the POL obtained the lowest average result while the AR obtained the highest. In the compressive strength test this logic was inverted, in other words, the POL obtained the highest average result and the AR the worst. Because these cylindrical specimens were molded under the same conditions, it is hypothesized that the orientation of the fibers may have influenced the result. It is verified that the results obtained in grill fire test are close to those obtained in furnace at 500°C.

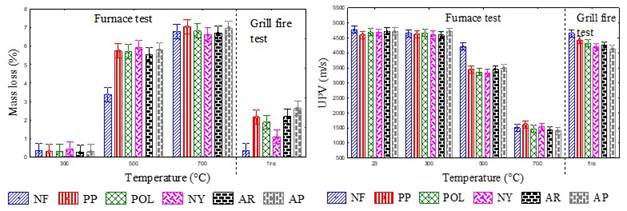

3.6 Mass loss

The mass loss results were significant for a 95% confidence interval.

From the 300 ° C the temperature already influences the loss of mass of the concretes tested. Both in this temperature range, where the great mass loss corresponds to the free water, and at 700 ° C, where all free water has already been released, many chemical transformations have already occurred, considerable cracks have already appeared and the concrete has already lost a large part of its structural characteristic [4].

In the range of 500 ° C it is verified that NF obtained the smaller loss of mass than the other concretes. This temperature range is enough to melt a large part of the fibers, providing the expected increase in pores, but not yet enough to perform all the chemical transformations of the concrete. The graph of mass loss as a function of temperature is in Fig. 8a.

Fig. 8.

Loss of mass (a) and UPV (b) as a function of temperature.

Although the final temperature of the grill fire test reaches almost 700°C, the concrete presents less loss than the concrete at 500°C in furnace, as can be seen in the results of mass loss and UPV.

3.7 Ultrasonic pulse velocity

Fig. 8b shows the result of UPV. It is suggested the existence of cracks and even increase of the pores with the addition of temperature.

By graphical analysis it was verified that up to 300°C there was no increase of cracks capable of presenting differences in the ultrasound analysis. The method of non-destructive testing to determine the speed of propagation of longitudinal waves, obtained by ultrasonic pulses through a component of concrete, its main applications detection of internal concreting flaws, depth of cracks and other imperfections (ABNT, 2013). Due to the heating rate, the maximum temperature reached and the cooling used, at 300 ° C, no moisture loss was detected. At 500°C the NF exhibited higher velocity than the concrete with fibers and the temperature of 700°C was enough to have the same result in all the concretes analyzed.

These numbers show that temperature is not the only variable that significantly influences the results of the same concrete after severe conditions, since heat flow, fire front and fire load are essential to determine behavior. Furnace tests, which are important for the sake of comparison, do not represent the reality of a real fire and other tests, such as the fire test, may complement the analysis.

3.8 Fire test in live fire simulator

In the Fig.9 are shown the temperature indices as a function of time of each of the sensors that monitored the fire in the live fire simulator.

Fig. 9.

Temperature vs time in the live fire simulator for the three sensors.

The mean temperature in the sensor outside the container was 42°C. It was observed that, in fact, the fire had an extreme behavior in the simulator, since in just 6 minutes after the fire began the temperature in the container reached its maximum range of 786°C in the sensor located at 1.60m.

The first 2 minutes were of slow burning only in the center of the ignition of the material and of much release of white smoke (water vapor from the wood). With 4 minutes of simulation there was already widespread burning of the center pallets and flame touching the ceiling. Up to 5 minutes it was clear the release of white smoke starting to turn gray. From there, the behavior began to change. In 6 minutes, the smoke was already light gray and already taking up the whole door. At that moment, it began to burn the wood from the bottom. At 10 minutes it occurred the general burn in the wood of the bottom and of the ceiling. At 11 minutes the smoke generated was already blurred, almost a khaki brown, which is an incomplete burning characteristic, which means, there was still a lot of combustible material being carried in the smoke. So much so that at this time of the test until the 12 minutes the smoke was burned with, even, the appearance of flames out of the container (this moment is called “flash”). That is why you can see almost a second peak of temperature rise in the upper sensor. After widespread burning, at 13 minutes the smoke was dark gray. At 23 minutes, slow burning only in the center (the reminder of the combustible material). Thereafter the temperature curve continues to decline. This is a real behavior of a fire.

