Revisión

Service life design and modelling of concrete structures – background, developments, and implementation

Diseño y modelado de vida útil de estructuras de hormigón: antecedentes, desarrollos e implementación

Construindo um projeto de vida útil de estruturas de concreto - histórico, desenvolvimentos e implementação

Service life design and modelling of concrete structures – background, developments, and implementation

Revista de la Asociación Latinoamericana de Control de Calidad, Patología y Recuperación de la Construcción, vol. 8, no. 3, 2018

Asociación Latinoamericana de Control de Calidad, Patología y Recuperación de la Construcción, A. C.

Received: 21 March 2018

Accepted: 05 July 2018

Published: 31 August 2018

Abstract: The paper presents an international overview of current knowledge and progress in service life design and modelling of concrete structures. It explores why service life modelling is needed, and indicates that modern demands for longevity, durability, and sustainability of concrete structures cannot be fulfilled without service life modelling. It addresses the current approaches to durability design and specification and concludes that a move to performance-based approaches is imperative for progress to be made. Examples from international experience are cited to illustrate progress that has been made. Lastly, the paper discusses ways of moving forward, recognizing that the philosophical bases are already in place in the form of general code formulations, but which need to be converted into useful approaches

Keywords: service life modelling, performance-based specifications, concrete durability, durability indicators, model code.

Resumen: El documento presenta una visión general internacional del conocimiento actual y el progreso en el diseño de vida útil y el modelado de estructuras de hormigón. Explora por qué es necesario el modelado de la vida útil e indica que las demandas modernas de longevidad, durabilidad y sostenibilidad de las estructuras de hormigón no pueden cumplirse sin un modelo de vida útil. Aborda los enfoques actuales del diseño y la especificación de la durabilidad y concluye que es imperativo avanzar hacia enfoques basados en el desempeño para avanzar. Se citan ejemplos de la experiencia internacional para ilustrar el progreso que se ha logrado. Por último, el documento analiza formas de avanzar, reconociendo que las bases filosóficas ya están en su lugar en la forma de formulaciones de código general, pero que deben convertirse en enfoques útiles

Palabras clave: modelado de vida de servicio, especificaciones basadas en el desempeño, durabilidad del concreto, indicadores de durabilidad, código modelo.

Resumo: O artigo apresenta uma visão internacional do conhecimento atual e do progresso na modelagem de um projeto de vida útil de estruturas de concreto. Explora porque a modelagem da vida útil é necessária e mostra que as demandas modernas de longevidade, durabilidade e sustentabilidade das estruturas de concreto não podem ser atendidas sem uma correta modelagem da vida útil. Discute as abordagens atuais de projeto e especificação da durabilidade e conclui que uma mudança para uma abordagem baseada em desempenho é imperativa para que um desenvolvimento significativo seja logrado. Exemplos da experiência internacional são citados para ilustrar o progresso que tem sido obtido. Por último, é discutido como avançar, reconhecendo que as bases filosóficas já estão em vigor na forma de formulações gerais nas normas prescritivas e de desempenho, mas que precisam ser transformadas em abordagens úteis ao exercício profissional

Palavras-chave: modelagem de vida de serviço, especificações baseadas em desempenho, durabilidade do concreto, indicadores de durabilidade, Código de modelo.

INTRODUCTION – WHY THE NEED FOR SERVICE LIFE MODELLING?

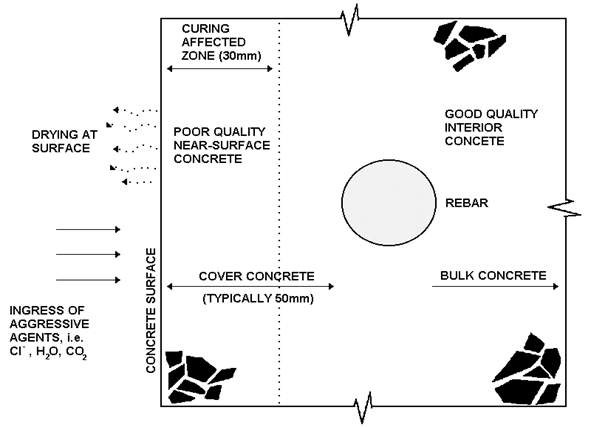

Concrete structures can deteriorate prematurely, giving rise to poor durability performance. Reasons include poor understanding of deterioration processes, inadequate acceptance criteria of site concrete, and changes in cement properties and construction practices with time (Neville, 1987). Durability problems in concrete structures cover a wide range including external destructive agents (e.g. sulphates), internal material incompatibilities (e.g. alkali-aggregate reaction), and aggressive environments such as freeze-thaw. The greatest threat for reinforced concrete is corrosion of reinforcing steel, leading to cracking, staining, and spalling of the concrete cover – see Figure 1. This in turn can lead to unserviceable structures that may be compromised in respect of safety, stability, and aesthetics. Such structures become a liability to their owners or managers, resulting in substantial economic loss, as well as being unsustainable by wasting valuable natural resources.

Currently, there is a ‘crisis of concrete durability’. This has several consequences: for infrastructure owners who increasingly require longer service life; for the imperative of proper stewardship of public infrastructure funding; and for developing engineering solutions that establish a basis for confidence in future infrastructure provision. These consequences are serious and need continual and urgent attention from the concrete community.

Durability and corrosion of reinforced concrete structures

As mentioned, the greatest threat to reinforced concrete (RC) durability is corrosion of the reinforcing steel. Corrosion is initiated by a change in the pore solution surrounding the steel, due either to acidification such as from carbonation, or more seriously, to ingress of chloride ions from a saline environment (e.g. marine or de-icing salts). Reinforcing steel is protected from the environment by a relatively thin cover layer, which must ‘guarantee’ the service life of the structure. Durability is therefore largely controlled by the quality of the cover, which is susceptible to the deteriorating influences of poor curing, early-age drying, inadequate compaction, and penetration of aggressive environmental agents. The durability problem in RC thus reduces largely to one of controlling the cover layer thickness and quality, which is a function of both design and construction decisions and actions. Figure 2 gives a schematic of the concrete cover layer, illustrating the important elements.

Consequently, durability strategies that are likely to give the greatest benefits must directly address the quality and quantity (depth) of the cover concrete. ‘Quality’ refers mainly to its ability to resist the ingress of aggressive fluids from the external environment, which is a function of the binder type and w/b ratio, assuming curing is effectively carried out (a false assumption in many cases, as it turns out!). The binder system is important because its chemical composition governs interaction and immobilisation of aggressive ions such as chlorides. For designers, this relates to two aspects: the ability to (i) quantify cover layer properties for specification purposes, and (ii) undertake service life prediction, which means being able to predict the rate of deterioration of a concrete structure. For constructors, the issue is to select the appropriate concrete materials and proportions, and to implement suitable site practices that ensure the specified cover properties are achieved in actual construction.

Service life

Engineers need tools for modelling or predicting the deterioration of RC structures over their service life. ‘Service Life Modelling’ (SLM) is intended to allow quantification of the design service life of structures, for purposes of economic optimisation, operational efficiency, and sustained structural and aesthetic performance. Thus, ‘service life modelling’ and ‘service life design’ are closely related: rational design needs good models, and models inform design. (Models are also used for other purposes such as research and diagnosis).

The fib Model Code for Service Life Design (fib, 2006) defines ‘Design service life’ as the assumed period for which a structure or part of it is to be used for its intended purpose, and in which:

deterioration and material performance are quantified as far as possible (including kinetics or rate effects)

a suitable ‘risk’ approach is adopted, usually based on probability which leads to measures of reliability

quantifications, costs, interventions (e.g. maintenance) and the like can be rationally considered.

