Editorial

BRIEF HISTORICAL NOTES

BRIEF HISTORICAL NOTES

Revista de la Asociación Latinoamericana de Control de Calidad, Patología y Recuperación de la Construcción, vol. 8, no. 3, 2018

Asociación Latinoamericana de Control de Calidad, Patología y Recuperación de la Construcción, A. C.

Abstract: Anniversaries are a good excuse to make some summaries of historical events. Very briefly, some advances made from the initial research in the specialty of reinforcement corrosion which started in the 60’s are summarized. The use of electrochemical techniques was a milestone which enabled, from the decade of the 1970, to study the effect of each variable with much more rigor. The studies on service life started in the decade of 1980, although they were not of general interest until the next decade. From 1990 RILEM Committees and the Iberoamerican Program on Corrosion of CYTED extended the knowledge so widely that in the XXI century the subject attracts much research interest.

Keywords: electrochemical techniques, service life, corrosion, reinforcement.

Resumen: Los aniversarios son una buena excusa para hacer algunos resúmenes de eventos históricos. Muy brevemente, se resumen algunos avances realizados a partir de la investigación inicial en la especialidad de la corrosión por armadura que comenzó en los años 60. El uso de técnicas electroquímicas fue un hito que permitió, desde la década de 1970, estudiar el efecto de cada variable con mucho más rigor. Los estudios sobre la vida útil comenzaron en la década de 1980, aunque no fueron de interés general hasta la próxima década. A partir de 1990 los Comités RILEM y el Programa Iberoamericano de Corrosión de CYTED ampliaron el conocimiento de manera tan amplia que en el siglo XXI el tema atrae mucho interés de investigación.

Palabras clave: técnicas electroquímicas, vida de servicio, corrosión, reforzamiento.

Resumo: Aniversários são uma boa desculpa para fazer alguns resumos de eventos históricos. Muito brevemente, alguns avanços da pesquisa inicial na especialidade de corrosão de reforço que começou nos anos 60 estão resumidos. O uso de técnicas eletroquímicas foi um marco que permitiu, a partir da década de 1970, estudar o efeito de cada variável com muito mais rigor. Os estudos sobre vida de serviço começaram na década de 1980, embora não fossem de interesse geral até a década seguinte. A partir de 1990, os Comitês RILEM e o Programa Ibero-americano de Corrosão de CYTED ampliaram o conhecimento de forma tão ampla que, no século XXI, o assunto atraiu muito interesse de pesquisa.

Palavras-chave: técnicas eletroquímicas, vida de serviço, corrosão, reforço.

INTRODUCTION

The corrosion of the reinforcement is currently one of the subjects in which more resources are invested to investigate and it is also recognized as the main problem for the durability of concrete. I have lived the development of the concrete corrosion research since the beginning. First I make a very brief account of some research milestones in a sequential historical way before developing the subject with which I contributed to this special issue.

RESEARCH TO 1980

When I began my research by suggestion of José Calleja at the "Eduardo Torroja" Institute of Construction and Cement, there were no more than 30 citations in all the bibliography that I consulted (Gouda and Monfore, 1965; Stratfull, 1964; Cigna et al, 1966). His suggestion came because they had detected corrosion due to the use of CaCl2 to accelerate the setting. of concrete. The corrosion of armors was a matter of completely marginal interest in the decade of 1960-70, when the constructed park was still very limited. In my bachelors and in my thesis (Hausmann, 1964) I studied a total of 8 cements with additions of CaCl2 and NaNO2, the latter as a possible corrosion inhibitor, manufacturing pre-stressed joists 2 m long with 6 embedded wires. The results clearly showed the corrosive effect of CaCl2 and the inhibitory capacity of Nitrite. To measure corrosion, the non-destructive measuring technique called Polarization Resistance was applied for the first time in concrete, which would later be recognized along with other novel results by the RILEM when the author was awarded the Robert L'Hermite Medal.

