Investigación Aplicada

Numerical simulation and fire experiment in residential dormitory

Simulação numérica e experimento de incêndio em dormitório residencial

Simulación numérica y experimento de incendio en dormitorio residencial

Numerical simulation and fire experiment in residential dormitory

Revista de la Asociación Latinoamericana de Control de Calidad, Patología y Recuperación de la Construcción, vol. 9, no. 1, 2019

Asociación Latinoamericana de Control de Calidad, Patología y Recuperación de la Construcción, A. C.

Received: 29 May 2018

Accepted: 06 November 2018

Published: 30 December 2018

Abstract: This article presents a computer-made simulation of a fire that had already been done through an experiment in a room that reproduced a bedroom of a one-family residence, which is a typical case of burned construction in the city of Recife (Pernambuco - Brazil). The experimental test of this fire has been presented by Corrêa et al. (2017), and the study presented in this article has as objective to compare the results on the development of the temperature of gases, got from the computer-made simulation with the software Fire Dynamics Simulator (FDS) with the values got by the experiment. We have found out that the temperature obtained through the model developed by the FDS were coherent with the ones obtained by experiment.

Keywords: Buildings' Fire Prevention (BFP), fire in rooms, fire in residences, computer-made fire simulation, fire dynamics simulator.

Resumo: Este artigo apresenta a simulação computacional de um incêndio realizado experimentalmente em um cômodo que reproduziu um dormitório de residência unifamiliar tipicamente incendiada na cidade de Recife (Pernambuco – Brasil). O ensaio experimental deste incêndio é apresentado por Corrêa et al. (2017), e o estudo discutido neste artigo tem por objetivo comparar os resultados de desenvolvimento de temperaturas dos gases obtidos através da simulação computacional com o software Fire Dynamics Simulator (FDS) com as aferições obtidas experimentalmente. Verificou-se que os resultados de temperaturas obtidos através do modelo desenvolvido no FDS foram coerentes com os obtidos experimentalmente.

Palavras-chave: Segurança Contra Incêndios em Edificações (SCIE), Incêndios em cômodos, Incêndios em residências, Simulação computacional de incêndios, Fire Dynamics Simulator.

Resumen: Este artículo presenta la simulación computacional de un incendio previamente realizado como un experimento en una habitación que reproducía un cuarto de residencia unifamiliar, y ejemplo tìpico de construcciòn incendiada en la ciudad de Recife (Pernambuco - Brasil). El ensayo experimental de este incendio es presentado por Corrêa et al. (2017), y el estudio discutido en este artículo tiene por objetivo comparar los resultados del desarrollo de las temperaturas de los gases obtenidos a través de la simulación computacional con el software Fire Dynamics Simulator (FDS) con las medidas obtenidas en el experimento. Se ha verificado que los resultados obtenidos a través del modelo desarrollado en el FDS han sido coherentes con los obtenidos experimentalmente.

Palabras clave: Seguridad Contra Incendios en Edificaciones (SCIE), Incendios en habitaciones, Incendios en residencias, Simulación computacional de incendios, Fire Dynamics Simulator.

INTRODUCTION

Fires are tragic events that happen frequently in Brazil and around the world, possessing a great destructive potential of patrimony and lives. According to the study carried out by Corrêa et al. (2015) on the occurrence of fires in the city of Recife (Pernambuco – Brazil) in years 2011-2013, about 33% of the occurrences of these events were in buildings. Of this percentage, about 40% corresponds to residential buildings, and the great majority of these events, approximately 75%, occur in single-family homes. According to the authors, this fact is worrying, since in Brazil this type of building does not have preventive normative guidelines on Fire Safety, showing the need for investment in research in this area of knowledge.

Studies of the behavior and development of fires in buildings are of importance to assist researchers in understanding this phenomenon. With these studies, it’s possible, among others, to estimate temperatures and predict the movement of smoke in burned buildings before the occurrence of the incident, helping in the development of strategies aimed at protecting the life of its occupants and the patrimony.

The computer simulation is a tool that presents great potential in the aid of studies on Building Fire Prevention (BFP), providing the researcher with a better understanding of the behavior of this phenomenon. Nowadays, the use of this tool is a common practice among researchers in this area around the world. However, in Brazil, the use of software for this purpose is still not widespread, a fact that results in a scarce availability of literature to aid in their understanding and use (Tabaczenski, et al, 2017a).

In sum, fire simulation software ‘scan be based on the zone model, such as software OZone, developed by University of Liège, and the Consolidated Model of Fire and Smoke Transport (CFAST), developed by National Institute of Standards and Technology from United States of America (NIST/EUA), or, based on computational fluid dynamics model, as the software Fire Dynamics Simulator (FDS), also developed by NIST, and the SMARTFIRE, developed by University of Greenwich.

From the fire simulation software, the SDS is the most used in technical-scientific research, and consequently the richest in available literature. Since the beginning of dissemination, in the year of 2000, it has been widely used in BFP studies worldwide. In Brazil, the first publications of research carried out with the aid of this software date back to the year of 2008 and, gradually, it has gained space in the technical-scientific environment as a tool to support studies aimed at both diagnosis and for predictions of buildings in a situation of fire.