While the training and experience of structural engineers focuses largely on mechanical and physical aspects of design and specification, the ‘new demand’ is for a more comprehensive toolbox containing ‘tools’ for practical solutions to problems of time-based deterioration. This should also include provisions for deterioration and maintenance costs which can be substantial, easily amounting to several percentage points of GDP and often exceeding 50% of construction budgets. Much more is now required of modern engineers, and service life modelling is one of the ‘new’ demands.

HOW DO WE DESIGN FOR SERVICE LIFE?

Practically, how do we design for a service life of, say, 50 or 100 years, when we have no objective evidence on which to base our decisions? Undertaking rational SLM is complicated by changing environments (e.g. global warming), rapidly changing materials (e.g. new cements), inadequate knowledge and models, variable construction quality, differing perceptions of what ‘service life’ means, and the impossibility of verifying our designs in the long term. Clearly, the problem is not simple! A historical example is the Coignet House in Paris, France, shown in Figure 3. This was probably the first reinforced concrete house, built in 1853, and now more than 160 years old. To place this in context: how should such a house have been designed in the 19th Century to conform to requirements of the 21st Century? Much can change over the service life of a structure that might render even the best attempts at SLM rather meaningless.

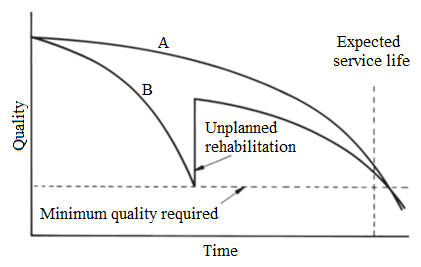

Service life of a RC structure is illustrated schematically in Figure 4, which shows the progress of deterioration over time of a structure (A), as it begins to deteriorate from its initial as-built condition (at time zero). Ideally, the time at which the structure reaches an unacceptable level of damage should equal or exceed the design service life and should be able to be modelled. However, many structures deteriorate prematurely, as in B in Figure 4, displaying inadequate durability and rapid deterioration, requiring rehabilitation during its service life. This deterioration is often unanticipated, which illustrates the need to accurately predict the performance of concrete structures during their service lives. The increasing frequency of inadequate durability and the associated high costs of repair mean that infrastructure owners are requiring that designers and contractors provide assurance of a pre-defined, repair-free service life of concrete structures.

To summarise: service life design requires service life modelling and service life prediction. Service life is essentially about adequate serviceability over the design life, which implies that the structure must have adequate durability, as a serviceability limit state condition (SLS), or preferably as a durability limit state condition (DLS) which can be thought of as a sub-limit of the SLS criteria. Therefore, in the context of this paper, it is necessary to review current durability design and specification.

Current durability design and specification

Durability design of RC structures is the process of determining the most appropriate combination of materials and structural details to ensure durability (serviceability) of the structure over its design life and in its design environment (Alexander and Santhanam, 2013). This should be framed in terms of acceptable reliability or probability of the structure performing satisfactorily. The problem involves weighing the risk of undue deterioration with the economics of ensuring durability and may include planned maintenance and repair.

Durability specifications are closely linked to design. The specification sets out requirements to ensure that the structure is constructed according to the intent of the design and should give clear information on the desired nature or outcomes of the construction. There are two main types of specifications:

Critique of current durability design

Currently, there is very little true durability design carried out for RC structures. Any durability ‘design’, if it does occur, is usually limited to rather vague specification clauses (or conversely, complex specifications that are unrealisable), in the hope that if the specification is adhered to, the structure’s durability should be ensured (i.e. a ‘deemed-to-satisfy’ approach). Further, durability specifications are often mired in outdated approaches and unrealistic assumptions. However, there are some notable examples of rational durability design (see for example Part Three of (Alexander, 2016a), which deals with practical case studies such as, inter alia, The Confederation Bridge in Canada, Marinas in the Gulf region, The Danish Strait Crossing Bridges, the Hong Kong- Zhuhai- Macau Sea Link project, and the New Panama Canal).

Current practice considers that compressive strength is the crucial factor, often used as a proxy for durability (Alexander, et al, 2008). However, different methods of achieving the same concrete strength do not all result in the same durability. In addition, strength of fully compacted, fully cured laboratory specimens cannot account for construction processes such as placing, compaction and curing, which affect the quality of the concrete cover. The important rate-controlling deterioration factors are the concrete material constituents, the cover quality of the as-built concrete, and the aggressiveness of the environment. It is usually impractical to control or modify the exposure conditions; therefore, strategies for improving service life must focus on the materials and the quality of construction. Such strategies require service life models and appropriate durability performance specifications (Mackechnie and Alexander, 2002). These developments facilitate innovative and responsive durability design, which is largely lacking at present.

Need for a new approach: from prescriptive to performance-based design and specification

While most specifications are still prescriptive, there are concerted international efforts to move from prescriptive to performance specifications, for example the P2P initiative of the US National Ready-mix Concrete Association (NRMCA, n.d.) and the French PERFDUB Programme (Linger & Cussigh, 2018). There are major benefits in moving from prescriptive to performance-based specifications, not least that the latter represents a more rational approach to improving concrete performance (Simons, 2004, Day, 2005, Bickley et al, 2006). Although the general philosophy of performance-based specifications is well established (Lobo et al, 2005, CAN/CSA, 2004), divergence remains on appropriate definitions and reliable measures of quality parameters. Appropriate test methods are crucial, and without these, little true progress can be made. Test approaches have been reviewed by RILEM TC-NEC (RILEM, 2005), and further developments can be expected. While some tests are well established, such as the rapid chloride permeability test (RCPT) (ASTM C1202, 2010), the challenge will be to standardise newer and improved test methods, and general acceptance in the concrete industry.

Critique of prescriptive specifications

Structural concrete is designed to meet specific criteria for workability, strength, durability, and so on. As indicated, current specifications are largely prescriptive, laying down values for limiting parameters such as minimum binder content, maximum w/b ratio, minimum compressive strength, amount of entrained air, etc. Prescriptive specifications work on a ‘deemed-to-satisfy’ basis, where if the requirements are met (which is frequently not verifiable in practice), the structure is ‘deemed-to-satisfy’ the durability requirements. Prescriptive specifications are usually obscure on issues such as exposure conditions for the structure. They hark from a previous period when material complexity was less, and durability was not the critical issue which it now is. Their main drawback is that they specify parameters that are often unverifiable in practice, more particularly on the as-built structure, and thus cannot be verified objectively. Usually, once the concrete has been mixed and placed, only the compressive strength is measured to ensure compliance with the design requirements and specifications, using specially prepared samples made, cured and tested under conditions that bear little resemblance to those in the actual structure.

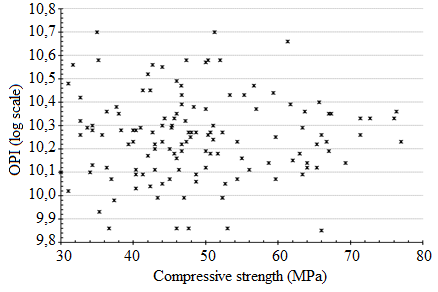

Taking compressive strength as a proxy for durability ignores the fact that strength and durability are not necessarily directly related. For example, the compressive strength test is not able to account for the physico-chemical nature of different binders and their resistance to the deteriorative effects of the environment. Also, strength is governed by the internal bulk of the concrete, whereas RC durability is primarily controlled by the thin cover zone, which is critically affected by handling, placement, consolidation, and curing. A reliable measure of the quality of the cover zone can be obtained only by assessing the concrete after hardening in the structure, rather than on companion strength specimens.