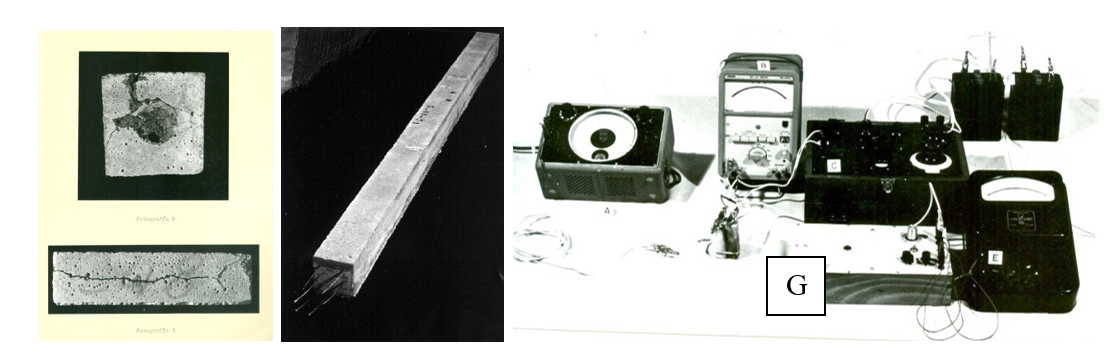

Figure 1 shows the specimens and joists used in the thesis of the author, as a curiosity, on the right side the devices used for measurements during the thesis are shown, one of which had already been used in the dissertation and another , the galvanostatic indicated with a G in the photograph, was manufactured by Jose Mª Tobio of the IETcc with the drawings yielded by Sebastián Feliú of the CENIM who is the one who had suggested using the Rp that was a very novel measurement technique.

The techniques that had been applied up to that moment to study the corrosion of the armor were of an accelerated type, mainly polarization curves (Gouda and Monfore, 1965) that were embodied in a potentiation test proposed by Kaesche and Baümel (Andrade, 1970; Andrade, 1978) later standardized by DIN and by CEN for the detection of corrosive substances in concrete additives.

Also outstanding in those years are Hausmann's works (Andrade, 1978) which establishes the critical relation of chlorides with respect to the pH of concrete at a value of Cl / OH = 0.6. Value that has remained valid to this day. Also, the works of Gouda (Gouda and Monfore, 1965) and Treadaway (Kaesche, 1959) all on electrochemical techniques to detect the corrosiveness of the additives and the protection of the inhibitors.

DECADES OF 1980-2000

The use of electrochemical techniques was a fundamental milestone that allowed (Baumel, 1959) from 1970 to approach the studies with much more rigor on the effect of each variable. This is how they began to study the effects of carbonation (González, Algaba and Andrade, 1980) and the possible methods to avoid corrosion, mainly hot galvanizing, inhibitors, epoxy coatings for reinforcements and cathodic protection.