Due to insufficient knowledge of the properties of materials (mainly combustible materials), and of complete pyrolysis and combustion behavior of these materials, there is still a need for improvements in simulation techniques in this software. Therefore, full-scale experimental fire tests are of importance to improve knowledge about the behavior of this phenomenon, allowing the comparison of measured measurements with the numerical results, in order to improve the precision of the developed models (Byström et al., 2012).

In order to demonstrate some of the potential uses of SDS in aid of BFP studies, this study aims to develop a computer model capable of reproducing the development of temperatures in the first minutes of a fire experimentally performed by Corrêa et al. (2017), in a room that represented a dormitory belonging to single-family residences typically burned in the city of Recife.

Bibliographic Review

In the world panorama, several studies of SCIE have been using experimental tests to calibrate the models of computational simulation of fires developed in the FDS (McGrattan et al., 2013; Wang et al., 2016; Yu Long-Xing et al., 2018). Byström et al. (2012), carried out an experimental fire test with wood pieces under low ambient temperature in a two-story concrete building and later developed a computational model of this experiment in the FDS. The experimental results of the development of temperatures were compared with the results of the numerical simulations, showing that the developed model presented results consistent with those obtained experimentally.

Yuenet al. (2014), conducted some experimental fire tests in a fully furnished dormitory and later developed a computational model of this scenario in the FDS. The analysis of the results showed that the computational model was able to provide predictions of temperature, heat flow, and propagation of fire and smoke consistent with those obtained experimentally.

Among the studies carried out in Brazil, a predominance of prognostic analyzes is noticed and there is a lack of experimental studies that can help in the validation of the developed computational models. Despite this, some studies have used experimental tests found in the literature to calibrate the models developed in the FDS. (Tabaczenski et al, 2017a)

Centeno et al. (2015) developed a computational model of a confined pool fire in a residential environment, based on an experimental study found in the literature. With this study, the authors observed that the temperature profile obtained with the FDS agreed with the experimental results, demonstrating the software's ability to reproduce the fire studied.

Tabaczenski et al.(2017b) developed a computational model of a fire in a subdivision representing an office, based on an experimental essay found in the literature. With this study the authors verified that the knowledge and application of the thermal properties not only of the combustible materials but also of the incombustible materials involved in a computational simulation in the FDS is of importance to obtain results consistent with the real situations. Therefore, the results obtained showed that, when properly calibrated, the models developed in the software can return reliable predictions of the development of gas temperatures in fire scenarios.

EXPERIMENTAL STUDY

The experimental study is presented by Corrêa et al. (2017). In this study, an analysis of the development of temperatures resulting from a fire in a room belonging to the ground floor of the Fire Fighting Training Workshop was carried out, within the Center for Teaching and Instruction of the Fire Brigade of Pernambuco. This room was adapted to reproduce a dormitory similar to those belonging to single-family dwellings typically burned in the city of Recife, according to the survey of Corrêa et al. (2016).

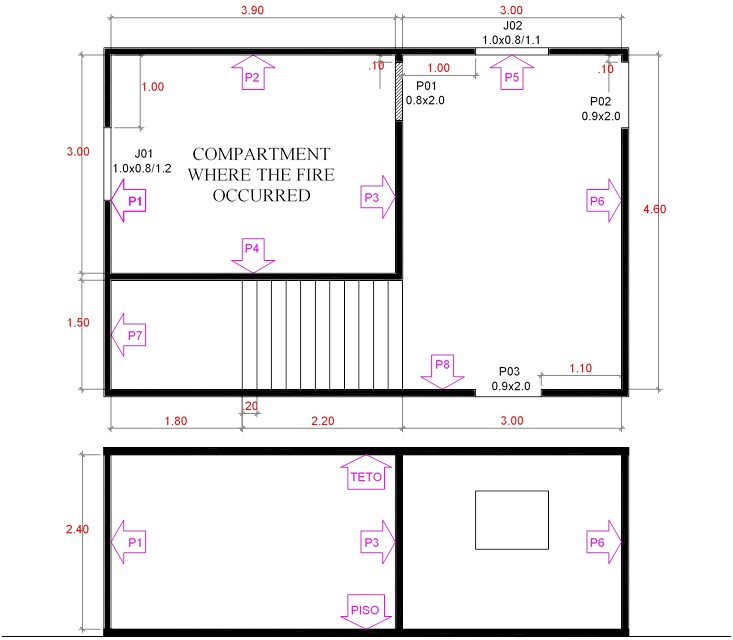

The fire load of this dormitory was materialized through the furniture and objects determined in the research of Corrêa et al. (2016), based on the mapping of fires in buildings in this city during the triennium of 2011-2013 conducted by Corrêa et al. (2015). Figure 1 shows the internal dimensions and furniture of this dormitory.

These furniture and objects had their dimensions and weight measured to, through the calorific potential of the predominant materials in their composition, determine the value of the fire load present in the dormitory. The calorific value of the materials was obtained through the CBMSC IN 003 (2014) and, with this, it was concluded that the fire load present in this dormitory was 499,56 MJ/m² (Corrêa et al., 2017).