The dis-connect between durability and compressive strength is given in Figure 5, showing correlations between a durability parameter (oxygen permeability index OPI (log scale)) measured on actual structures and cube compressive strength measured on standard moist-cured lab cubes from the same concretes placed in the structures. It is clear – there is no correlation! This illustrates powerfully that measurements on actual structures are the only reliable way to assess and verify concrete durability.

Day (Day, 2005) suggests that prescriptive specifications offer little advantage to the concrete producer, because they limit the extent to which newer developments in materials technology and mixture proportioning techniques can be applied. Simply put, prescriptive specifications stifle innovation in the manufacture and use of concrete.

Notwithstanding the above, some elements of prescriptive specifications are still useful, for example guidance on processes such as compaction and curing. In practice therefore, and in the foreseeable future, a hybrid approach for specifications, with greater emphasis on performance criteria, is appropriate, where the owner and designer decide on the desired performance level in the service environment and propose appropriate ‘index’ or indicator tests (see later), which are used to prepare specifications. The supplier and contractor then provide a concrete system (prequalified using tests conducted before actual construction) that satisfies the index parameters or limits set by the owner/designer. The ‘concrete system’ not only describes the mixture requirements, but also encompasses the concreting procedures adopted.

Performance-Based Specifications

The discussion above indicates deficiencies in prescriptive specifications and raises the importance that key durability-related parameters are measured on actual as-built constructions. Thus, performance-based specifications are gaining ground, which assist in assessing and ensuring the required level of concrete quality for long-term durability in the given service environment. Lobo et al. (2005) describe performance specifications as ‘a set of clear, measurable, and enforceable instructions that outline the application-specific functional requirements for hardened concrete’. Performance-based specifications also shift the locus of responsibility for design and construction. In a prescriptive specification, the primary risk is placed on the owner and designer, while performance specifications separate and allocate risk and responsibility more clearly to owner/designer, concrete producer, and constructor (Taylor, 2004). By specifying and testing the concrete at the point of supply, and after placement and early hardening in the structure, the risk and responsibility appropriate to the supplier of the concrete is distinguished from that of the constructor who places and cures the concrete.

The main drawback for performance-based specifications is the lack of agreement, consistency, or standardisation on tests for measuring the concrete cover properties (or other criteria of the specification). For example, EN 206-1 (2013), which deals with specification, performance, production and conformity for concrete construction, ‘avoids’ a performance-based approach on the ground of lack of agreement on test methods.

As argued earlier, compressive strength is not an adequate indicator of durability. Rather, tests and parameters are needed that reflect rate-controlling deterioration factors, such as material constituents, the cover quality of the finished concrete, and the aggressiveness of the environment. Therefore, durability specifications for RC must rely on measuring transport properties of the cover zone. Such developments pave the way for crafting innovative performance specifications.

To summarise: the key to improving reinforced concrete durability is to require that as-built structures meet certain critical performance criteria in respect of probable modes of deterioration, notably reinforcement corrosion. The purpose is to ensure that the structure, during its service life, does not approach a “limit state” beyond which serviceability of the structure becomes compromised. The goal of performance-based specifications is to ensure that an acceptable probability of durability performance is achieved. A shift from prescriptive to performance specifications is one of the important steps necessary to address the shortcomings that are often apparent in current reinforced concrete construction.

Durability indicators, or durability indexes

The concept of ‘durability indicators’ or ‘durability indexes’ (DIs) originated in the 2000s from work of, inter alia, Andrade (Andrade & Izquierdo, 2005), Alexander (Alexander et al, 2001) and Baroghel-Bouny and co-workers (Baroghel-Bouny, 2004), all of whom proposed the use of ‘indicators’ or ‘indexes’ for control of durability. Such DIs are intended to describe, and hence control, a range of deterioration problems, and include physical, chemical, and electro-chemical parameters. DIs generally describe a transport property or deterioration mechanism and may be used to characterise the concrete in terms of its ‘potential’ durability (Alexander, et al, 2017). ‘Potential’ durability refers to the potential for the concrete to be durable in the given environment, provided it is properly proportioned with the correct constituents and then cured appropriately ab initio. To obtain durable concrete structures using this concept, various parameters are needed that can serve as ‘indexes’ of the durability of the material or structure. By measuring these in the short-term, they can be used as indicators of the likely durability performance of the structure in the long-term. They should be fundamental material parameters that relate to transport mechanisms and deterioration processes. These parameters should characterise the key material property (or properties) that govern the durability issue of concern, measurable in tests that are relatively simple, quick, and accurate in the sense that they properly represent the ‘real’ durability problem.

The usefulness of indicators or indexes will be assessed ultimately only by reference to actual durability performance of structures built using the indexes for quality control purposes - a long-term undertaking. Thus, a framework for durability studies should incorporate at least the following elements: early-age material indexing, direct durability testing, and observations of long-term durability performance; these elements should be linked by the relevant DI(s), so that an integrated approach emerges that can be used in durability design and specification of concrete structures (Alexander & Ballim, 1993).

Service life modelling and prediction

Service life modelling for reinforced concrete structures involves quantitative calculations or estimates to predict the time to unacceptable damage (e.g. cracking, corrosion, loss of section, etc.) for a given environment. Service life models are often semi-empirical in nature, based on laboratory and site data that are necessary for calibration. Alternatively, SLMs can be constructed from ‘first principles’, using ionic or reactive transport models and principles of flow in porous media (Van der Lee, et al., 2008); these models elaborate the ‘transport-interaction’ aspects of fluid or ionic flow in the concrete, with approaches based on thermodynamic and geochemical principles (Guillon et al, 2013). However, such models are not necessarily more accurate or reliable in their predictions, and the added complexity does not always justify the results obtained. In any event, these models must also be calibrated from laboratory and site data, and herein lies the rub: in almost all cases, concretes of a range of mix constituents and proportions need to be tested in appropriate environments to collect data which can be used to calibrate or construct the model, and subsequently to predict the ingress of harmful substances. SLMs are also useful in ‘back-analysis’ of existing structures when the penetration of contaminants such as chlorides is known for a particular concrete and environment at a particular time; it is then possible to use the model to determine the time to corrosion and possibly damage as well if there is a linked damage model. For a full probabilistic approach, variability also needs to be considered (Muigai, et al, 2009).

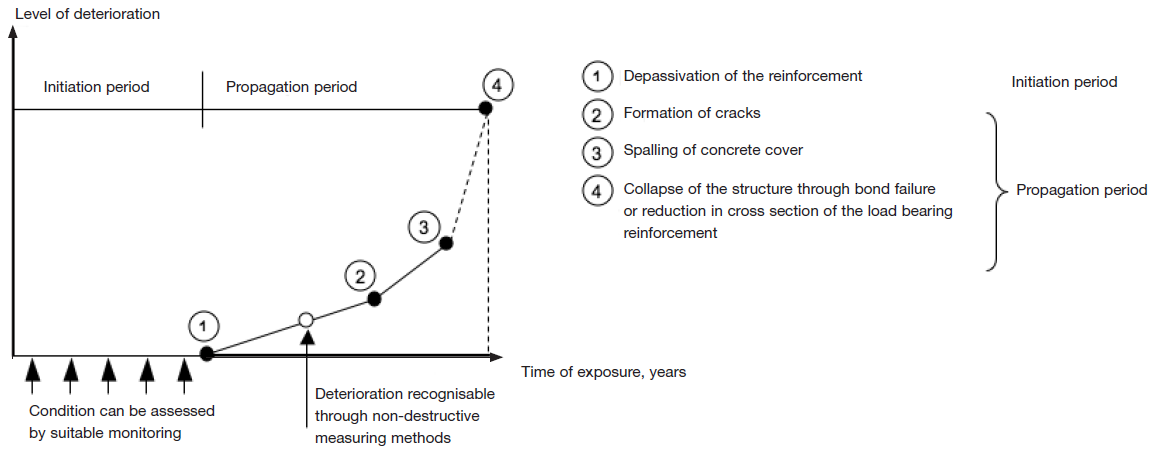

The two-stage conceptual service life model

The well-accepted conceptual ‘model’ for service life is the two-stage model proposed by Tuutti, (Tuutti, 1992). Deterioration is conceptualised into two distinct phases, the initiation phase and the propagation phase – see Figure 6. During the initiation period, contaminants enter the concrete to the depth of the reinforcing (in sufficient concentration), at which stage the protective passive layer on the steel is depassivated, resulting in an active corrosion state. The length of this period depends on concrete quality, cover depth, exposure conditions and the threshold or critical concentration required to initiate corrosion. Once corrosion initiates, the corrosion propagation phase commences in which active corrosion ensues, leading in time to structural damage. Figure 6 shows that the propagation period can be further sub-divided into different limit states, namely the onset of corrosion, cracking due to expanding corrosion products, delamination and spalling of concrete cover, and possible ultimate collapse of the structure.