After the test and the total cooling of the site, the visual analysis of each column was performed in the following day. Fig. 10 shows the columns side by side. The signs made in the columns show the displacements that happened in some of the concretes.

|

||||

| Fig. 10. Columns after being subjected to the fire and focus in NF and AP post fire, showing the top (a), center (b) and base (c). | ||||

It was observed that NF exhibited the highest spalling, followed by AP. AR also showed a small spalling at the base. The pillars of PP and POL did not present spalling, that is, the damages were not observed in the visual analysis. These concretes only showed a burning mark from the wood. At least one phase of each pillar showed this soot mark, a very common feature found in fires due to incomplete burning of combustible materials.

From this analysis conclude that the polymeric fibers decrease the incidence of spalling in the concrete and that the fibers with lower melting temperature are more efficient, because they melt at lower temperatures and open pores, thus releasing water vapor inside the concrete.

High performance polymeric fibers, such as aramid, were not efficient in the spalling aspect. Aramid pulp, being smaller and creating more nets and fiber interlacements, did not melt before the 500°C range and did not release pores, offering resistance to the concrete. This fact was essential for the appearance of spalling.

Fig. 10 also shows the detail of the most affected pillars. Both surface and edge spalling were observed in NF and AP too. As the main influences, besides the presence of the fiber in the case of PA, can mention the concrete permeability, thermal expansion of the aggregate, presence of steel and heating rate.

4. Conclusions

Based on the results of this experimental study, the following conclusions are drawn:

- Fire test with standard fire load may be an alternative or complementary analysis of concrete subjected to high temperatures, since the furnace tests do not represent faithfully the conditions found in a real fire in a compartment.

- Temperature is not the only variable that significantly influences concrete results after severe conditions, as heat flow, fire front and fire load are essential to determine the behavior, indicating that complementary testing is important for broad analysis.

- Polymeric fibers decrease the incidence of spalling in concrete and fibers with lower melting temperature (polypropylene and polyester) are more efficient because they melt at lower temperatures and open pores, thereby releasing water vapor into concrete. The polymeric fibers considered as high performance, as in the case of aramid, were not efficient in the spalling aspect.

- Although the grill fire test reached a temperature close to 700°C, the concrete showed less cracking than concrete in furnace at 500°C.

- In the mechanical tests performed after 700°C the results obtained were the same for all concretes, confirming that all the important transformations in the concrete have already happened, the fibers have already melted, and important cracks are already presented in this temperature range.

- The live fire simulator provided the most extreme behavior of the fire and it was possible to observe the spalling of concrete of some columns, showing an indication that type of cure, size of test specimen, presence of fibers and type of burning influence the behavior of the concrete exposed to fire.

5. ACKNOWLEDGEMENTS

The authors are grateful for the support provided by Espírito Santo Fire Department (CBMES), the Construction Materials Testing Laboratory (LEMAC) of the Civil Engineering Department of the Federal University of Espirito Santo (UFES) and Concrevit. In addition, a thanks to the Foundation for Support to Research and Innovation of Espírito Santo (FAPES) for the financial support to carry out this research.

References

ABNT Brazilian association of technical standards (1998). NBR NM 67: Concrete - Slump test for determination of the consistency. Rio de Janeiro.

ABNT Brazilian association of technical standards (2000). NBR 14432: Fire-resistance requirements for building construction elements - Procedure. Rio de Janeiro.

ABNT Brazilian association of technical standards (2007). NBR 5739: Concrete - Compression test of cylindric specimens - method of test. Rio de Janeiro.

ABNT Brazilian association of technical standards (2010). NBR 12142: Concrete - Determination of tension strength in flexure of prismatic specimens. Rio de Janeiro.