The structure of this dormitory, as well as of the whole building, is reinforced concrete; the floor is simple concrete and the pre-shaped slab is lined with ceramic tiles and concrete cover. The walls of the dormitory are made of non-structural ceramic bricks, externally lined with cement mortar and internally with different materials, such as: cement slab (walls P1 e P4), plaster mortar (wall P2) e cement mortar (wall P3) (Corrêa et al., 2017).

The ignition of the fire occurred through a paraffin device for igniting fireplaces positioned under the lower bed of the bunk. For temperature gauging, 24 K type thermocouples were installed, distributed in the furniture, center and walls of the compartment as shown in Figure 2.

During the 48-minute experimental test, the window belonging to the burning dormitory was fully opened while the door remained closed for the first few minutes, causing the fire to be controlled by ventilation and to develop combustion and exhaust cycles. At 18 minutes, in order to prevent the natural extinction of the fire, the compartment door was opened, providing a cross ventilation, bringing the heat flow quickly to the compartment adjacent to the test. However, despite this strategy, there was no generalization of the fire, instead, after a few more cycles of combustion and exhaustion it went into decline until a fire fighting team of the fire department entered the environment promoting the extinguishing of the flame’s remnants and wall cooling (Corrêa, et al. 2017).

COMPUTATION MODEL DEVELOPED IN THE FDS

The development of the computational model in FDS was done in order to reproduce in the best possible way the experimental test carried out by Corrêa et al. (2017). The input parameters and strategies adopted to develop the model were based on the event's chronology, geometry and specificities of the building, observation of environmental conditions and relevant technical standards.

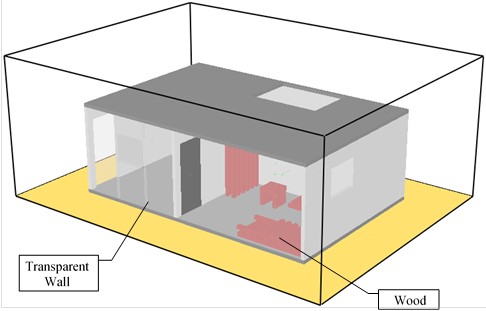

The FDS is a CFD model-based fire simulation software that, among other things, allows the achievement of gas temperatures and solid objects, as well as graphically represent the behavior of fire propagation and smoke movement throughout the simulated building. In this software it is possible to simulate several rooms at the same time, allowing to perform analyzes not only in the room that is set on fire but also in the adjacent ones. Thus, to perform a closer analysis of reality, all the ground floor of the building used to carry out the experimental study was considered in the computational model developed in the FDS. Figure 3 shows the schematic diagram of the ground floor of the building where the experimental test took place.

Following the orientation of McGrattan et al. (2016) and, in order to analyze the flow of smoke through the openings to the outside, it was considered a computational domain that extrapolated some meters beyond the dimensions of the pavement (Figure 3), with the following dimensions: 10.0 m (axis x) x 7.5 m (axis y) x 4.0 m (axis z), with a cubic mesh of 10 cm, totalizing 300 000 elements. This way, all the geometries of the model (walls, ceiling, floor, doors, windows, ladder and combustible material) had their dimensions and positioning adjusted so that their edges were multiple of 10 cm, always occupying an entire element in the computational domain.

At the maximum and minimum ends of the x and y axes, and at the maximum end of the z axis, open surfaces called OPEN VENTS were created, indicating an opening to the exterior of the computational domain, ensuring that there is communication between the internal and external environments of the domain and fire supply with oxygen.

As initial environmental parameters, the following were considered: ambient temperature of 29.50 °C, according to the readings obtained by Corrêa et al. (2017); atmospheric pressure at sea level of 101 325 Pa; air humidity of 80% and wind speed of 3.0 m/s, as occurred on the day of the test as indicated by INMET (2017).

In the absence of parameters indicated by Corrêa et al. (2017), the thermal properties attributed to the walls, roof and floor of the building, with the exception of the Emissivity that had its value adopted, were defined according to the indications of the standard ABNT NBR 15220-2 (2005). These properties, which were assumed as constants during the simulation, are shown in Table 1.

| Material | Density (kg/m³) | Thermal conductivity (W/m.K) | Specific heat (kJ/kg.K) | Emissivity |

| Ceramic Brick | 1400 | 0.90 | 0.92 | 0.90 |

| Plaster Mortar | 1200 | 0.70 | 0.84 | 0.90 |

| Cement Mortar | 2000 | 1.15 | 1.00 | 0.90 |

| Concrete | 2300 | 1.75 | 1.00 | 0.90 |

| Steel | 7800 | 55.00 | 0.46 | 0.70 |

Analogously to the experimental study, the computational simulation of the walls of the dormitory was considered with different internal coatings. Due to the impossibility of representing the roughness resulting from the cementitious slab, this was described in the software as being a layer of cement mortar with a smaller thickness than the other layers composed by this material. The thicknesses and materials that made up the layers of walls, ceiling and floor are shown in Table 2.

From this table, Layer 1 is the inner layer, Layer 2 is the middle layer and Layer 3 is the outer layer to the compartment. The other walls of the building were assumed with the same characteristics of the wall P3. It should be noted that these thicknesses are independent of the dimensions of the mesh adopted.

