Investigación Básica

A holistic conceptual approach to concrete service life: a split into different time-stages

Un enfoque conceptual holístico para la vida de servicio del concreto: división en diferentes etapas de tiempo

Uma abordagem conceitual holística para a vida útil das estruturas de concreto: divisão em diferentes estágios de tempo

A holistic conceptual approach to concrete service life: a split into different time-stages

Revista de la Asociación Latinoamericana de Control de Calidad, Patología y Recuperación de la Construcción, vol. 8, no. 3, 2018

Asociación Latinoamericana de Control de Calidad, Patología y Recuperación de la Construcción, A. C.

Received: 15 June 2018

Accepted: 29 August 2018

Published: 31 August 2018

Abstract: The goal of this paper is to analyze and discuss a conceptual approach that considers the holistic character of concrete service life but splits it into seven time-stages that can be compared, for understanding purposes, with those of a human being. The existing concepts about service life may be incomplete regarding those that must consider the whole life of a concrete structure. One of the reasons for this is the lack of certainty of the service life predictions which are based on models that consider a series of non-clearly defined time-stages. The life of a structure has many similarities with that of a human being. In fact, it is no coincidence that engineering has adopted some terms from the medical sciences like “pathology” to refer to structures with problems of “health”. The paper discusses the overlapping of the different time-stages as well as the reasons why the prediction models can fail.

Keywords: service life, durability, structure.

Resumen: El objetivo de este documento es analizar y discutir un enfoque conceptual que considera el carácter holístico de la vida de servicio concreta, pero lo divide en siete etapas de tiempo que se pueden comparar, para fines de comprensión, con las de un ser humano. Los conceptos existentes sobre la vida útil pueden ser incompletos con respecto a aquellos que deben considerar toda la vida de una estructura concreta. Una de las razones para esto es la falta de certeza de las predicciones de la vida útil que se basan en modelos que consideran una combinación de etapas de tiempo no claramente definidas. La vida de una estructura tiene muchas similitudes con la de un ser humano. De hecho, no es coincidencia que la ingeniería haya adoptado algunos términos de las ciencias médicas como "patología" para referirse a estructuras con problemas de "salud". El documento analiza la superposición de las diferentes etapas de tiempo, así como las razones por las que los modelos de predicción pueden fallar.

Palabras clave: vida de servicio, durabilidad, estructura.

Resumo: O objetivo deste artigo é analisar e discutir uma abordagem conceitual que considere o caráter holístico da vida útil das estruturas de concreto, dividida em sete estágios de tempo que podem ser comparados, para fins de compreensão, com os de um ser humano. Os conceitos existentes sobre a vida útil podem estar incompletos em relação àqueles que devem considerar toda a vida de uma estrutura de concreto. Uma das razões para isso é a falta de certeza das previsões de vida útil baseadas em modelos que consideram uma mistura de estágios não claramente definidos. A vida de uma estrutura tem muitas semelhanças com a de um ser humano. De fato, não é coincidência que a engenharia tenha adotado alguns termos das ciências médicas como “patologia” para se referir a estruturas com problemas de “saúde”. O artigo discute a sobreposição dos diferentes estágios de tempo, bem como as razões pelas quais os modelos de previsão podem falhar.

Palavras-chave: vida útil, durabilidade, estrutura.

INTRODUCTION

The introduction of parameters to define service life of concrete as a holistic concept has been very common during the last thirty years. These parameters are more quantitative today than a few years ago and include concepts which are closely related, like serviceability, functionality, security, reliability and durability. Service life has been defined in codes, standards and articles by many authors. Each author or code has own reasons to propose modifications and inclusions to the definition. Three of the most common definitions of service life, as defined by certain organizations, are given below:

American Concrete Institute: the period of time after installation, during which all the properties exceed the minimum acceptable values when routinely maintained (ACI-365, 200).

DURAR Network: the period of time during which the structure conserves the project requirements in security, functionality and aesthetics, without unexpected maintenance cost (Troconis el al, 1998)

Construction Products Directive (CPD): the period of time during which the performance of the works will be maintained at a level compatible with the fulfillment of the essential requirements (E. Community, 1989).