ABNT Brazilian association of technical standards (2011). NBR 7222: Concrete and mortar - Determination of the tension strength by diametrical compression of cylindrical test specimens. Rio de Janeiro.

ABNT Brazilian association of technical standards (2013). NBR 8802: Hardened concrete - Determination of ultrasonic wave transmission velocity. Rio de Janeiro.

ABNT Brazilian association of technical standards (2015a). NBR 5738: Procedure for molding and curing concrete test specimens. Rio de Janeiro.

ABNT Brazilian association of technical standards (2015b). NBR 8953: Concrete for structural use - Density, strength and consistence classification. Rio de Janeiro.

ABNT Brazilian association of technical standards (2018). NBR 16697: Portland cement - Requirements. Rio de Janeiro.

ACI Committee on Fireproofing (1919). Fireproofing. Journal Proceedings. 15 (6), 314-316.

Akca, A. H.; Zihnioǧlu, N. Ö. (2013). High performance concrete under elevated temperatures. Construction and Building Materials, 44, 317-328. https://doi.org/10.1016/j.conbuildmat.2013.03.005

Alhozaimy, A. M., Soroushian, P., Mirza, F. (1996). Mechanical properties of polypropylene fiber reinforced concrete and the effects of pozzolanic materials. Cement and Concrete Composites. 18 (2), 85-92. https://doi.org/10.1016/0958-9465(95)00003-8

ASTM International. (2018). ASTM E119-18a: Standard Test Methods for Fire Tests of Building Construction and Materials. USA. https://doi.org/10.1520/E0119-18A

Bangi, M. R., Horiguchi, T. (2012). Effect of fibre type and geometry on maximum pore pressures in fibre-reinforced high strength concrete at elevated temperatures. Cement and Concrete Research. 42 (2), 459-466. https://doi.org/10.1016/j.cemconres.2011.11.014

Behnood, A., Ghandehari, M. (2009). Comparison of compressive and splitting tensile strength of high-strength concrete with and without polypropylene fibers heated to high temperatures. Fire Safety Journal. 44(8),1015-1022. https://doi.org/10.1016/j.firesaf.2009.07.001

Bei, S., Zhixiang, L. (2016). Investigation on spalling resistance of ultra-high-strength concrete under rapid heating and rapid cooling. Case Studies in Construction Materials. 4. 146-153. https://doi.org/10.1016/j.cscm.2016.04.001

Castellote, M., Alonso, C., Andrade, C., Turrillas, X., Campo, J. (2004). Composition and microstructural changes of cement pastes upon heating, as studied by neutron diffraction. Cement and Concrete Research. 34 (9), 1633-1644. https://doi.org/10.1016/S0008-8846(03)00229-1

Choumanidis, D., Badogiannis, E., Nomikos, P., Sofianos, A. (2016). The effect of different fibres on the flexural behaviour of concrete exposed to normal and elevated temperatures. Construction and Building Materials. 129, 266-277. https://doi.org/10.1016/j.conbuildmat.2016.10.089

Cree, D., Green, M., Noumowé, A. (2013). Residual strength of concrete containing recycled materials after exposure to fire: A review, Construction and Building Materials. 45, 208-223. https://doi.org/10.1016/j.conbuildmat.2013.04.005

Çavdar, A. (2013). The effects of high temperature on mechanical properties of cementitious composites reinforced with polymeric fibers, Composites Part B: Engineering. 45 (1), 78-88. https://doi.org/10.1016/j.compositesb.2012.09.033

Corpo de Bombeiros Militar do Estado do Espírito Santo (CBMES). (2009). NT 04/2009 - Carga de incêndio nas edificações e áreas de risco. p.12, Vitória, Brazil.