In the absence of parameters indicated by Corrêa et al. (2017) and, due to the difficulty of obtaining thermal properties of all the combustible materials present in the experimental test, to model the fire in the room was considered a simplified strategy where the fire load was materialized by wooden rafters, distributed in the environment according to the distribution of the experimental objects, whose thermal properties were: density, thermal conductivity and specific heat, with respective values of 400 kg/m³, 0.12 W/m.K and 1.34 kJ/kg.K, defined according to the instructions of ABNT NBR 15220-2 (2005); Emissivity, with adopted value of 0.9; calorific power of 17500 kJ/kg, defined according to the indications of NP EN 1991-1-2 (2010); ignition temperature of 210 °C, according to the study by Figueroa & Moraes (2009); heat release rate of 100 kW/m², according to the study of Rocha (2014).

| Side | Layer 1 | Layer 2 | Layer 3 | |||

| Thickness (cm) | Material | Thickness (cm) | Material | Thickness (cm) | Material | |

| Wall P1 | 2.5 | Cement Mortar | 10.0 | Ceramic Brick | 2.5 | Cement Mortar |

| Wall P2 | 2.5 | Plaster Mortar | 10.0 | Ceramic Brick | 2.5 | Cement Mortar |

| Wall P3 | 2.5 | Cement Mortar | 10.0 | Ceramic Brick | 2.5 | Cement Mortar |

| Wall P4 | 1.0 | Cement Mortar | 10.0 | Ceramic Brick | 2.5 | Cement Mortar |

| Roof | 7.0 | Ceramic Brick | 3.0 | Concrete | ||

| Floor | 10.0 | Concrete | ||||

| Door | 0.03 | Steel | ||||

The geometry of the model developed for computational fire simulation in FDS is shown in Figure 4.

In simulations of fires in the FDS, it is necessary to define a gaseous fuel reaction that will act as a substitute for all potential fuel sources. If this reaction is not defined in the standard software library, the user can specify the chemical formulation of the fuel along with the CO, soot, and other related parameters. (McGrattan et al., 2016). In the model developed in this study, the wood fuel was represented by the chemical formulation CH1.7O0.74N0.002, yields of carbon monoxide and soot of 0.004 kg/kg e 0.015 kg/kg respectively. These yields are expressed in amount of carbon monoxide and soot emitted per unit mass of fuel consumed (Weinschenk et al., 2014).

To account for the ignition of the fire that occurred through the paraffin device in the experimental test of Corrêa et al. (2017), a burner was used similarly to the device in the experimental test. This burner was deactivated after 150 seconds, releasing approximately 0.06% of the total fire load, and had the function of only starting the fire. As a result, the increase in temperature generated a chain reaction, causing the fire to spread through the burning of the wooden rafters that combust after reaching their respective ignition temperature.

To obtain readings of the temperatures developed during the fire, some meters positioned similarly to the thermocouples were inserted in the experimental test (see Figure 2). The following thermocouples: 01 – 08 (gas in the center of the room), 09 e 10 (internal and external faces of the wall P3), 11 e 12 (inner and outer faces of wall P2), and, 13 e 14 (internal and external faces of the wall P1).

As in the experimental test, in this computational simulation the window of the burned dormitory was considered open during the whole simulation, while the door was opened only at 18 minutes. During this time, between the start of the fire and the opening of the door, in the experimental test the maximum temperatures varied between 600 °C and 800 °C. Under these temperature conditions the integrity of human life would have already been corrupted. Thus, in the comparison of the obtained results, this study was stopped at the initial minutes of the fire until the door opening, as shown below.

RESULTS

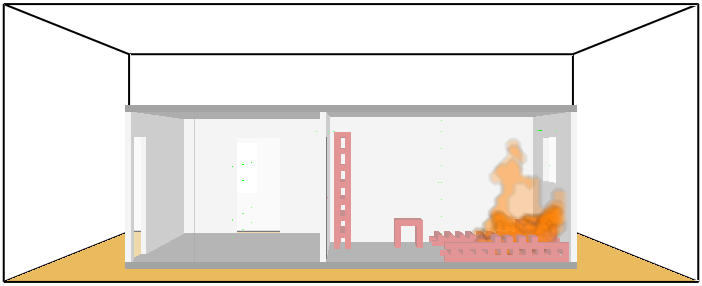

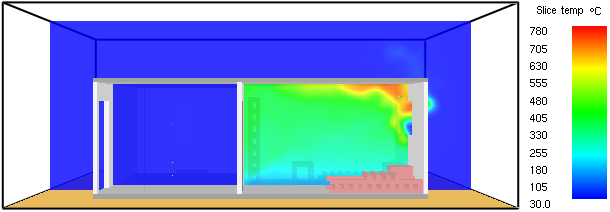

As in the experimental test, in the computer simulation performed through the FDS software (up to 18 minutes) there was no generalization of the fire (Flashover). This was due to the depletion of oxygen in the environment, since with the closed door there was no cross ventilation that could provide enough supply of the combustion agent for fire development. In this way, as can be observed in the Figure 5, the fire was restricted to the wooden rafters that represented the bunk present in the experimental test. In this figure the smoke was concealed for the purpose of visualizing the fire only.