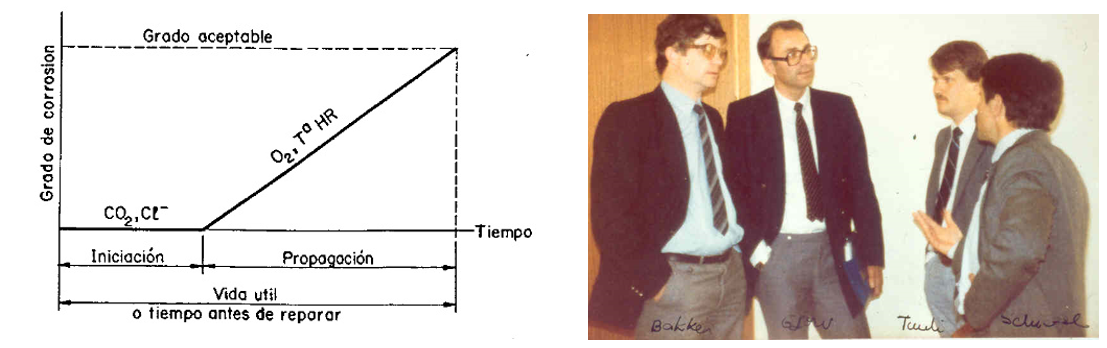

It is however in the 1980s when the calculation of useful life was addressed, which was not the subject of general attention until 1990. Thus K. Tuutti publishes his doctoral thesis (González, Algaba and Andrade, 1980) in 1982 with the diagram shown in figure 2 and that has articulated all subsequent studies. Figure 2 also shows K. Tuutti during a meeting of the Rilem Committee 60-CSC- "Corrosion of Steel in concrete" (Tuutti, 1982). Both this committee and subsequent ones, as well as the Subprogram "Durar" of CYTED (Schiess, 1988) and the publication of Page and Treadaway in Nature (Page and Treadaway, 1982) supposed a disclosure of the problem in its basic aspects that contributed significantly to the multiplication of congresses and publications.

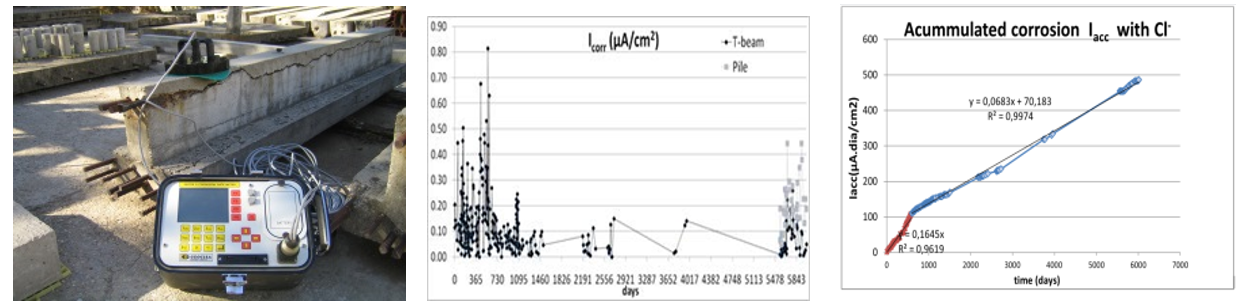

During the 1990s, enormous advances were made in basic knowledge, among which the possibility of in situ measurement (GECOR corrosion meter that allows measuring on site through confinement of the current (Page and Treadaway, 1982)) can be mentioned (Figure 3): the practice of cathodic protection both in new structures (Feliú et al, 1990) and already deteriorated, and the detection of problems with epoxy coatings (Lazzari and Pedeferri, 2006).

In those years RILEM established several committees, both on measurement techniques (TC-154), and on the models based on the diffusion of chlorides and carbonation (TC-178 and TC-213). In this regard, it is worth mentioning the contribution of D. Whiting proposing in the 1980s to reduce the duration of the chloride resistance test (Sagüés et al, 2001) by applying a potential difference to the concrete. These works led to an intense debate that led to the work (Whiting, 1981) that allowed to lay the theoretical basis for the diffusion of chlorides and their migration through electric fields, which have led to the profusion of numerical models on concrete life.

FROM 2000 TO THE PRESENT DAY

The most remarkable thing in these years can be summarized in the work done in the DURAR project (Andrade, 1993) in terms of the disclosure of basic principles. The CONTECVET Manual (CONTECVET IN30902I, 2001) which considers how to calculate the residual structural capacity when the structures are corroded and the probabilistic treatment of the models and calculation of the useful life, of which we can mention as a summary all the work carried out in the DURACRETE project (DURACRETE, 2000) that has led to the incorporation of the fib Model Code of the probabilistic durability treatment.

One area in which a lot of technology has been developed is related to repair methods, given the growing number of structures that have had to be repaired. However, in the 21st century, the corrosion of armor is one of the areas that constantly attracts research interest, there are many aspects to be clarified, especially in the effectiveness of repairs and in the calibration of life models.