Dias, D., Calmon, J., Degen, M. (2017). Concreto reforçado com fibras poliméricas submetido a temperaturas elevadas. In: Anais do 59º Congresso Brasileiro do Concreto - CBC2017 - IBRACON, At Bento Gonçalves, Rio Grande do Sul, Brazil, October 31 to November 3, 2017. ISSN: 2175-8182

Drzymała, T., Jackiewicz-rek, W., Tomaszewski, M., Kuś, A., Gałaja, J., Šukysc, R. (2017). Effects of High Temperature on the Properties of High Performance Concrete (HPC), Procedia Engineering. 172, 256-263. https://doi.org/10.1016/j.proeng.2017.02.108

European Committee for Standardization (CEN). (2004). EN 1992-1-2, Eurocode 2 - Design of Concrete Structures. Part 1.2: General Rules - Structural Fire Design, p. 97. Brussels.

Ezziane, M., Kadri, T., Molez, L., Jauberthie, R., Belhacen, A. (2015). High temperature behaviour of polypropylene fibres reinforced mortars. Fire Safety Journal. 71: 324-331. https://doi.org/10.1016/j.firesaf.2014.11.022

Gernay, T., Franssen, J.M. (2015). A performance indicator for structures under natural fire. Engineering Structures. 100, 94-103. https://doi.org/10.1016/j.engstruct.2015.06.005

Haddad, R. H., Al-Saleh, R. J., Al-Akhras, N. M. (2008). Effect of elevated temperature on bond between steel reinforcement and fiber reinforced concrete. Fire Safety Journal. 43 (5), 334-343. https://doi.org/10.1016/j.firesaf.2007.11.002

Hartin, E. (2008). Extreme Fire Behavior: Understanding the Hazards. 2008. Access in: <http://cfbt-us.com/pdfs/ExtremeFireBehavior.pdf>. Acess 17 fev. 2018.

International Organization for Standardization (ISO) (2015). ISO 834-1: 1999(R2015) - Fire-Resistance Tests - Elements of Building Construction - Part 1: General Requirements. Switzerland.

Khalaf, J., Huang, Z. (2016). Analysis of the bond behaviour between prestressed strands and concrete in fire. Construction and Building Materials. 128, 12-23. https://doi.org/10.1016/j.conbuildmat.2016.10.016

Khoury, G. A. (1992). Compressive strength of concrete at high tem- peratures: a reassessment. Magazine of Concrete Research 44 (161), 291-309. https://doi.org/10.1680/macr.1992.44.161.291

Kim, Y., Lee, T., Kim, G. (2013). An experimental study on the residual mechanical properties of fiber reinforced concrete with high temperature and load. Materials and Structures. 46, 607-620. https://doi.org/10.1617/s11527-012-9918-y

Kurtz, S., Balaguru, P. (2000). Postcrack creep of polymeric fiber-reinforced concrete in flexure. Cement and Concrete Research. 30 (2), 183-190. https://doi.org/10.1016/S0008-8846(99)00228-8

Lee, G., Han, D., Han, M.C., Han, C. G., Son, H. J. (2012). Combining polypropylene and nylon fibers to optimize fiber addition for spalling protection of high-strength concrete. Construction and Building Materials. 34, 313-320. https://doi.org/10.1016/j.conbuildmat.2012.02.015

Lennon, T., Rupasinghe, R., Canisius, G., Waleed, N., Matthews, S. (2007). Concrete structures in fire - Performance, design and analysis. IHS BRE Press; 1 edition, 1-81. ISBN-13: 978-1860819131, ISBN-10: 1860819133

Lourenço, L. A. P., Barros, J. A. O., Alves, J. G. A. (2011). Fiber reinforced concrete of enhanced fire resistance for tunnel segments. ACI Symposium Publication 276, p. 1-34. ISBN: 9781618392046, ISSN: 0193-2527.