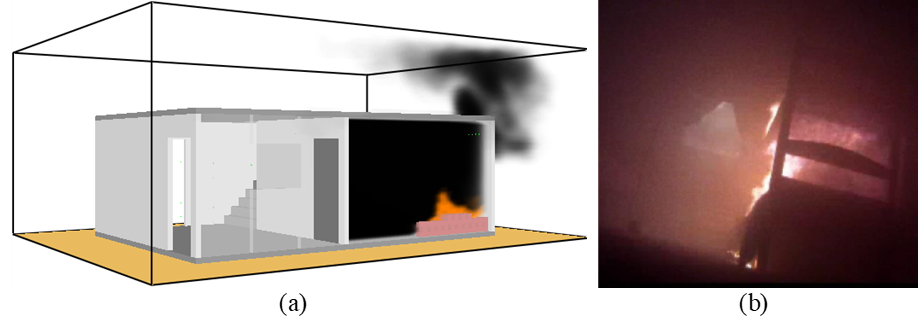

As in the experimental test, it was observed that in less than 5 minutes the room was totally taken up by smoke, as can be observed in the Figure 6.

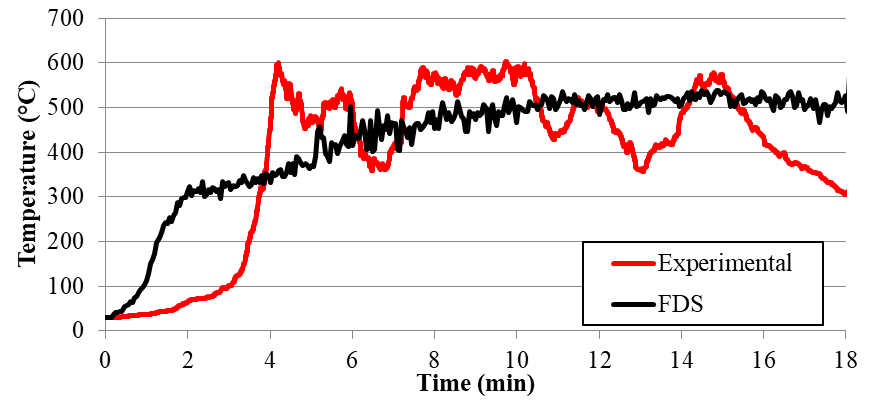

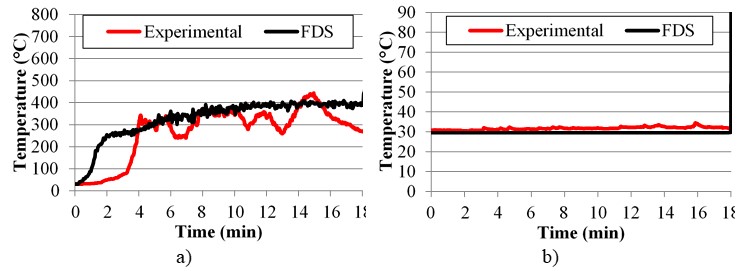

In the computational simulation the combustion and exhaust cycles were not observed as in the experimental test presented by Corrêa et al. (2017). Despite this, in general it was observed that the temperatures obtained with the developed model were close to the average temperatures obtained in the experimental test. Figure 7 shows the temperatures of the gases obtained through the thermocouple 08, positioned just below the compartment ceiling (top layer), the computer simulation in the FDS and the experimental test.

In the computational simulation, there is a rapid growth of temperatures up to 2 minutes, reaching 300 °C, after that the growth occurs more slowly until reaching the level of 500 °C at 6 minutes. In the experimental test this sudden growth occurs between 2 and 4 minutes until the dormitory is taken up by the smoke promoting a gas saturation in the environment, after which the combustion and exhaust cycles begin, culminating in peaks up to 600°C and valleys up to 360°C in temperature.

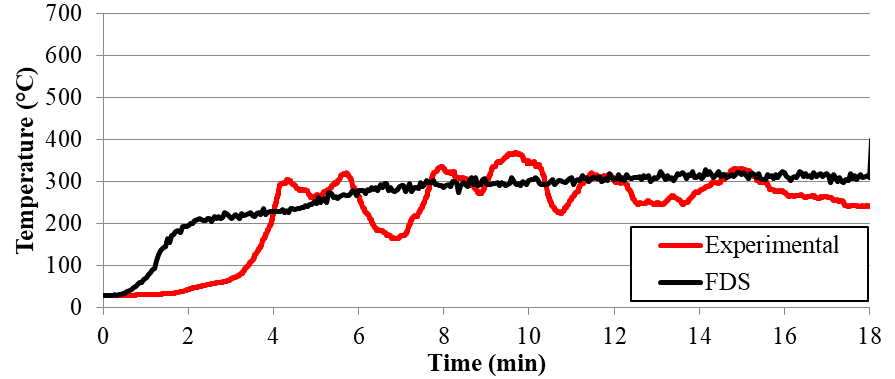

This behavior is repeated at all measuring points in the center of the room. Figure 8 shows the temperatures of gases obtained through thermocouple 04, positioned at a height of 120 cm from the floor of the compartment (intermediate layer).