Practical service life models

Various service life models exist in different parts of the world, largely in response to conditions in the various localities where the SLMs were developed. Most models cover both chloride and carbon dioxide ingress into concrete, such as the European model “DuraCrete” (DuraCrete, 1998) and the North American “LIFE-365” (2005). In South Africa, carbonation and chloride ingress models have also been developed (Mackechnie & Alexander, 2002).

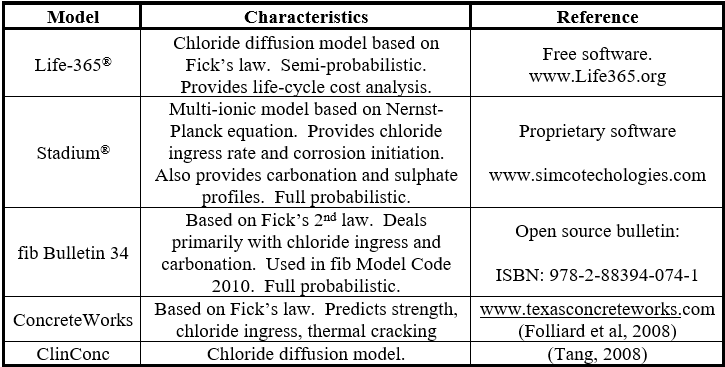

Table 1 provides a summary of some of the more prominent service life models available at present. Chloride modelling is commonly represented, with carbonation modelling also evident. (Further details on SLMs is given in the section on International efforts.)

International efforts in developing SLMs and performance-based specifications

This section outlines developments in SLMs and performance-based specifications in various parts of the world. Most models are concerned with prediction of onset of steel corrosion in concrete, and therefore with ingress of carbon dioxide or chlorides, and so the discussion will be limited to these deterioration mechanisms. General remarks are given first, followed by salient details for each country or region.

The European, Scandinavian and South African chloride prediction models are performance-based approaches, i.e. they are based on actual measurement of material properties of the concrete mix or structure under consideration. The onset of corrosion is predicted using Fick’s second law of diffusion which permits chloride profiles to be modelled using a relevant diffusion coefficient, the exposure conditions, and the chloride surface concentration. Diffusion coefficients based on various materials and mix proportions are experimentally determined or obtained from experience. Different test methods are used in different parts of the world to estimate chloride diffusion coefficients. The European and Scandinavian models apply the Rapid Chloride Migration (RCM) test (NTBUILD 492, 1999) while the chloride conductivity index (CCI) test (Streicher and Alexander, 1995) is used in South Africa. For carbonation models, the carbonation resistance of concrete is usually found from accelerated carbonation tests typically using laboratory-cured specimens.

By contrast, the North American “LIFE-365” model is based on computer simulations and does not involve testing. The service life and life-cycle costs of reinforced concrete structures are estimated from input parameters such as mix proportions and materials, preventative measures (corrosion inhibitors, coatings, stainless or epoxy-coated steel) and environmental conditions.

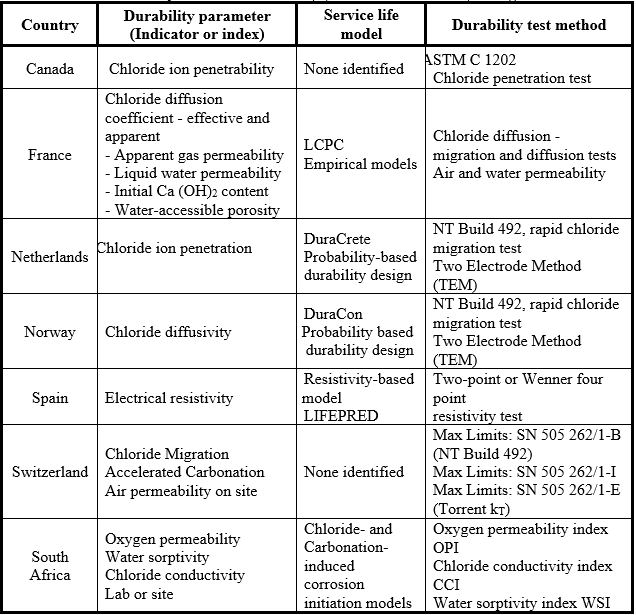

Several countries around the world have, to varying degrees, adopted the use of performance-based specifications for concrete construction, and are discussed below.

Canada and Australia

Bickley et al. (2006) give a brief review of the use of performance specifications in Australia and Canada. A common factor in these countries is the refinement of the definitions of exposure classes, enabling a clear description of the type of performance desired in a specific situation. The Australian concrete specification (AS, 2007) provides for special grade concrete that can be ordered using either performance or prescriptive criteria. According to Day (2005), Australian specifications provide a good platform for competent concrete producers, with the producer conducting the main tests on the concrete and independent labs performing only limited checks for quality assurance. An essential component of this arrangement is the presence of a good ‘quality system’ that monitors the concrete throughout and allows control of deviations. However, the main thrust of these specifications remains control of concrete strength, rather than overt attempts to measure ‘durability’ directly.

The Canadian concrete standards (CAN/CSA, 2004) give the choice to specify either performance or prescriptive criteria. Exposure classes have been extensively defined, and limits are suggested for constituents or properties that will lead to the production of durable concrete for the specific exposure condition. These limits can be interpreted in both prescriptive or performance specifications; in the former, compliance to the limits would be required, while for the latter, limits would serve as a valuable guideline to the supplier.

Bickley et al. (2006) indicate that the Canadian standards use performance requirements such as total charge passed (Coulombs) for special categories of chloride exposure, in addition to the routine prescriptive requirements. Several standardized testing methods are available to use in performance specifications, namely, the RCPT (ASTM C1202, 2010), air void system (ASTM C457, 2010), sorptivity (ASTM C1585, 2004), and chloride bulk diffusion (ASTM C1556, 2004). These tests can be conducted either on samples cast during concreting or from drilled cores. However, not all these tests are useful for routine quality control purposes.

USA

As mentioned, the North American “LIFE-365” service life model for chloride ingress is based on computer simulations and does not involve testing directly. However, Thomas et al showed that the model successfully predicted the ingress of chlorides into different concretes in a marine exposure site in Maine, USA (Thomas et al, 2012, Alexander and Thomas, 2015). For other types of deterioration, Simons (2004) outlined experience with performance specifications in New Mexico, where there is a high risk of alkali silica reaction in concrete. From a specification that prescribed safety against only ASR, freezing and thawing, and salt related damage, newer specifications were developed that addressed issues of variability in aggregate quality around the state, differences in operating equipment and procedures, and minimization of cracking, in addition to the three durability issues stated earlier. This led to controls on the cement quantity as well as controlled gain of strength of concrete. In the newer specifications, references to minimum cement content, maximum water content, and sand-aggregate ratio were removed, while appropriate tests for measuring ASR potential, permeability, and freeze–thaw were outlined. The older specifications could not ‘guarantee’ protection against the durability issues, as there was no direct testing

Scandinavia

In Scandinavia, the “ClinConc” chloride ingress model has been developed (Nilsson et al, 1996, Tang, 2008). It models chloride transport in the concrete pore structure, taking free chlorides as the diffusion potential, and then calculates the total chloride content taking into account non-linear chloride binding. It is therefore a type of ‘transport-interaction’ model.