REFERENCES

Andrade, C. (1970), Aportación al estudio de la corrosión de armaduras en el hormigón armado. Tesina de licenciatura, Universidad Complutense. Facultad de Químicas, Madrid, Julio.

Andrade, C. (1973), Nueva técnica electroquímica de medida de la corrosión de armaduras en hormigones armados y pretensados. Empleo de aditivos inhibidores como método de protección. Universidad Complutense, Facultad de Químicas – Junio.

Andrade, C. and González, J. A. (1978), Quantitative measurements of corrosion rate of reinforcing steels embedded in concrete using polarization resistance measurements, Materials and Corrosion, 29 (8), pp. 515. https://doi.org/10.1002/maco.19780290804

Andrade, C. (1993), Calculation of chloride diffusion-coefficients in concrete from ionic migration measurements. Cement and Concrete Research 23 (3), pp. 724-742. https://doi.org/10.1016/0008-8846(93)90023-3

Baumel, A. (1959), The effect of additives on the corrosion behaviour of steel in concrete, Zement-Kalk-Gips, July, no.7 pp 294.

Cigna, R., Maraghini, M., Schippa, G. (1966), Effeto del contenuto di Ca2Cl sul cmportamento dei ferri affogati in malte cementizie. L’Industria italiana del Cemento Marzo, p 139.

CONTECVET IN30902I (2001) “A validated user’s manual for assessing the residual life of concrete structures”, DG Enterprise, CEC, (The manual for assessing reinforced structures affected by reinforcement corrosion can be seen at the web sites of IETcc (www.ietcc.csic.es) and GEOCISA (www.geocisa.es))

DURACRETE. (2000), Probabilistic performance based on durability design of concrete structures. EU-Brite EuRam Project BE95-1347. A number of reports available from CUR Centre for Civil Engineering Research and Codes, Gouda, The Netherlands.

Feliú, S., González, J. A., Feliú Jr., S., Andrade, C. (1990), "Confinement of the electrical signal or in-situ measurement of Polarization Resistance in Reinforced concrete," ACI Materials Journal. 87(5), pp. 457-460.

González, J. A., Algaba, S., Andrade, C. (1980), Corrosion of reinforcing bars in carbonated concrete, British Corrosion Journal, 3 135-139.

Gouda, V. K., Monfore, G. E. (1965), A rapid method for studying corrosion inhibiton of steel in concrete, Journal Porland Cement Asocietion, Septiembre, nº 3, 24.

Hausmann, D. A. (1964), “Electrochemical behaviour of steel in concrete”, Journal A. C. I., 171.

Kaesche, H. (1959) Testing corrosion danger of steel reinforcement due to admixtures in concrete, Zement-Kalk-Gips, July, no.7 pp 289.

Lazzari, L., Pedeferri, P. (2006), Cathodic Protection, Milano: Polipress.

Page, C. L., Treadaway, K. W. J. (1982), Aspects of the electrochemistry of steel in concrete. Narute 297 No. 5862, 109-115. https://doi.org/10.1038/297109a0

Sagüés, A. A., Powers, R. G., Kessler, R. (2001) “Corrosion Performance of Epoxy-Coated Rebar in Florida Keys Bridges,” NACE International. CORROSION 2001, 11-16 March, Houston, Texas. ID: NACE-01642

Schiess, P. (1988) Corrosion of steel in concrete: report of the Technical Committee 60 CSC, RILEM (the International Union of Testing and Research Laboratories for Materials and Structures), London, New York, Chapman and Hall.

Stratfull, R.F. (1964), Effect of reinforced concrete in ClNa and SO4Na2 environments. Materials Protection, Dic, p 75.

Tuutti, K. (1982), “Corrosion of steel in concrete”, Swedish Cement and Concrete Institute (CBI) nº 4-82. Stockholm.

Whiting, D. 1981, “Rapid determination of the chloride permeability of concrete”, Federal Highway Administration, Report FHWA/RD-81/119.