In the middle layer of the compartment the differences in results: experimental and computational become more discreet. It is observed that in the experimental test the maximum temperature is reached at 10 minutes with 360 °C. In this same moment in the computational simulation the measured temperature is of 300 °C.

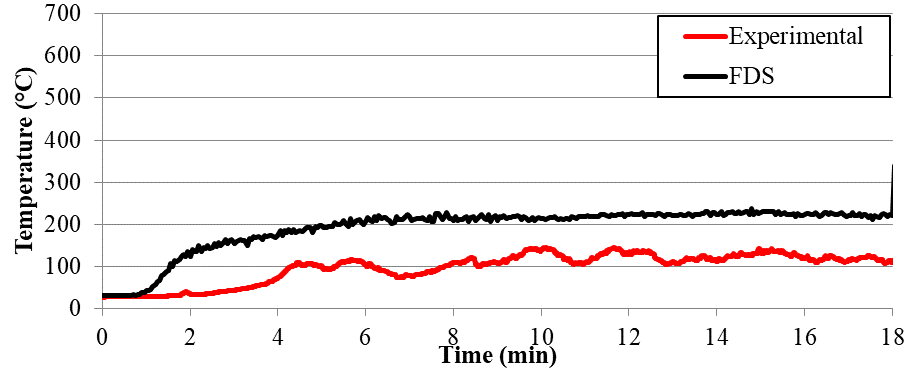

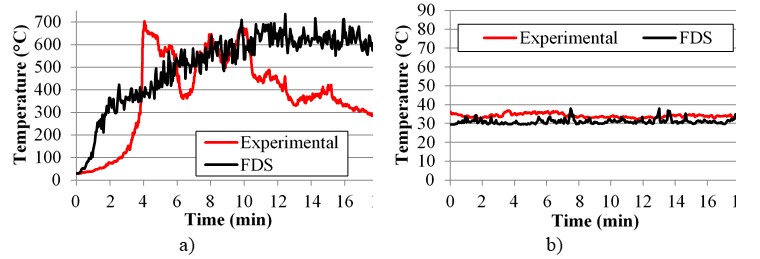

In the lowest layer of the compartment the values are reversed. At this point, the temperatures measured through the computational simulation become larger than those measured experimentally, yet the difference between these values always remains between 50 °C and 100 °C. Figure 9 shows the temperatures of gases obtained through thermocouple 01, positioned at a height of 30 cm from the floor of the compartment (lower layer).

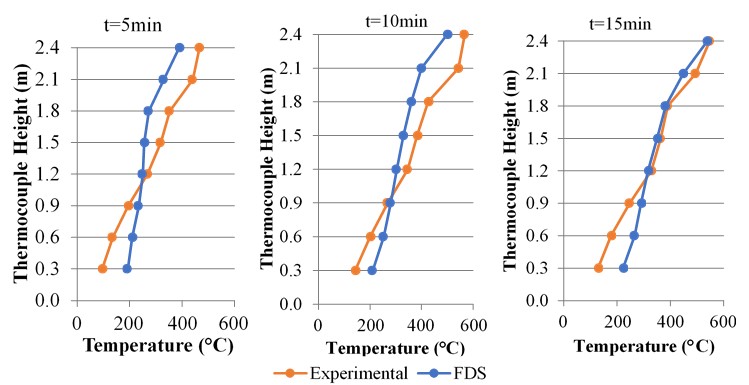

As seen through the Figure 7, Figure 8 and Figure 9, the computational simulation presented results of more homogeneous temperatures along the height of the compartment. From these results, it is possible to draw some temperature profiles obtained in the center of the studied compartment, as shown in Figure 10.

It is observed that, in the lower layers of the dormitory, the results of temperatures obtained through the computational simulation were generally higher than those obtained experimentally. In the upper layers this behavior is inversely, that is, the results obtained experimentally were generally higher than those obtained through the computational simulation.

Although the computational simulation provides a less expressive temperature gradient, it is evident the difference between the analyzed heights. At 15 minutes of simulation, the lowest layer of the compartment (30 cm from the floor) is 220 °C, while the uppermost layer (close to the ceiling, 240 cm from the floor) is 540 °C, behavior resulting from the convection of hot gases into the environment.

Figure 11 shows the temperature profile in the XZ plane of the computational domain in the center of the flared dormitory at 15 minutes of simulation.

Through this profile it is possible to visualize the temperature gradient developed in the entire XZ plane in the dormitory due to the convection of the gases in the environment. It is evident that the maximum temperatures occur close to the window that was open. In this same place you can also see a small entrance of fresh air coming from outside the building.

As for the measured temperatures on the wall faces, due to measurement uncertainties, thermocouples were positioned analogously to the experimental test, providing the gauging of temperatures that were actually absorbed by the walls through the thermal radiation of the fire, and, in addition thermocouples were placed a few centimeters apart from their faces, allowing the measurement of temperatures in the gases close to them.

In the analysis of the results, it was verified that the temperatures captured in the computational simulation that more closely approximated those obtained experimentally were the ones measured in the gases near the walls, and not in the face of the same ones. Figure 12 shows the development of measured temperatures in the wall P3, whose inner coating was cement mortar.