In Norway, Gjørv pioneered an approach to probability-based durability design using DuraCrete guidelines but expressed in a probability-based model called DuraCon (Gjørv, 2014). Using a modified Fick’s second law and a Monte Carlo simulation, the probability of corrosion during a certain “service period” for the structure in the given environment is obtained, with the following input parameters:

A certain “service period” is specified before the probability for onset of steel corrosion exceeds an upper serviceability level of 10%, which is in accordance with current standards for reliability of structures. Based on the calculations, a combination of concrete quality and concrete cover can be selected, which will meet the specified “service period.” In the case of North Sea offshore concrete platforms, performance requirements based on chloride diffusivity (measured in the NT Build 492 “Rapid chloride migration test”) and concrete resistivity, as well as cover thickness were specified. Gjorv suggests that resistivity can be used to assess chloride diffusivity of the structural concrete, as well as for site quality control.

Spain

In Spain, Andrade et al (1993) proposed the use of electrical resistivity to characterize mass transport processes universally in concrete, i.e. for both chloride diffusion and gas permeation. Resistivity provides a fast, easy and cheap measure of concrete penetrability, also suitable for on-site use for quality control of new structures. A test limitation is that it cannot consider the influence of the binding capacity on transport mechanisms. Resistivity has the advantage of enabling assessment of existing structures through systematic mapping, described in the RILEM TC 154-EMC Recommendation (Andrade et al, 2004). In addition to resistivity measurements and RCPT, Andrade proposed the use of half–cell potential measurements and site determination of the corrosion rate using Polarization Resistance (Andrade et al, (2004).

Service life models (SLM) for the initiation and propagation period of corrosion, based on electrical resistivity, have been developed and are reported in Andrade (2004) and Andrade and d’Andrea (2010). The SLM considers the reaction or retarder factor of chlorides (rcl) for different cement types accounting for chlorides that are immobilized by cement phases through binding, environmental factors (kcl,CO2) based on exposure classification as in EN 206, and the aging factor (ρ t). The input parameters in the model are the cement type which determines the value of rcl, exposure class from which a value of kcl,CO2 is obtained, service life e.g. 100 years, cover depth and the aging factor. From these input parameters, the resistivity is obtained as a corrosion indicator (or durability indicator) that can be used to assess performance of a structure.

Switzerland

The Swiss Standard SN 505 262/1:2013 incorporates several DIs, prescribing limiting values for compliance by the concrete producers. Among them are a chloride migration test (similar to NT Build 492 (1999)) and an accelerated carbonation test, for chloride- and carbonation-induced corrosion respectively. A DI is also prescribed for conformity control of the end-product, using the site air-permeability test developed by Torrent, (Torrent, 1992) with limiting values for chloride- and carbonation-induced corrosion.

Rules for the application of the Torrent air permeability test for quality and durability control are provided in Swiss Standard SN 505 262/1 (2013), summarized by Torrent et al (2012). Limiting coefficient of permeability values, kT, are provided based on the exposure conditions in EN 206-1. The in-situ concrete should be tested at 28 to 90 days after placing. For slow-reacting cements such as with fly ash, a minimum test age of 60 days should be considered. Precautions should be taken to avoid testing concrete at very low temperatures or with high degrees of saturation. Moisture content is checked using an electrical impedance-based instrument, with an upper moisture limit of 5.5% (by mass). Further details on conformity evaluation and acceptance testing are given in the Swiss Standard or in (Jacobs et al., 2009), (Torrent and Jacobs, 2014).

South Africa

The South African concrete industry has been experimenting with performance specifications and durability design for two decades now (Alexander et al, 2001). A “durability index” approach has been developed to improve the quality of reinforced concrete construction, i.e. it specifically aims to control rebar corrosion. It is based on measurement of transport properties of the cover layer, for either laboratory or in-situ concrete, which reflect the dual aspects of material potential and construction quality. Key stages in formulating this approach were developing suitable test methods to measure durability indexes, characterising a range of concretes using these tests, studying in-situ performance, and applying the results to practical construction. The approach has progressed to the point where rational durability design and performance-based durability specifications exist and are being applied in actual construction.

Reinforced concrete durability depends primarily on the quality of the cover or surface layer, i.e. its ability to protect the reinforcing steel.

Improved durability can only be assured if a relevant durability parameter(s) can be measured.

The quality of the cover layer should be characterised using parameters that influence deterioration processes and that are linked with relevant transport mechanisms.

Index tests are needed to cover the range of durability problems, each index test being linked to a transport mechanism relevant to that process.

The usefulness of index tests is assessed by reference to actual durability performance of structures built using the indexes for quality control purposes.

Three DI tests have been developed: oxygen permeability index, chloride conductivity index, and water sorptivity index tests (see Table 2). DIs are quantifiable ‘engineering’ parameters that characterise concrete in the as-built structure (or from the lab), and are sensitive to material, processing, and environmental factors such as cement type, water: binder ratio, type and degree of curing, etc. Material indexing provides reproducible engineering measures of microstructure and key properties of concrete at a relatively early age (e.g. 28 days).

Testing for DI values is done on cores that are removed either from laboratory specimens, or from test panels or actual structures. Rigorous site proving trials have shown that coring from site cubes is not adequate, with test panels being more representative of in-situ construction (Ronny and Everitt, 2010). Typically, test panels (400 mm wide, 600 mm high and 150 mm thick) are constructed adjacent to the structure with the same concrete, shutter type, compaction and curing methods used for the actual structure, and at the same time as the actual structure. Cores are removed at 28 – 35 days and taken to an approved laboratory for durability testing. For precast median barriers, samples for testing are obtained directly from the actual elements.

The approach has also derived correlations between durability indexes, direct durability testing results, and actual structural performance, and the indexes can therefore be used as follows:

For controlling a particular property or quality of the cover zone, reflected by a construction specification in which limits to index values are specified

For assessing the quality of construction for compliance with a set of performance criteria

For fair payment for the achievement of concrete quality.

For predicting the performance of concrete in the design environment, by being linked with Service Life Models. Two SLMs incorporating the relevant durability indexes have been developed for SA conditions – a carbonation ingress model, and a chloride ingress model (Mackechnie and Alexander, 2002).

Importantly, the South African work represents an ‘integrated’ approach in which measured durability indexes giving actual material quality either in pre-trials, lab situations, or the as-built structure, are linked to the construction specifications for quality control purposes and to rational service life prediction models used in design. Such an approach allows complete integration and consistency between design, specification, and construction quality. (Implementation of the South African approach is further explored later).

Summary: performance-based approaches

Table 2 summarises provisions in selected countries for performance-based specifications.

Table 2 indicates that there has indeed been progress towards performance-based methods in various parts of the world. Problems still exist, and it is doubtful that a universal approach will easily emerge soon. However, it is probably more appropriate that local or regional solutions be found which can assist in moving concrete construction forward in those localities.

There is an important caveat, however: performance specifications must require as-built assessment of concrete quality in relation to durability to be regarded as truly ‘performance-based’. Pre-qualification and testing of laboratory mixes is not sufficient, which means that many of the so-called ‘performance’ approaches are only partial at this stage. (Further information on implementation of performance-based approaches in parts of the world can be found in Chapter 6 of Alexander et al, 2017).