APROY-NMX-C-530-ONNCCE (2017): Es el tiempo durante el cual el desempeño de un material, elemento o estructura de concreto conserva las características del proyecto en términos de seguridad (resistencia mecánica y estabilidad, seguridad en caso de fuego, seguridad en uso), funcionalidad (higiene, salud y medio ambiente, protección contra el ruido y ahorro energético y confort térmico) y estética (deformaciones, agrietamientos, desprendimientos), con un mínimo de mantenimiento que le permita soportar los efectos ambientales y naturales en su entorno durante su uso.

Although apparently similar, these concepts of service life have differences and do not consider a split into time-stages during which some specific and particular phenomena occur. These particular phenomena like cracking, carbonation, chloride movement, etc., can have different effects according to determined time-stages like beginning or end of service life. Then, modelling and prediction of behaviour must correspond to specific time-stages unless we know exactly how their specific behaviour could be at any time-stage.

This may be the reason why extrapolation of predictions from deterministic, semi-probabilistic or probabilistic models to different time-stages cannot be accurately and completely verified. In other words, the service life of concrete should be divided into different time-stages where the material is exposed to different circumstances besides ageing. Each time-stage is defined as the specific time where the specific materials and environmental effects may be known, without circumstances that could be attributed to other time-stages and then to affectation of predictions from quantitative models.

On the other hand, we still need to understand the concept of service life as a ‘whole life’ concept and as the way we see our own existence as human beings. In fact, we use some concepts in engineering such as “pathology” that are adopted from the medical sciences to refer to problems of “health” of the structure. The objective of this paper is to discuss an approach that considers the holistic character of concrete service life, but splits it into seven time-stages that can be compared, for understanding purposes, with those of a human being. The paper discusses the overlapping of the different time-stages as well as the reasons why the prediction models can fail.

SOME ASPECTS ABOUT THE EVOLUTION OF SERVICE LIFE MODELS

Probably one of the most important approaches to service life has been that provided by Tuutti´s model in 1982 (Tuutti, 1982). This model was the first one to propose two stages for the service life: initiation and propagation. Much of the present knowledge to prevent damage and to repair structures is based on this conceptual model. New materials, the aggressiveness of the environment and the new construction techniques have made improvements to Tuutti´s model necessary.

The inclusion of the total amount of damage as well as specific stages like inspection, diagnosis, prognosis, repair and maintenance options were introduced in 1994 by Andrade (Andrade, 1994).

In 1996 (Sarja and Vesikari, 1996), several levels of models were proposed to include elements such as materials or complete buildings. The help of deterministic models to predict the programmed service life was discussed together with the importance of stochastic ones. In 1996, two limit states of depassivation and cracking of concrete were taken into account in the conceptual models. A conceptual model showing distributions of degradation, service life and serviceability limits was also presented in that year (Sarja and Vesikari, 1996). Obsolescence of the structures was taken into account in the conceptual models during 1997 (Somerville, 1997) and the idea of designing for the final life was introduced.

The need to include new concepts in the service life approaches continued in 1998 (Helene, 2003) when the concept of service life was divided into several parts. Helene (2003) presented the service life stage divided into four specific and overlapped parts. All these approaches have helped to improve the predictions of service life through deterministic or probabilistic models. However, the overlapping of their different stages has complicated the precision of the predictions because many chemical, physical or electro-chemical phenomena can have totally different behaviour in different stages of the service life. Therefore, an approach is needed with defined and not overlapped stages that could allow better service life predictions in any of its stages. In other words, we should not make predictions of service life if we do not know the expected behaviour of all the phenomena during the whole service life, which is practically impossible.

In this regard, the literature has provided several other models with interesting concepts and sub-divisions of service life in several stages. However, despite these important contributions, little information has been found dealing with the philosophy with which we should analyse the service life of a structure. Since the term “pathology” has been adapted from the medical sciences to the construction field, it is consistent to speak about “construction pathology problems”. This is familiar to us because of the existing analogies between the medical and the constructional sciences; this is between a human being and structures. Therefore, the following approach considers the similarities of the total life between a human being and a structure.