In the inner face of the wall (face exposed to fire), the maximum temperatures developed were 400 °C, value very close to that obtained experimentally. In the external face of the wall, the measured temperatures, both computationally and experimentally, did not exceed 35 °C.

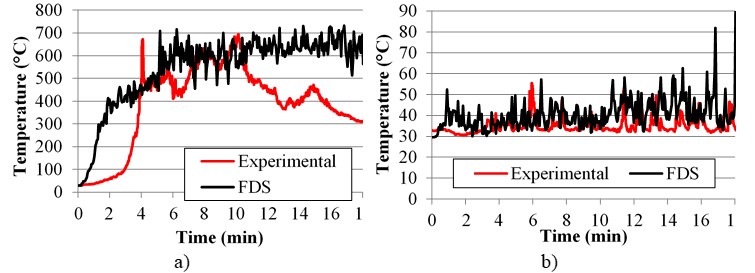

Figure 13 and Figure 14 show the development of measured temperatures in the walls P2 and P1, whose internal coating was gypsum mortar and cement slab respectively.

On the inner faces of the walls (faces exposed to fire), the maximum temperatures developed were approximately 700 °C, value very close to that obtained experimentally. In these measurements there is a greater oscillation in the results on the outer faces of the walls, especially on the wall P1. Vvm. This fact is justified by the thermocouples being positioned near the dormitory window. Thus, due to the incidence of the wind in the place, this meter gauged the temperatures coming from the convection of the gases that left the dormitory.

In the external face of the wall P2, the measured temperatures, both computationally and experimentally, did not exceed 38 °C. In wall P1 the difference between the results was slightly higher: In the experimental test, the maximum temperature recorded was 65 °C, while in computer simulation this value was 82 °C.

CONCLUSIONS

This study presented the computational simulation of a fire in dormitory of single-family homes typically burned in the city of Recife (Pernambuco, Brazil), whose experimental trial was presented by Corrêa et al. (2017).

As in the experimental test, there was no generalization of the fire due to oxygen depletion in the environment;

The computational simulation did not present cycles of combustion, intense gas production and exhaustion as in the experimental test. The occurrence of this behavior raised two hypotheses: (1) the admission of simplified strategies for model development does not contemplate all the phenomena that occurred in the experimental test, due to the absence of oxygen and excess smoke in the compartment. It should be emphasized that in the FDS there is the possibility of insertion of numerous physical-chemical properties of the materials, which allow a more accurate characterization of these in a computational simulation, however, these properties are difficult to obtain, making such refinement also difficult to execute; (2) the FDS combustion model is not suitable for scenarios in which there is no oxygen in the compartment, leading to the computational simulation under this condition to develop a behavior different from the experimental test;

In the lower layers of the dormitory, the temperature results obtained through the computational simulation were generally higher than those obtained experimentally. In the upper layers, the experimental results were generally higher than those obtained through computational simulation;

The maximum temperatures developed in the fire occurred near the dormitory window, which is the only source of supply of fire retardant in the initial 18 minutes of the experimental test;

In the center of the dormitory, the highest temperature measured was 530 °C close to the ceiling (240 cm from the floor), at 15 minutes of simulation;

On the walls, the highest measured temperatures were approximately 730 °C after 10 minutes of simulation, on the inner faces of walls P1 and P2. This behavior was already expected, since these were the closest to the initial focus of the fire;

Despite the simplified strategy adopted, the developed temperatures were close to the average temperatures obtained in the experimental test, showing that, despite not faithfully reproducing the behavior of the actual fire, the developed model was able to represent results consistent with the temperatures developed during the fire.

Acknowledgements

The authors thank the Coordination of Improvement of Higher Education Personnel (CAPES) for the promotion of this research.

REFERENCES

Associação Brasileira de Normas Técnicas (2005), ABNT NBR 15220-2:Desempenho térmico de edificações - Parte 2: Métodos de cálculo da transmitância térmica, da capacidade térmica, do atraso térmico e do fator solar de elementos e componentes de edificações. Rio de Janeiro.

Byström, A., Cheng, X., Wickström, U., Veljkovic, M. (2012), Full-scale experimental and numerical studies on compartment fire under low ambient temperature. Building and Environment, v.51, p. 255-262.

Centeno, F. R., Cassol, F., Rodrigues, E. E. C. (2015), Validação de modelagem numérica empregando o Software Fire Dynamics Simulator para um ambiente habitacional em situação de incêndio. In: 3°Congresso Ibero-Latino-Americano sobre Segurança Contra Incêndios (3º CILASCI), Porto Alegre – RS (Brasil).

Corrêa, C., Silva, J. J. R., Oliveira, T. A. C. P., Braga, G. C. (2015), Mapeamento de Incêndios em Edificações: um estudo de caso na cidade do Recife. Revista de Engenharia Civil IMED, Passo Fundo – RS (Brasil), v.2 n.3, p. 15-34.

Corrêa, C., Silva, J. J. R., Pires, T. A., Braga, G. C., Melo, I. A. V. (2018), Edifício Modal: Uma representação para o Estudo de Incêndios na cidade de Recife. Revista Cientec, Recife – PE (Brasil), v.10, n.2, p.01-10.