WAY FORWARD, AND PRACTICAL STEPS

‘Service Life Modelling’ and ‘Service Life Design’ are related: i) they both involve assessing durability performance of a structure over its design life, ii) rational design for durability needs predictive deterioration models that provide the chemistry and kinetics of the problem by way of rate equations, and iii) predictive modelling provides the basis for design.

However, ultimately, design engineers work to Codes of Practice and other standards such as specification documents. Thus, predictive models need to be linked to Codes and Standards either implicitly by being incorporated into them, or explicitly by being accepted as suitable models for design that link with the design code requirements. Practically, ‘real progress’ will occur only with the formulation and ratification of design codes and standards.

This section reviews aspects of current codification for durability design and provides an example from South African practice of the implementation of a durability performance specification.

Moves toward codification of service life design

The fib Model Code for Service Life Design (SLD) (2006) categorizes approaches for service life design as: full probabilistic, partial factor design, deemed-to-satisfy, and avoidance of deterioration (see also later). Any of these approaches can be used, although a full probabilistic approach is desirable for large public infrastructure projects or prestigious structures.

Currently, approaches for rational durability design are limited and of variable implementation. For example, the approaches in the European DuraCrete, (1998) and Life-365 (2005), while useful, are location specific and do not fully represent an integrated approach, which requires site-measurable durability parameters which are used in a performance specification and coupled with Service Life Models. Durability design also needs a specification for implementation during construction, to ensure that the design assumptions for concrete quality and composition are achieved. Since the approaches mentioned are not ‘codified’, design and specifying authorities find limited justification to use them, especially if they do not have the needed expertise.

Service life design approaches and limit states

Walraven suggests that practical application of a performance-based approach for service life assessment and codification requires the following elements (Walraven, 2008): (i) limit state criteria, (ii) a defined service life, (iii) deterioration models, (iv) compliance tests, (v) maintenance and repair strategies, and (vi) quality control systems. Limit state criteria for concrete durability should be quantified, with clear physical meaning such as percentage of cracking or loss of surface, and the like. Deterioration models are generally mathematical and should include parameters that are linked to the performance criteria.

As indicated, the importance of codes of practice makes it essential that any usable approach be codified. Structural codes, which include durability provisions, are often slow in being updated so that new knowledge from research and practice takes a long time to enter the standards. As an example of performance-based durability design, (ISO 13823, 2008) outlines a limit-state methodology, summarised in Figure 7, which is related to different service life design approaches.

Figure 7 is also reflected in the fib Model Code (2010), with several approaches to service life design. In principle, the design approaches in the Model Code avoid or minimise deterioration caused by environmental action, similar to present approaches to design for loading; they are therefore ‘intelligible’ to structural design engineers. Based on quantifiable models for the “loading” (i.e. environmental actions) and the resistance (i.e. resistance of the concrete against the considered environmental action), the design options as given earlier in the fib SLD Model Code are mirrored, viz. full probabilistic approach; semi-probabilistic approach (partial safety factor design); deemed-to-satisfy rules; and avoidance of deterioration.

The full probabilistic approach should be used for exceptional structures only and is based on probabilistic models that are sufficiently validated to give realistic and representative results of deterioration mechanisms and material resistance. The basis is formed by appropriate test methods and statistical evaluation models, both of which lack significantly at present. The first two options involve quantitative evaluation of the performance of a structure using limit-state theory, documented in ISO 2394 (2015), with three limit states: ultimate limit-state (ULS), serviceability limit-state (SLS), and durability-limit-state (DLS). The ULS addresses the safety and stability of the structure (see e.g. EN 1990-1: 2002). The SLS considers failure due to material deterioration (e.g. sulphate attack) or excessive deflection, cracking and vibration. The DLS marks the onset of durability failure e.g. corrosion initiation in a RC structure (ISO 13823: 2008). Each of the three limit states is characterized by an inequality: the performance (R) (‘Resistance’) of the structure should be larger than the target design requirements (S) (‘Loading’, in this case, environmental loading). This is expressed by Equation (1).

The task of the designer is to carry out performance verification of a structure to ensure that the chosen design variables are such that the specified limit-state is not reached within the design working life. The performance verification depends on the probabilistic approach used i.e. full probabilistic or partial safety factor (semi-probabilistic) approaches.

Discussing further the partial safety factor approach, the probabilistic nature of the problem (scatter of material resistance and load data) is considered through partial safety factors. It is based on the same models as the full probabilistic approach and is intended to present a practical, statistically reliable design tool.

The deemed-to-satisfy approach is comparable to durability specifications given in most current codes and standards, i.e. prescriptive specifications based on a selection of certain design values (dimensioning, material and product selection, execution procedures) depending on environmental classes. The difference between the deemed-to-satisfy approach in the fib Model Code and traditional service life design rules is that the latter are commonly not based on physical and chemical models for concrete, but largely on practical experience, whereas the fib method is intended to be calibrated against the full probabilistic approach. The limiting values for design, material selection and execution, are determined either (i) from statistical evaluation of experimental data and field observations, and/or (ii) from calibration with long-term experience of building tradition. However, a specific service life estimate is not required in the ‘deemed-to-satisfy’ approach, rendering it not a performance-based approach, although if the specified limits relate to actual performance criteria such as a relevant durability indicator, it is a step in the right direction. Nevertheless, it remains largely prescriptive. For example, the European Standard EN 206-1:2013 adopts a deemed-to-satisfy approach and prescribes minimum cement content, maximum w/c ratio, and minimum compressive strength class for concrete components in various environmental exposure classes.

The fourth level of service life design (avoidance of deterioration) requires use of deterioration-resistant materials such as stainless steel, or concrete protection systems such as coatings, thus limiting or eliminating deterioration of the structure. Maintenance may still be required such as renewal of coatings from time to time.

Further, many structures or portions of structures are not exposed to severe environmental or operating deterioration mechanisms, in which case simple attention to good construction practices, which should include good mix design, compaction, curing and so on, should help to ensure adequate durability. This is exemplified in the exposure category XO of EN 206-1: 2013, described as: “Concrete with reinforcement or embedded metal: Very dry”, i.e. “Concrete inside buildings with very low air humidity”, which represents a large proportion of concrete construction in mild or benign environments.

Implementation example: The South African DI approach in practice

The approach to durability design and modelling in South Africa was reviewed earlier, and this section briefly outlines an implementation example (Alexander, 2016b). The approach has progressed to the point that both rational durability design and performance-based durability specifications are in place and being applied in actual construction (Nganga et al, 2013, Alexander et al, 2001, Gouws et al, 2001, Raath, 2004). The approach allows material and production variability to be quantified in deciding on suitable DI limits to be achieved by both concrete producer and concrete constructor, based on statistical principles (Alexander et al, 2008).