The best known criteria consider the service life of a structure divided into service life and residual life. In recent years and in coincidence with the appearance of durability problems, total service life was divided into more parts like service life, useful life, residual life and others that apply also for a human being, with some obvious exceptions.

ANALOGIES BETWEEN THE SERVICE LIFE OF A HUMAN BEING AND A STRUCTURE

Let us consider the following similarities of the service life stages between a human being and a structure.

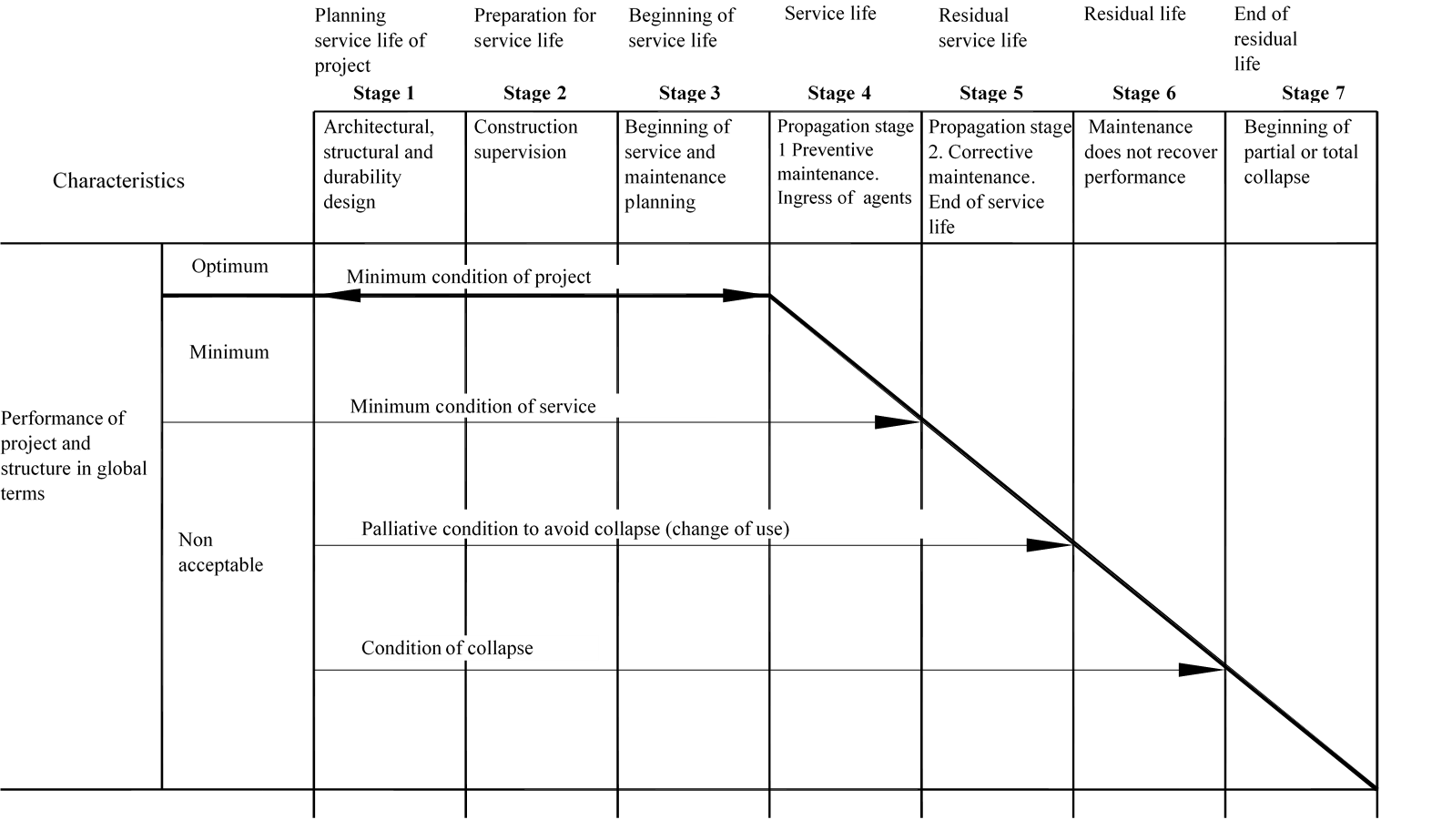

The first stage is that of the conception. The conception of a human being is given by the relationship between the couple. In the case of a project, the conception is given by the first discussions about the project and its preparation. Depending on the kind of project, the structure can last for many years. This is the stage where the total life is projected. This stage can be called the project planning of the structure´s total life (stage 1) and includes the structural, architectural and durability design (figure 1). The product of this stage or boundary condition, is the executive project. (Error 1: La referencia: figure 1 está ligada a un elemento que ya no existe)

The second stage is that of the gestation. This is the time in which the mother gestates the new-born. Some professionals like the gynecologist supervise this stage. The analogy with this stage is given by the construction period of the structure. Following the project specifications with adequate supervision will determine the total life period of the structure. This stage can be called the preparation for the service life (stage 2). The product of this stage, or boundary condition, is the final new structure.

The third stage is that of the delivery. A group of professionals like the gynaecologist, paediatrician and the anaesthesiologist are in charge to receive the new-born and assure good conditions during this period. In terms of a structure, this is the day the structure is placed in service, the in-service day. This is the time when the service life starts and constitutes a specific point of time which is the boundary condition. This stage can be called the initiation of the service life (stage 3).

The fourth stage is that from delivery until adulthood (say, 18 years old). This is a critical stage where the parent’s supervision is important to prevent, detect and correct any kind of problem related to mental, emotional or physical health, or accidents that would affect the long-time development of the person. The analogy with this stage is that in which the new structure may or may not receive preventive maintenance to avoid future damage. The duration of this stage will depend on the evident needs for corrective maintenance to the structure. A boundary condition for this stage four can be stated as the moment when the aggressive agents reach the reinforcing bar.