Ma, Q., Guo, R., Zhao, Z., Lin, Z., He, K. (2015). Mechanical properties of concrete at high temperature-A review. Construction and Building Materials. 93, 371-383. https://doi.org/10.1016/j.conbuildmat.2015.05.131

Mehta, P. K., Monteiro, P. J. M. (2008). Concrete: Microstructure, Properties, and Materials (3er. ed.) McGraw-Hill Education (India) LTD. 659 pp. New York. ISBN: 0070636060 / 9780070636064

Noumowe, A. (2005). Mechanical properties and microstructure of high strength concrete containing polypropylene fibres exposed to temperatures up to 200 °c. Cement and Concrete Research. 35 (11), 2192-2198. https://doi.org/10.1016/j.cemconres.2005.03.007

Pai, S., Chandra, K. L. (2013). Analysis of polyester fibre reinforced concrete subjected to elevated temperatures. International Journal of Civil, Structural, Environmental and Infrastructure Engineering Research and Development (IJCSEIERD) 3 (1) 1-10. ISSN(Print): 2249-6866, ISSN(Online): 2249-7978.

Park, S., Yim, H. J. (2016). Evaluation of residual mechanical properties of concrete after exposure to high temperatures using impact resonance method. Construction and Building Materials. 129, 89-97. https://doi.org/10.1016/j.conbuildmat.2016.10.116

Petrucci, E. G. R. (1981). Concreto de cimento Portland. (8va. ed.). Globo. 307 pp. Rio de Janeiro.

Pliya, P., Beaucour, A. L., Noumowé, A. (2011). Contribution of cocktail of polypropylene and steel fibres in improving the behaviour of high strength concrete subjected to high temperature. Construction and Building Materials. 25 (4), 1926-1934. https://doi.org/10.1016/j.conbuildmat.2010.11.064

Poon, C. S., Shui, Z. H., Lam, L. (2004). Compressive behavior of fiber reinforced high-performance concrete subjected to elevated temperatures. Cement and Concrete Research. 34 (12), 2215-2222. https://doi.org/10.1016/j.cemconres.2004.02.011

Polícia militar do estado de São Paulo (2011). Instrução Técnica 14 - Carga de incêndio nas edificações e áreas de risco. Corpo de Bombeiros de São Paulo.

Sekhar, M. P., Raju, K. (2017). A Study on Effect of Mechanical Properties of Recron 3S Fibre Concrete on Different Grades Exposed to Elevated Temperatures. International Journal for Innovative Research in Science & Technology 4 (1), 41-46. ISSN(Online): 2349-6010

Shihada, S. (2011). Effect of polypropylene fibers on concrete fire resistance. Journal of Civil Engineering and Management, 17(2), 259-264. ISSN(Print): 1392-3730 / ISSN(Online): 1822-3605. https://doi.org/10.3846/13923730.2011.574454

Song, P. S., Hwang, S., Sheu, B. C. (2005). Strength properties of nylon- and polypropylene-fiber-reinforced concretes. Cement and Concrete Research. 35 (8), 1546-1550. https://doi.org/10.1016/j.cemconres.2004.06.033

Srikar, G., Anand, G., Suriya Prakash, S. (2016). A Study on Residual Compression Behavior of Structural Fiber Reinforced Concrete Exposed to Moderate Temperature Using Digital Image Correlation. International Journal of Concrete Structures and Materials. 10 (1), 75-85. ISSN(Print): 1976-0485 / ISSN(Online): 2234-1315. https://doi.org/10.1007/s40069-016-0127-x

Suresh, N., Bindiganavile, V., Prabhu, M. (2014). Compressive Behaviour of Polyester Fiber Reinforced Concrete Subjected To Sustained Elevated Temperature. International Journal of Emerging Technology and Advanced Engineering, 4 (8), 220-224. ISSN: 2250-2459

Xiao, J., Falkner, H. (2006). On residual strength of high-performance concrete with and without polypropylene fibres at elevated temperatures. Fire Safety Journal . 41 (2), 115-122. https://doi.org/10.1016/j.firesaf.2005.11.004

Yermak, N., Pliya, P., Beaucour, A. L., Simon, A., Noumowé, A. (2017). Influence of steel and/or polypropylene fibres on the behaviour of concrete at high temperature: Spalling, transfer and mechanical properties. Construction and Building Materials. 132, 240-250. https://doi.org/10.1016/j.conbuildmat.2016.11.120