Durability Index performance-based implementation on major freeway bridge projects

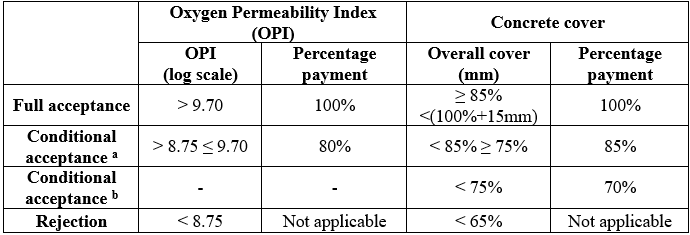

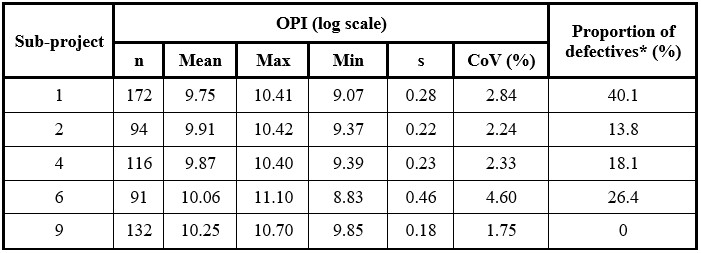

A significant and large-scale implementation using the DI performance-based approach was undertaken in a major infrastructure project – the Gauteng Freeway Improvement Project (GFIP) – which upgraded the freeway system in urban Gauteng Province between 2007 and 2012 to alleviate traffic congestion. Work involved freeway widening by addition of traffic lanes and construction of interchanges with associated bridges at a cost of about US $2 billion. Due to the inland environment, the DI approach required only the OPI and sorptivity tests to be performed on site concrete. Limiting values adopted were a minimum of 9.70 for OPI, and a maximum sorptivity of 10 mm/√hr. Cover depths were also monitored (see Table 3).

The specified limiting values and reduced payment criteria applied in the GFIP are summarized in Table 3. For the water sorptivity test, no reduced payment criterion was applied as the test was used only as an internal control to monitor the effectiveness of curing.

It was found that, although the limiting values were generally achieved on average, individual sets of results (from different sub-projects) showed high variability, illustrated in Table 4. The spread of variability obtained in selected sub-projects is clear, and the differences between construction ‘quality’ (here represented by variability) are quite stark. Only sub-project 9 (a precast median barrier construction yard) achieved acceptable low variability with all results meeting the project specifications. The in-situ results from the other sub-projects are a good illustration of the variability that can be introduced into as-built structures by site construction processes, since essentially the concretes all came from the same source.

CLOSURE

It is clear that, for service life design and modelling of concrete structures, considerable progress has been made in recent decades, although much remains to be done. The need for performance-based approaches, without which service life design cannot be implemented, is now reasonably well recognised, but not always by concrete practitioners.

Approaches have emerged in different parts of the world largely in response to perceived needs for better durability of concrete structures. However, a truly universal approach is still lacking, although the Model Code documents of the fib have outlined the basic philosophy and needed approaches. Major progress can be expected in this important area of concrete design and construction in the coming years.

REFERENCES

Alexander, M. G. & Ballim, Y. (1993), “Experiences with durability testing of concrete: a suggested framework incorporating index parameters and results from accelerated durability tests”. Proc. 3rd Canadian Symp. on Cement and Concrete, Ottawa, August 1993, Nat. Res. Council, Ottawa, Canada, 1993: 248-263.

Alexander, M. G., Mackechnie, J. R., Ballim, Y. (2001), "Use of durability indexes to achieve durable cover concrete in reinforced concrete structures, Chapter, Materials Science of Concrete, V. VI, Ed. J. P. Skalny and S. Mindess, American Ceramic Society, pp 483 – 511.

Alexander, M. G., Ballim, Y., Stanish, K. (2008), “A framework for use of durability indexes in performance-based design and specifications for reinforced concrete structures”, Materials & Structures, V. 41, No. 5, pp. 921-936.

Alexander, M. G., Santhanam, M. (2013), “Achieving durability in reinforced concrete structures: durability indices, durability design and performance-based specifications”. Keynote paper at International Conferences on Advances in Building Sciences & Rehabilitation and Restoration of Structures, IIT Madras, Chennai, India, 21pp.

Alexander, M. G. & Thomas, M. (2015), “Service Life Prediction and Performance Testing – Current Developments and Practical Applications”. Cement & Concrete Research, Vol 78, pp. 155-164.

Alexander, M. G. Ed. (2016a), “Marine concrete structures. Design, durability and performance”. Ed. M.G. Alexander, Cambridge: Woodhead Publishers (Imprint of Elsevier). 400 pp.

Alexander, M. G. (2016b), “Performance-based concrete durability design and specification in South Africa – background, implementation, and quo nunc?” Proceedings fib Symposium, Cape Town, Lausanne, fib, pp. 52-62.

Alexander, M. G., Bentur, A., Mindess, S. (2017), “Durability of Concrete: Design and Construction”. CRC Press, Taylor & Francis Group, U.K.

Andrade, C., Alonso, C., Goni, S. (1993), “Possibilities for electrical resistivity to universally characterize mass transport processes in concrete”. In Concrete 2000 Economic and durable construction through excellence Volume Two: Infrastructure, research, new applications. Dhir, R. K. and Jones, M. R. ed. Scotland, UK: E & FN SPON, pp. 1639–1652.

Andrade, C. (2004), “Calculation of initiation and propagation periods of service life of reinforcements by using the electrical resistivity”. In International Symposium: Advances in Concrete through Science and Engineering. Evanston, Northwestern University, USA, (2004) p. 8.

Andrade, C., Alonso, C., Gulikers, J., Polder, R., Cigna, R., Vennesland, Ø., Salta, M., Raharinaivo A, Elsener, B. (2004), "RILEM TC 154-EMC: Electrochemical Techniques for Measuring Metallic Corrosion. Recommendations Test methods for on-site corrosion rate measurement of steel reinforcement in concrete by means of the polarization resistance method", Materials & Structures V. 37, No. 273, pp. 623-643.

Andrade, C., Izquierdo, D. (2005), “Benchmarking through an algorithm of repair methods of reinforcement corrosion: the Repair Index Method”, Cement & Concrete Composites, V. 27, No. 6, pp.727-733.

Andrade, C., d’ Andrea, R. (2010), “Electrical resistivity as microstructural parameter for modelling of service life of reinforced concrete structures”, In 2nd International symposium on service life design for infrastructure. pp. 379–388.

Australian Standard (AS) (2007), AS 1379: “Specification and Supply of Concrete”. Sydney:

ASTM International. (2010). ASTM C457/C457M-10a Standard Test Method for Microscopical Determination of Parameters of the Air-Void System in Hardened Concrete. Retrieved from https://doi.org/10.1520/C0457_C0457M-10A

ASTM International. (2010). ASTM C1202-10 Standard Test Method for Electrical Indication of Concrete's Ability to Resist Chloride Ion Penetration. Retrieved from https://doi.org/10.1520/C1202-10

ASTM International. (2004). ASTM C1556-04 Standard Test Method for Determining the Apparent Chloride Diffusion Coefficient of Cementitious Mixtures by Bulk Diffusion. Retrieved from https://doi.org/10.1520/C1556-04

ASTM International. (2004). ASTM C1585-04e1 Standard Test Method for Measurement of Rate of Absorption of Water by Hydraulic-Cement Concretes. Retrieved from https://doi.org/10.1520/C1585-04E01

Bickley, J. A., Hooton, D. and Hover, K. C. (2006), “Performance specifications for durable concrete”. Concrete International, 28(9): 51-57.

Canadian Standards Association (2004), CAN/CSA-A23.1-04/A23.2-04: Concrete Materials and Methods of Concrete Construction/Methods of Test and Standard Practices for Concrete, Toronto, 516 pp.

Day, K. W. (2005), “Prescriptive on prescriptions”, Concrete International, V. 7, pp.27–30.

DuraCrete (1998), “Probabilistic performance-based durability design: modelling of degradation”, Document, D. P. No. BE95-1347/R4-5, The Netherlands.

EN 1990-1 (2002), Eurocode: “Basis of structural design”, CEN, Brussels, 2002.

EN 206-1 (2013), “Concrete - Part 1: Specification, performance, production and conformity, CEN, Brussels, 2013.

fib Model Code for Service Life Design (2006) fib Bulletin 34, fib, EPFL Lausanne, 116 pp.

fib Model Code (2010, 2013), International Federation for Structural Concrete (fib), Lausanne, Switzerland.