In terms of durability, this can be the so-called corrosion initiation stage, or the so-called service life (stage 4). It will be the period from the in-service day until the day in which the aggressiveness of the environment and/or loads result in direct deterioration of the steel/concrete. This stage must consider just the expected behaviour when the structure is healthy and without showing evident deterioration. The boundary condition here is just before the presence of visual evidences of deterioration may be the sign that the behaviour model prediction has to be modified or changed to include different conditions.

The fifth stage includes adulthood until just before the senior citizen age. This is a maturity period where the right development depends on the person and the right habits during previous stages. Certain aspects about health or emotional problems determine the behaviour or boundary condition at the end of this stage. In terms of durability, this stage corresponds to the propagation period. However, as actually defined, the propagation period finishes when the original ability of the structure to support structural and environmental loads cannot be restored to the structure. In reality, this ability has a high probability of being restored if the structure is adequately repaired/rehabilitated at a certain critical time. This is like cancer that can be cured through a correct and in-time diagnosis.

This stage can be called residual service life (stage 5). It is a stage at which the structure will be useful despite its problems, but only if it receives a correct and in-time treatment. The limit or boundary condition between this and the following stage is given by the fact that not every “medicine”, or intervention, will have the desired effect.

The sixth stage may be that from the senior citizen to the instant before dying. In this stage, all the functions of the person must be carefully followed because they can fail due to ageing and previous conditions or effects of life. In the case of a structure, it is the time when any preventive or corrective action cannot restore its expected conditions of functionality, serviceability, durability, load carrying ability, etc. It is this period where the inspector and owner must think about a change of use for the structure boundary condition. Some activities like discharging of some zones, evacuation of people, disassembling of some installations, etc, must be planned prior to the ‘death’ of the structure. This stage finishes just before the death of the structure and can be called just residual life (stage 6). The boundary condition here corresponds to the moment when the structure is not longer useful.

The seventh and final stage is that of death as a result of failures, collapses or prolonged ‘pain’. In the case of a structure, this stage corresponds to the beginning of the partial or total collapse. This stage can be called the end of residual life (stage 7).