Corrêa, C., Braga, G. C., Junior, J. B., Silva, J. J. R., Tabaczenski, R., Pires, T. A. (2017), Incêndio em compartimento de residência na Cidade do Recife: Um estudo experimental. Revista ALCONPAT, 7(3), p. 215-230

Figueroa, M. J. M., Moraes, P. D. (2009), Comportamento da madeira a temperaturas elevadas. Ambiente Construído, Porto Alegre – RS (Brasil), v. 9, n. 4, p. 157-174.

Instituto Nacional de Meteorologia – INMET (2017), Estações automáticas - gráficos. Brasil. Disponível em: . Acessado em: 20 mar. 2017.

McGrattan, K. B., McDermott, R. J., Weinschenk, C. G., Forney, G. P. (2013), Fire dynamics simulator, technical reference guide. Special Publication (NIST SP) – 1018, https://dx.doi.org/10.6028/NIST.sp.1018

McGrattan, K., Hostikka, S., McDermott, R., Floyd, J., Weinschenk, C., Overholt, K. (2016), Fire Dynamics Simulator – User’s Guide: Sixth Edition. NIST – Special Publication 1019: National Institute of Standards and Technology – NIST & Technical Research Centre of Finland – VTT, Maryland (EUA).

Norma Portuguesa (2010), NP EN 1991-1-2: Acções em estruturas Parte 1-2: Acções gerais Acções em estruturas expostas ao fogo. Caparica (Portugual).

Rocha, M. A. F. (2014), Determinação experimental de propriedades de combustão de madeiras maciças brasileiras. Dissertação de Mestrado em Engenharia Civil, Programa de Pós-graduação em Engenharia Civil, Universidade Federal do Rio de Janeiro – UFRJ, Rio de Janeiro – RJ (Brasil), pp. 147.

Tabaczenski, R., Corrêa, C., Santos, M. M. L., Pires, T. A. C., Silva, J. J. R. (2017), Aplicação do Software Fire Dynamics Simulator (FDS) no Estudo da Segurança Contra Incêndios (SCI) no Brasil. Revista Flammae, Recife – PE (Brasil), v.3, n.7, p.87-116, 2017.

Tabaczenski, R., Pires, T. A. C., Silva, J. J. R., Negreiros, R. (2017), Simulação computacional de um incêndio natural compartimentado: validação com um estudo experimental. In: 4° Congresso Ibero-Latino-Americano sobre Segurança Contra Incêndios (4º CILASCI), Recife – PE (Brasil).

Wang, X., Fleischmann, C., Spearpoint, M. (2016), Assessing the influence of fuel geometrical shape on fire dynamics simulator (FDS) predictions for a large-scale heavy goods vehicle tunnel fire experiment. Case Studies in Fire Safety, v. 5, p. 34-41.

Weinschenk, C. G., Overholt, K. J., Madrzykowski, D. (2014), Simulation of an Attic Fire in a Wood Frame Residential Structure -Chicago, IL. NIST – Technical Note 1838: National Institute of Standards and Technology (EUA), pp. 39.

Yu, L.-X., Beji, T., Maragkos, G., Liu, F., Weng, M.-C., Merci, B. (2018), Assessment of Numerical Simulation Capabilities of the Fire Dynamics Simulator (FDS 6) for Planar Air Curtain Flows. Fire Technology, Volume 54, Issue 3, pp 583–612, https://doi.org/10.1007/s10694-018-0701-7

Yuen, A. C. Y., Yeoh, G. H., Alexander, R., Cook, M. (2014), Fire scene reconstruction of a furnished compartment room in a house fire. Case Studies in Fire Safety, v.1, p. 29-35.

Author notes

cristianocorreacbmpe@gmail.com

Additional information

Cite as: R. Tabaczenski,

C. Corrêa, T. Ancelmo

Pires, J. J. Rêgo Silva (2019), "Numerical simulation and fire experiment in

residential dormitory", Revista ALCONPAT,

9(1), pp. 15 – 29, DOI: http://dx.doi.org/10.21041/ra.v9i1.315

Legal Information: Revista ALCONPAT is a quarterly publication by the Asociación Latinoamericana de Control de Calidad,

Patología y Recuperación de la Construcción, Internacional, A.C., Km. 6 antigua

carretera a Progreso, Mérida, Yucatán, 97310, Tel.5219997385893, alconpat.int@gmail.com,

Website: www.alconpat.org

Responsible editor: Pedro

Castro Borges, Ph.D. Reservation of rights for exclusive use

No.04-2013-011717330300-203, and ISSN 2007-6835, both granted by the Instituto

Nacional de Derecho de Autor. Responsible for the last update of this issue,

Informatics Unit ALCONPAT, Elizabeth Sabido Maldonado, Km. 6, antigua carretera a Progreso, Mérida, Yucatán, C.P. 97310.

The views of the authors do

not necessarily reflect the position of the editor.

The total or partial

reproduction of the contents and images of the publication is strictly

prohibited without the previous authorization of ALCONPAT Internacional

A.C.

Any dispute, including the

replies of the authors, will be published in the third issue of 2019 provided

that the information is received before the closing of the second issue of 2019.