Gjørv, O. E. (2014), “Durability Design of Concrete Structures in Severe Environments”, 2nd edition, Taylor & Francis, CRC Press, London.

Gouws, S. M., Alexander, M. G., Maritz, G. (2001), “Use of durability index tests for the assessment and control of concrete quality on site”, Concrete Beton, 98 pp. 5-16.

Guillon, E., Le Bescop, P., Lothenbach, B., Samson, E. and Snyder, K. (2013), “Modelling degradation of cementitious materials in aggressive aqueous environments”, Part II in Star 211-PAE, Performance of cement-based materials in aggressive aqueous environments, pp. 1- 39. Springer.

ISO 13823-1 (2008), “General Principles on the design of structures for durability”, International Organization for Standardization, Geneva.

ISO 2394 (2015), “General Principles on Reliability for Structures”, International Organization for Standardization, Geneva, 111pp.

Jacobs, F., Leemann, A., Denarié, E., Teruzzi, T. (2009), SIA 262/1. “Recommendation for the quality control of concrete with air permeability measurements”, VSS report, Zurich. 22 pp.

LIFE-365 (2005). ACI-Committee-365, “Service life prediction model, Computer program for predicting the service life and life-cycle costs of reinforced concrete exposed to chlorides”. American Concrete Institute.

Linger, L., Cussigh, F. (2018), “PERFDUB: A New French Research Project on Performance-Based Approach for Justifying Concrete Structures Durability”. In High Tech Concrete: Where Technology and Engineering Meet.1. https://doi.org/10.1007/978-3-319-59471-2

Lobo, C., Lemay, L. and Obla. K. (2005), “Performance-based specifications for concrete”. The Indian Concrete Journal, 79(12): 13-17.

Mackechnie, J. R, Alexander, M. (2002), “Durability predictions using early-age durability index testing”. Proceedings, 9th Durability and Building Materials Conference, Australian Corrosion Association, Brisbane, (2002) 11pp.

Muigai, R. N., Alexander, M. G., Moyo, P. (2009), “Use of chloride conductivity index in probabilistic modelling for durability design of RC members”. Restoration of Building Monuments Journal, V. 15, No. 4, pp. 267-276.

National Ready-mix Concrete Association, (NRMCA), n.d. www.nrmca.org/P2P

Neville, A. M. (1987), “Why we have concrete durability problems”, ACI SP-100, Katherine and Bryant Mather International Conference on Concrete Durability, American Concrete Institute, Detroit, USA, pp. 21-48.

Nganga, G., Alexander, M. G., Beushausen, H. (2013), “Practical implementation of the durability index performance-based design approach”. Construction & Building Materials, Published online: 6-MAY-2013. Construction and Building Materials. V. 45, pp. 251-261.

Nilsson, L. O., Poulsen, E., Sandberg, P., Sørensen, H.E., Klinghoffer, O. (1996), “Chloride penetration into concrete”, State of the Art, Transport processes, corrosion initiation, test methods and prediction models, Copenhagen: Danish Road Directorate, pp.23-25.

NTBUILD 492, (1999), “Concrete, mortar and cement based repair materials: chloride migration coefficient from non-steady state migration experiments”. Esbo, Finland: Nordtest.

Raath, B. (2004), “Practical Issues of Concrete Specification”. Concrete Society of Southern Africa, National Seminar: Specifying Concrete for Durability - State of the Art of South African Practice, Presented at Johannesburg Durban, Port Elizabeth and Cape Town, South Africa.

RILEM TC 189-NEC (2005), “Non-destructive evaluation of the concrete cover: Comparative test - Part I: Comparative test of ‘penetrability’ methods”. Materials and Structures (284), 2005.

Ronny, R., Everitt, P. (2010), “Durability specification and testing results from four bridge structures in Kwa Zulu-Natal”, In Concrete for a sustainable environment, Emperor's Palace, Kempton Park, Gauteng, South Africa.

The South African National Roads Agency Limited (SANRAL) (2010), “Project document: Project specifications”.

Simons, B. (2004), “Concrete performance specifications: New Mexico Experience”. Concrete International, 26(4): 68-71.

Streicher, P., Alexander, M. G. (1995), "A chloride conduction test for concrete." Cement and Concrete Research, V. 25, No. 6, pp 1284-1294.

Swiss Standard SN 505 262/1 (2013), "Concrete Construction – Complementary Specifications", Schweizer Norm, 52 p. (in German and French)

Tang, L. (2008), “Engineering expression of the ClinConc model for prediction of free and total chloride ingress in submerged marine concrete”, Cement and Concrete Research, 38(8–9), 1092–1097.

Taylor, P. (2004), “Performance-Based Specifications for Concrete”, Concrete International, 8: 91 – 93.

Thomas, M. D. A., Green, B., O’Neal, E., Perry, V., Hayman, S. Hossack, A. (2012), “Marine Performance of UHPC at Treat Island”, Proceedings of Hipermat, 3rd International Symposium on UHPC and Nanotechnology for High Performance Construction Materials (Editors Michael Schmidt et al), Kassel, pp. 365-370.

Torrent, R. J. (1992), “A two-chamber vacuum cell for measuring the coefficient of permeability to air of the concrete cover on site, Materials & Structures, V. 25, No. 6, pp.358-365.

Torrent, R., Denarié, E., Jacobs, F., Leemann, A., Teruzzi, T. (2012), “Specification and site control of the permeability of the concrete cover: The Swiss approach”, Materials and Corrosion, V. 63, No. 12, pp.1127-1133.

Torrent, R., Jacobs, F. (2014), "Swiss Standards 2013: World's most Advanced Durability Performance Specifications", 3rd Russian Intern. Confer. on Concrete and Ferrocement, Moscow.

Tuutti, K. (1992), “Corrosion of steel in concrete”. Swedish Cement and Concrete Research Institute, CBI Research Report, No. 4 p 82.

Van der Lee, J., De Windt, L., Lagneau, V. (2008), “Application of reactive transport models in cement-based porous media”. Proceedings in the International RILEM Symposium on Concrete Modelling – CONMOD’08, Delft, The Netherlands.

Walraven, J. (2008), “Design for service life: how should it be implemented in future codes”, International Conference on Concrete Repair, Rehabilitation and Retrofitting, Proceedings ICCRRR Cape Town, (2008) pp. 3-10.

Author notes

mark.alexander@uct.ac.za

Additional information

Cite as: M. G. Alexander (2018) “Service life design and modelling of

concrete structures – background, developments, and implementation”, Revista ALCONPAT, 8 (3), pp. 224-245, DOI: http://dx.doi.org/10.21041/ra.v8i3.325

Legal Information: Revista ALCONPAT is a quarterly publication by the Asociación Latinoamericana de Control de Calidad,

Patología y Recuperación de la Construcción, Internacional, A.C., Km. 6 antigua

carretera a Progreso, Mérida, Yucatán, 97310, Tel.5219997385893, alconpat.int@gmail.com,

Website: www.alconpat.org

Responsible editor: Pedro

Castro Borges, Ph.D. Reservation of rights for exclusive use

No.04-2013-011717330300-203, and ISSN 2007-6835, both granted by the Instituto

Nacional de Derecho de Autor. Responsible for the last update of this issue,

Informatics Unit ALCONPAT, Elizabeth Sabido Maldonado, Km. 6, antigua carretera a Progreso, Mérida, Yucatán, C.P. 97310.

The views of the authors do

not necessarily reflect the position of the editor.

The total or partial

reproduction of the contents and images of the publication is strictly

prohibited without the previous authorization of ALCONPAT Internacional

A.C.

Any dispute, including the

replies of the authors, will be published in the second issue of 2019 provided

that the information is received before the closing of the first issue of 2019.