Every stage of the conceptual model must be accompanied by some specific tests. The results of a kind of test could mean different interpretation if applied in different stages. As an example, we could think about the permeability test (Basheer, 1993). Permeability values could be different in dependence of the aggressive conditions for the structure during certain stages: applying this test in stage 3 may indicate good concrete, but a better one in stage 4 (because of a longer curing period, etc). NMX-C-530 takes this into consideration.

THE NEW APPROACH FOR SERVICE LIFE OF CONCRETE

Figure 1 shows an approach for service life of concrete structures which is based on the best characteristics from other approaches as well as on the described analogies between a structure and a human being, given above. This approach is presented with a similar philosophy but with a division of time-stages which is more in accordance with project planning as well as to future predictions. (Error 1: La referencia: está ligada a un elemento que ya no existe) (Error 2: La referencia Figure 1 debe estar ligada) (Error 3: El tipo de referencia Figure 1 es un elemento obligatorio) (Error 4: No existe una url relacionada)

The optimum performance is obtained during the first three stages and includes the planning, the preparation, and the in-service day of service life. The minimum condition of service will be maintained only during the fourth stage where preventive maintenance against the ingress of aggressive substances is required. In global terms, the stages five, six and seven are those where the structure is no longer capable of exhibiting acceptable performance. These stages include the residual service life, the residual life and the end of residual life.

OVERLAPPING AMONG THE DIFFERENT STAGES

Any of the stages from Figure 1, but particularly the last four, must be analyzed individually when performing service life predictions. The literature has given much importance to stages 4 and 5 because it is thought that the information obtained in such stages is enough to predict the future behaviour. The events of each single time-stage must be interpreted and considered for any prediction because of the influence of the phenomena occurring during previous time-stages. The overlapping of phenomena occurring in different stages can result in misleading predictions.

A simple example is the prediction of the carbonation front or chloride profile adjacent to the reinforcing bar after a few years of exposure to a determined environment. Stage 4, service life, includes the ingress of these agents, but the predictions usually do not take into account stages 5, 6 and 7 where cracking or other phenomena can occur.

This is one of the main reasons why we cannot easily find a valid prediction verification of these phenomena. The best thing in this case is to circumscribe a prediction model to stage 5 and think about modifications or a different one after stage 5. The items included in the seven stages as well as the data needed for predictions will be published elsewhere.

EXAMPLE OF APPLICATION OF THE CONCEPTUAL SEVEN STAGE MODEL

The Progreso pier is the oldest reported concrete structure with use of 304 SS. It was designed and constructed by the danish company Christiani and Nielsen. This company thought about a 50 year-service life structure with a minimum of maintenance. Six of the stages of the conceptual model can be easily identified. Several published articles, cited here, can support the use of the conceptual model:

Stage 1.- Planning service life (2 years). The pier was designed to be in service for 50 years. The project preparation lasted about two years.

Stage 2.- Preparation for service life (construction period, 5 years). The structure was constructed between 1936 and 1941.

Stage 3.- Beginning of service life. The structure was inaugurated in 1941

Stage 4.- Service life (60 years). The structure had a satisfactory service from 1941 to 2001, after 60 years in service, when a hurricane (Isidore, 2002) evidenced diverse problems like scour that affected piles, beams and deck.

Stage 5.- Residual service life (15 years). The structure, since then (2002), has been in service thanks to in-time interventions. A new pier was proposed to the ministry of construction, that was finally constructed and inaugurated in 2016. This was the end of stage 5 for the old pier, since most of the strong loads were moved to the new pier.

Stage 6.- Residual life (2 years and counting). Maintenance do not recover original performance and cannot help the pier to sustain the 10 times-increased loads. Then, the use of the pier was modified to allow just part of the original planned loads that are equivalent, nowadays, to touristic cars and trucks, persons and maintenance traffic. In fact, it is having an intervention, to make sure it can sustain a certain percentage of the original loads of design. Under these circumstances, it is expected at least a stage 6 duration of 22 years, that is the complement to have twice the expected initial service life, this means a total of 100 years.

CONCLUSION

The contribution of several approaches for service life of concrete structures was discussed. A new approach that takes into account the similarities among the several stages of service life from a human being and concrete structures was proposed. The influence of overlapping service life stages in the predictions of future behaviour was briefly discussed. Based on the new approach, the use of simple prediction models whose results apply to individual stages is recommended.

Acknowledgements

The authors acknowledge their Institutes as well as to CONACYT and CNPq for partial support for this paper and collaboration. The help of M. Balancan with the art work is acknowledged. The opinions expressed here are those of the authors and not necessarily of the supporting organizations

REFERENCES

American Concrete Institute (2000), “ACI-365: Service-Life Prediction- State-of-the-Art Report”.

Andrade, C. (1994), Quantification of durability of reinforcing steel, methods and calculation procedures of Concrete technology: New Trends, Industrial Applications, A. Aguado, R. Gettu and S.P. Shah, Editors. RILEM. Published by E&FN Spon, 2-6 Boundary Row, London SE1 8HN, UK ISBN 0 419 20150 5. pp: 158-175.

APROY-NMX-C-530-ONNCCE (2017), “Industria de la construcción – Durabilidad – Norma general de durabilidad de estructuras de concreto reforzado – Criterios y Especificaciones”.

Basheer, P. A. M. (1993), A brief review of methods for measuring the permeation properties of concrete in-situ, Structures and Buildings, Proceedings of the ICE, vol 99, 74-83. https://doi.org/10.1680/istbu.1993.22515

European Community (1989), “COUNCIL DIRECTIVE of 21 December 1988 on the approximation of laws, regulations and administrative provisions of the Member States relating to construction products.”, Off. J. Eur. Communities, vol. 40, no. L, pp. 12–26.

Helene, P. (2003), A nova NB 1/2003 (NBR 6118) e a vida útil das estruturas de concreto, University of Sao Paulo PCC USP.

Sarja, A., Vesikaeri, E. (1996), Chapter 7 Durability models, In Durability Design of Concrete Structures. Manuscript of RILEM Report of TC 130-CSL, RILEM Report Series 14. pp: 97-111, E & FN Spon, Chapman and Hall, 165 p.

Somerville, G. (1997), “Engineering design and service life: a framework for the future”, In Prediction of concrete durability: Proceedings of the STATS 21st anniversary conference /1997, J. Glanville and A. M. Neville, Editors, pp. 58-76, E & FN Spon, UK.

Troconis, O., Romero, A., Andrade, C., Helene, P., Díaz, I. (1998), Manual de inspección, evaluación y diagnóstico de corrosión en estructuras de hormigón armado, 2nd ed. Red Durar.

Tuutti, K. (1982), “Corrosion of steel in concrete”, Swedish Cement and Concrete Research Institute, Stockholm.

Additional information

Cite as: P. Castro-Borges, P. Helene (2018),

“A holistic conceptual approach to

concrete service life: a split into different time-stages”, Revista ALCONPAT, 8 (3), pp. 280-287, DOI: http://dx.doi.org/10.21041/ra.v8i3.324

Legal Information: Revista ALCONPAT is a quarterly publication by the Asociación Latinoamericana de Control de Calidad,

Patología y Recuperación de la Construcción, Internacional, A.C., Km. 6 antigua

carretera a Progreso, Mérida, Yucatán, 97310, Tel.5219997385893, alconpat.int@gmail.com,

Website: www.alconpat.org

Responsible editor: Pedro

Castro Borges, Ph.D. Reservation of rights for exclusive use

No.04-2013-011717330300-203, and ISSN 2007-6835, both granted by the Instituto

Nacional de Derecho de Autor. Responsible for the last update of this issue,

Informatics Unit ALCONPAT, Elizabeth Sabido Maldonado, Km. 6, antigua carretera a Progreso, Mérida, Yucatán, C.P. 97310.

The views of the authors do

not necessarily reflect the position of the editor.

The total or partial

reproduction of the contents and images of the publication is strictly

prohibited without the previous authorization of ALCONPAT Internacional

A.C.

Any dispute, including the replies

of the authors, will be published in the second issue of 2019 provided that the

information is received before the closing of the first issue of 2019.